Compounded high-viscosity high-elasticity asphalt material and preparation method therefor

An asphalt material and high-elasticity technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problem that the thermal stability and storage stability need to be further optimized, the high elastic properties of rubber cannot be fully utilized, and the low-temperature frost-heave resistance is not good. Clarify and other issues to achieve significant socio-economic and environmental benefits, improve storage stability, improve low-temperature ductility and high-temperature thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

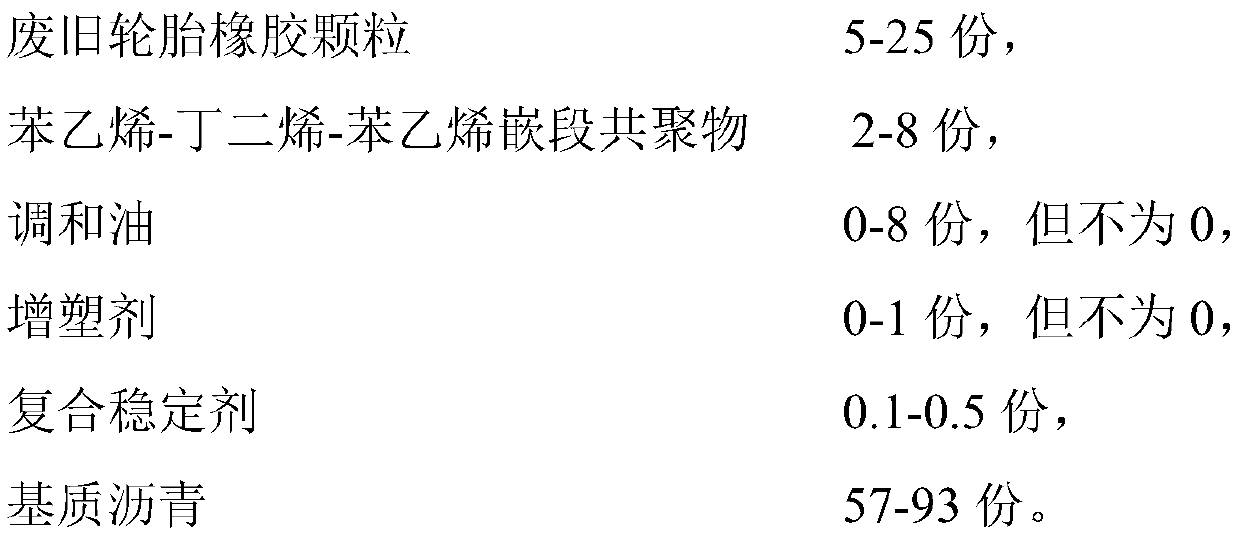

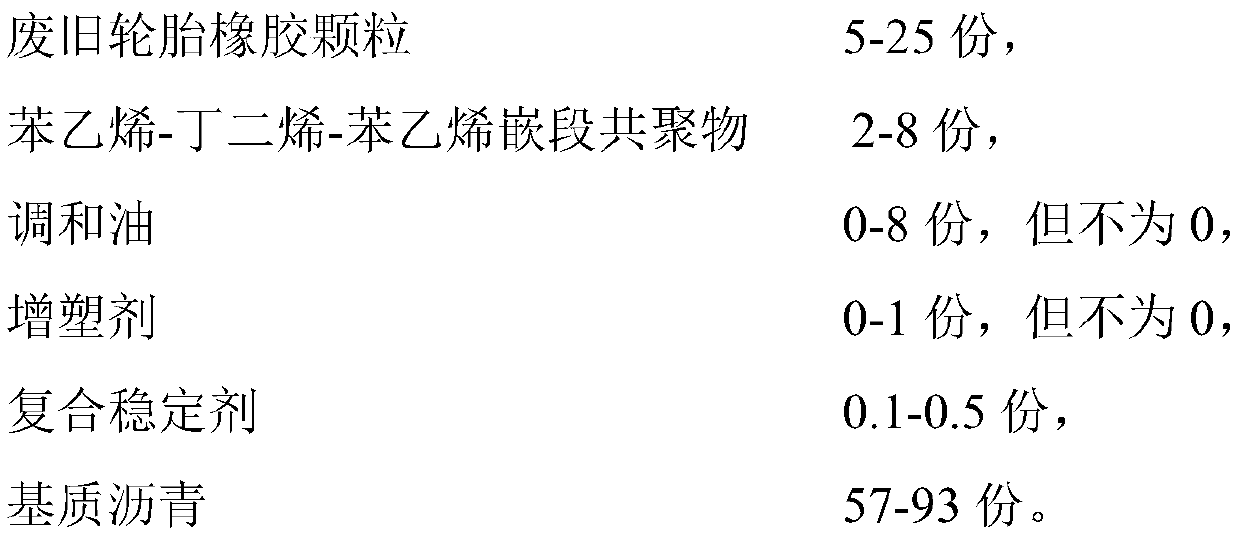

Method used

Image

Examples

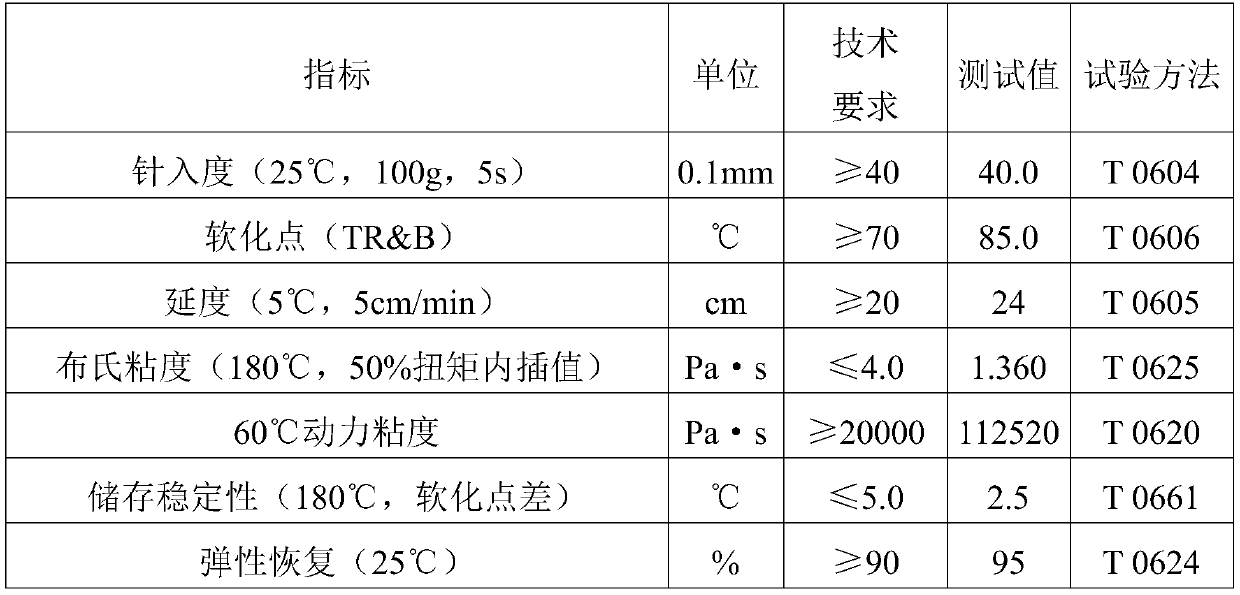

Embodiment 1

[0026] 82.8 parts by mass of No. 70 base asphalt (petroleum asphalt, purchased from Shandong Dongbo Petrochemical Co., Ltd.) with a penetration (25°C, 0.1mm) of 63.0 was first heated to 165°C, and then 4 parts by mass of benzene was slowly added. Ethylene-butadiene-styrene block copolymer modifier (Korea LG101) and 2.5 parts by mass of rubber oil and 0.5 parts by mass of plasticizer (dioctyl phthalate: dioctyl maleate o Dibutyl phthalate=3:1), using a high-speed shearing machine to shear at a shear rate of 3000r / min, the shearing time is 1 hour, and then stirred for 1 hour. Replace the agitator afterwards, stir with a stirring rate of 500r / min, set the temperature at the same time as 180°C, then slowly add 0.2 parts by mass of composite stabilizer and 10 parts by mass of dry rubber particles (20 mesh), the required temperature is Stabilize at 180°C within 5 minutes, and then stir at a stirring rate of 1000r / min for 45 minutes to prepare a compound high-viscosity and high-elast...

Embodiment 2

[0030]76.3 parts by mass of No. 90 base asphalt (petroleum asphalt, purchased from Shandong Dongbo Petrochemical Co., Ltd.) with a penetration (25°C, 0.1mm) of 90.5 was first heated to 165°C, and then 8 parts by mass of benzene was slowly added. Ethylene-butadiene-styrene block copolymer modifier (Korea LG101) and 1.5 parts by mass of biomass pitch and 0.5 parts by mass of plasticizer (dioctyl phthalate: dioctyl maleate Dibutyl phthalate=3:1), using a high-speed shearing machine to shear at a shear rate of 5000r / min, the shearing time is 1 hour, and then stirred for 2.0 hours. Replace the agitator afterwards, stir with a stirring rate of 600r / min, and set the temperature at 190°C, then slowly add 0.2 parts by mass of a composite stabilizer and 20 parts by mass of dry rubber particles (24 mesh), requiring a temperature of Stabilize at 190°C within 5 minutes, and then stir at a stirring rate of 1000r / min for 60 minutes to prepare a compound high-viscosity and high-elasticity asp...

Embodiment 3

[0035] 69.8 parts by mass of No. 100 base asphalt (petroleum asphalt, purchased from Shandong Dongbo Petrochemical Co., Ltd.) with a penetration (25°C, 0.1mm) of 98.5 was first heated to 165°C, and then 6 parts by mass of benzene was slowly added. Ethylene-butadiene-styrene block copolymer modifier (Korea LG101) and 2.0 parts by mass of furfural extract oil and 0.5 parts by mass of plasticizer (dioctyl phthalate: dioctyl maleate Dibutyl phthalate=3:1), using a high-speed shearing machine to shear at a shear rate of 4000r / min, the shearing time is 1 hour, and then stirred for 1.5 hours. Replace the agitator afterwards, stir with a stirring rate of 300r / min, and set the temperature at 200°C, then slowly add 0.2 parts by mass of a composite stabilizer and 15 parts by mass of dry rubber particles (30 mesh), requiring a temperature of Stabilize at 200°C within 5 minutes, and then stir at a stirring rate of 1000r / min for 75 minutes to prepare a compound high-viscosity and high-elast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com