A kind of asphalt mixture and preparation method thereof

A technology of asphalt mixture and mixture, which is applied in the fields of anti-hugging asphalt mixture and its preparation, and anti-rutting. It can solve the problems such as the viscosity of asphalt at 60°C is not up to standard, and achieve improved rutting dynamic stability, simple production process, and improved anti-rutting. Effects of rutting and anti-hugging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

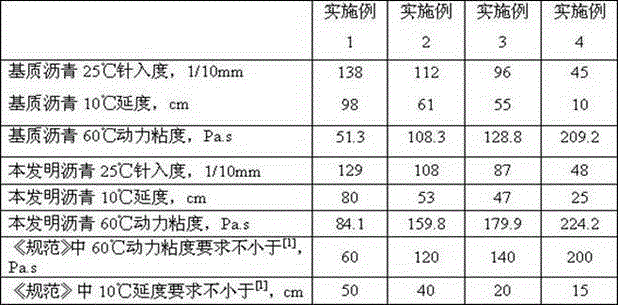

Embodiment 1

[0034] Weigh 99.8kg of vacuum residue (penetration of 1381 / 10mm) produced by Panjin Asphalt Plant as base asphalt, heat to 110°C; weigh 0.2kg of p-phenanthrenequinone. Set the stirring speed at 1400rpm, slowly add p-phenanthrenequinone to the asphalt, after all the p-phenanthrenequinones are added, stir for 40 minutes to obtain the special road petroleum asphalt used in the present invention. The properties of asphalt are shown in Table 1.

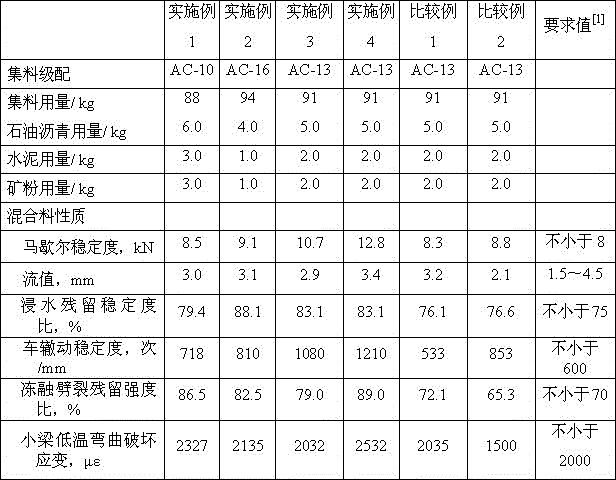

[0035] Pre-heat the special asphalt mixture mixing tank to 130°C constant temperature; prepare Liaoyang andesite aggregates into AC-10 aggregates with a total weight of 88kg, and heat them to 130°C for later use; weigh the above-mentioned special road petroleum asphalt 6.0 kg, heated to 110°C for later use; weigh 3.0kg each of cement and mineral powder. After the temperature of the stirring tank, aggregate and asphalt is constant, add the above-mentioned aggregate, cement and mineral powder together into the stirring tank, and stir for 2 ...

Embodiment 2

[0037] Weigh 97.7kg of blended asphalt (penetration of 1121 / 10mm) produced by Yingkou Asphalt Plant as the base asphalt, and heat it to 120°C; weigh 1.0kg of o-benzoquinone, 0.9kg of α-position anthraquinone, and 0.4kg of o-phenanthrenequinone , set the stirring speed at 1000rpm, and slowly add the above-mentioned quinone compounds into the asphalt, either separately or after mixing. After all the addition is completed, stir for 70 minutes to obtain the road petroleum pitch of the present invention. The properties of asphalt are shown in Table 1.

[0038]Pre-heat the special asphalt mixing tank to 150°C constant temperature; prepare Tieling basalt aggregates into AC-16 aggregates with a total weight of 94kg, and heat them to 150°C for later use; weigh the above-mentioned special road petroleum asphalt 4.0kg, heated to 120°C for later use; weigh 1.0kg each of cement and mineral powder. After the temperature of the stirring tank, aggregate and asphalt is constant, add the abov...

Embodiment 3

[0040] Weigh 98.5kg of straight-run asphalt (penetration of 961 / 10mm) produced by Qilu Petrochemical Company as base asphalt, heat to 130°C; weigh 0.5kg of α-(1,4) naphthoquinone and 1.0kg of β-position anthraquinone , set the stirring speed at 1100rpm, slowly add α-(1,4) naphthoquinone and β-position anthraquinone to the asphalt, the two can be added separately or after mixing. After all the addition is completed, stir for 60 minutes to obtain the road petroleum pitch of the present invention. The properties of asphalt are shown in Table 1.

[0041] Pre-heat the special asphalt mixture stirring tank to 160°C constant temperature; prepare the Fushun limestone aggregate into AC-13 aggregate with a total weight of 91kg, and heat it to 160°C for later use; weigh the above-mentioned special road petroleum asphalt 5.0 kg, heated to 130°C for later use; weigh 2.0kg each of cement and mineral powder. After the temperature of the stirring tank, aggregate and asphalt is constant, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com