Patents

Literature

98results about How to "Solving Segregation Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

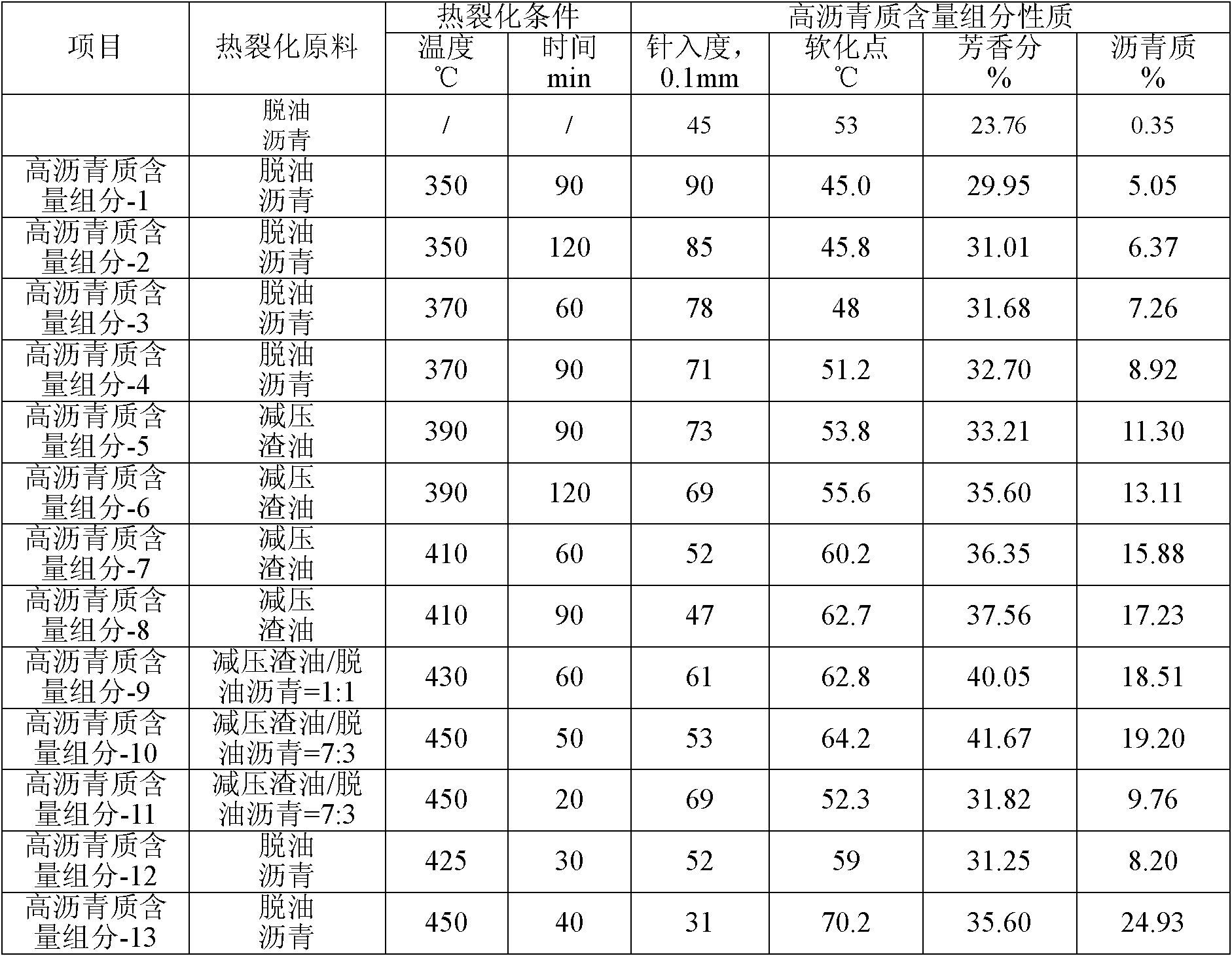

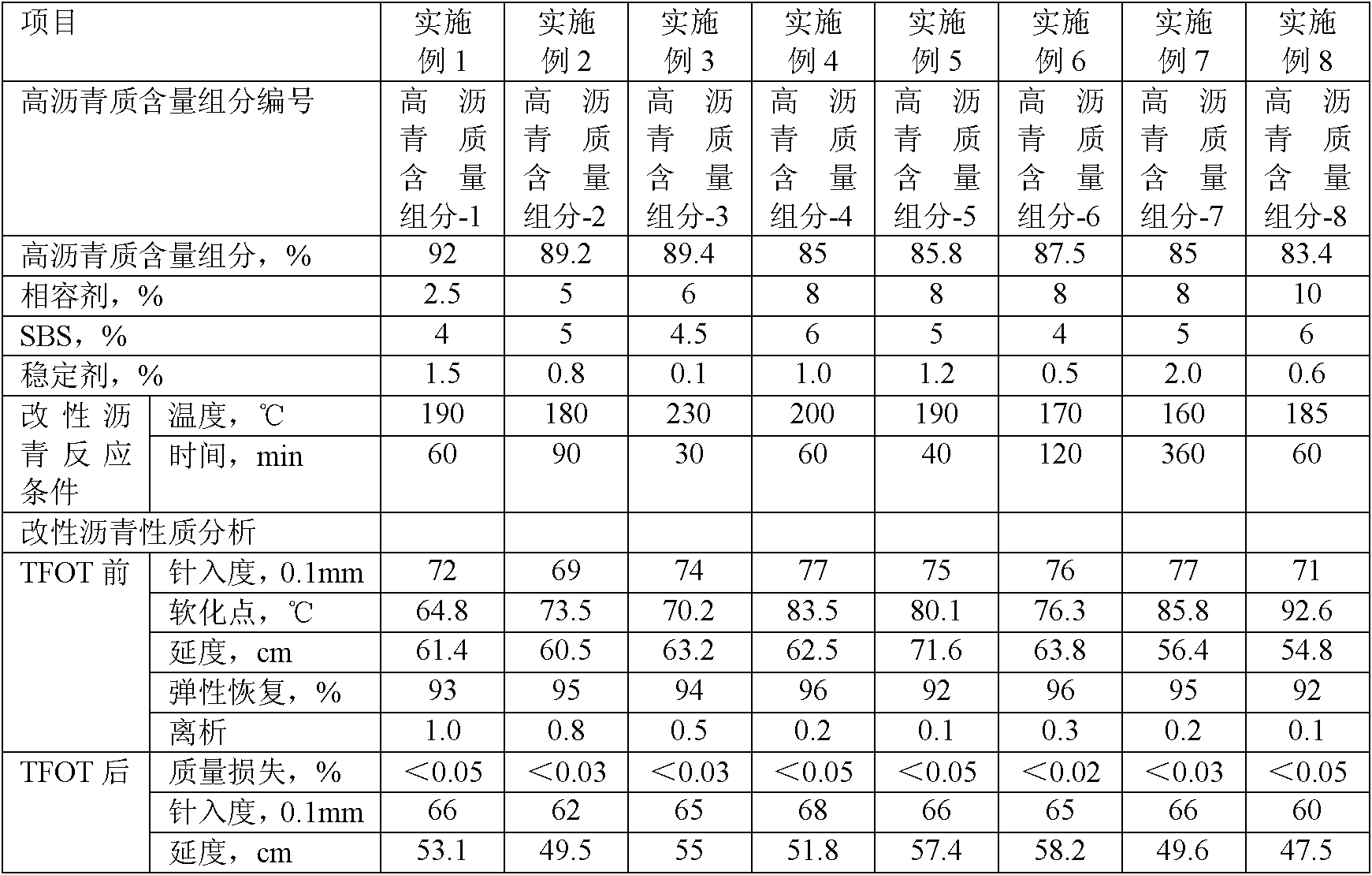

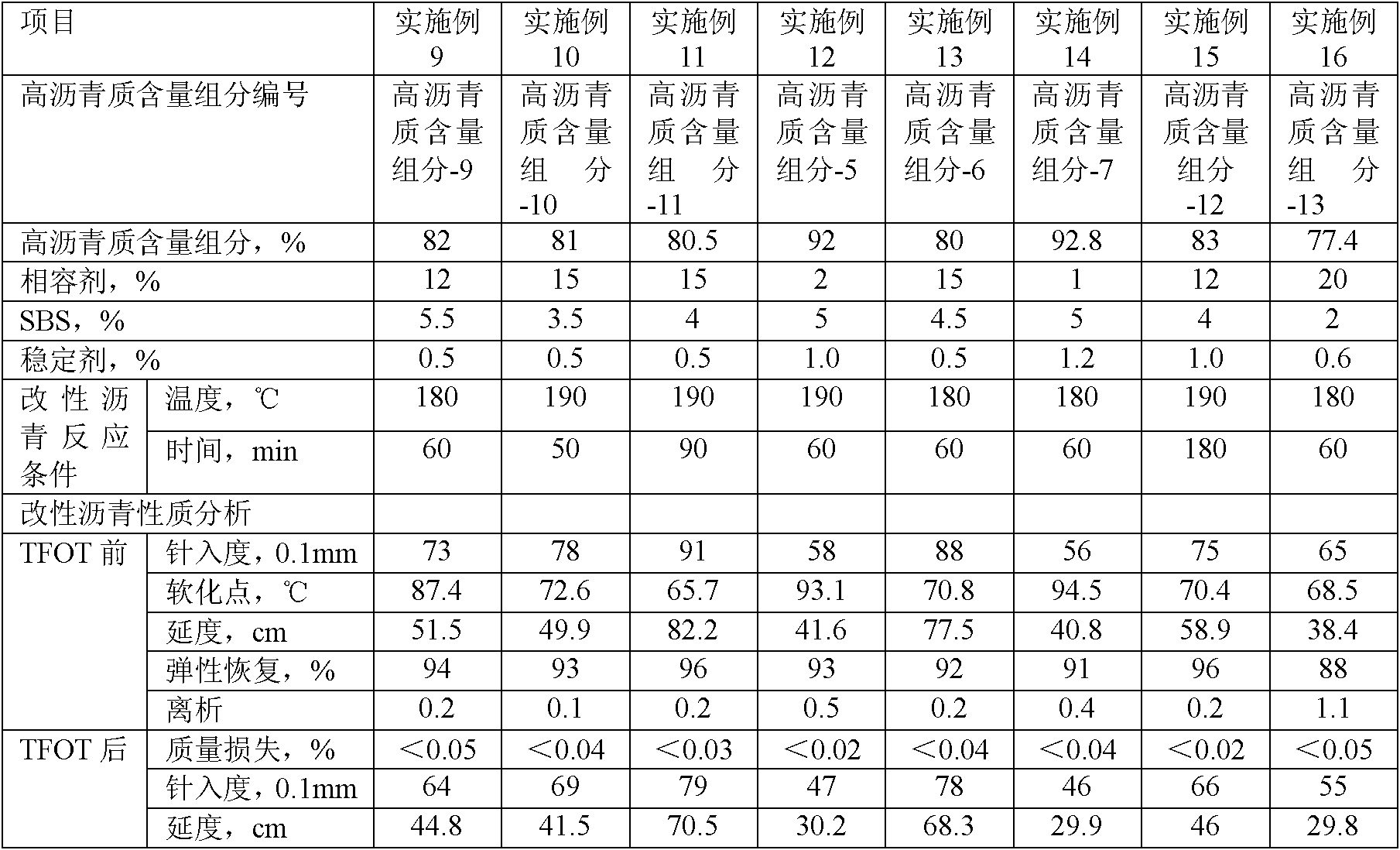

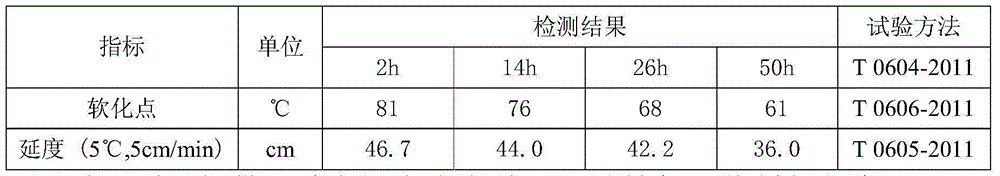

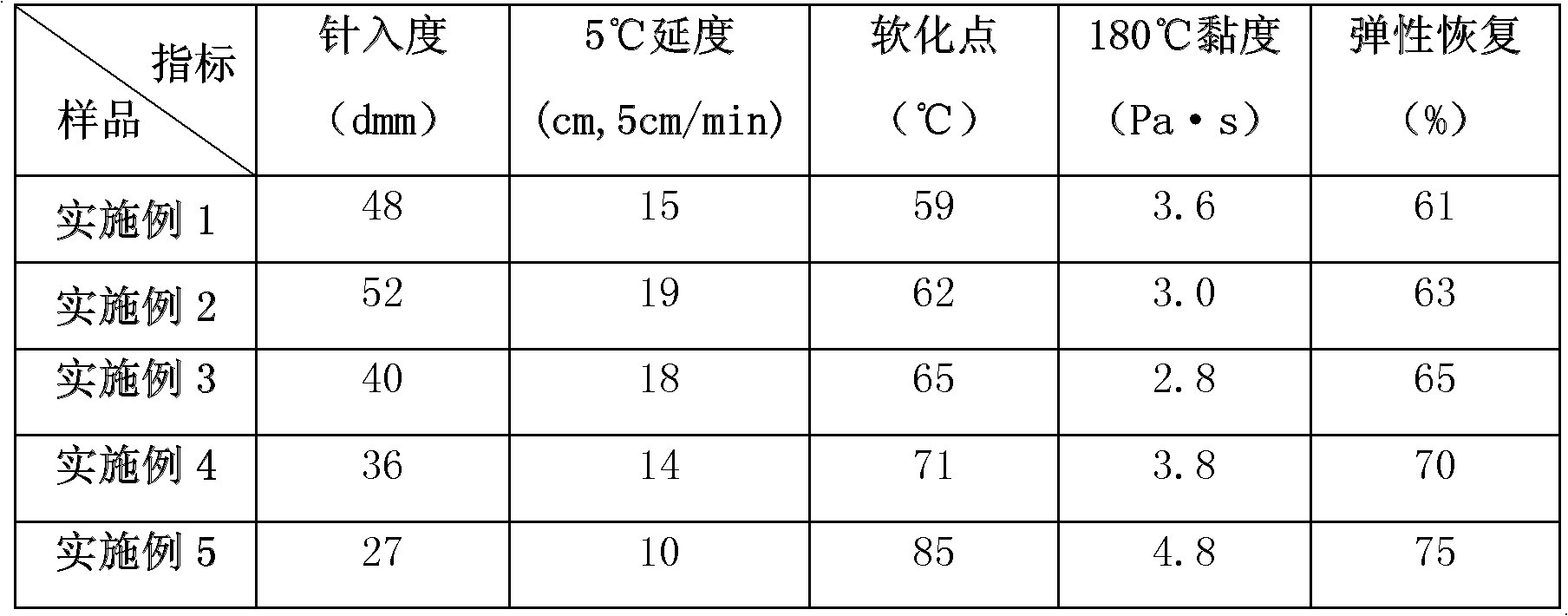

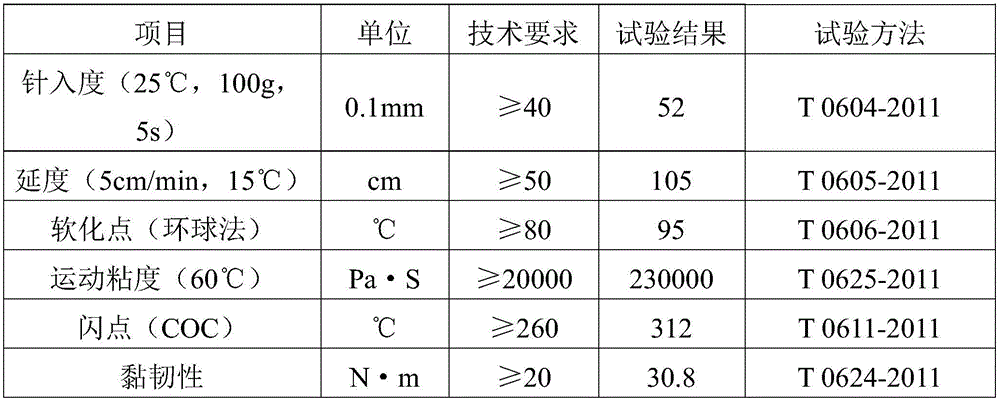

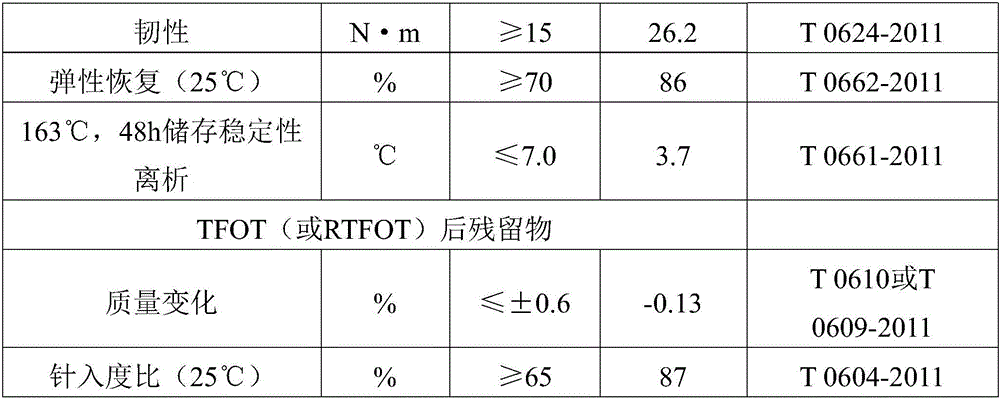

Method for preparing modified asphalt by adopting raw material with low asphaltene content

ActiveCN103044932AIncreased asphaltene contentGood compatibilityTreatment with plural serial stages onlyBuilding insulationsHigh temperature storagePolymer modified

The invention relates to a method for preparing modified asphalt by adopting a raw material with low asphaltene content. The method provided by the invention comprises the following steps of: carrying out thermal cracking reaction with reduced pressure residual oil, deoiled asphalt or mixture with the asphaltene content to be less than 5% at the temperature of 350-450 DEG C, then distilling and cutting to obtain tower bottom residue high-asphaltene-content component with the atmospheric boiling point of being higher than 350 DEG C; mixing the high-asphaltene-content component with a compatilizer at the temperature of 140-190 DEG C, adding a polymer modifier, shearing for 5-120 minutes at the temperature of 160-200 DEG C by adopting a high-speed shearing machine or a colloid mill, so as to disperse polymer into asphalt physically; and warming to a reaction temperature of 160-230 DEG C, adding stabilizer composition, stirring and reacting for 30-360 minutes, and carrying out chemical reaction on the polymer and the asphalt, so that the modified asphalt is obtained. The polymer modified asphalt obtained by the method provided by the invention has the advantages of high temperature storage stability, excellent high-and-low temperature performances and high ageing resistance, a technological process is simple, and production efficiency is high.

Owner:PETROCHINA CO LTD +1

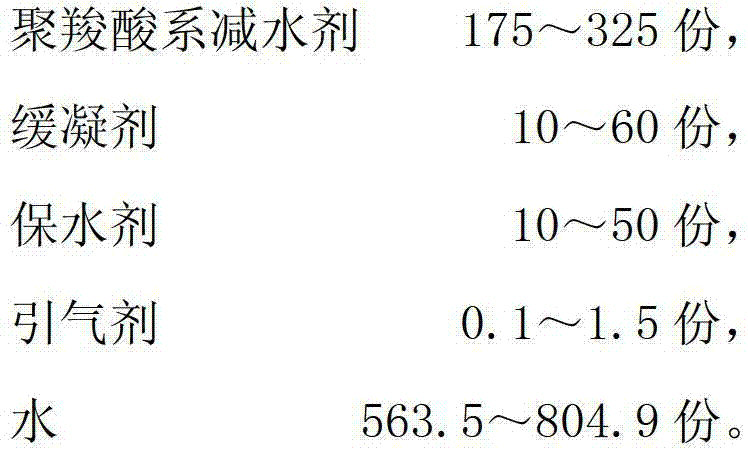

Pumping agent and application thereof

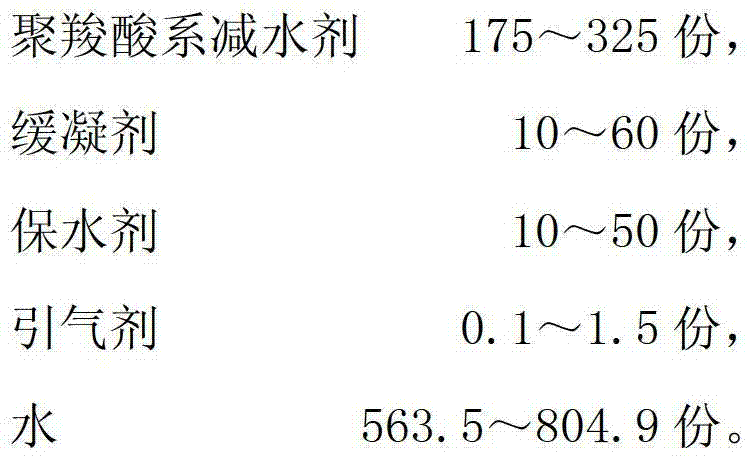

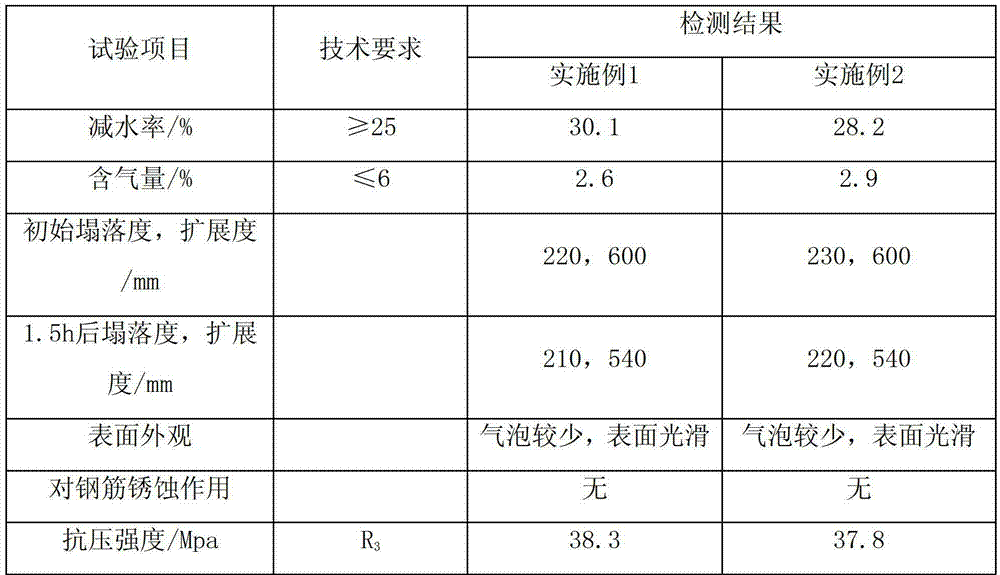

The invention relates to a pumping agent and application thereof, belonging to the field of construction materials. The invention aims to provide the pumping agent and the application thereof. The pumping agent provided by the invention comprises 175-325 parts by weight of polycarboxylic acid water reducing agent, 10-60 parts by weight of retarder, 10-50 parts by weight of water retention agent, 0.1-1.5 parts by weight of air entraining agent and 563.5-804.9 parts by weight of water. The invention also relates to the application of the pumping agent in C15-C70 concrete. The addition amount of the pumping agent accounts for 0.9-2.2 wt% of a cementing material in the concrete. The pumping agent prepared by the invention has the advantages of favorable material adaptability, low addition amount, high water reducing rate, low air content, high concrete strength contribution and the like, mainly solves the problem that the polycarboxylic acid pumping agent is easily subjected to over-addition in practical situations, can effectively prevent the defects of the concrete such as weepage, isolation and the like, and ensures the quality of the concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Lightweight aggregate high-performance concrete and preparation method thereof

InactiveCN106830988AImproved particle size distributionGood adhesivenessCeramicwareOperabilityUltimate tensile strength

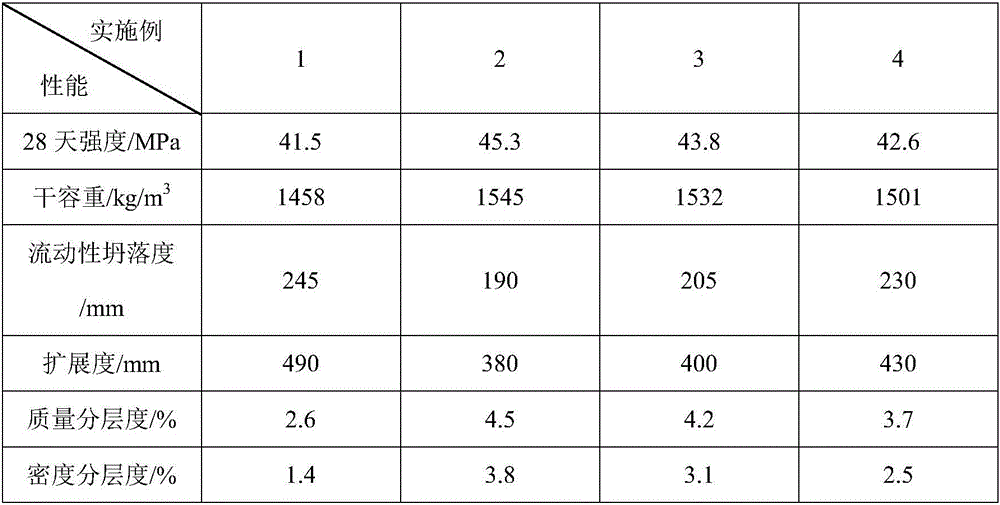

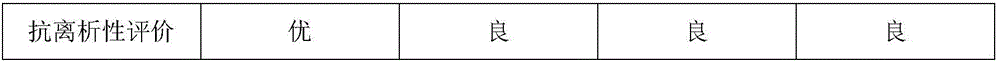

The invention discloses a lightweight aggregate high-performance concrete and a preparation method thereof. The lightweight aggregate high-performance concrete contains the following raw materials: 180-310 parts of cement, 580-650 parts of ceramsite, 420-500 parts of pottery sand, 0-80 parts of sand regenerated from construction waste, 100-130 parts of coal ash, 100-210 parts of mineral powder, 130-160 parts of water, 4.5-6.5 parts of water reducer, 1-1.5 parts of enhanced modified material and 0.45-0.60 part of anti-separation material. The lightweight aggregate high-performance concrete has the advantages of light unit weight (1450-1550kg / m3), high 28-day strength (40-50MPa), separation resistance, capability of being pumped, slump of 190-250mm, divergence of 400-550mm, no aggregate floating, simple preparation method, high operability and low cost.

Owner:JIANGSU UNIV OF SCI & TECH

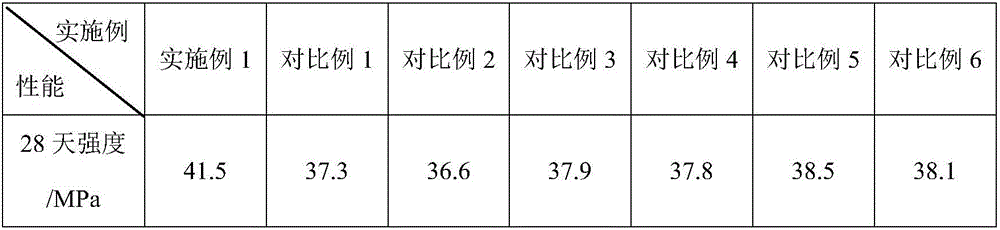

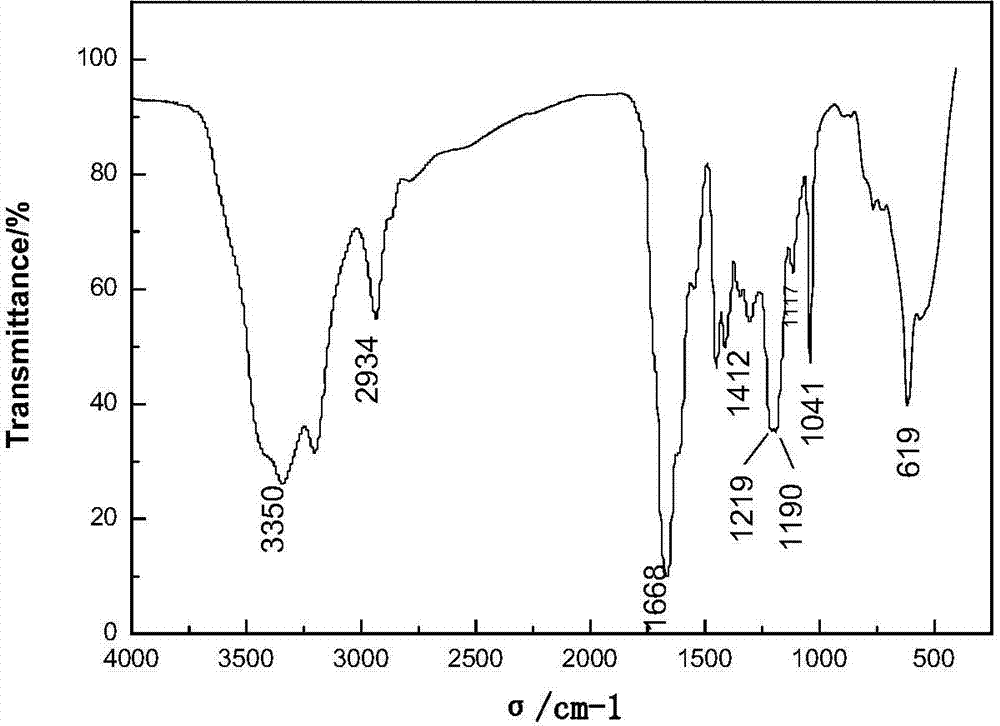

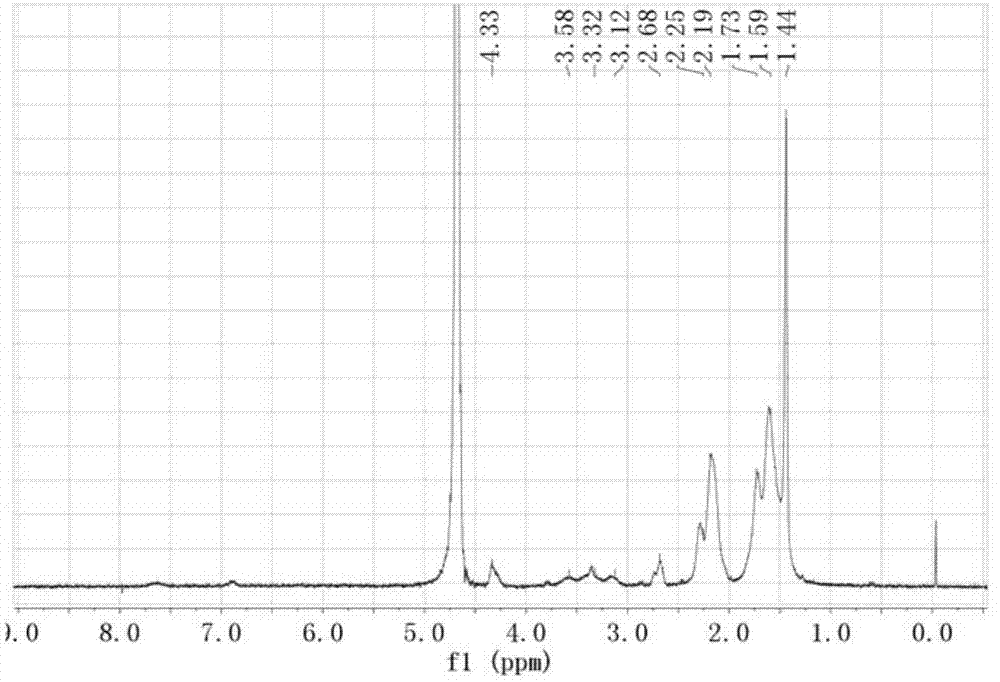

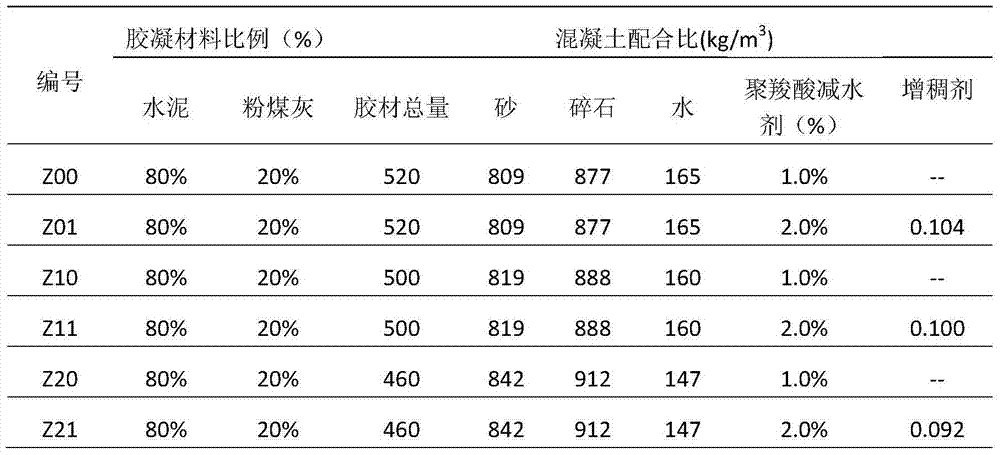

Thickener used for self-compact concrete, preparation method thereof, and self-compact concrete using thickener

The invention discloses a preparation method of a thickener used for self-compact concrete. The method comprises the following steps: 1, weighing 2-acrylamide-2-methylpropanesulfonic acid and acrylic acid in proportion, processing to prepare an aqueous solution, and adjusting the pH value to 6.5-7.0; 2, adding a prepared monomer acrylamide solution with the concentration of 25-35% while stirring, uniformly stirring, dumping the obtained mixed solution into a flask, carrying out constant temperature water bath, and introducing nitrogen for protection; and 3, adding an initiator in a dropwise manner when the reaction temperature rises to 30-40DEG C, carrying out heat insulation at 40DEG C, carrying out a stirring reaction for about 1.5-2h, stopping the introduction of nitrogen when reactants are a viscous liquid, and carrying out constant temperature slaking for a period of time to obtain a white transparent colloid which is the thickener. The thickener obtained in the invention is used for preparing the self-compact concrete, has a good water solubility and a good thickening effect, can effectively improve the plastic viscosity of the self-compact concrete, and solves the water segregation and separation problems of the self-compact concrete.

Owner:CCCC FOURTH HARBOR ENG INST +4

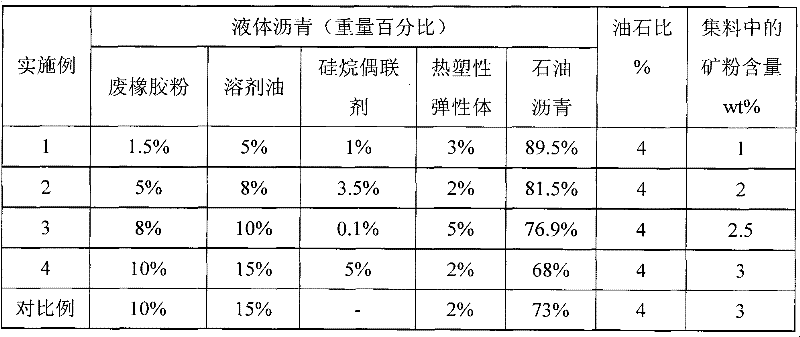

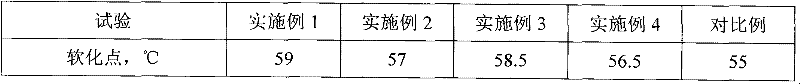

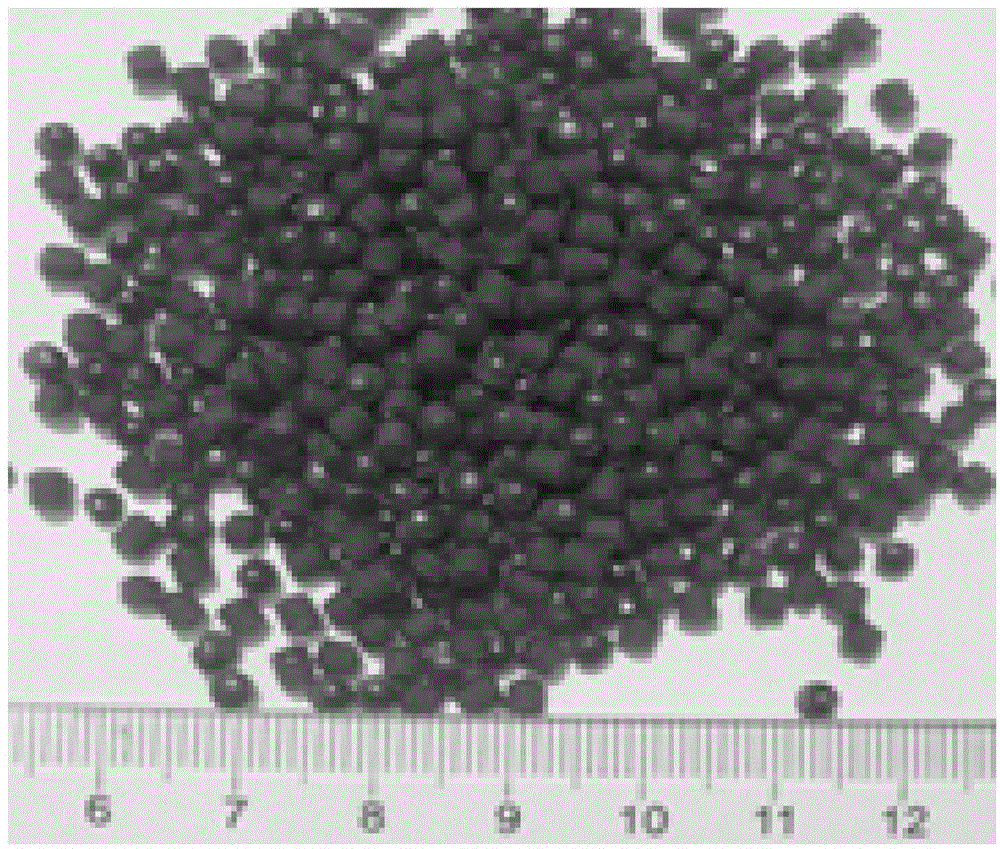

Hot-mix cold-lay rubber asphalt mixture

InactiveCN102329103ASolving Segregation ProblemsImprove loose stateSolid waste managementPolymer scienceNaphtha

The invention provides a hot-mix cold-lay rubber asphalt mixture. The mixture is characterized in that: the mixture comprises rubber asphalt and an aggregate; the aggregate comprises a coarse aggregate, a fine aggregate and ore powder; and the rubber asphalt comprises the following components, by weight, 1.5-10% of rubber powder, 5-15% of solvent naphtha, 0.1-5% of a silane coupling agent, 2-5% of a thermoplastic elastomer, and the balance petroleum asphalt. The silane coupling agent, which is added to rubber powder modified asphalt in the invention, allows a separation problem of the rubber powder and asphalt to be effectively solved. The obtained hot-mix cold-lay rubber powder modified asphalt mixture can keep a good loosened state for several months and all performances are stable in normal temperature conditions.

Owner:上海道柯特沥青科技有限公司

High-fluidity pumping ceramsite concrete and preparation method thereof

The invention provides high-fluidity pumping ceramsite concrete and a preparation method thereof. A formula of the concrete comprises cement, coal ash, water, fine aggregate, limestone flour, pumping aid, ceramsites, ceramic sand, redispersable emulsion and hydroxypropyl methyl cellulose. The method comprises the following steps: reasonably selecting respective raw materials and usage thereof according to a unit weight of concrete to be prepared, soaking the ceramsites to a saturated water absorption state in advance, then mixing with other raw materials, and stirring to prepare the ceramsite concrete. By controlling the grain size of the ceramsites and a fineness modulus of the fine aggregate, the redispersable emulsion and hydroxypropyl methyl cellulose are cooperatively added to promote the cementation of the cementing materials such as the cement, the coal ash and the limestone flour with the ceramsites, and the cohesiveness and water retaining property of the concrete are increased, and the problems of easy floating, layering and separation of the ceramsites in the ceramsite concrete are effectively solved, moreover, separation and layering of the ceramsites can be effectively avoided by using the ceramsite concrete produced according to the invention, and slump loss in a material transporting and waiting process is obviously reduced.

Owner:重庆富普新材料有限公司

Direct-adding type instant SBS (Styrene Butadiene Styrene) modifier as well as preparation method and application thereof

The invention discloses a direct-adding type instant SBS (Styrene Butadiene Styrene) modifier prepared from the following raw materials in parts by mass: 60-85 parts of SBS, 5-25 parts of ethylene-vinyl acetate copolymer (EVA), 5-10 parts of naphthenic oil, 1-3 parts of a compatilizer and 2-4 parts of an antioxidant. The SBS modifier disclosed by the invention can be directly added into a blending tower (a process for directly adding the modifier into the blending tower is called a 'dry method' according to industry habits) to quickly melt with an aggregate and base asphalt during short-time mixing, thereby achieving micron-scale dispersion and giving play to a modification effect which is the same as that of a wet method.

Owner:BEIJING ZHONGLU PAVING TECH

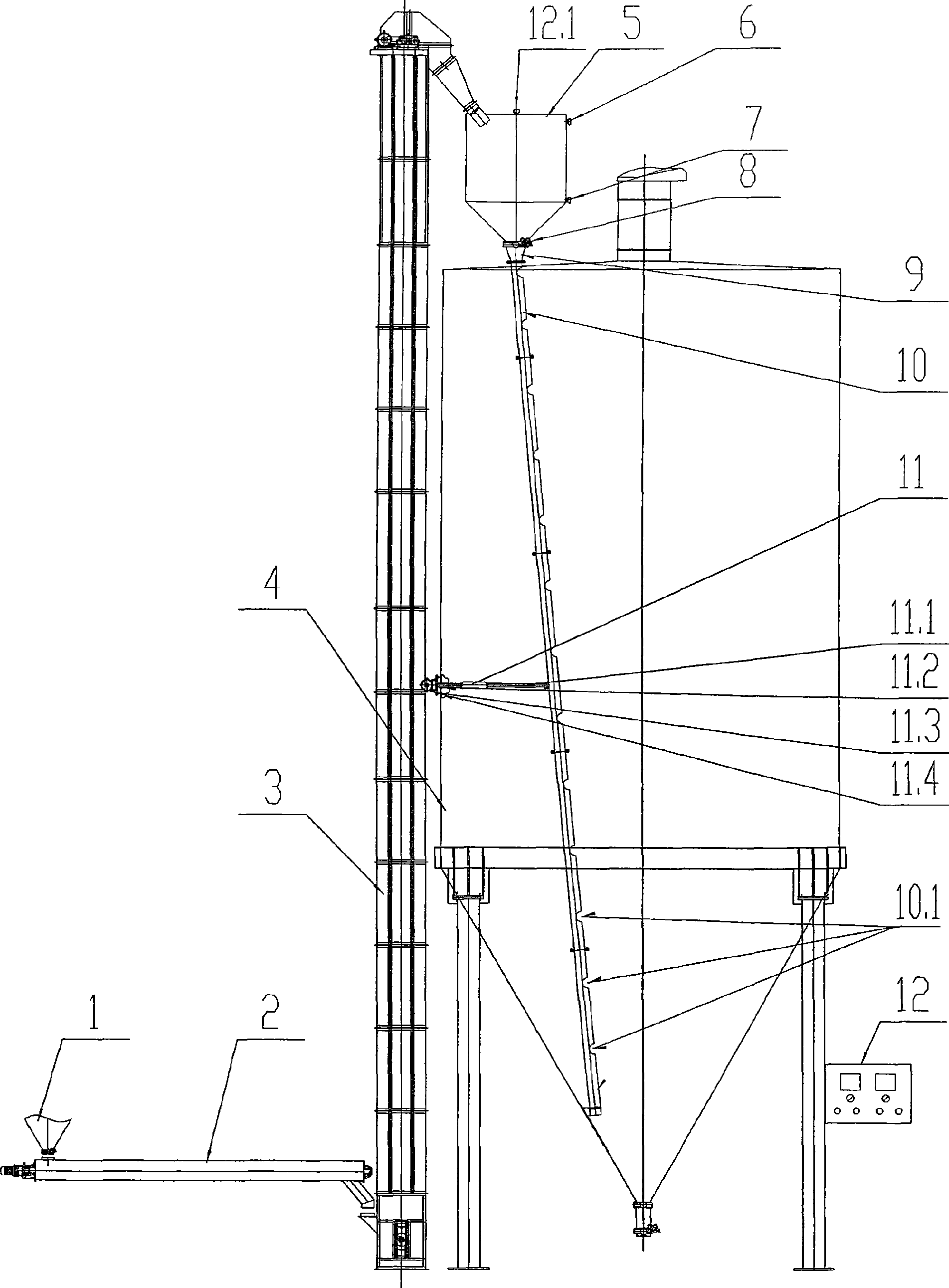

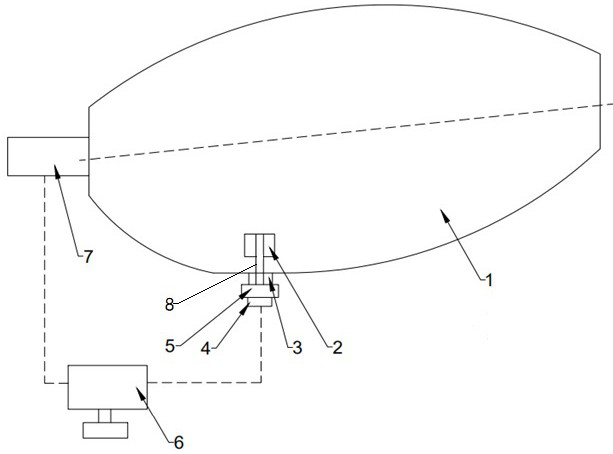

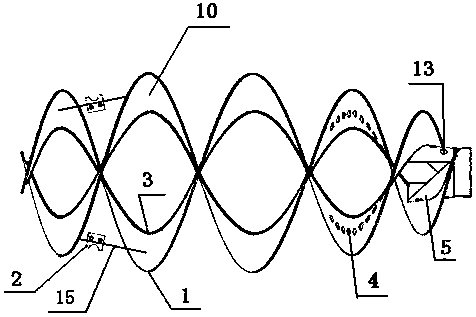

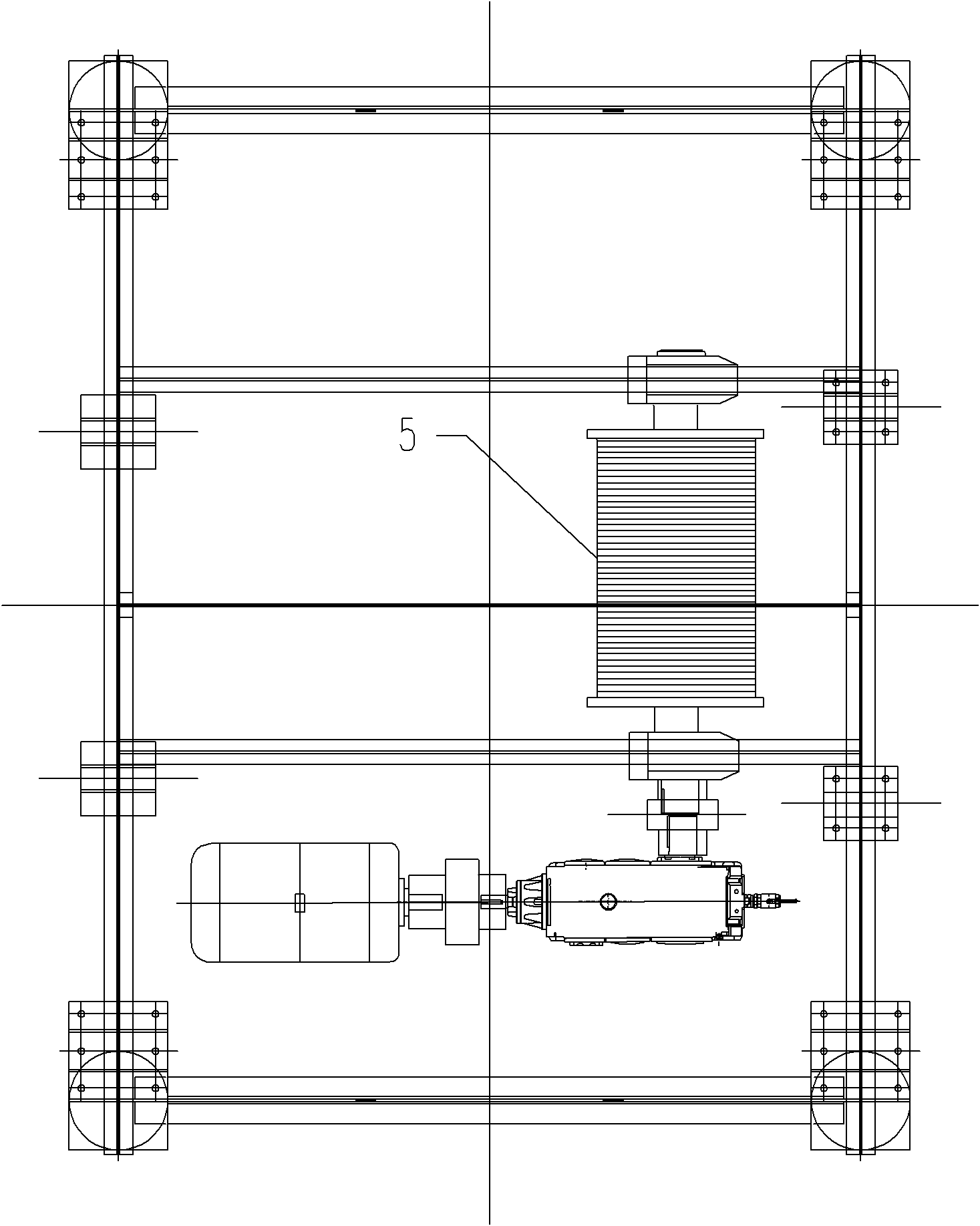

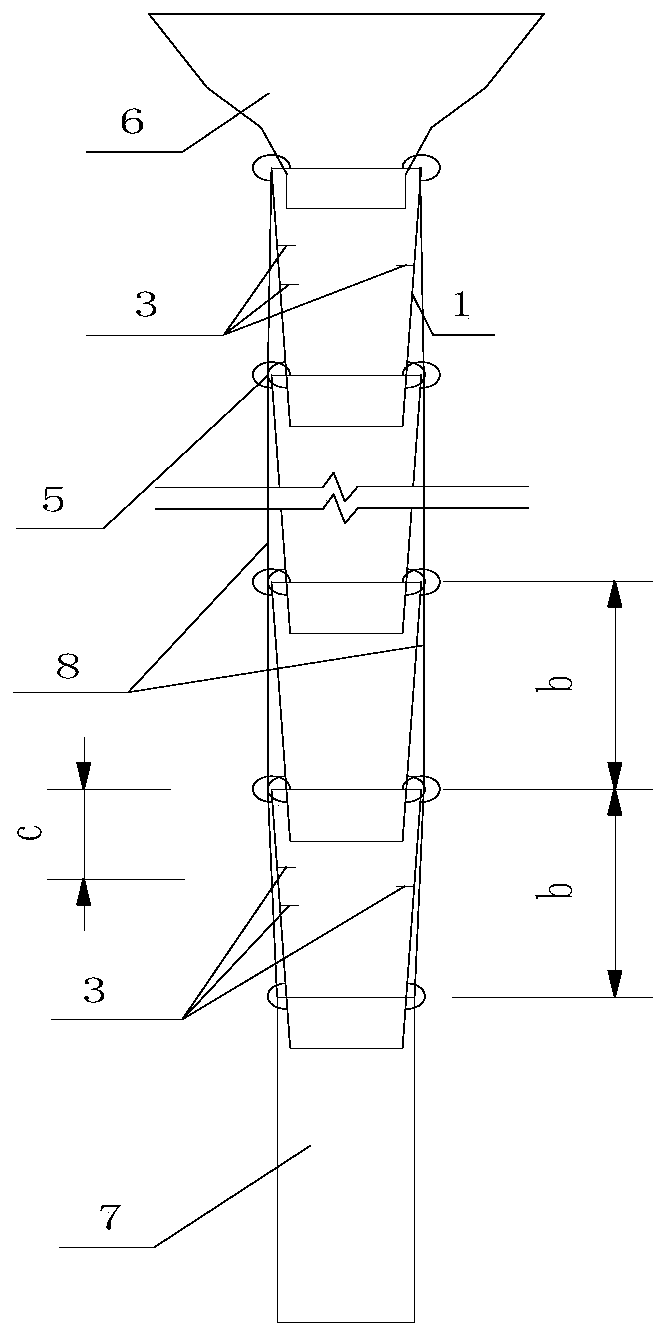

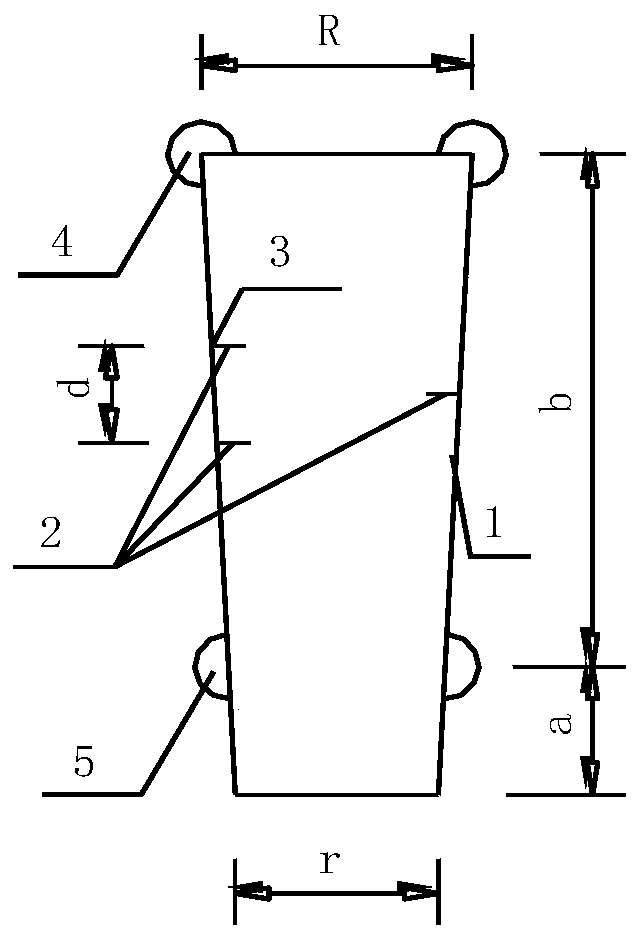

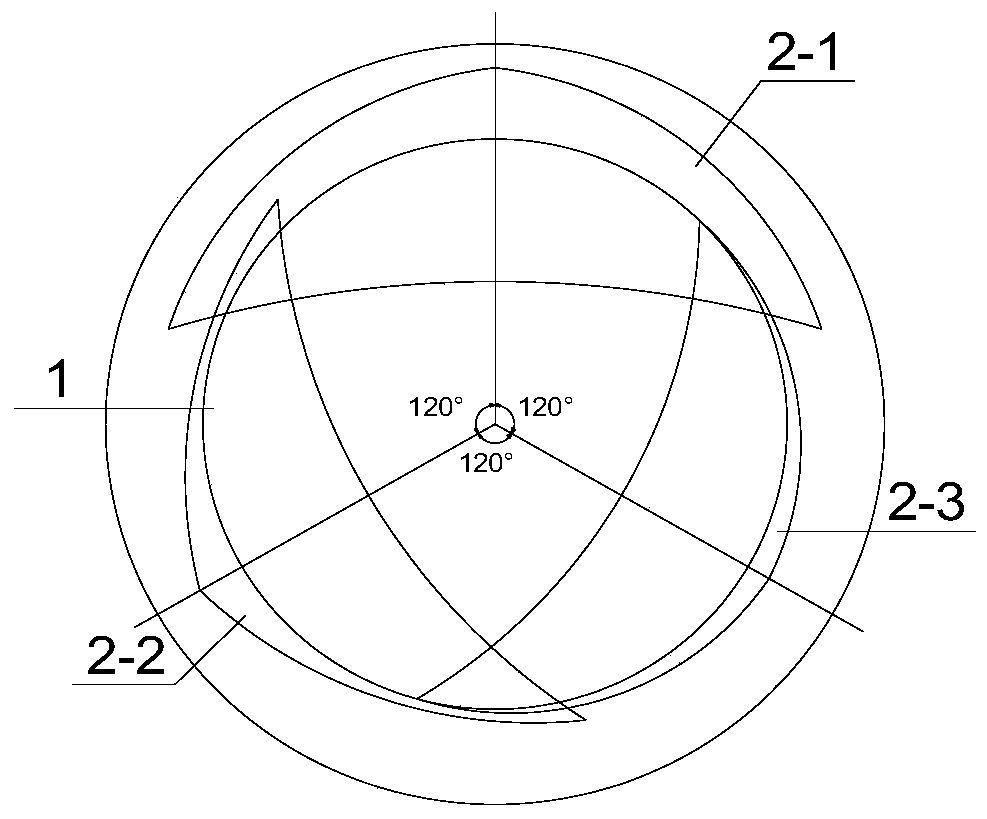

High discharge system for loose unpacked material

InactiveCN101376463AControl segregationSegregation reduction and controlLarge containersLoading/unloadingFree fallingBucket elevator

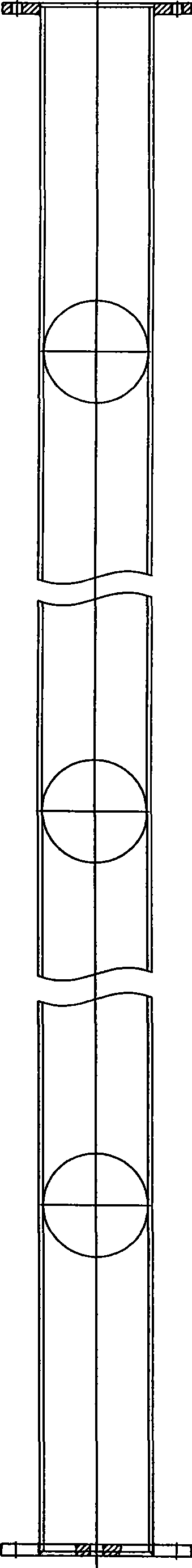

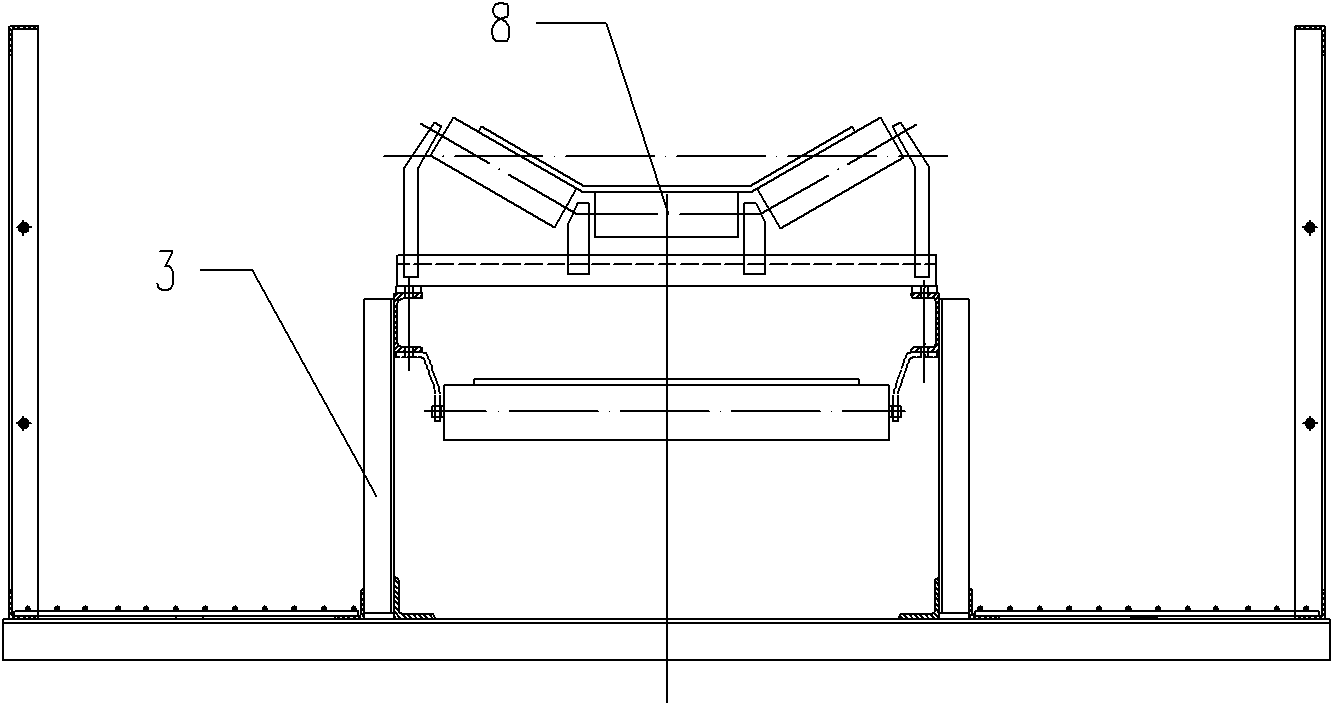

The invention relates to a bulk material high discharge system, which is used for discharging dry bulk material with certain flowability into a preset storage bin from a high position of tens of meters. The system comprises a mixer discharge hopper (1), a horizontal screw conveyor (2), a vertical bucket elevator (3), a transition bin (5), a cone-shaped transition hopper (9), a bulk bin (4) and a discharge pipe (10), wherein, the mixer discharge hopper (1) is arranged at the upper part of the horizontal screw conveyor (2), the vertical bucket elevator (3) is arranged on the rear side of the horizontal screw conveyor (2), the transition bin (5) is arranged on the rear side of a discharge port at the upper part of the vertical bucket elevator (3), the cone-shaped transition hopper (9) is arranged at the bottom part of the transition bin (5), the discharge pipe (10) is arranged in the bulk bin (4), the upper end of the discharge pipe (10) is connected with the discharge port of the cone-shaped transition hopper (9), the lower end is arranged in the bulk bin (4), and a plurality of discharge holes (10.1) are laterally arranged on the discharge pipe (10). The system can limit and eliminate the free falling body state of various materials, thereby effectively reducing and eliminating segregation.

Owner:WUXI JIANGJIA CONSTR MACHINERY

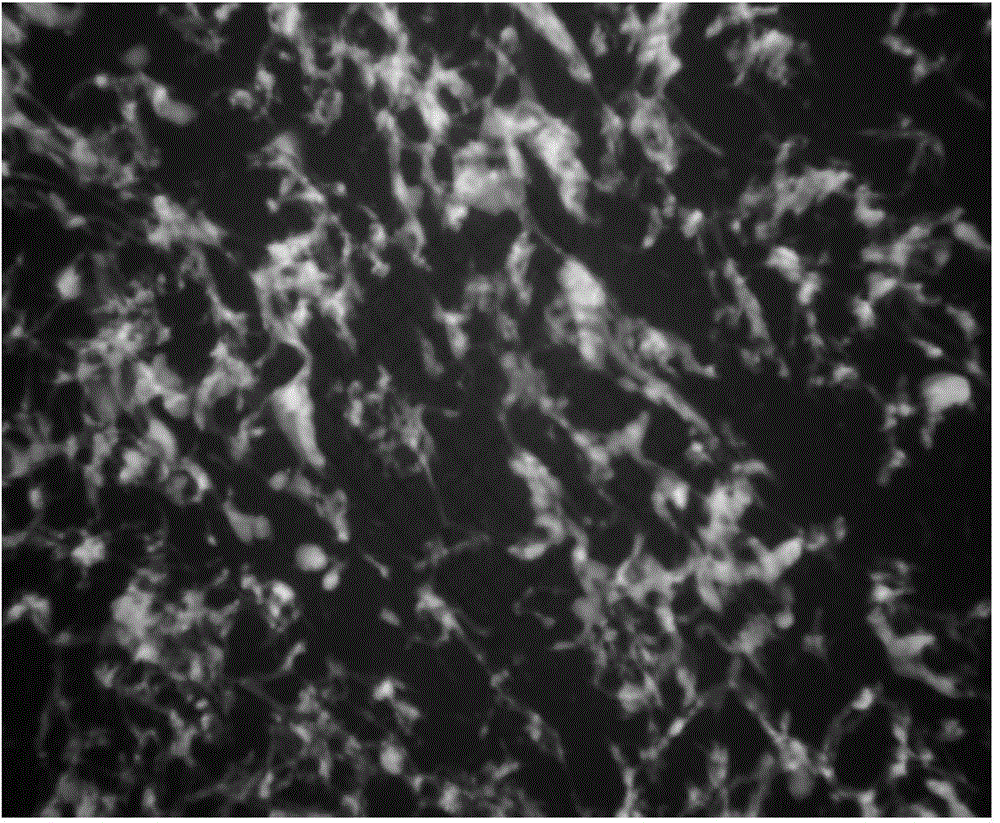

High-concentration crumb rubber modified asphalt and preparation method thereof

ActiveCN102558886AEasy to useReduce absorptionBuilding insulationsHigh concentrationPretreatment method

The invention relates to high-concentration crumb rubber modified asphalt and a preparation method thereof, and belongs to the field of modified asphalt for road construction. Aiming at the problems that the dosage of crumb rubber is not high enough in the traditional crumb rubber modified asphalt technology, and secondary pollution and high energy consumption exist in the wet method modification, the invention adopts a crumb rubber pretreatment method to prepare modified crumb rubber, and then the modified crumb rubber and a reinforcing agent are mixed with asphalt to prepare the high-concentration crumb rubber modified asphalt with a high-speed shearing method, and the filler content of the modified crumb rubber can reach more than 50 parts. The crumb rubber modified asphalt is simple in preparation technology, high in the dosage of the crumb rubber, superior in performance and high in cost performance, and has significant social meaning and environmental protection value.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

Carbon fiber concrete pipe and manufacture method thereof

InactiveCN101619781ASolving Segregation ProblemsReduced strengthShaping reinforcementsRigid pipesFiberCarbon fibers

The invention discloses a carbon fiber concrete pipe and a manufacture method thereof. The manufacture method is characterized by comprising the following steps: (1) sticking carbon fibers in a pipe die and surrounding a layer of carbon fibers in the pipe die; arranging a steel bar framework; (3) pouring concrete; (4) pressurizing and establishing prestress in the concrete and a steel bar by the water injection and the pressurization of a rubber inner die, the pressure reaches 25MPa-30MPa, and the duration is 40 minutes to 45 minutes; (5) maintaining by steam at 50 DEG C-55 DEG C for 1 hour or so; (6) demolding when the concrete strength reaches 8MPa-12MPa; (7) maintaining by hot water, maintaining by hot water at 50 DEG C-60 DEG C for previous seven days and maintaining at lower temperature after seven days. The concrete pipe has the advantages of high strength, light weight, favorable plasticity, impact resistance, fatigue resistance, and the like.

Owner:浙江处州建设管理有限公司

Method for preparing circular granule nitrogen and potassium fertilizer

InactiveCN101423433AReduce energy consumptionHigh total nutrientFertiliser formsFertilizer mixturesFertilizerAmmonium sulfate

The invention relates to a method for preparing a nitrogen-kalium fertilizer with circular particles. The method comprises the following steps: (1) firstly, sulphuric acid, synthetic ammonia and washing water react to generate ammonium sulfate slurry through a tube-type reactor; the molar ratio of the sulphuric acid to the synthetic ammonia is between 1.8 to 1 and 2.2 to 1; the volume ratio of the washing water to the sulphuric acid is between 1 to 3 and 1 to 1; (2) the ammonium sulfate slurry generated in the step one is directly sprayed on a material of a rotary drum pelletizer for pelletization; and (3) particles formed in the step two are dried, sifted and cooled to obtain the qualified product. The method fully utilizes heat of reaction between the sulphuric acid and the synthetic ammonia and reduces energy consumption; in addition, the sulphuric acid contains nutrients of nitrogen and sulphur essential to plants, thereby improving total nutrients of the product.

Owner:中国-阿拉伯化肥有限公司

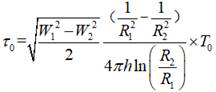

Asphalt and SBS compatibility evaluation method based on molecular dynamics simulation

PendingCN110489858AImprove high temperature deformation resistanceSolving Segregation ProblemsBuilding insulationsSpecial data processing applicationsSolubilityInteraction energy

The invention relates to an asphalt and SBS compatibility evaluation method based on molecular dynamics simulation, belongs to the technical field of modified asphalt compatibility, and mainly solvesthe problem that no specific and accurate method for evaluating the compatibility of SBS and asphalt exists at present. A molecular dynamics simulation method is used as a basis. The method comprises:using molecular dynamics simulation software, respectively constructing a single asphalt system unit cell model, an SBS block copolymer molecular structure model and an SBS modified asphalt blendingsystem model, respectively carrying out molecular dynamics simulation on the models, calculating to obtain solubility parameters and interaction energy, and characterizing and evaluating the compatibility of SBS and asphalt by taking the solubility parameters and interaction energy as indexes. The compatibility evaluation method disclosed by the invention provides an idea for researching the compatibility mechanism of the SBS and the asphalt. The method provides guidance for the establishment of a modified asphalt compatibility evaluation system and an evaluation system thereof, provides a theoretical basis for the formula of the SBS modifier, and has very important significance for solving the problem of asphalt segregation and improving the stability of the modified asphalt.

Owner:NANJING FORESTRY UNIV

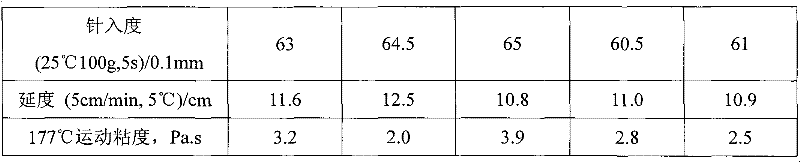

Preparation method of direct-stirring type SBS (styrene-butadiene-styrene) asphalt modifier and preparation method of asphalt mixture

The invention relates to a preparation method of a direct-stirring type SBS (styrene-butadiene-styrene) asphalt modifier and a preparation method of an asphalt mixture. The preparation method comprises the following steps of respectively metering 4303 star-shaped SBS, 1301 linear SBS and lubricating oil, feeding into a mixer according to a ratio, uniformly mixing, and uniformly stirring; feeding petroleum resin and calcium carbonate into the mixer, and uniformly stirring; feeding the mixture into a double-screw extruder, enabling the mixture to form a melting mixture at high temperature, and enabling the double-screw extruder to extrude the melting mixture after the forced shearing, extrusion, dispersing and kneading are continuously maintained; cooling the melting mixture extruded by thedouble-screw extruder by a water tank, enabling a pelletizer to cut into granules, enabling an air dryer to dry, and packaging. The preparation method has the advantages that the production technologyof the modified asphalt is simplified, the production quality of the mixture is favorably controlled, the construction quality of a road pavement is ensured, the use property of the road is improved,the service life of the road is prolonged, the pollution to the environment is decreased, and the engineering investment is reduced.

Owner:SHANDONG JIAOTONG UNIV

High-viscosity asphalt additive modifier and preparation method thereof and high-viscosity modified asphalt and preparation method thereof

The invention relates to a high-viscosity asphalt additive modifier and a preparation method thereof. The high-viscosity asphalt additive modifier is prepared from, by weight, 100 parts of thermoplastic resin, 10-20 parts of viscosity resin, 20-30 parts of EVA and 1-2 parts of zinc stearate. The invention further relates to a high-viscosity modified asphalt and a preparation method thereof. To solve the problem of traditional high-viscosity modified asphalt, the high-viscosity asphalt additive modifier with low cost and good performance is provided, the high-viscosity modified asphalt is not needed to be prepared in advance, only the modifier is manually or automatically added in a asphalt mixture when in use, and the high-viscosity modified asphalt mixture is then formed after aggregating, shearing and stirring are conducted in sequence.

Owner:SUZHOU TOPOLINE TECH

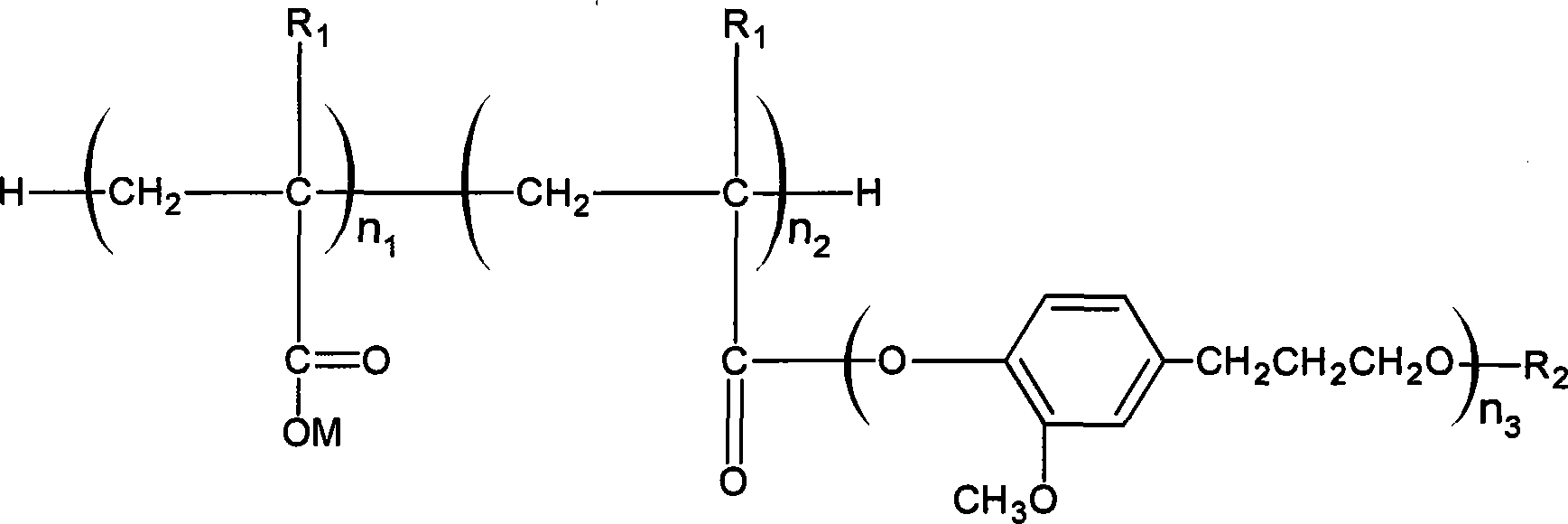

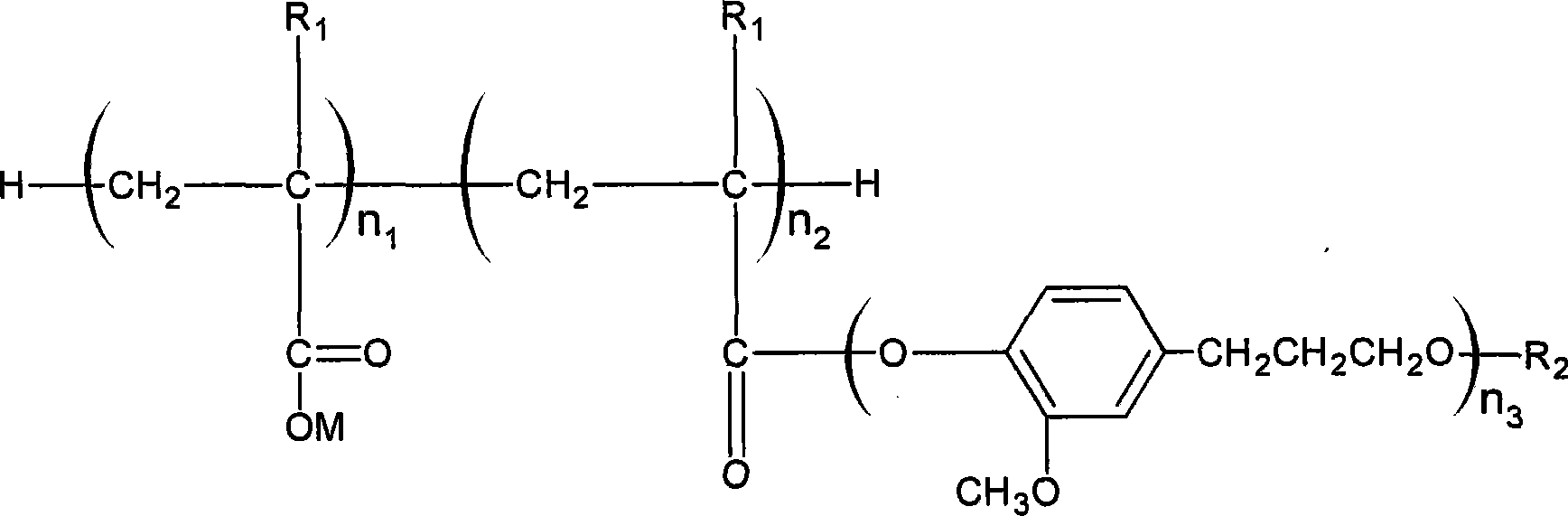

Tackifier of cement-base material and its preparation method and application

InactiveCN101239794AGood viscosity increasing effectSolving Segregation ProblemsCarboxylic acidPhenol

The present invention discloses an adhesion promoter of a cement-based material and the preparing method and the use thereof, the invention is the adhesion promoter of the cement-based material which is obtained using the papermaking waste liquor, extracting the methyphenylpropane of the phenol-containing hydroxyl group, generating esterifying reaction with the carboxyl monomer under the function of the catalyst and then copolymerizing with the carboxyl acid, or graft-copolymerizing with the acidamide substance and ahs a comb-shaped structure. When the adhesion promoter is mixed into the cement-based material the appropriate thickness and workability can be endowed to the cement-based material, the mixed water is leaded to be uniformly distributed in the cement-based material and can be kept stable for a long time without discharging out, at the same time the adhesion promoter of the invention increases the viscosity of the paste and leads to that the particles of aggregate is not easily moved thereby effectively preventing the disengagement and facilitating that the cement-based material always keeps better homogeneity.

Owner:HOHAI UNIV

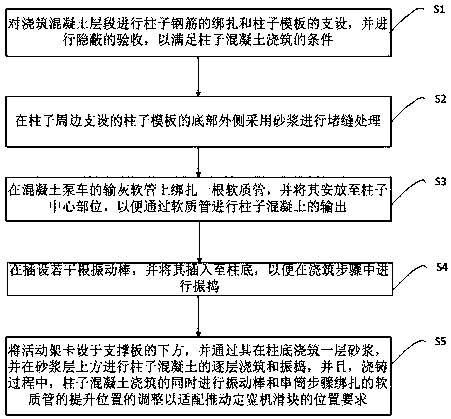

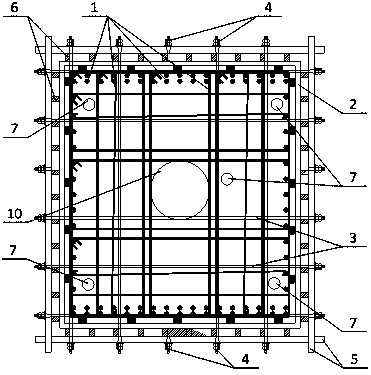

Concrete column pouring method

InactiveCN109594719AGuarantee the pouring qualityImprove pouring qualityStrutsBuilding material handlingFree fallingHoneycomb

The invention provides a concrete column pouring method. The concrete column pouring method comprises the following steps of formwork plugging: mortar is adopted for conducting crack plugging treatment on the outer side of the bottom of a column formwork erected on the periphery of a column; tube stringing: binding a soft tube on a dust conveying hose of the concrete pump truck, and placing the soft tube at the central part of the column, so as to output column concrete through the rubber hose; and pouring: a layer of mortar is poured at the bottom of the column, pouring and vibrating are carried out on the column concrete layer by layer above the mortar layer, and the vibrating bar and the soft tube bound in the tube stringing step are lifted while pouring the column concrete in the pouring process. According to the method, the root rotting problem of the column is solved by adopting a mortar pre-pouring method, the segregation problem caused by large free fall of the column concreteis avoided by additionally adopting the tube stringing method, and the quality defects of concrete honeycombs, pitted surfaces and incompact vibration are further overcome by multi-point layered vibration during pouring.

Owner:CHINA MCC20 GRP CORP

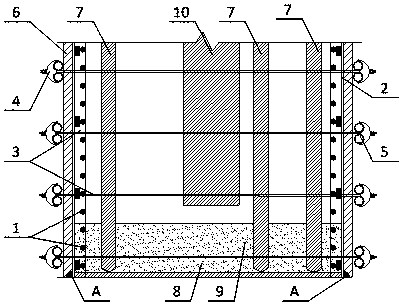

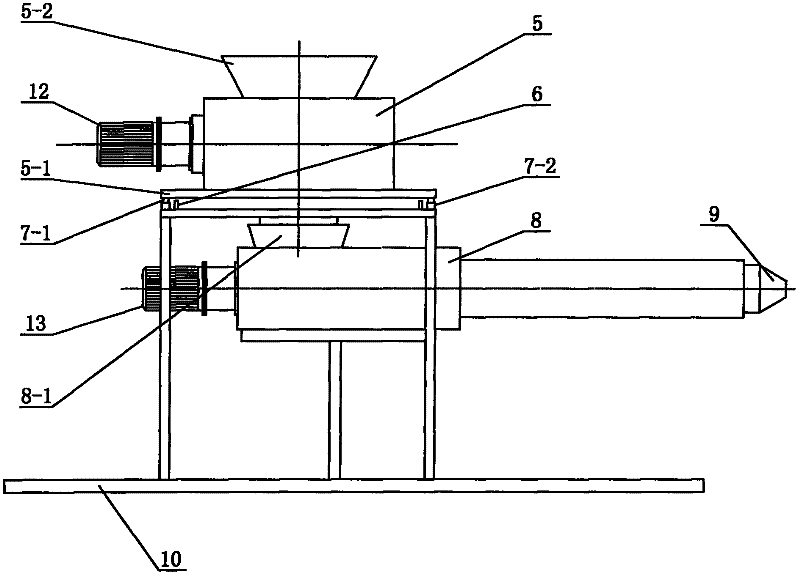

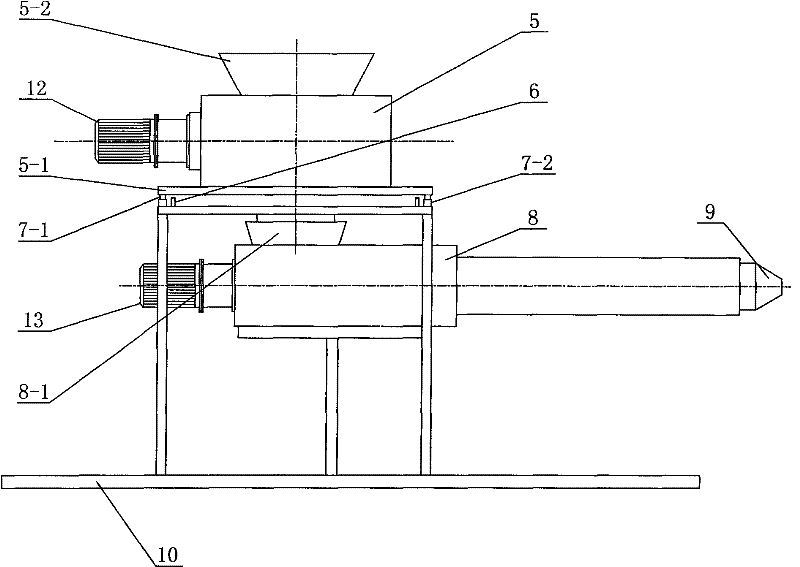

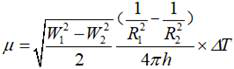

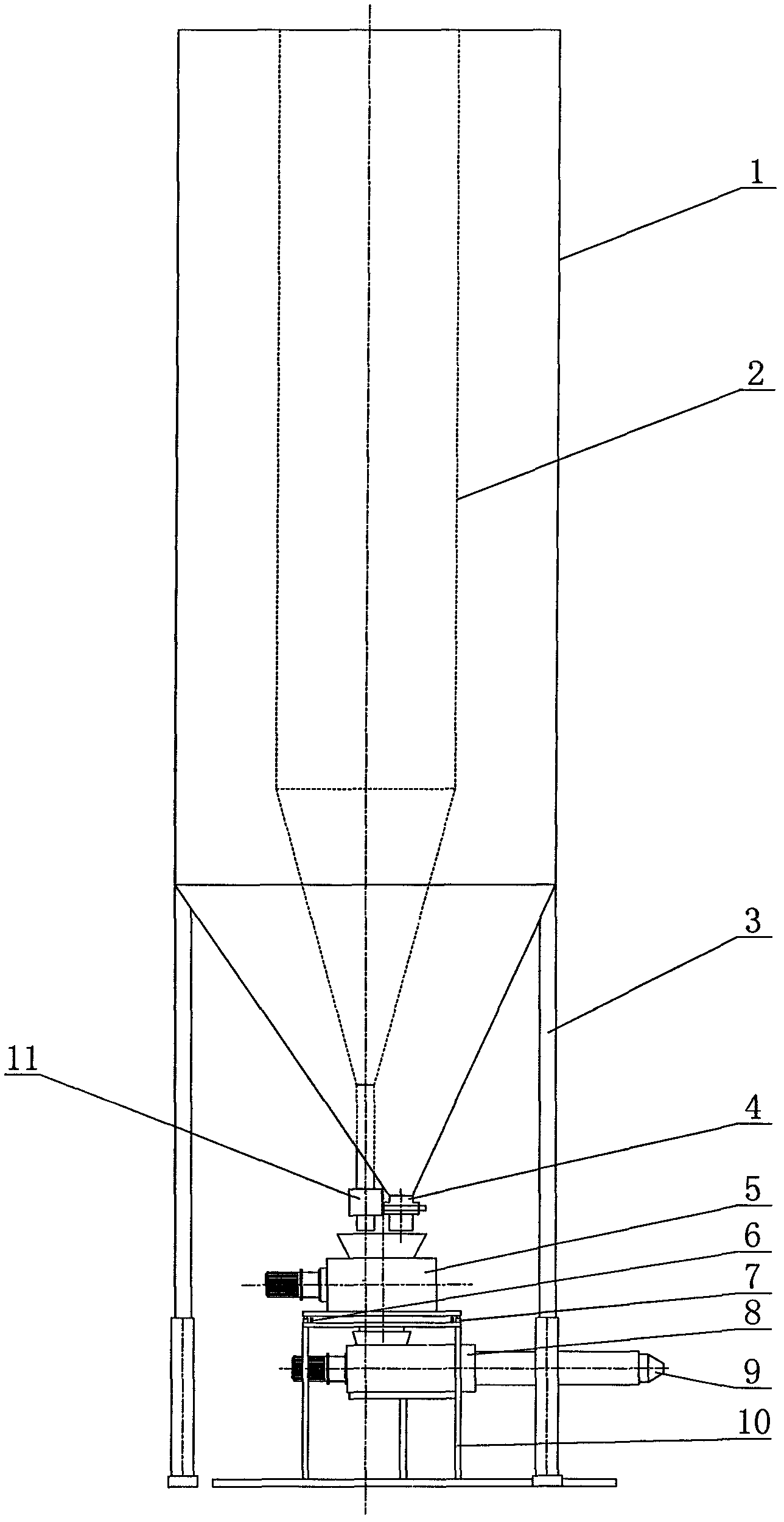

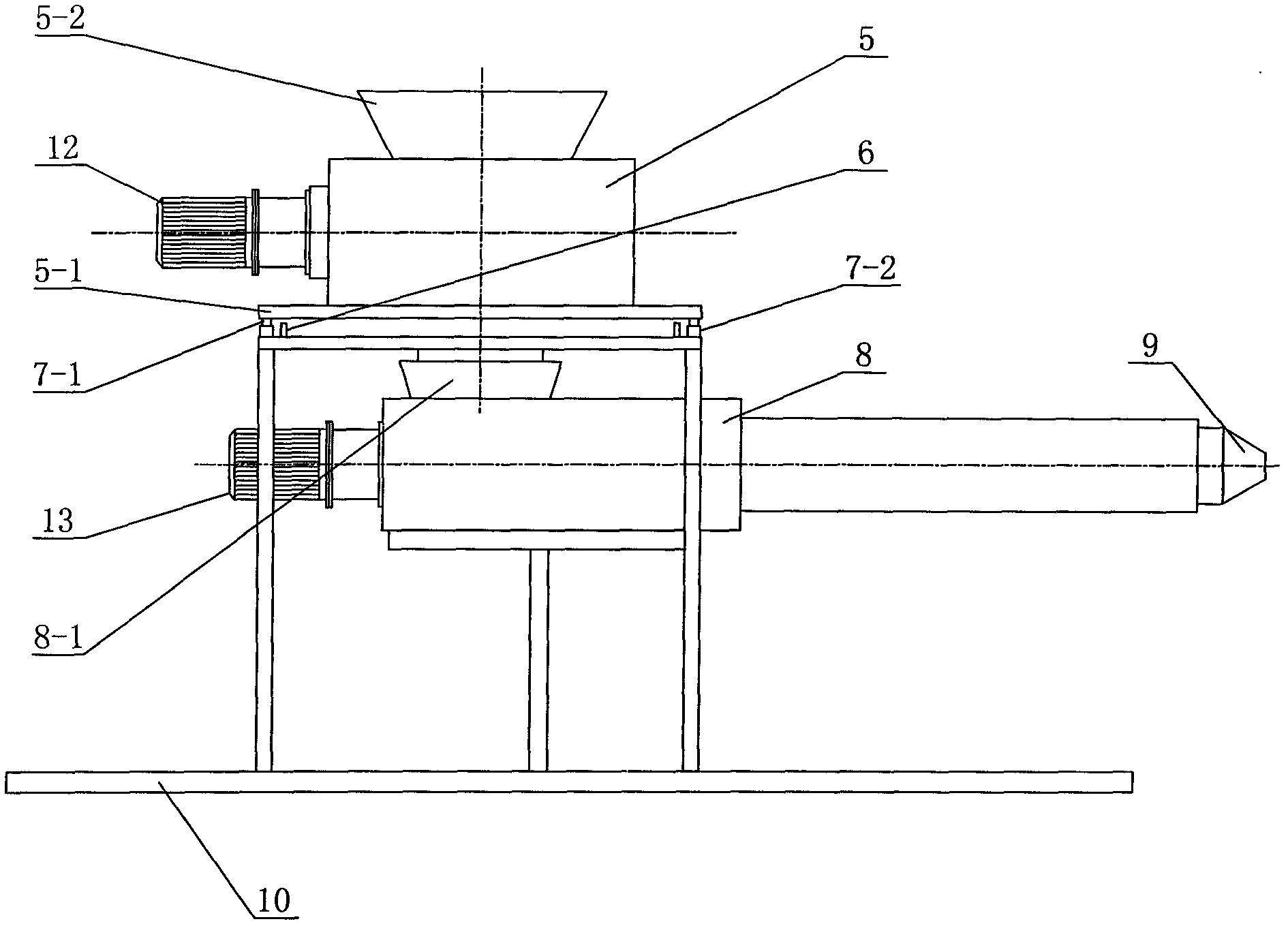

Dry and wet composite mixing equipment for power particles

InactiveCN102371625ASolving Segregation ProblemsQuality assuranceCement mixing apparatusMixed materialsEngineering

The invention discloses dry and wet composite mixing equipment for power particles. The dry and wet composite mixing equipment comprises a wet mixing machine (8) and a dry mixing machine arranged above the wet mixing machine, wherein a dry mixed material outlet of the dry mixing machine (5) is located at a position right above a dry mixed material feeding bucket (8-1) of the wet mixing machine (8). The dry and wet composite mixing equipment further comprises a weighing sensor (6) and a telescopic supporting and fixing seat (7), which are arranged on a bracket (10). A cement admixture and sand are conveyed to a site and subjected to metering, dry mixing and wet mixing in sequence to prepare wet mixed mortar for a building. According to the invention, the dry mixing and the wet mixing are integrated and realized in one piece of equipment, and the dry mixing and the metering are completed in a same container. Because the cement admixture and the sand for preparing the dry mixed mortar are not conveyed in a mixing manner any more, the segregation problem in a dry mixed mortar conveying process is thoroughly solved, and the mortar quality is ensured. In addition, by adopting the dry and wet composite mixing equipment, the sand is unnecessary to dry in advance, so that the energy-consumption cost for drying the sand is reduced on the premise of realizing the commercialized and specialized production and utilization of the dry ready mixed mortar.

Owner:盛富春

Stirring cylinder rotating speed self-adaptive control device, method and equipment and storage medium

InactiveCN112265150AQuality improvementLight in massCement mixing apparatusControl apparatusRotational axisClassical mechanics

The invention discloses a stirring cylinder rotating speed self-adaptive control device, method and equipment and a storage medium. The real-time quality state of concrete in a stirring cylinder is sensed through newly-added rotating blades and a rotating shaft, the real-time quality state is obtained by collecting parameters such as the torque and the rotating speed of the newly-added rotating blades through a torque and rotating speed collecting module and then converting the parameters through a conversion relation, then the segregation state of the concrete in the stirring cylinder is judged through the quality state, self-adaptive adjustment of the rotating speed of the stirring cylinder is achieved through a rotating speed adjusting module according to the segregation state, the segregation problem of the concrete is prevented, the quality of the concrete is improved, meanwhile, under the condition that the quality of the concrete is stable, the rotating speed of the stirring cylinder is properly decreased, fuel consumption is reduced, and mechanical abrasion of a hydraulic system and mechanical parts is reduced.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Preparation method of environment-friendly gelling material for mine pit filling

PendingCN109265125AOvercome deficienciesSolve delivery problemsCement productionCeramicwareRed mudSlag

The invention relates to a preparation method of an environment-friendly gelling material for mine pit filling. Fly ash, colored ore slag powder, red mud, cement, quick lime, gypsum powder and vesuvianite powder are mixed and are subjected to ball grinding into blank powder; the blank powder is subjected to calcination and ball grinding to obtain mixed powder; the mixed powder, sodium silicate andfoaming agents are mixed and stirred uniformly; the environment-friendly gelling material for mine pit filling is prepared. The prepared gelling material consumes a large number of solid wastes; theenergy is saved; the environment is protected; the technical defects of poor conveying, separation, draining, water discharging and filling body early-period compressive strength are overcome; the water content is high; the slurry is not separated; the dehydration is not needed; the pumpability is high; the slurry concentration can be changed in a range being 30 percent to 70 percent; after filling for 2h, the compressive strength can reach 3.3MPa; after 24h, the compressive strength can reach 5.9MPa; the final compressive strength can reach 11.9MPa.

Owner:铜陵铜冠建安新型环保建材科技有限公司

Thermal-insulating mortar proportioning and stirring equipment

The invention discloses thermal-insulating mortar proportioning and stirring equipment, belonging to the field of mixing and stirring production equipment for a construction thermal-insulating material. The thermal-insulating mortar proportioning and stirring equipment comprises two feeding hoppers, two lifting machines, an upper material cabin, a lower material cabin, two metering mixers and a packaging machine. The thermal-insulating mortar proportioning and stirring equipment is characterized in that the two feeding hoppers, the two lifting machines and the packaging machine are fixedly arranged on a foundation; the two material cabins and the two metering mixers are supported and fixed on the foundation through metal pillars; the two feeding hoppers are respectively mounted at the feeding openings of the bottoms of the two lifting machines; one metering mixer is connected with the front parts of the feeding hoppers; the two lifting machines are connected with the cylindrical upper material cabin through articulated chutes; a spiral mixer is mounted between the upper material chamber and a funnel-shaped lower material cabin; a discharging opening of the lower material cabin is connected with the other metering mixer through a hose; and discharging openings of the metering mixers are connected with the packaging machine. The thermal-insulating mortar proportioning and stirring equipment is used for sufficiently and uniformly mixing a light material with powder, and accurately weighting, so that the problem in the traditional thermal-insulating mortar assembly line that the light material is easy to crack, and the powder and the light material are separated can be solved.

Owner:HUNAN ZHONGZHENG CONSTR MATERIALS

Bituminous pavement cold filling mixture and preparation method and application method thereof

The invention belongs to the technical field of bituminous pavement cold filling, and discloses a bituminous pavement cold filling mixture and a preparation method and application method thereof. Thebituminous pavement cold filling mixture comprises A components and B components, wherein the weight ratio between the A components and the B components is (35-55):100, the A components comprise, by weight, 90-120 parts of concrete, 45-75 parts of water, 0.1-0.5 part of early strength agent and 1-3 parts of fatty alcohol alkoxy ether; the B components comprise, by weight, 50-80 parts of rubber modified asphalt, 200-300 parts of building stone and 5-10 parts of trichloro ethylene; the preparation method of the bituminous pavement cold filling mixture comprises the following steps of 1) A component preparation and 2) B component preparation; the application method of the bituminous pavement cold filling mixture comprises the following steps of c1, pit slot paving; c2, grouting and c3, traffic opening after flushing. The bituminous pavement cold filling mixture and the preparation method and application method thereof have the advantages that the permeability performance and void ratio are reduced, the problem of bituminous pavement separation is solved, the influence of retarder thinner on the cold filling material is weakened, and the service life of the bituminous pavement is prolonged.

Owner:四川巴南高速公路有限责任公司

Machine-made sand conditioning agent

InactiveCN110950571AImprove adaptabilityAvoid slag and other phenomenaFirming agentStructural engineering

The invention relates to the technical field of buildings, and discloses a machine-made sand conditioning agent which can be freely prepared by a user according to requirements by separately preparingmultiple conditioning agents and then combining the multiple conditioning agents, so that the machine-made sand conditioning agent adapting to the environment is prepared, and the machine-made sand conditioning agent has good adaptability and practicability; coal tar, furfural, a curing agent and other materials are added into epoxy resin, so that the phenomenon that the whole concrete binder isdried and the binding degree of the concrete binder is reduced after the cement is dried along with time due to addition of the cement is avoided, the phenomena of concrete slag falling and the like are avoided, and meanwhile, when new concrete and old concrete are bound, the binding strength of the concrete binder is improved. A thickening agent is arranged, so that when self-compacting concreteis prepared, the water solubility of the self-compacting concrete is good, the thickening effect of the self-compacting concrete is good, the plastic viscosity of the self-compacting concrete can be effectively improved, and the problems of bleeding and segregation of the self-compacting concrete are solved.

Owner:深圳市君辰装饰设计工程有限公司

Asphalt mixture modifying agent and production method and application thereof

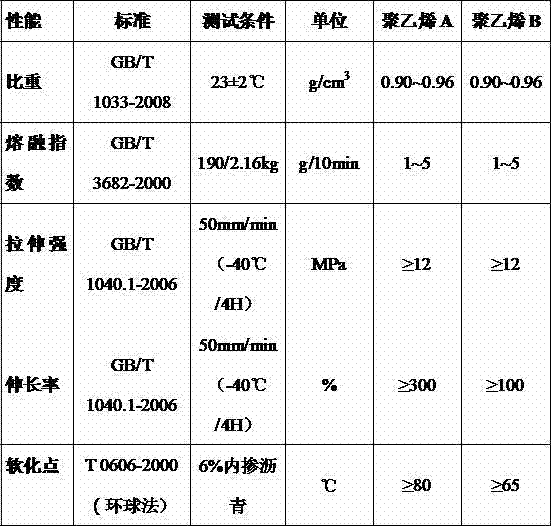

The invention discloses an asphalt mixture modifying agent and a production method and the application thereof. The asphalt mixture modifying agent comprises components of 60 to 90 parts of polyethylene A, 0 to 30 parts of polyethylene B, 0.1 to 0.6 part of antioxidant A, 0.1 to 0.6 part of antioxidant B, 0.2 to 0.8 part of weather resistance agent, 0.4 to 1.2 parts of lubricant A, 3 to 12 parts of lubricant B and 0.8 part of toner.

Owner:GUANGZHOU HONGJIN SYNTHETIC MATERIAL CO LTD

Wear-resistant spiral blade for concrete mixing tank

InactiveCN104108135AIncrease the carrying areaWeld firmlyCement mixing apparatusCentral cylinderLogarithmic spiral

The invention discloses wear-resistant spiral blades for a concrete mixing tank. A tank body is divided into a front cone, a middle cylinder and a rear cone. A pair of spiral blades are designed in an isometric logarithmic spiral line; both thread pitch and spiral angles are different; cross sections of the spiral blades are in a unique concave shape to realize a three-dimensional mixing function; the front cone is provided with mixing blades; the mixing blades are fixed on the rod member in a manner of smaller than the spiral angle of the blade; two ends of a rod member are connected to two adjacent blades respectively; the rear cone is provided with a central cylinder; one end of the central cylinder is in a straight tube shape and fixedly connected to a tank opening; the other end of the central cylinder is in a notched horn shape; the horn surface is provided with through holes in different apertures, so as to facilitate smooth material feeding; the tail end of the blade is fixedly connected to an outer wall of the central cylinder; an inner wall of the tank opening of the rear cone is fixedly connected to a streamlined auxiliary vane for accelerating material-discharging speed and material-discharging shunting effect. The blades provided by the invention have the three-dimensional mixing function, have good mixing performance, are fast and smooth in material feeding and discharging, are firm and wear-resistant, and prolong a service life.

Owner:GUANGXI KELIANG ROAD & BRIDGE MACHINERY

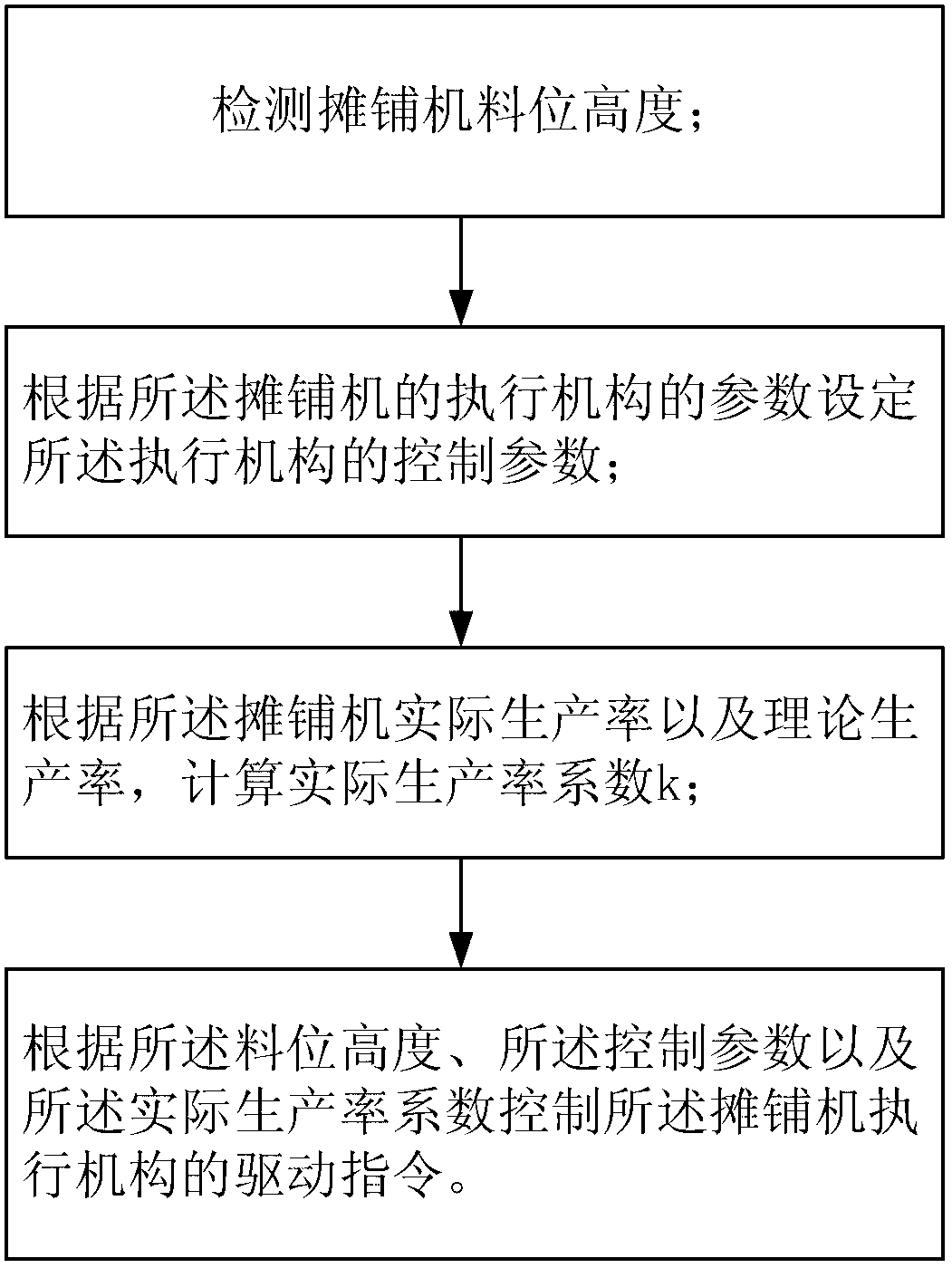

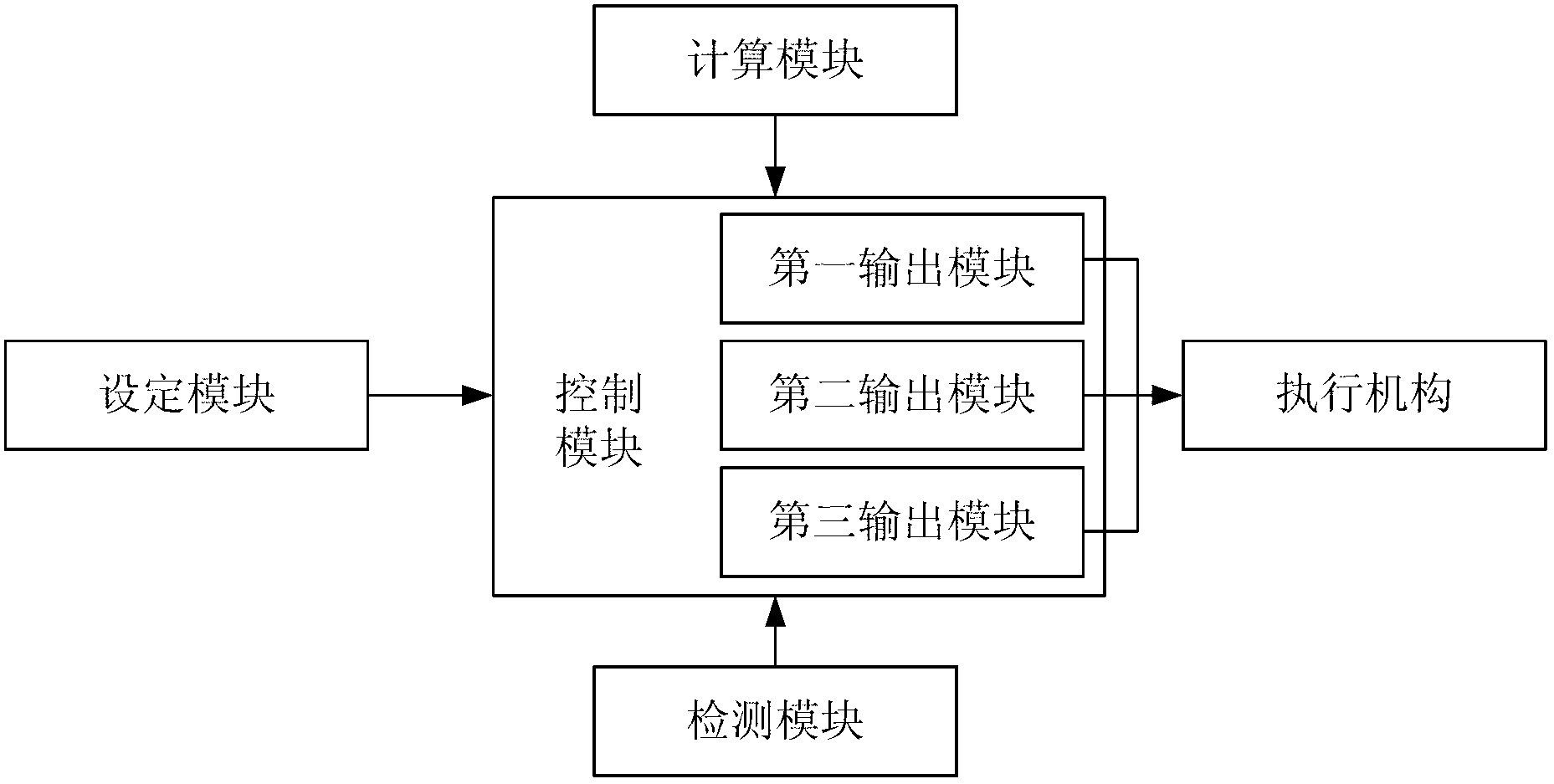

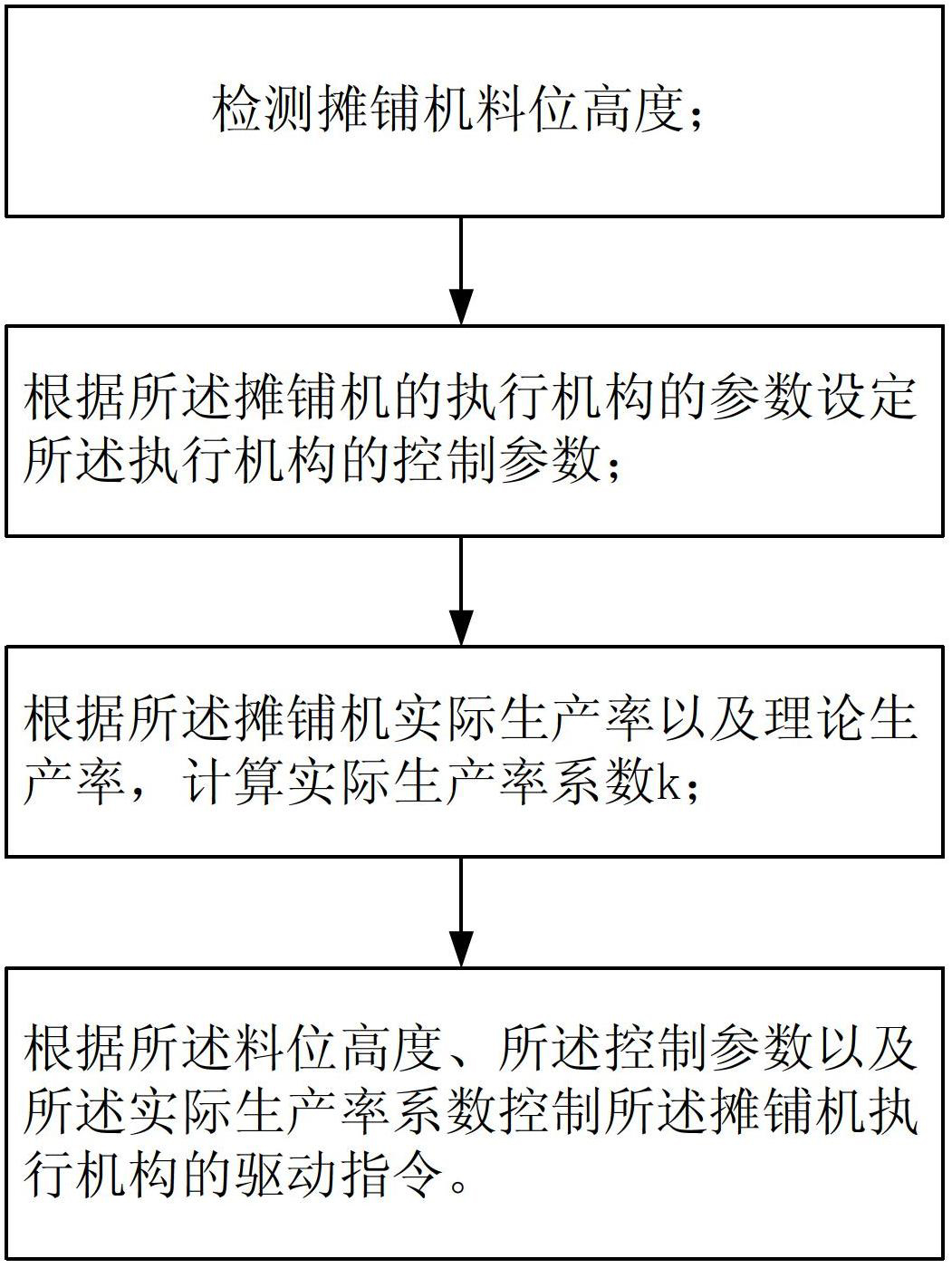

Spreading machine, and method and device for controlling material level of spreading machine

The invention relates to the spreading machine field, which discloses a spreading machine, and a method and device for controlling material level of the spreading machine. The method includes detecting a material level of the spreading machine; setting control parameters of an actuating mechanism according to parameters of the actuating mechanism of the spreading machine; calculating a practical productivity coefficient according to the practical productivity and theoretical productivity of the spreading machine; and controlling a driving command of the actuating mechanism according to the material level, the control parameters and the practical productivity coefficient. Therefore, according to the spreading machine, and method and device provided by the invention, the problems of relatively large variation of a conveying scraper and a distributing screw and material segregation caused by overhigh speed during the conveying process of asphalt mixed material can be solved.

Owner:SANY HEAVY IND CO LTD (CN)

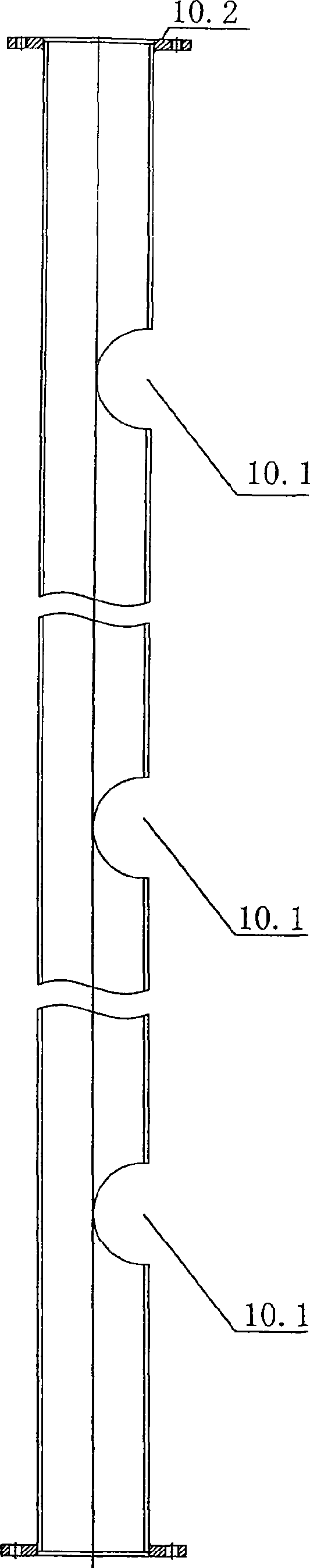

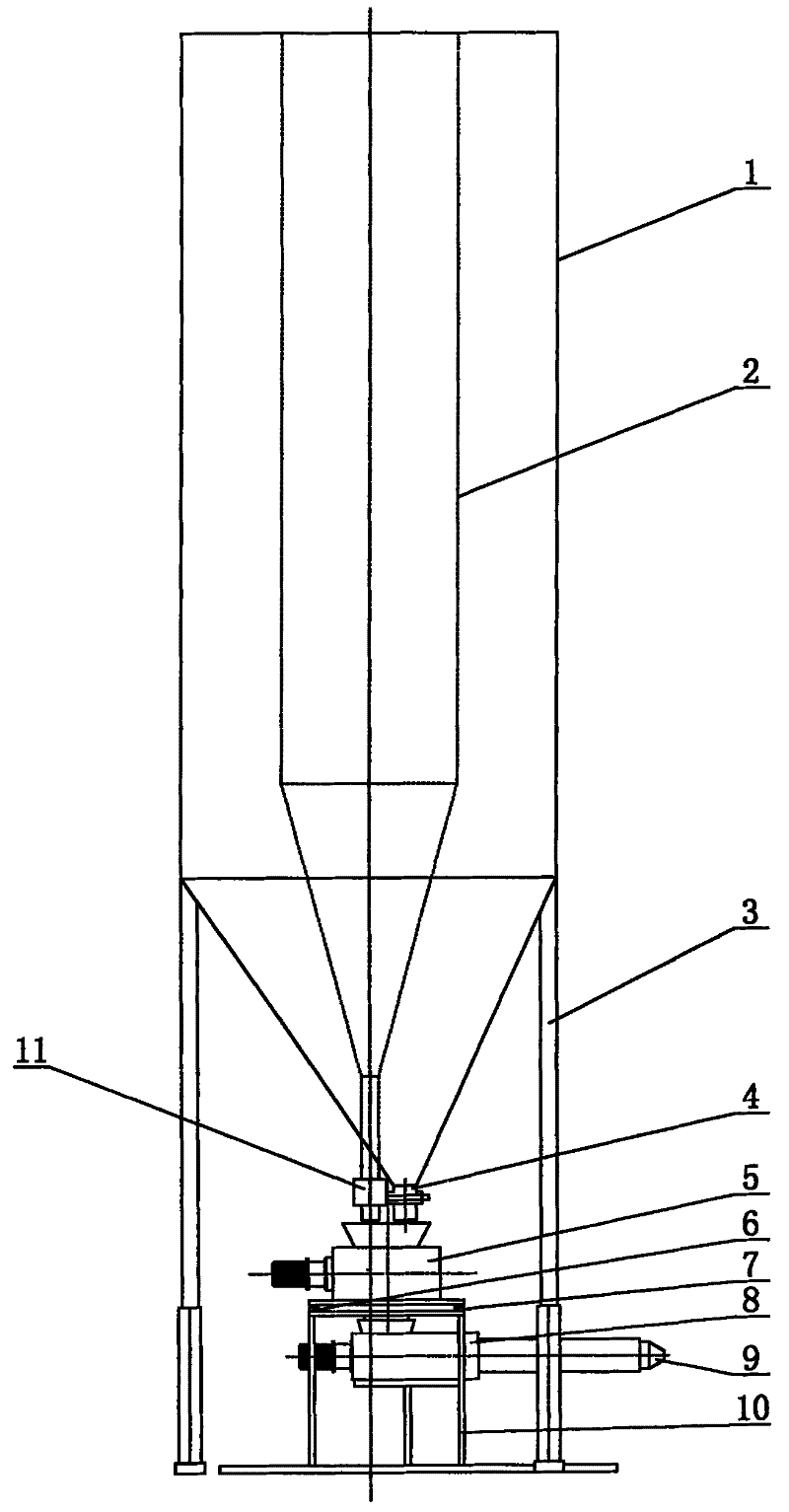

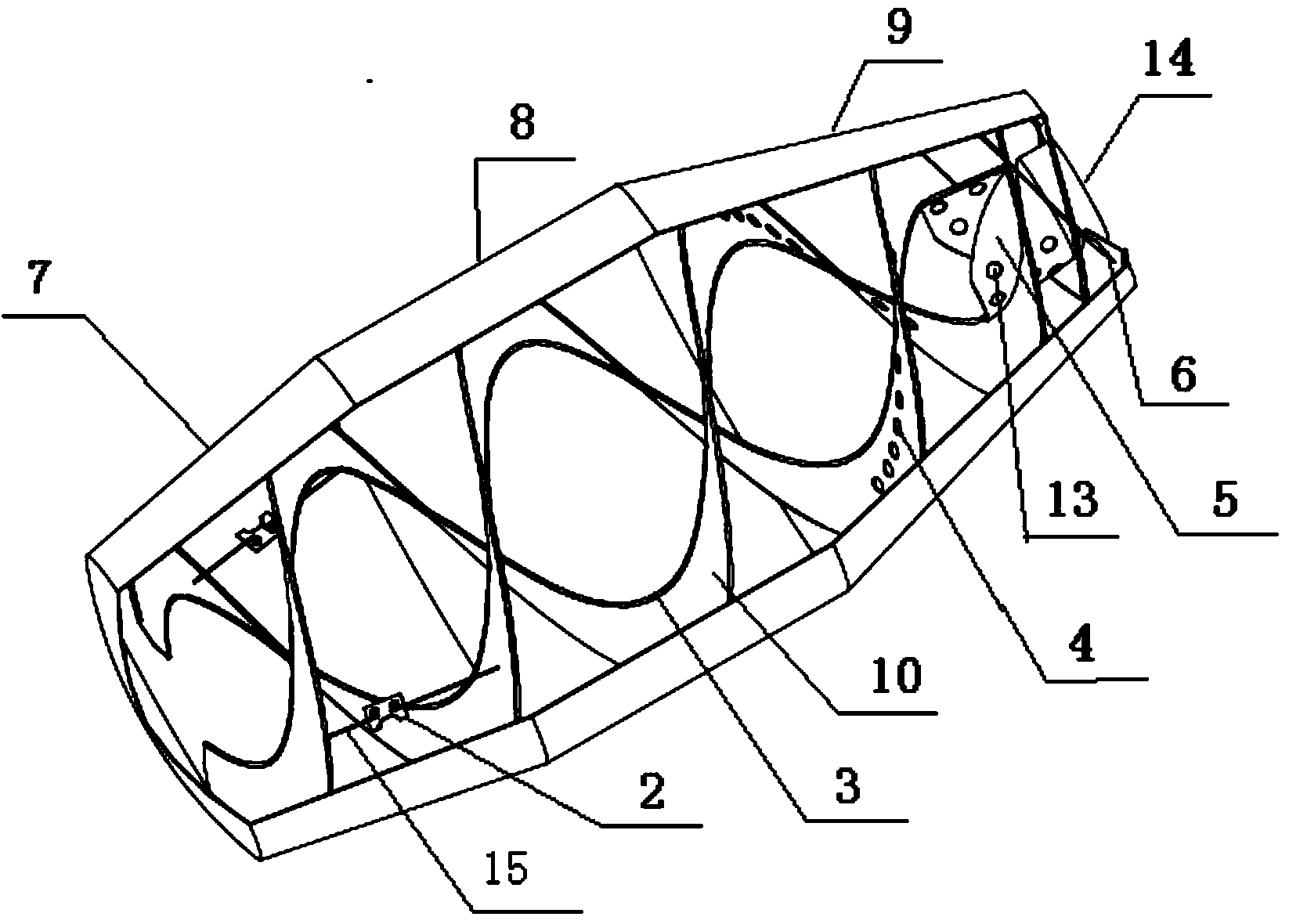

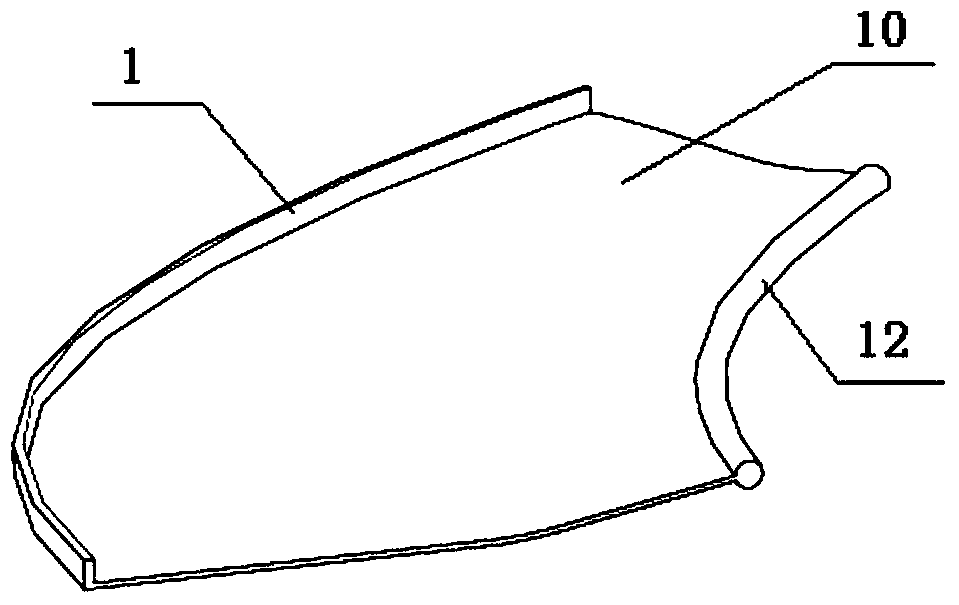

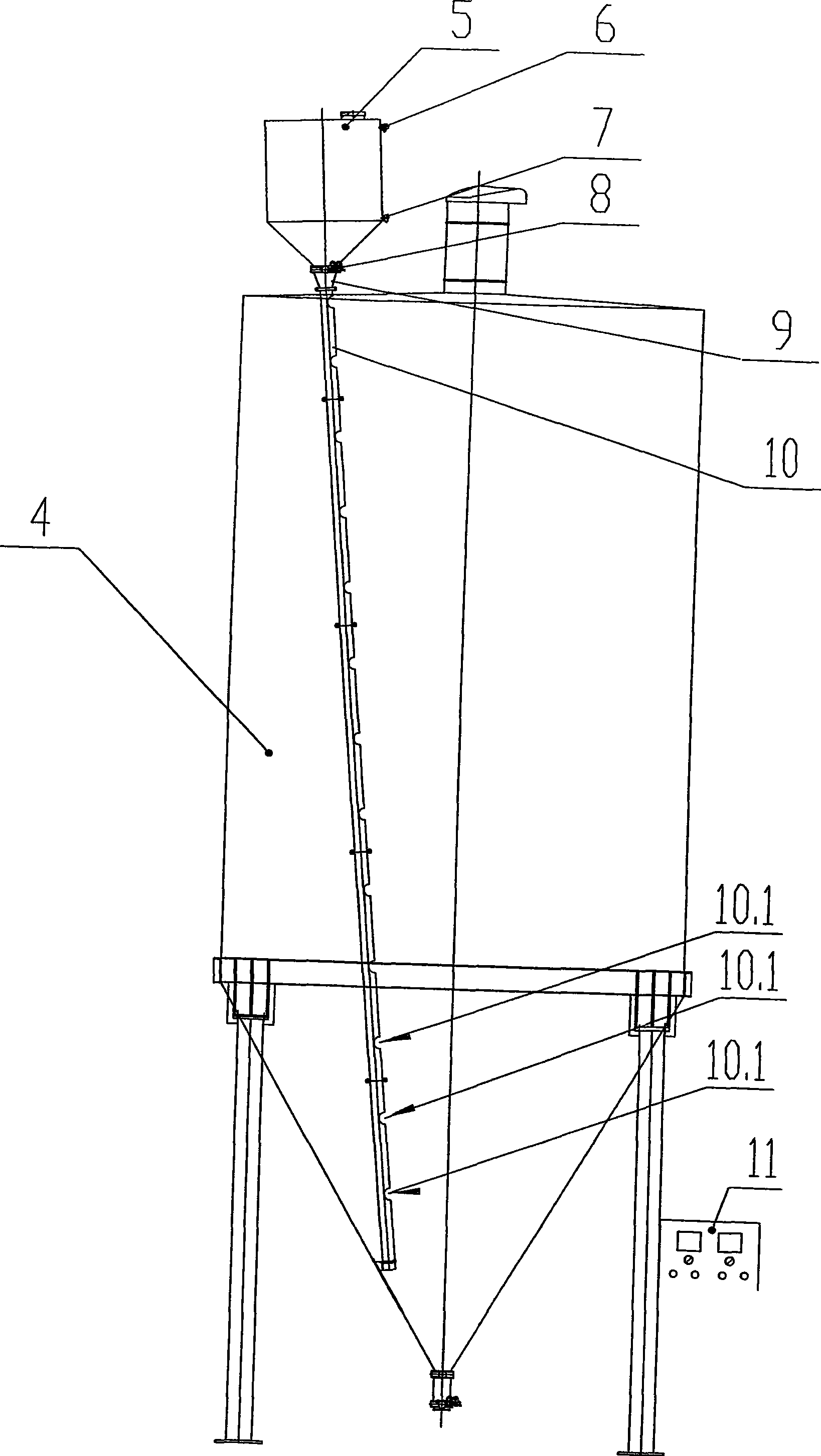

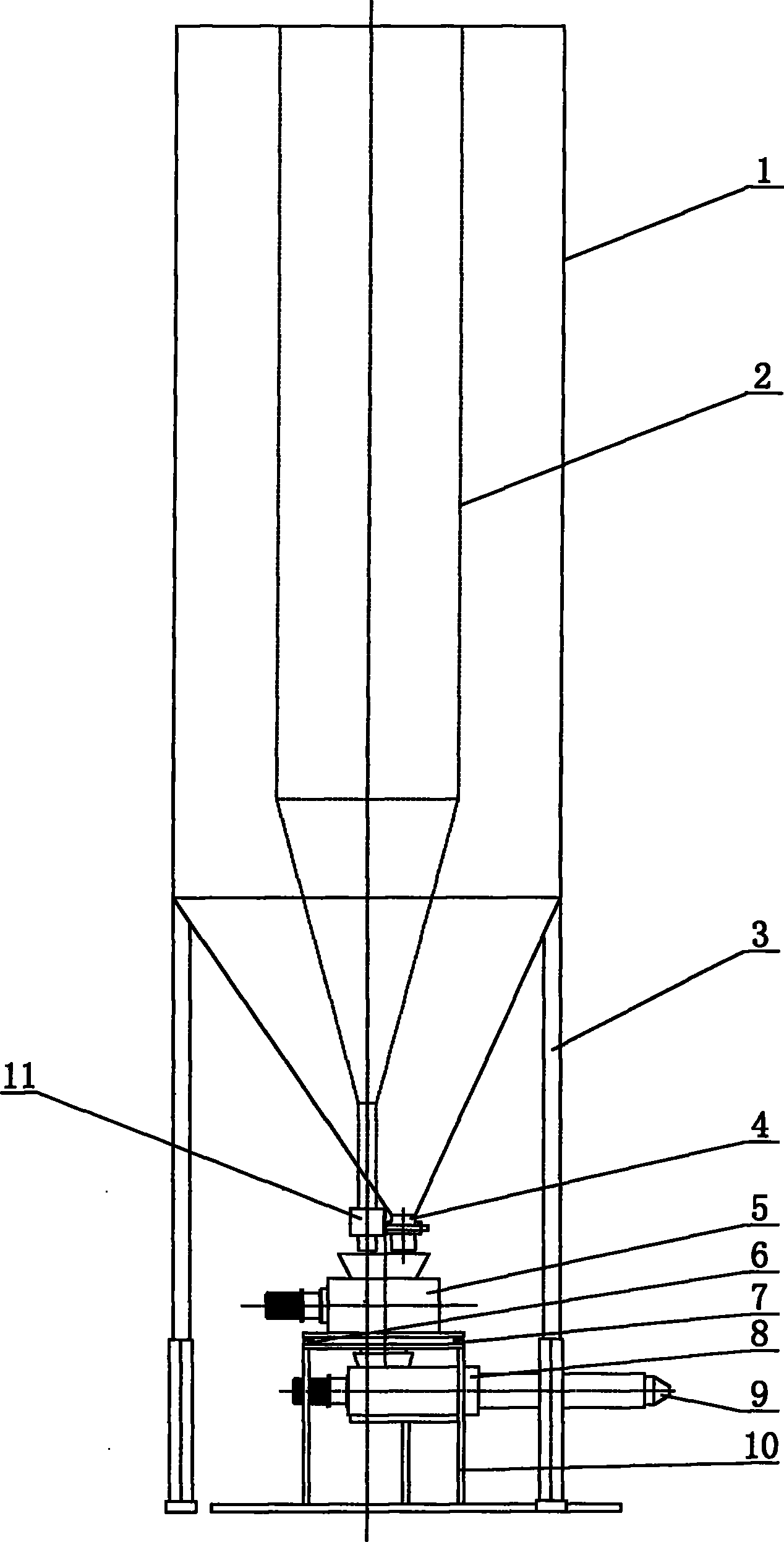

High discharge device for loose unpacked material

InactiveCN101376464AReduces the chance of free fallReduce and control material segregationLarge containersLoading/unloadingEngineeringFree falling

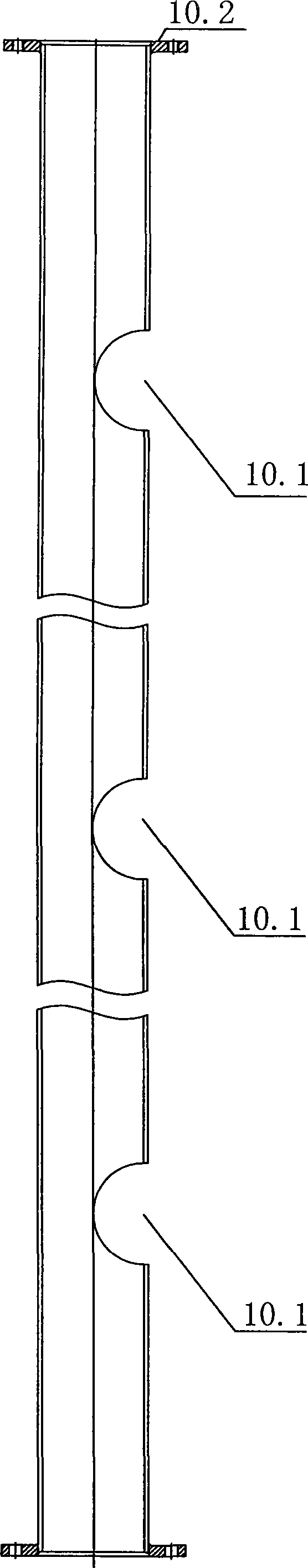

The invention relates to a bulk material high discharge system, which is used for discharging dry bulk material with certain flowability into a preset storage bin from a high position of tens of meters. The system comprises a transition bin (5), a cone-shaped transition hopper (9), a bulk bin (4) and a discharge pipe (10), the cone-shaped transition hopper (9) is arranged at the bottom part of the transition bin (5), the bulk bin (4) is arranged at the lower part of the cone-shaped transition hopper (9), the cone-shaped transition hopper (9) is arranged in the bulk bin (4), the upper end of the discharge pipe (10) is connected with the discharge port of the cone-shaped transition hopper (9), the lower end is arranged in the bulk bin (4), and a plurality of discharge holes (10.1) are laterally arranged on the discharge pipe (10). The system can limit and eliminate the free falling body state of various materials, thereby effectively reducing and eliminating segregation.

Owner:WUXI JIANGJIA CONSTR MACHINERY

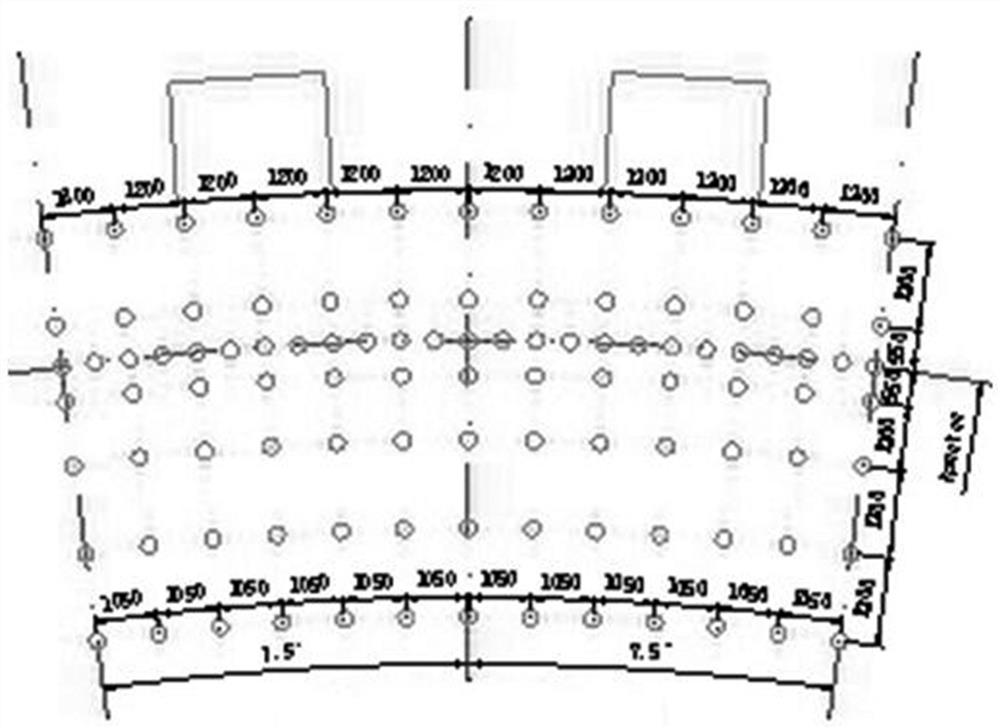

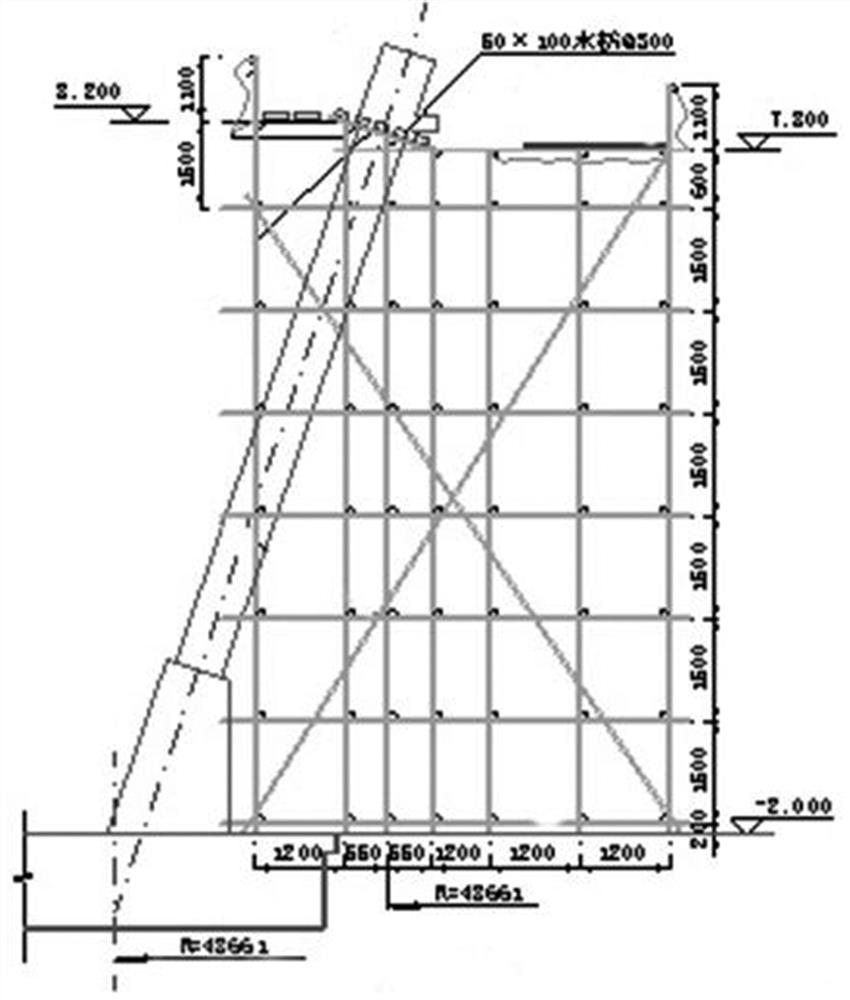

Device for composting concrete aggregate with large particle diameter

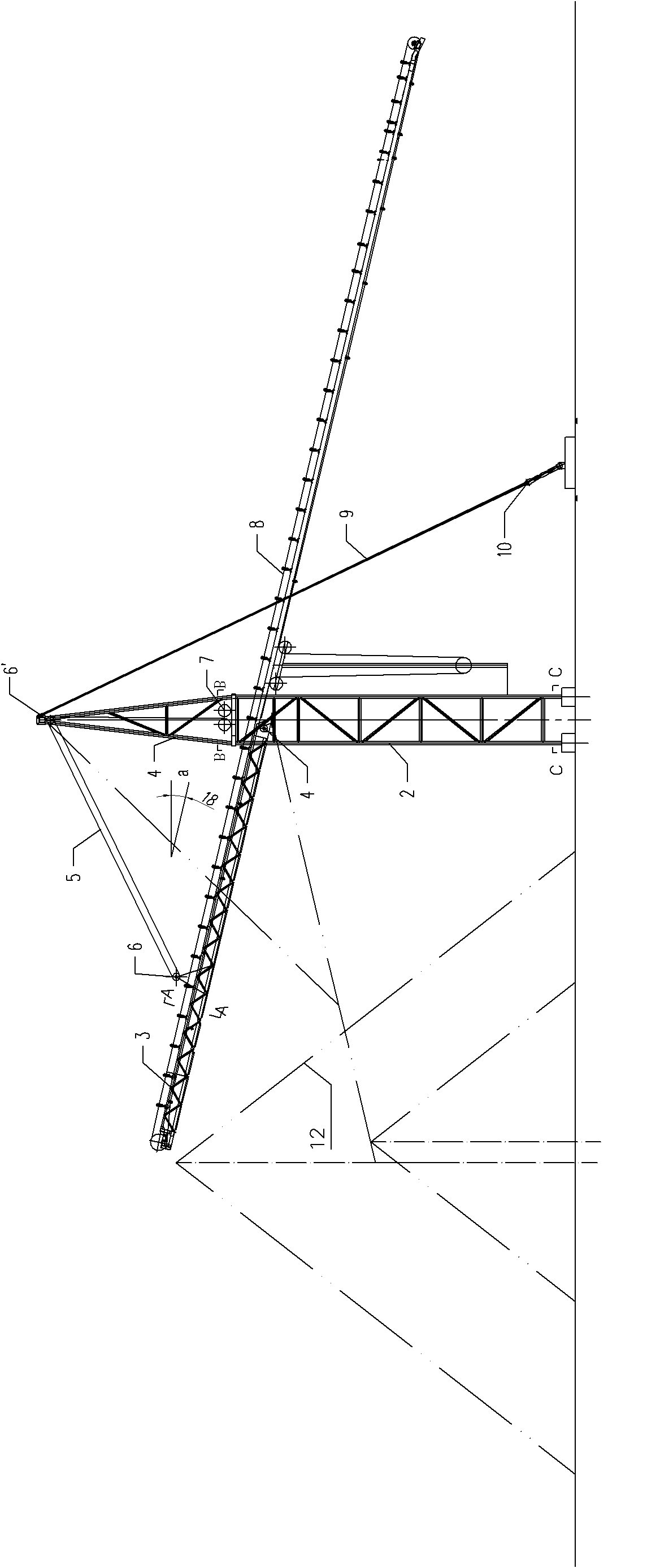

Device for composting concrete aggregate with large particle diameter comprises a tower, a steel upright column and a backstay cable, wherein the steel upright column is provided with a hoist workbench, two hinge supports are arranged on the hoist workbench, and a movable cantilever truss girder is connected with the hinge supports via axle pins; a hoist is equipped on the hoist workbench, a sealing-tape machine is arranged on the movable cantilever truss girder, and a steel wire rope of the hoist is connected with the movable cantilever truss girder via two assembly pulleys. Compared with the current scheme of adopting a stocker, the device provided by the invention saves the cost of purchasing stocker equipment, and reduces construction land occupation and civil engineering expense; and compared with the scheme of adopting a sealing-tape machine for blanking and stockpiling at fixed point, the device of the invention can maximally avoid second fragmentation of the aggregate with large particle diameter in stockpiling, and reduces the undersize index of the particle diameter aggregate by 8% to 18%, at the same time, guarantees continuous aggregate grading, avoids aggregate separation, and solves concrete separation problem caused by unreasonable particle diameter of coarse aggregate, so as to reach the quality requirement of concrete aggregate.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Fishbone-shaped string barrel suitable for deep foundation pit concrete warehousing pouring

PendingCN110700264ASlow down vertical fallControl segregationFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses a fishbone-shaped string barrel suitable for deep foundation pit concrete warehousing pouring. The fishbone-shaped string barrel comprises multiple sections of string barrel bodies which are sequentially connected end-to-end into a whole. A plurality of groups of fishbone-shaped sliding grooves are formed in the inner wall of each section of the string barrel body in the form of spiral extending at intervals. Each fishbone-shaped sliding groove is of a streamline form space curved surface structure and extends downwards. The fishbone-shaped string barrel can comprehensively adapt to foundation pit environmental conditions such as narrow, high and steep, deep and narrow foundation pits. The fishbone-shaped string barrel is simple in structure, low in cost and rapid in construction.

Owner:湖北水总水利水电建设股份有限公司

Storage, transportation and mixed preparation method for building mortar and special device thereof

ActiveCN102312577ASave social investmentReduce energy costsBuilding material handlingDry mixingArchitectural engineering

The invention discloses a storage, transportation and mixed preparation method for building mortar and a special device thereof. The method comprises the following steps of: firstly, dividing the raw materials of dry-mixed mortar into a cement mixed material and sand, and transporting the two raw materials to a construction site by virtue of mutually independent containers; and then, at the construction site, respectively weighing a raw material A and a raw material B, and carrying out dry mixing and wet mixing on the raw material A and the raw material B. The method and the special device overcome the defect of high energy consumption due to the baking of the sand in the existing manufacturing and using processes of the mortar, save energy resources, solve the separation problem in the existing production and transportation processes of the mortar, and improve the product quality on the premise that the energy resources are saved.

Owner:盛富春

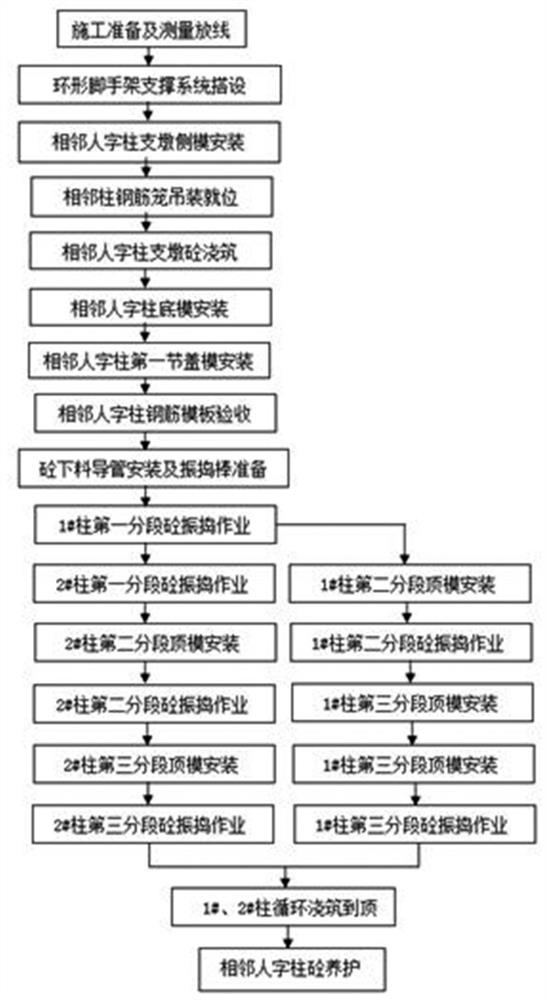

Construction method for pouring circular herringbone column of cooling tower in segmented mode

InactiveCN112227817ASolve the use of securitySolve the durability problemForms/shuttering/falseworksTowersPipeCooling tower

The invention relates to the technical field of cooling tower construction, and discloses a construction method for pouring a circular herringbone column of a cooling tower in a segmented mode. The method comprises the following operation steps that 1, construction preparation is carried out, specifically, a design construction drawing is familiarized, safe technical disclosure is carried out on construction workers, and meanwhile preparation work of materials, machines, tools and equipment is carried out. According to the construction method for pouring the circular herringbone column of thecooling tower in the segmented mode, a UPVC guide pipe discharging method is adopted in herringbone column concrete pouring construction, the problem that mixtures are separated due to the fact that the free falling height of concrete is large is mainly solved, a column top mold is covered and reinforced in a segmented mode, observation and manual auxiliary vibration can be convenient, two vibrating rods are adopted to work at the same time, and the problem that the use safety and durability of the structure are affected due to the fact that concrete is vibrated uncompactly can be effectivelysolved; and compared with a traditional pouring method, the construction method is simple in construction and easy to operate, and it can be effectively guaranteed that herringbone column concrete achieves the effect of solid inside and smooth outside.

Owner:贵州建工集团第三建筑工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com