Glass, glass product and manufacturing method of glass product

A glass product and glass technology, applied in the field of near-infrared light-absorbing glass and glass products, can solve problems such as difficulty in obtaining light absorption performance, easy changes in valence state, and reduced glass stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127]

[0128] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

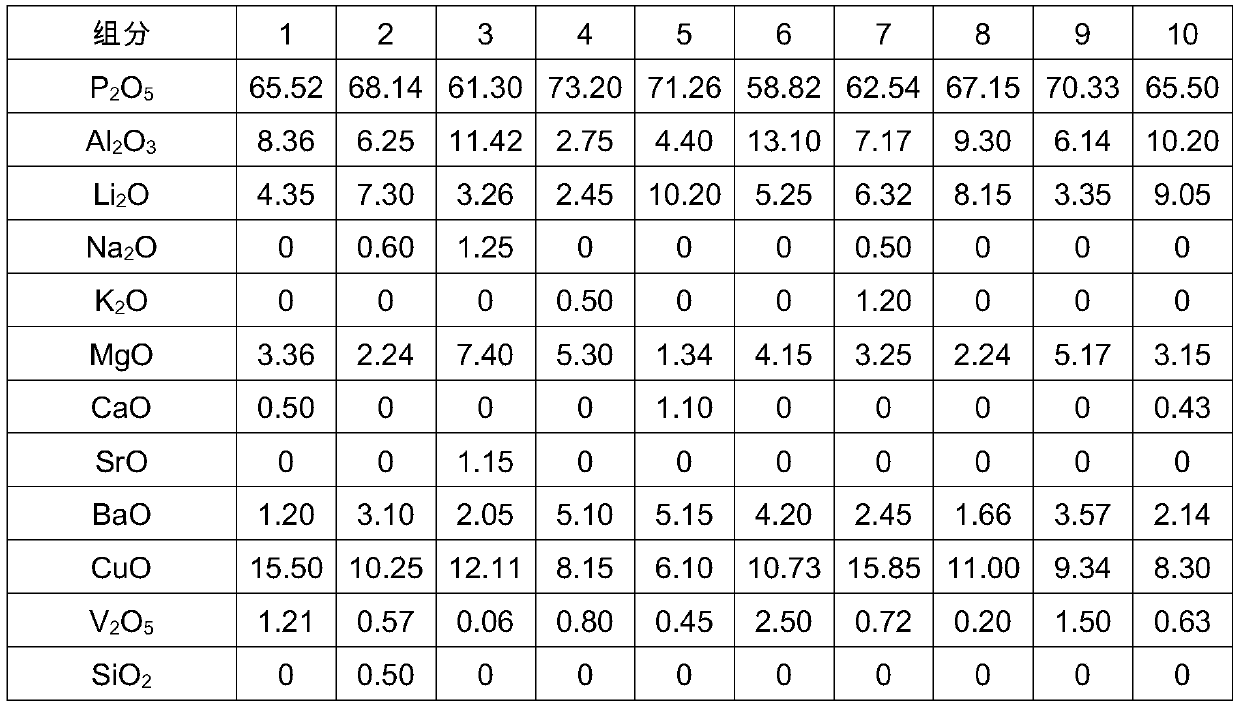

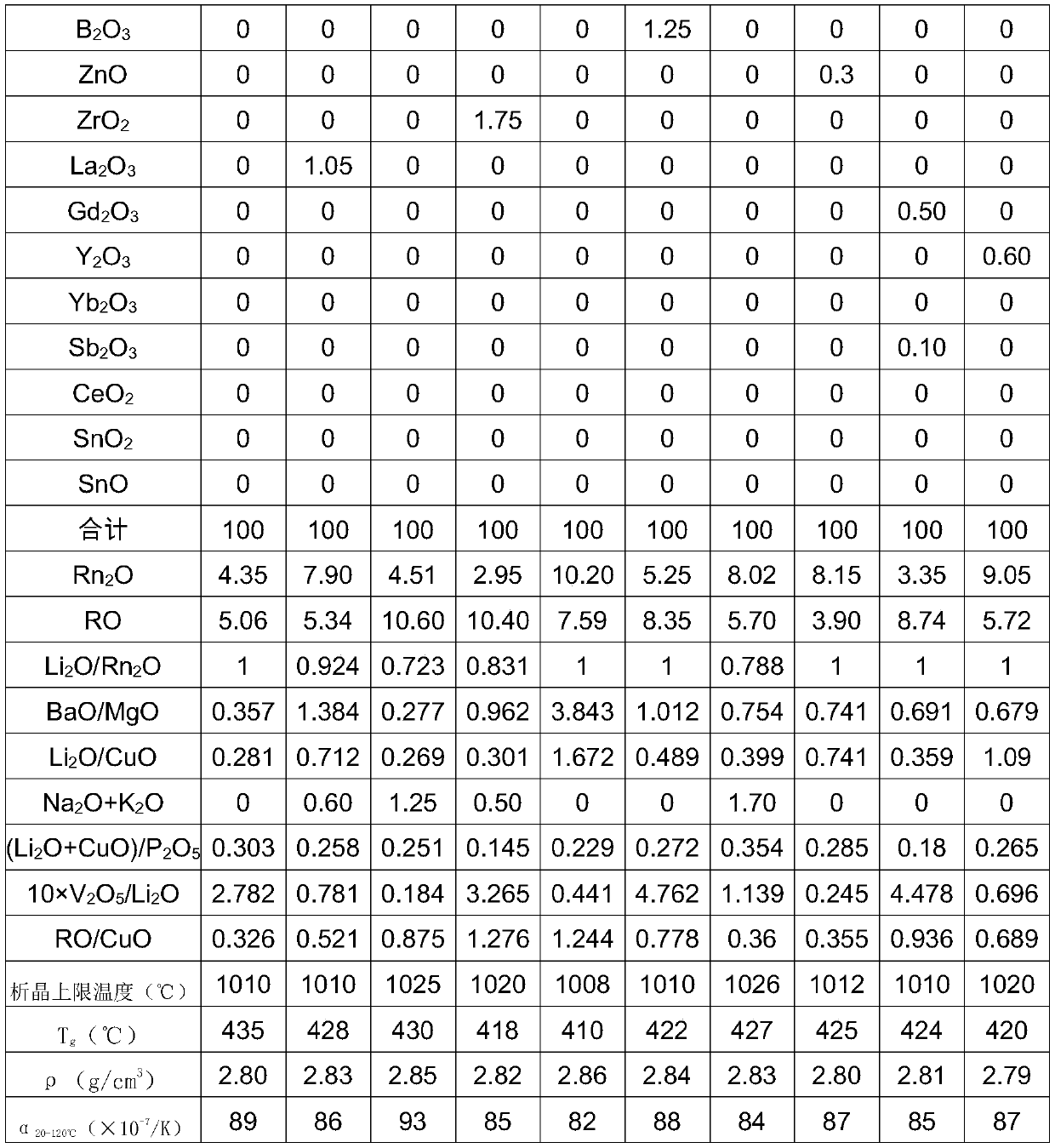

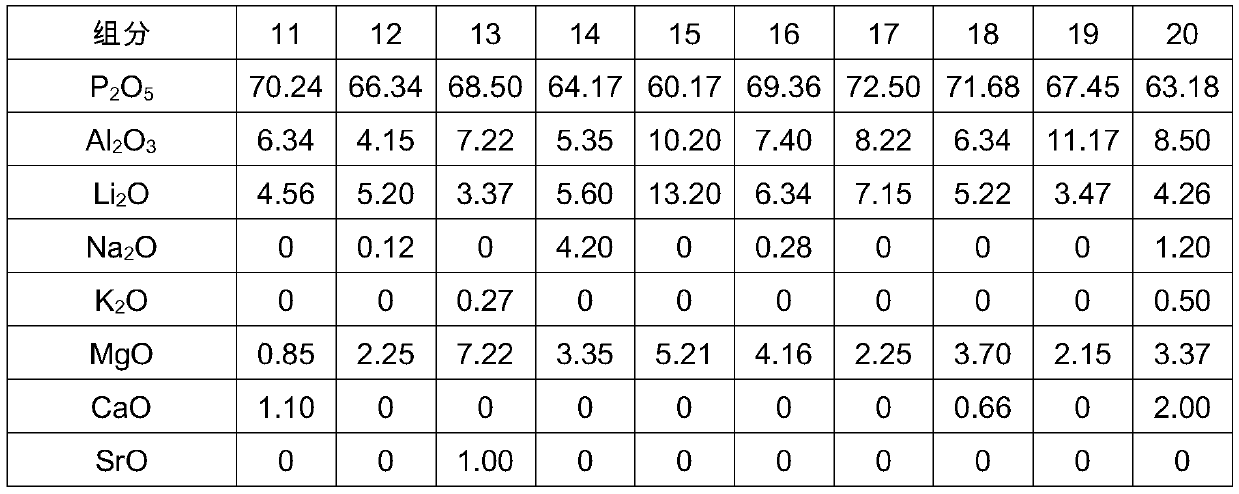

[0129] In this example, glass having the compositions shown in Tables 1 to 3 was obtained by using the above-mentioned glass manufacturing method. In addition, the properties of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 1 to 3.

[0130] Table 1

[0131]

[0132]

[0133] Table 2

[0134]

[0135]

[0136] table 3

[0137]

[0138]

[0139] The glass made in the examples described in the above Tables 1 to 3 was processed into a glass sheet with a thickness of 0.11 mm, and the spectral transmittance of the glass of each example was measured according to the test method described above, and the results are shown in Table 4 ~ Table 6.

[0140] Table 4

[0141] Example 1 2 3 4 5 6 7 8 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com