Flame-retardant polyester-based fiber for artificial hair

A technology of artificial hair and polyester, which is applied in the manufacture of single-component polyester artificial filaments, single-component copolyester artificial filaments, fire-resistant and flame-retardant filaments, etc., which can solve the difficulties of melt spinning, polyester Decreased heat resistance, increased stickiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

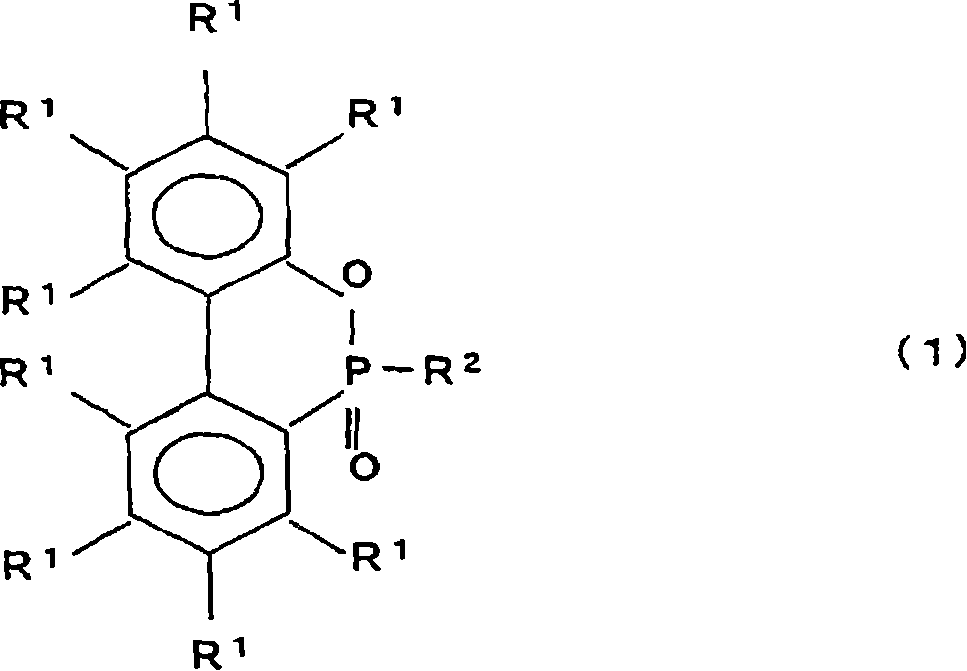

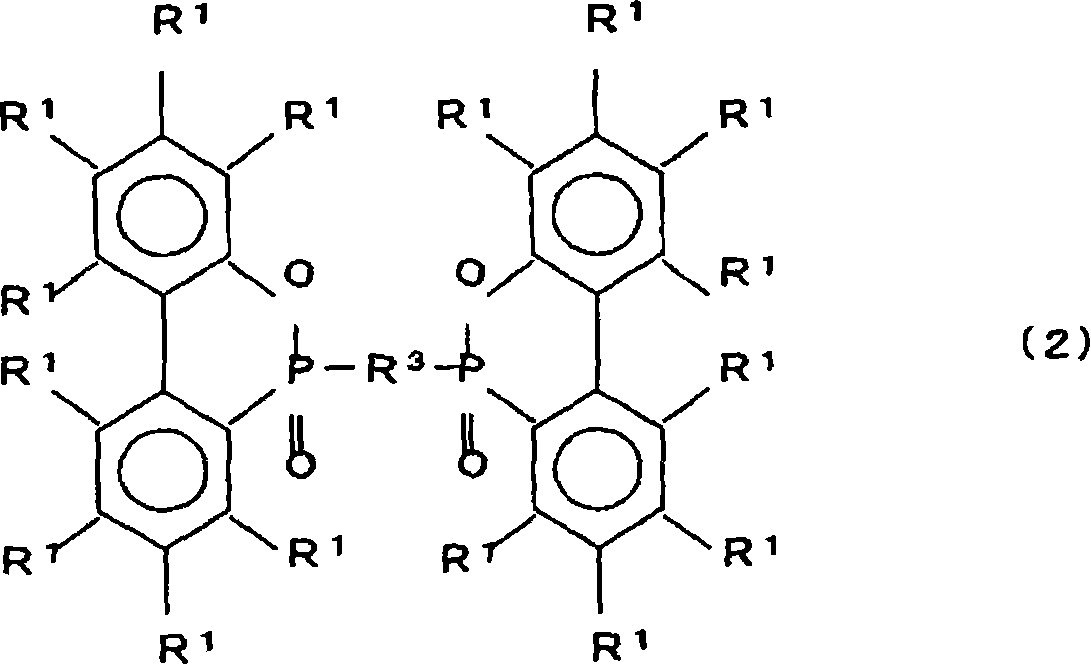

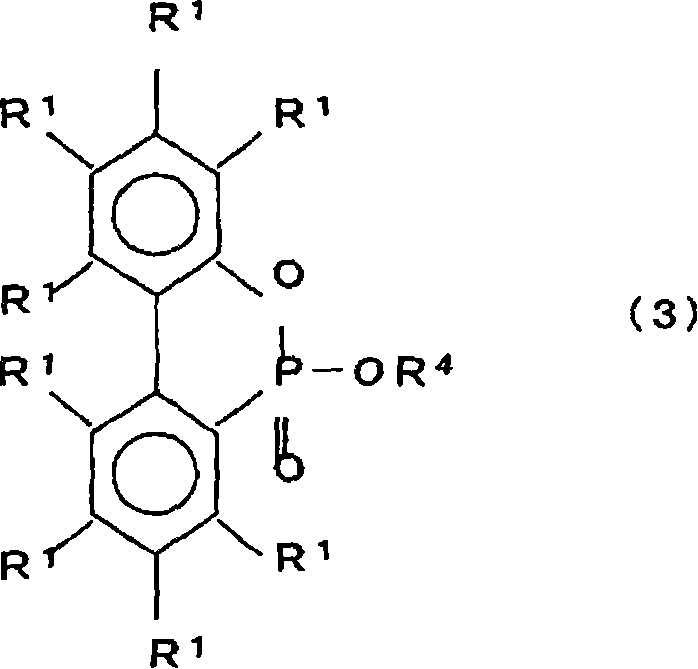

Method used

Image

Examples

Embodiment 1~16

[0111] In the composition shown in Table 1, which is composed of polyethylene terephthalate dried to a moisture content of 100ppm or less, phosphorus-containing flame retardant, organic particles, and inorganic particles in the proportions shown in Table 1, polyester for coloring is added. Two parts of granule PESM6100 BLACK (manufactured by Dainichi Seika Co., Ltd., carbon black content 30%, containing polyester (A) component) were dry-blended, supplied to a twin-screw extruder, and melt-kneaded at 280° C. to produce After being granulated, it is dried to a moisture content of 100ppm or less. Then, with a melt spinning machine, at 280°C, the molten polymer is ejected from a spinning spinneret with a nozzle diameter of 0.5mm in a circular cross-section orifice at 280°C. Cool in a water bath, and wind up at a speed of 100 m / min to obtain an undrawn yarn. Stretch the obtained unstretched yarn in a hot water bath at 80°C to make a 4-fold stretched yarn, wind it with a heating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com