A method for preparing a corrosion-resistant, anti-fouling, high-plasticity multi-principal alloy with high copper content and no segregation

A multi-principal alloy, corrosion-resistant technology, applied in the field of marine metal materials, can solve the problems of anti-fouling, corrosion resistance, mechanical property conflict, etc., and achieve the effects of improving mutual solubility, excellent marine anti-fouling performance, and excellent high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

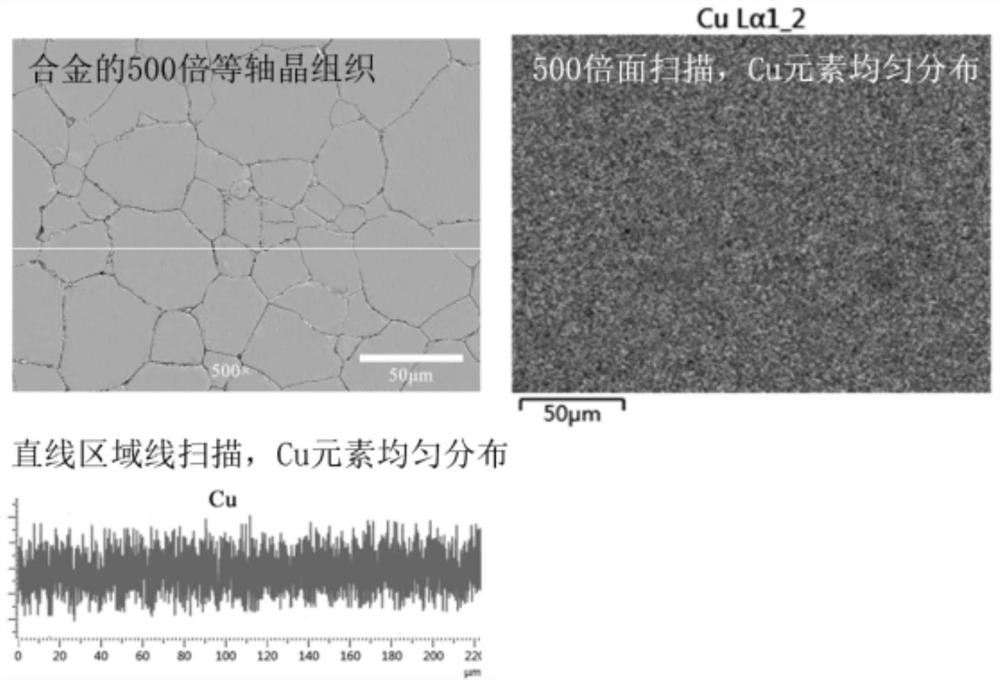

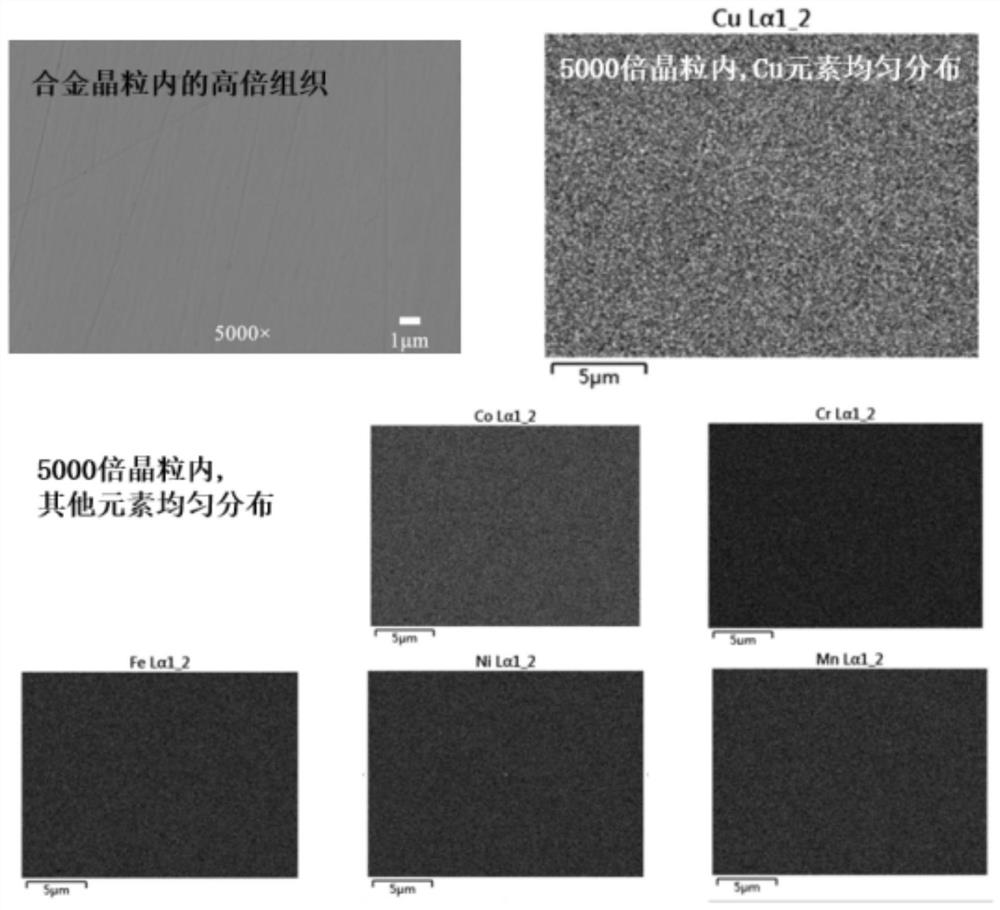

[0040] Preparation method of 80wt%[Co(20)Cr(20)Fe(20)Ni(20)Mn(20)]+20wt%Cu alloy with high copper content, no segregation, anti-corrosion, antifouling and high plasticity:

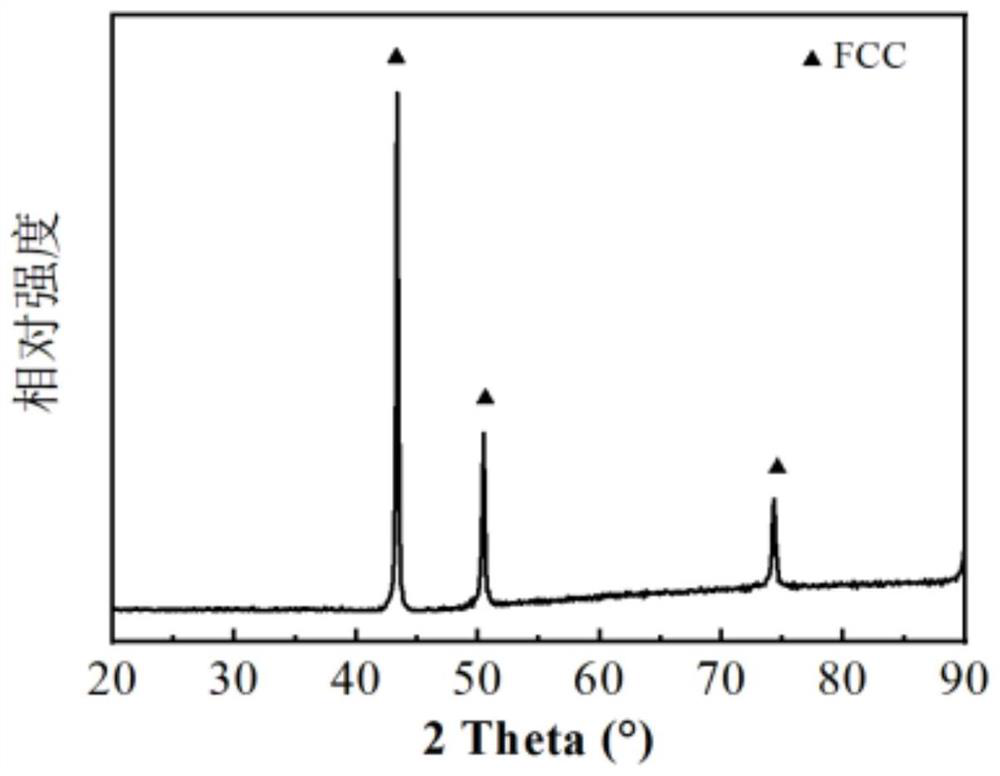

[0041] 1) Preparation of initial corrosion-resistant FCC phase high-entropy alloy

[0042] Co(20)Cr(20)Fe(20)Ni(20)Mn(20) high-entropy alloy was used as the initial high-entropy alloy, and the metal raw materials were weighed according to the proportion, and the amounts of Co, Cr, Ni, Fe, and Mn metal raw materials were Purity >99.9%, after cleaning and drying the metal raw material, put it into the arc melting equipment, and repeat the melting for more than 4 times to ensure that the alloy is prepared uniformly and obtain the initial high-entropy alloy block;

[0043] 2) Preparation of initial corrosion-resistant FCC phase high-entropy alloy powder

[0044] Place the initial high-entropy alloy block prepared in step 1) in the atomization pulverization equipment, vacuumize <10Pa, and then fill it with hig...

Embodiment 2

[0051] Preparation method of 95wt% [Co(15)Cr(25)Fe(20)Ni(18)Mn(22)]+5wt%Cu alloy with high copper content, no segregation, corrosion resistance, antifouling and high plasticity:

[0052] 1) Preparation of initial corrosion-resistant FCC phase high-entropy alloy

[0053] Co(15)Cr(25)Fe(20Ni(18)Mn(22) high-entropy alloy is used as the initial high-entropy alloy, and the metal raw materials are weighed according to the proportion, and the purity of Co, Cr, Ni, Fe, and Mn metal raw materials> 99.9%, after the metal raw material is cleaned and dried, it is put into the arc melting equipment and smelted repeatedly for more than 4 times to ensure that the alloy is evenly prepared and the initial high-entropy alloy block is obtained;

[0054] 2) Preparation of initial corrosion-resistant FCC phase high-entropy alloy powder

[0055] Place the initial high-entropy alloy block prepared in step 1) in the atomization powder making equipment, vacuum <5Pa, and then fill it with high-purity ...

Embodiment 3

[0062] Preparation method of 85wt%[Co(20)Cr(15)Fe(22)Ni(25)Mn(18)]+15wt%Cu alloy with high copper content, no segregation, corrosion resistance, anti-fouling and high plasticity:

[0063] 1) Preparation of initial corrosion-resistant FCC phase high-entropy alloy

[0064] Co(20)Cr(15)Fe(22)Ni(25)Mn(18) high-entropy alloy was used as the initial high-entropy alloy, and the metal raw materials were weighed according to the proportion, and the amounts of Co, Cr, Ni, Fe, and Mn metal raw materials were Purity >99.9%, clean and dry the metal raw material, put it into the induction melting equipment, and repeat the melting for more than 4 times to ensure that the alloy is prepared uniformly and obtain the initial high-entropy alloy block;

[0065] 2) Preparation of initial corrosion-resistant FCC phase high-entropy alloy powder

[0066] Place the initial high-entropy alloy block prepared in step 1) in the atomization pulverization equipment, vacuumize <8Pa, and then fill it with hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com