Method for preparing modified asphalt by adopting raw material with low asphaltene content

A technology of asphaltene content and modified asphalt, which is applied in the direction of only multi-stage series refining and cracking process, building insulation materials, building components, etc., can solve the problems of poor low temperature performance, poor compatibility, cumbersome process steps, etc. Achieve the effects of increasing the content of aromatic hydrocarbons and asphaltene, excellent high and low temperature performance, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

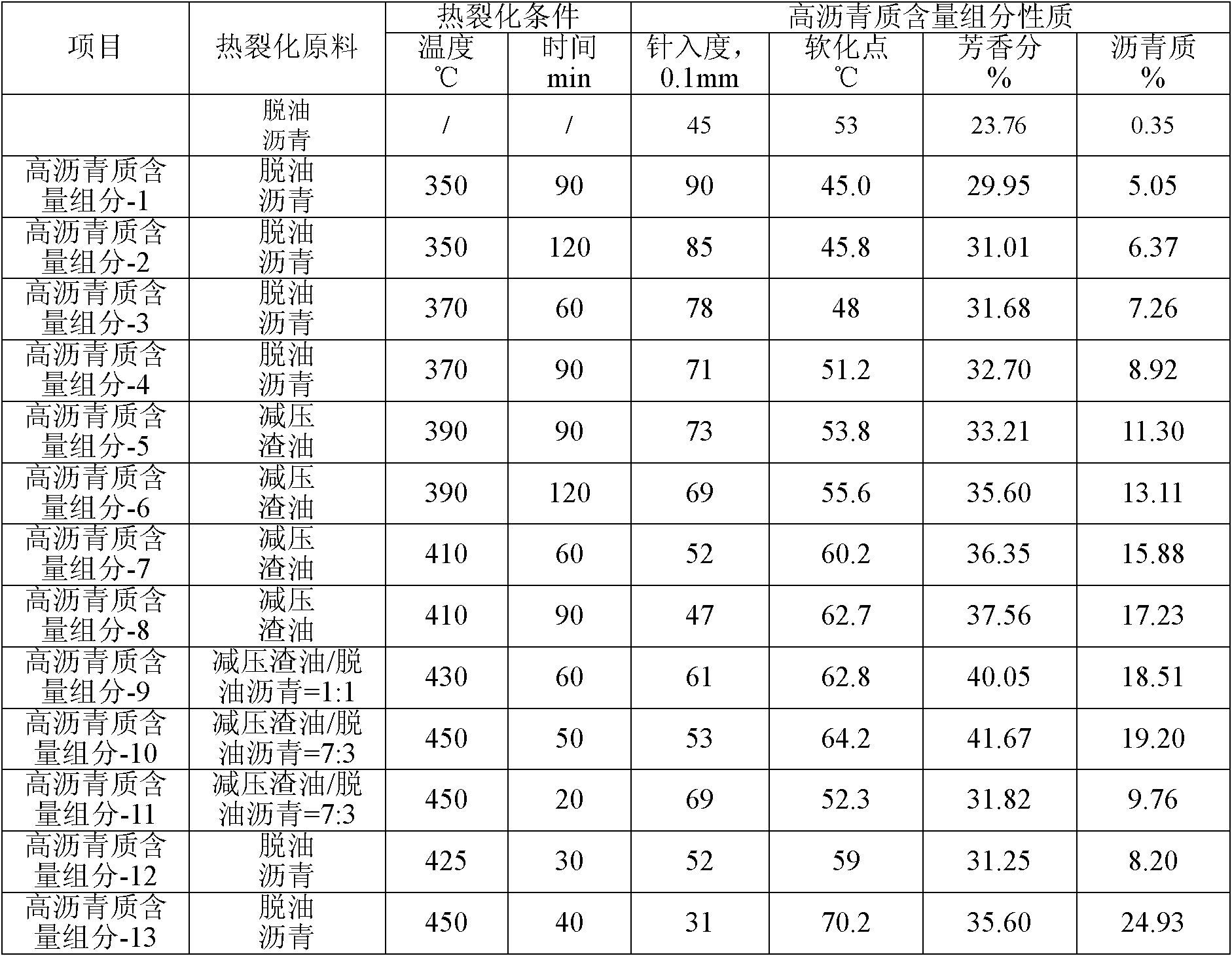

Examples

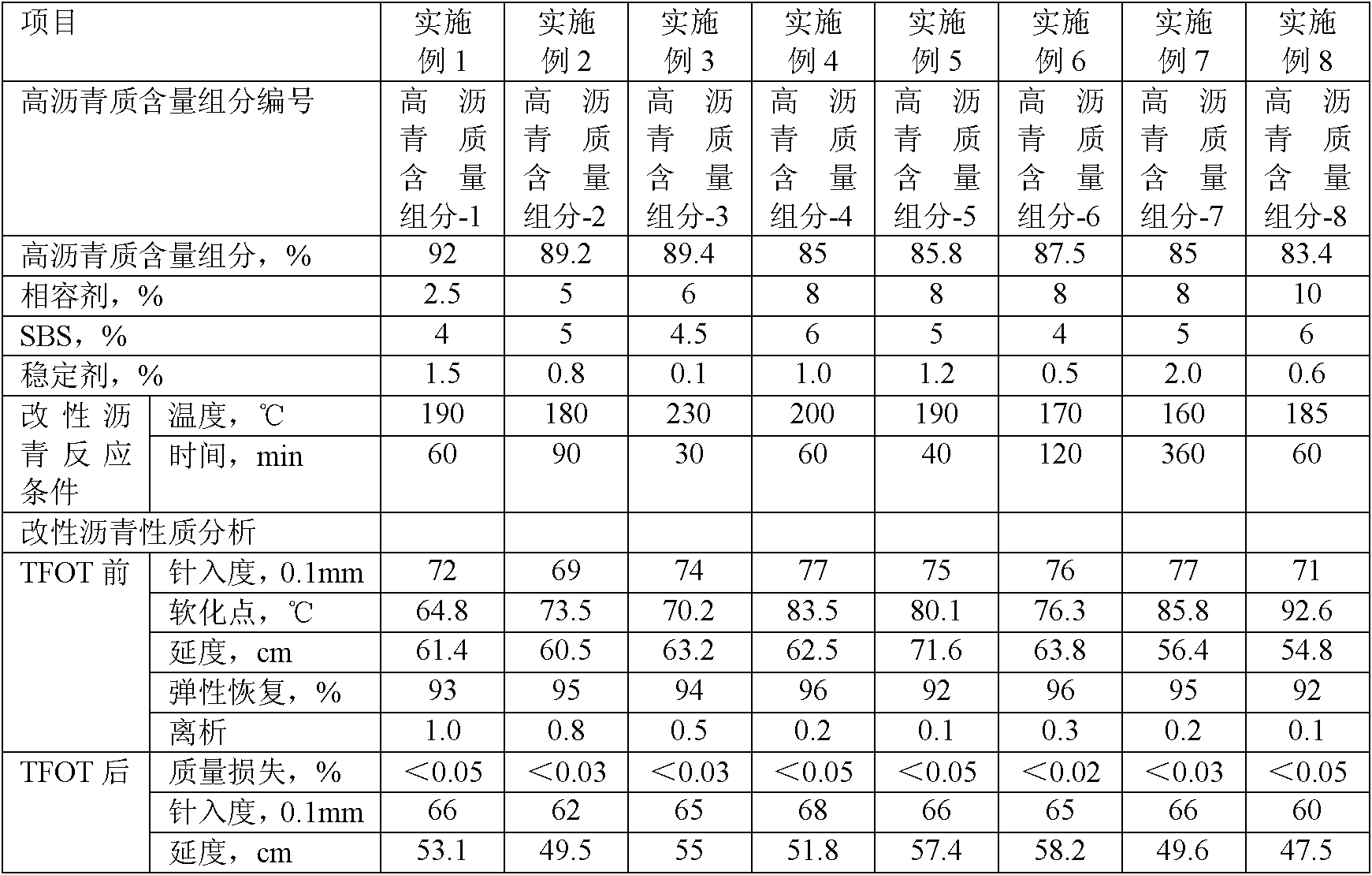

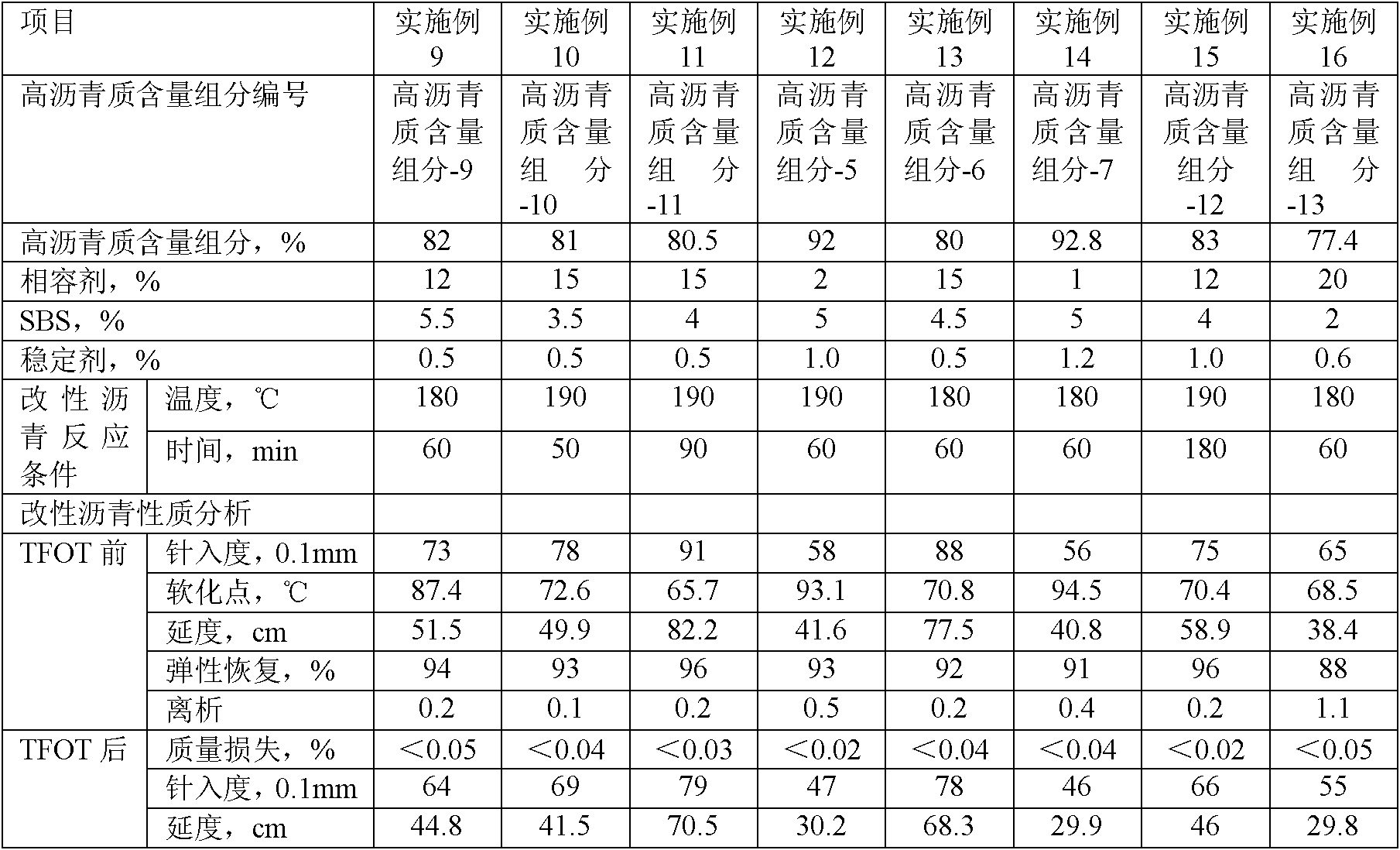

Embodiment 1

[0041] Add 92% high asphaltene content component-1, 2.5% catalytic cracking oil slurry in the container with stirring device, the two are stirred and mixed evenly at 140 ℃, add 4% SBS (YH-791 type produced by Yueyang Petrochemical) ), at 170°C, disperse at 4500r / min high-speed shear for 20min at 170°C, add 1.5% stabilizer composition after heating up to 190°C, wherein 0.5% stearic acid, 0.5% naphthenic acid ethylene glycol ester (NAEP) , Sulfur 0.5%, mixed for 60 minutes to obtain modified asphalt (see Table 2 for the properties analysis results of modified asphalt), the obtained SBS modified asphalt index meets the I-C polymer modified asphalt in "Technical Construction Specifications for Highway Asphalt Pavement" JTG F40-2004 technical requirements.

Embodiment 2

[0043] Add 89.2% high asphaltene content component-2 and 5% coker wax oil in a container with a stirring device, stir and mix evenly at 150°C after the two are mixed, add 5% SBS (YH-791 produced by Yueyang Petrochemical) type), at 180°C, disperse at 4500r / min high-speed shear for 30min at 180°C, add 0.8% stabilizer composition after heating up to 180°C, wherein 0.16% phosphoric acid, pentaerythritol naphthenate (molecular formula is [C 6 h 5 (CH 2 ) 10 COOCH 2 ] 2 -C(CH 2 Oh) 2 ) 0.32%, powdered sulfur 0.32%, mixed for 90 minutes to obtain modified asphalt (see Table 2 for the properties analysis results of modified asphalt), the obtained SBS modified asphalt index meets the I-C polymerization in "Technical Construction Specifications for Highway Asphalt Pavement" JTG F40-2004 Technical requirements for chemically modified asphalt.

Embodiment 3

[0045] Add 89.4% high asphaltene content component-3 in a container with a stirring device, minus 6% of the oil extracted from the fourth line, stir and mix evenly at 170 ° C after the two are mixed, add 4.5% SBS (produced by Yueyang Petrochemical YH- 791 type), at 190°C, disperse at 4500r / min high-speed shear for 40min at 190°C, add 0.1% stabilizer composition after heating up to 185°C, wherein pyrophosphoric acid is 0.02%, sorbitan monooleate is 0.05%, Insoluble sulfur 0.03%, mixed for 30 minutes to obtain modified asphalt (see Table 2 for the property analysis results of modified asphalt), the obtained SBS modified asphalt index meets the I-C polymer modified asphalt in "Technical Construction Specifications for Highway Asphalt Pavement" JTG F40-2004 technical requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com