A corrosion-resistant high-entropy alloy thin film, its preparation method and its application in seawater environment

A high-entropy alloy and corrosion-resistant technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problem that the high-entropy alloy target is difficult to control the element content, and it is difficult to obtain a high-entropy coating with uniform composition. Complex process and other problems, to achieve the effect of high hardness, excellent performance, and obvious changes in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the base material is 304 stainless steel, and the surface of the base is a VAlTiCrCu high-entropy alloy film with a single-phase body-centered cubic structure.

[0033]The preparation method of the VAlTiCrCu high-entropy alloy thin film is as follows:

[0034] Using magnetron sputtering technology, a VAlTiCrCu high-entropy alloy thin film is prepared on the surface of the substrate, which specifically includes the following steps:

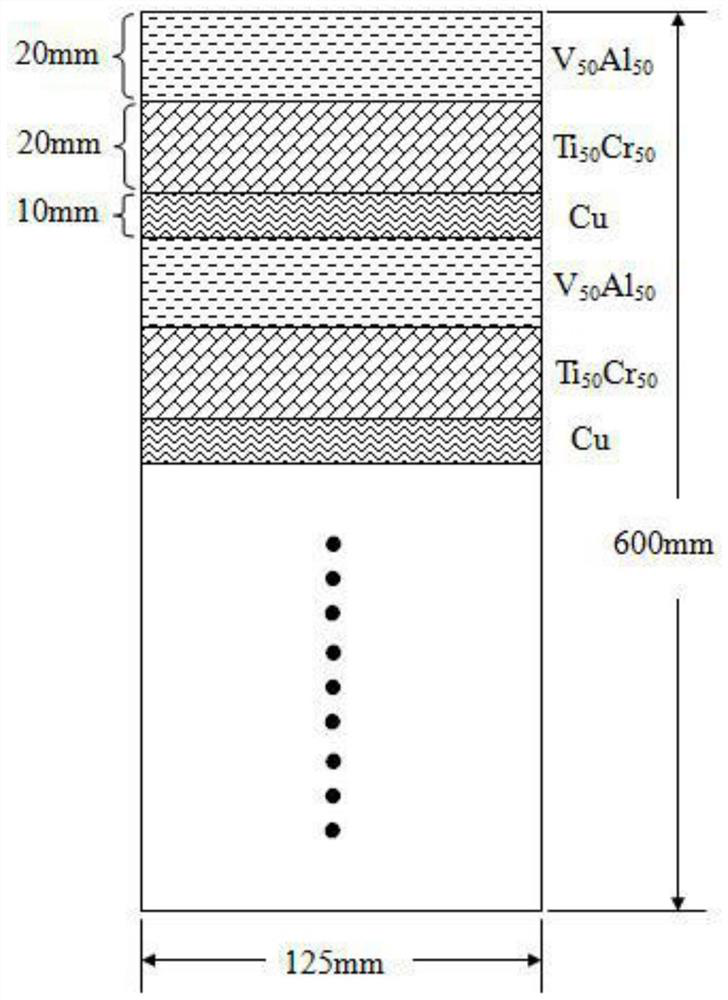

[0035] (1) If figure 1 shown, select a raw material purity ≥99.9% equiatomic ratio of V 50 Al 50 Target, Ti of equal atomic ratio 50 Cr 50 Target and Cu target, in the vertical direction according to V 50 Al 50 -Ti 50 Cr 50 -The order of Cu is stacked and arranged from top to bottom with thicknesses of 20mm, 20mm, and 10mm, respectively, which is one target cycle; then, 12 target cycles are included in the vertical direction to form a spliced composite target.

[0036] (2) The surface of the substrate is subjec...

Embodiment 2

[0047] In this embodiment, the base material is 304 stainless steel, and the base surface is a VAlTiCrCu high-entropy alloy thin film.

[0048] The preparation method of the VAlTiCrCu high-entropy alloy thin film is as follows:

[0049] Using magnetron sputtering technology, a VAlTiCrCu high-entropy alloy thin film is prepared on the surface of the substrate, which specifically includes the following steps:

[0050] (1) If figure 1 shown, select a raw material purity ≥99.9% equiatomic ratio of V 50 Al 50 Target, Ti of equal atomic ratio 50 Cr 50 Target and Cu target, in the vertical direction according to V 50 Al 50 -Ti 50 Cr 50 -The order of Cu is stacked and arranged from top to bottom with thicknesses of 20mm, 20mm, and 10mm, respectively, which is one target cycle; then, 12 target cycles are included in the vertical direction to form a spliced composite target.

[0051] (2) The surface of the substrate is subjected to mechanical grinding and polishing, and then ...

Embodiment 3

[0062] In this embodiment, the base material is 304 stainless steel, and the base surface is a VAlTiCrCu high-entropy alloy thin film.

[0063] The preparation method of the VAlTiCrCu high-entropy alloy thin film is as follows:

[0064] Using magnetron sputtering technology, the VAlTiCrCu high-entropy alloy thin film is prepared on the surface of the substrate, which mainly includes the following steps:

[0065] (1) If figure 1 shown, select a raw material purity ≥99.9% equiatomic ratio of V 50 Al 50 Target, Ti of equal atomic ratio 50 Cr 50 Target and Cu target, in the vertical direction according to V 50 Al 50 -Ti 50 Cr 50 -The order of Cu is stacked and arranged from top to bottom with thicknesses of 20mm, 20mm, and 10mm, respectively, which is one target cycle; then, 12 target cycles are included in the vertical direction to form a spliced composite target.

[0066] (2) The surface of the substrate is subjected to mechanical grinding and polishing, and then ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com