High-performance mineral compounded modified asphalt and preparation method thereof

A modified asphalt, high-performance technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of reducing the quality of asphalt pavement, shortening the service life, increasing maintenance costs, etc., to improve the ability to resist high temperature softening and low temperature ductility, improve elasticity and toughness, and improve the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

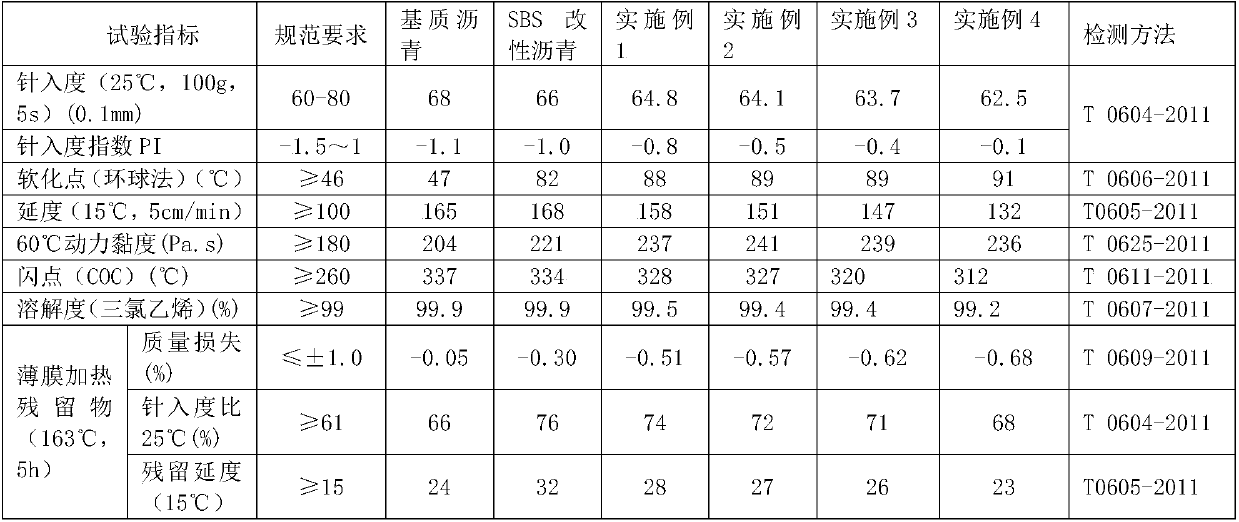

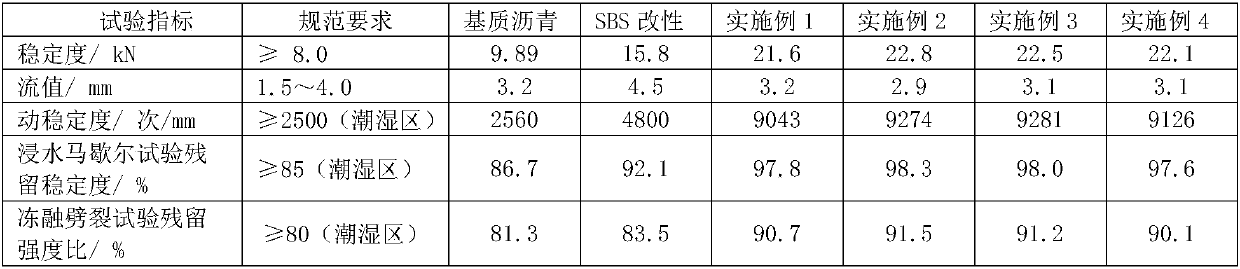

Embodiment 1

[0026] According to one aspect of the present invention, this embodiment provides a kind of high-performance mineral composite modified asphalt and its preparation method, comprising the following steps:

[0027] (1) Weigh by weight: 86 parts of base asphalt, 2 parts of SBS modifier, 2 parts of rubber fine powder, 8 parts of manganese slag fine powder, the selected base asphalt is Esso 70 imported by COSCO SHIPPING International Trade Co., Ltd. #A grade road petroleum asphalt;

[0028] (2) Put the block matrix asphalt in a 170°C constant temperature box for heating to obtain the matrix asphalt raw material; dry the blast furnace water-quenched manganese slag waste slag in an oven at a temperature of 110°C ± 5°C until it contains water The rate is less than 1%, and the triethanolamine grinding aid of 0.5% of manganese slag weight is added for grinding treatment, and the manganese slag grinding powder is passed through a 200 mesh sieve to obtain the manganese slag fine powder mo...

Embodiment 2

[0035] According to one aspect of the present invention, this embodiment provides a kind of high-performance mineral composite modified asphalt and its preparation method, comprising the following steps:

[0036](1) Weigh by weight: 84 parts of base asphalt, 4 parts of SBS modifier, 1 part of rubber fine powder, 12 parts of manganese slag fine powder, the selected base asphalt is Esso 70 imported by COSCO SHIPPING International Trade Co., Ltd. #A grade road petroleum asphalt;

[0037] (2) Put the block matrix asphalt in a 170°C constant temperature box for heating to obtain the matrix asphalt raw material; dry the blast furnace water-quenched manganese slag waste slag in an oven at a temperature of 110°C ± 5°C until it contains water The rate is less than 1%, and the triethanolamine grinding aid of 0.5% of manganese slag weight is added for grinding treatment, and the manganese slag grinding powder is passed through a 200 mesh sieve to obtain the manganese slag fine powder mod...

Embodiment 3

[0044] According to one aspect of the present invention, this embodiment provides a kind of high-performance mineral composite modified asphalt and its preparation method, comprising the following steps:

[0045] (1) Weigh by weight: 82 parts of base asphalt, 6 parts of SBS modifier, 4 parts of rubber fine powder, 10 parts of manganese slag fine powder, the selected base asphalt is Esso 70 imported by COSCO SHIPPING International Trade Co., Ltd. #A grade road petroleum asphalt;

[0046] (2) Put the block matrix asphalt in a 170°C constant temperature box for heating to obtain the matrix asphalt raw material; dry the blast furnace water-quenched manganese slag waste slag in an oven at a temperature of 110°C ± 5°C until it contains water The rate is less than 1%, and the triethanolamine grinding aid of 0.5% of manganese slag weight is added for grinding treatment, and the manganese slag grinding powder is passed through a 200 mesh sieve to obtain the manganese slag fine powder m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com