Pumping agent and application thereof

A pumping agent and application technology, applied in the field of pumping agent, can solve the problems of ineffective prevention of concrete bleeding and segregation, and achieve the effect of preventing concrete bleeding, preventing bleeding, and contributing greatly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

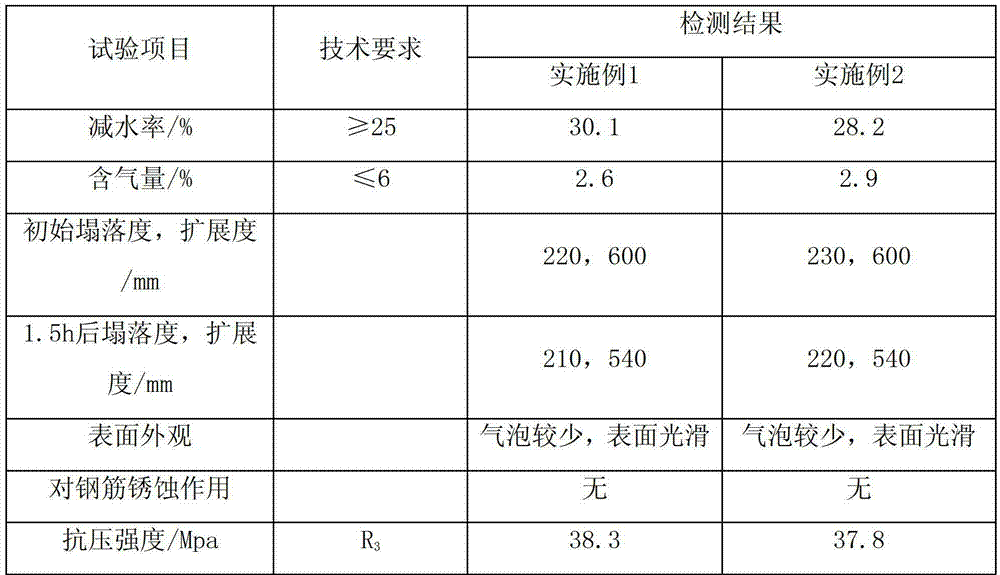

Embodiment 1

[0037] Embodiment 1 Preparation of pumping agent of the present invention

[0038]Take polycarboxylic acid mother liquor (ethers, APEG type, 40% solid content, trade name LonS-Mw water-reducing type, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., product number 20120829-0) 3.25kg, water 6.227kg and mix well Then, add 0.3kg of sodium gluconate (purity 98.5%), 0.07kg of white sugar (sucrose content ≥99.6%), 0.15kg of methyl cellulose, and 0.003kg of sodium lauryl sulfate (content ≥99%) in sequence, and stir well. That is to get the pumping agent. The dosage of the obtained pumping agent is 0.9-1.4 wt % of the dosage of the cementitious material in the concrete.

Embodiment 2

[0039] Example 2 Preparation of the pumping agent of the present invention

[0040] Take 1.75kg of polycarboxylic acid mother liquor (ethers, APEG type, 40% solid content, trade name LonS-Mw water-reducing type, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., product number 20121207-0), mix 7.928kg of water evenly Then, add sodium gluconate (purity ≥98.5%) 0.21kg, sodium hexametaphosphate (purity ≥68wt%) 0.03kg, white sugar (sucrose content ≥99.6%) 0.07kg, triterpenoid saponin 0.012kg in turn, stir evenly, that is, Gotta pump. The dosage of the obtained pumping agent is 1.5-2.2 wt % of the cementitious material in the concrete.

Embodiment 3

[0041] Example 3 Preparation of the pumping agent of the present invention

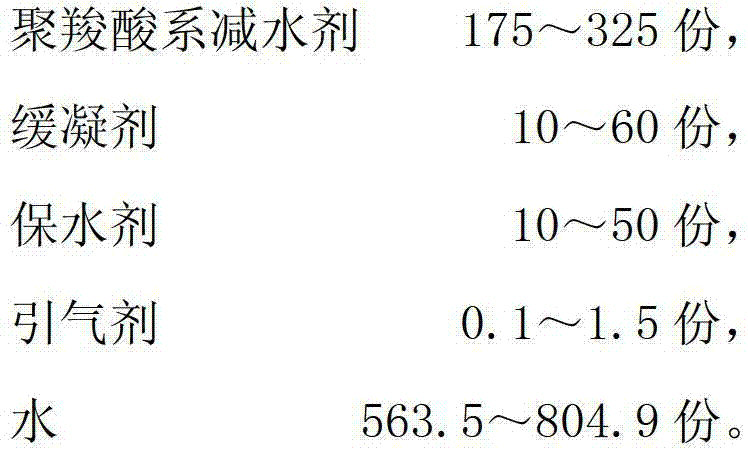

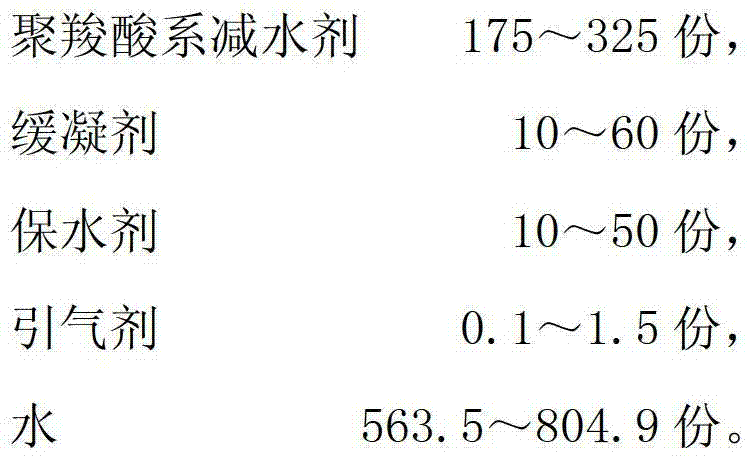

[0042] Mix 200 parts by weight of polycarboxylic acid mother liquor (ethers, APEG type, 40% solid content, trade name LonS-Mw water-reducing type, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., product number 20121207-0) with 760.8 parts by weight. After the water is uniformly mixed, 23 parts by weight of sodium gluconate, 6 parts by weight of sodium hexametaphosphate, 10 parts by weight of methyl cellulose, 0.2 parts by weight of sodium lauryl sulfate are added in turn, and the mixture is stirred evenly to obtain a pump. delivery agent. The dosage of the obtained pumping agent is 1.2-1.7wt% of the cementitious material in the concrete. The pumping agent is used in the production of ready-made concrete C15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com