Patents

Literature

36results about How to "Solve bleeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

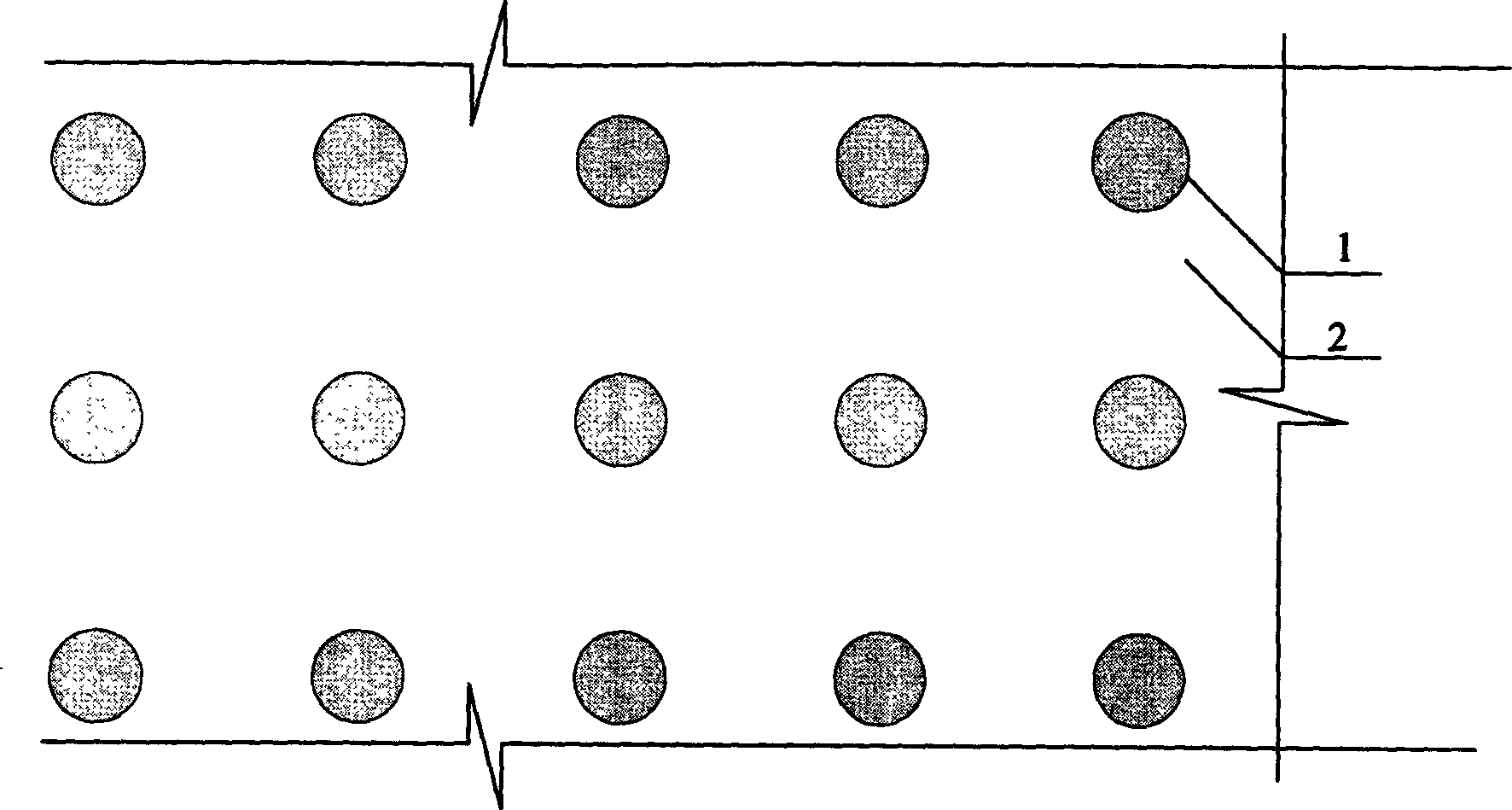

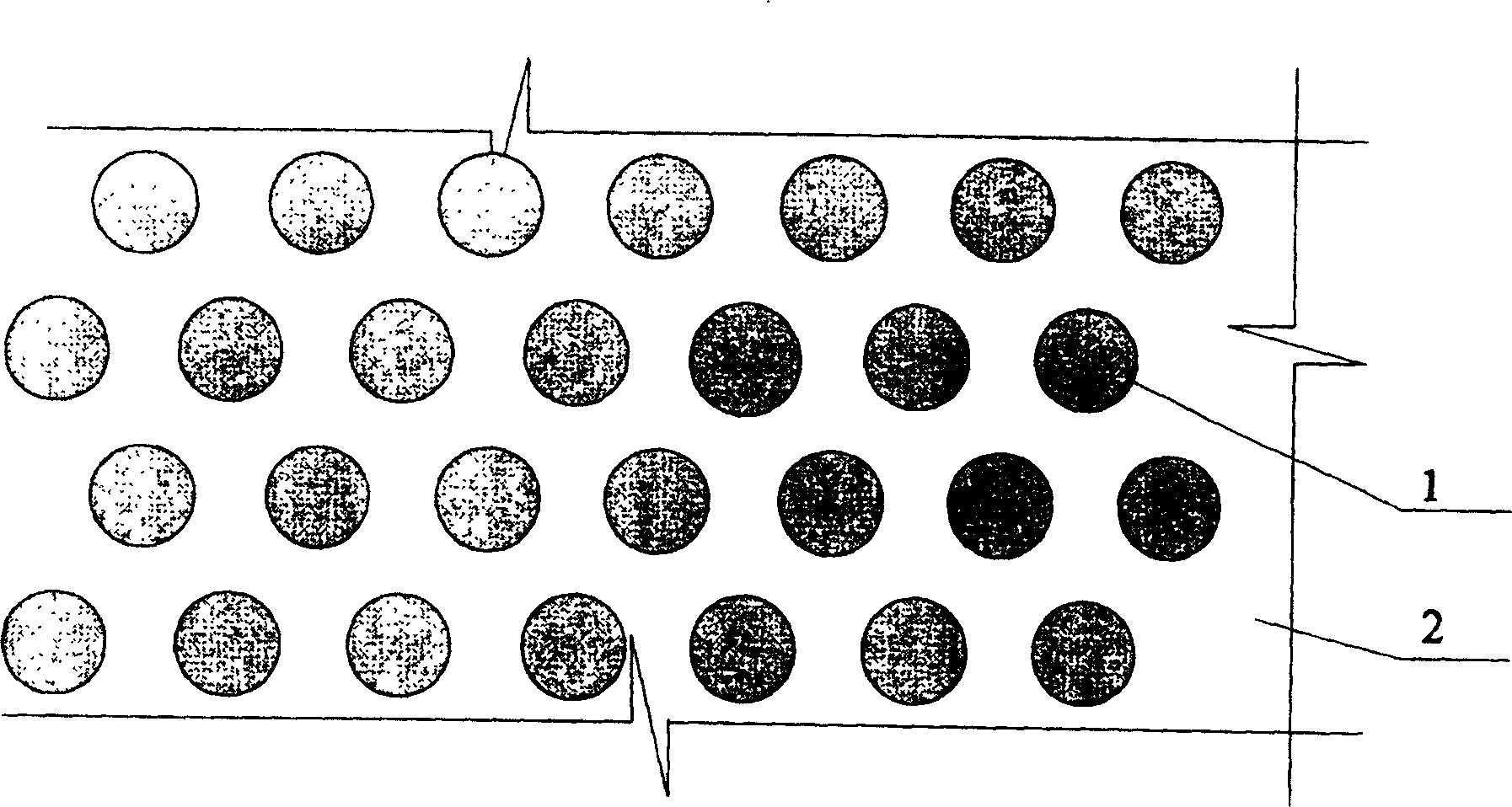

Pile forming operation method for bi-directional stirring piles

The piling operation method of two-way mixing pile is a foundation treatment method, which is suitable for soft soil foundation treatment. The operation method is: a: leveling the site; Centering; c: Stirring and sinking: start the two-way stirring pile driver, make the drill pipe of the two-way stirring pile driver cut the soil downward along the guide frame, turn on the slurry pump, spray cement slurry to the soil, and the drill pipe of the two-way stirring pile driver is respectively positive , The counter-rotating blades rotate at the same time to stir the cement and soil; d: The drill pipe of the two-way stirring pile machine continues to sink and stir the cement and soil until the design depth; e: While stirring and lifting, the drill pipe of the two-way stirring pile machine rotates forward and reverse f: lift and stir to the ground surface or 50cm above the design elevation, and complete the construction of the two-way mixing cement-soil mixing pile (1). The cement-soil mixing pile (1) is arranged in a plum blossom shape or square to ensure quality and pile quality.

Owner:南京路鼎搅拌桩特种技术有限公司

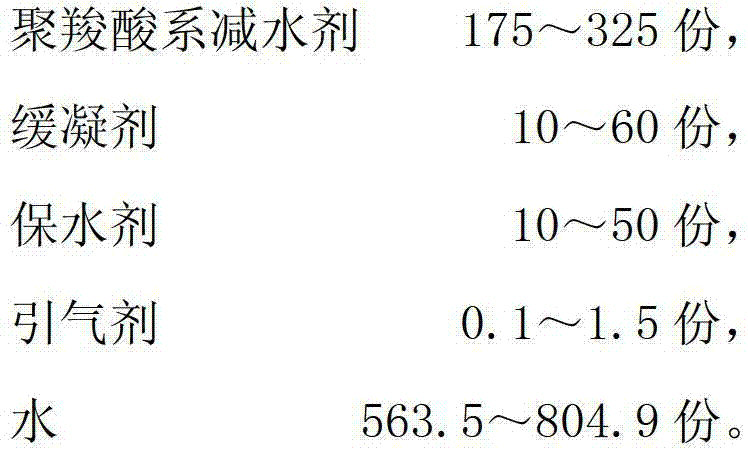

Pumping agent and application thereof

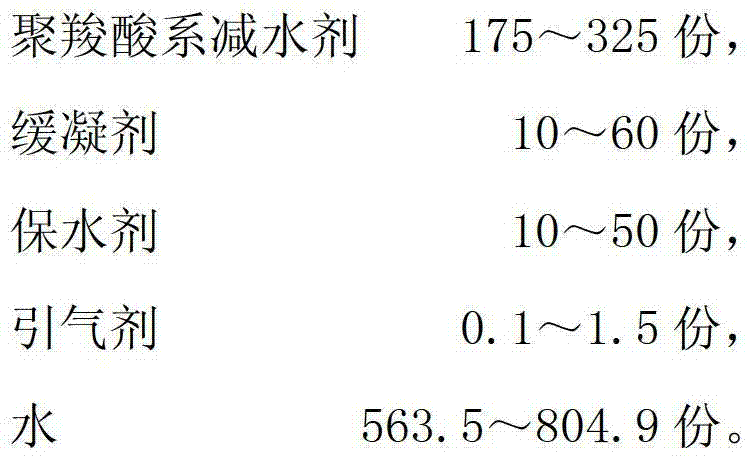

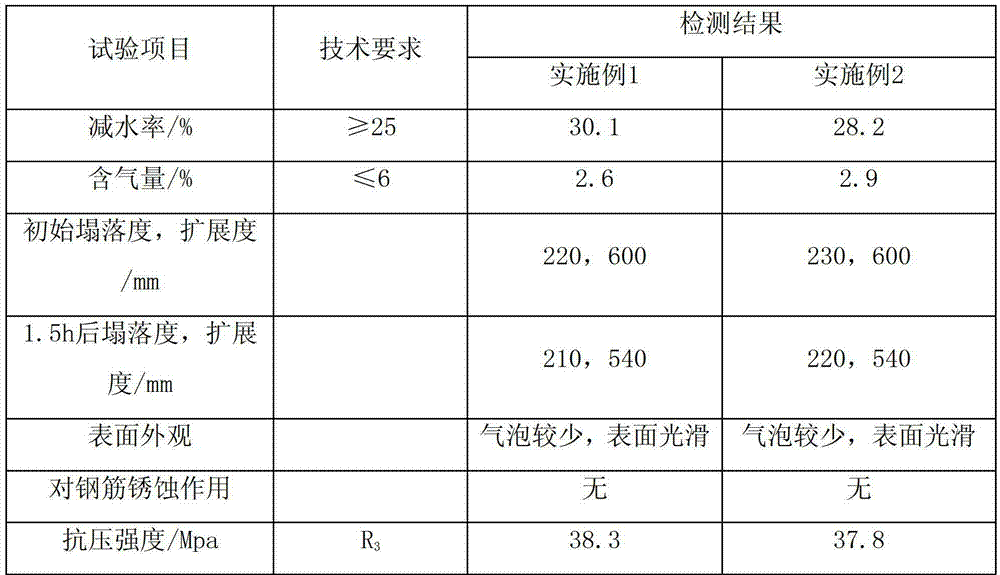

The invention relates to a pumping agent and application thereof, belonging to the field of construction materials. The invention aims to provide the pumping agent and the application thereof. The pumping agent provided by the invention comprises 175-325 parts by weight of polycarboxylic acid water reducing agent, 10-60 parts by weight of retarder, 10-50 parts by weight of water retention agent, 0.1-1.5 parts by weight of air entraining agent and 563.5-804.9 parts by weight of water. The invention also relates to the application of the pumping agent in C15-C70 concrete. The addition amount of the pumping agent accounts for 0.9-2.2 wt% of a cementing material in the concrete. The pumping agent prepared by the invention has the advantages of favorable material adaptability, low addition amount, high water reducing rate, low air content, high concrete strength contribution and the like, mainly solves the problem that the polycarboxylic acid pumping agent is easily subjected to over-addition in practical situations, can effectively prevent the defects of the concrete such as weepage, isolation and the like, and ensures the quality of the concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

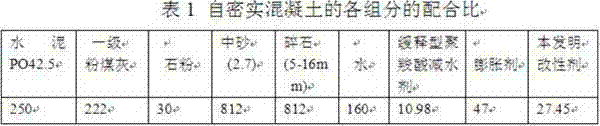

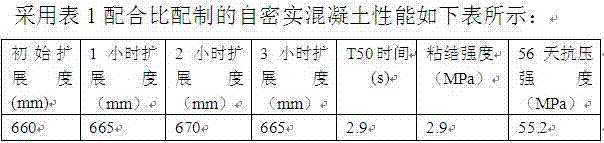

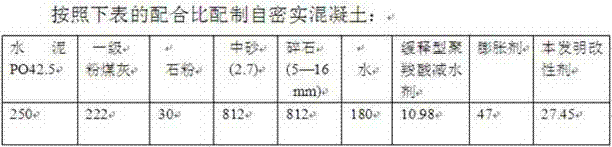

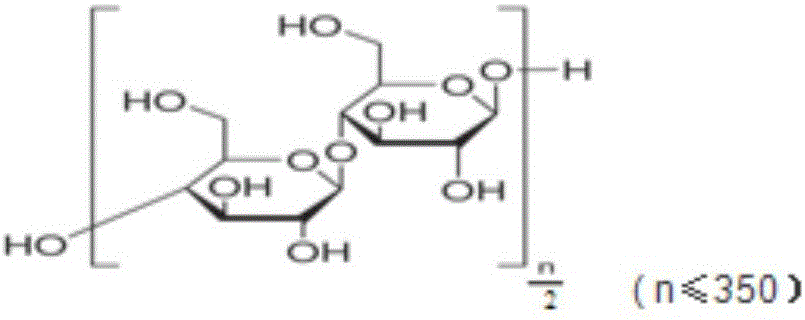

Thickener used for self-compact concrete, preparation method thereof, and self-compact concrete using thickener

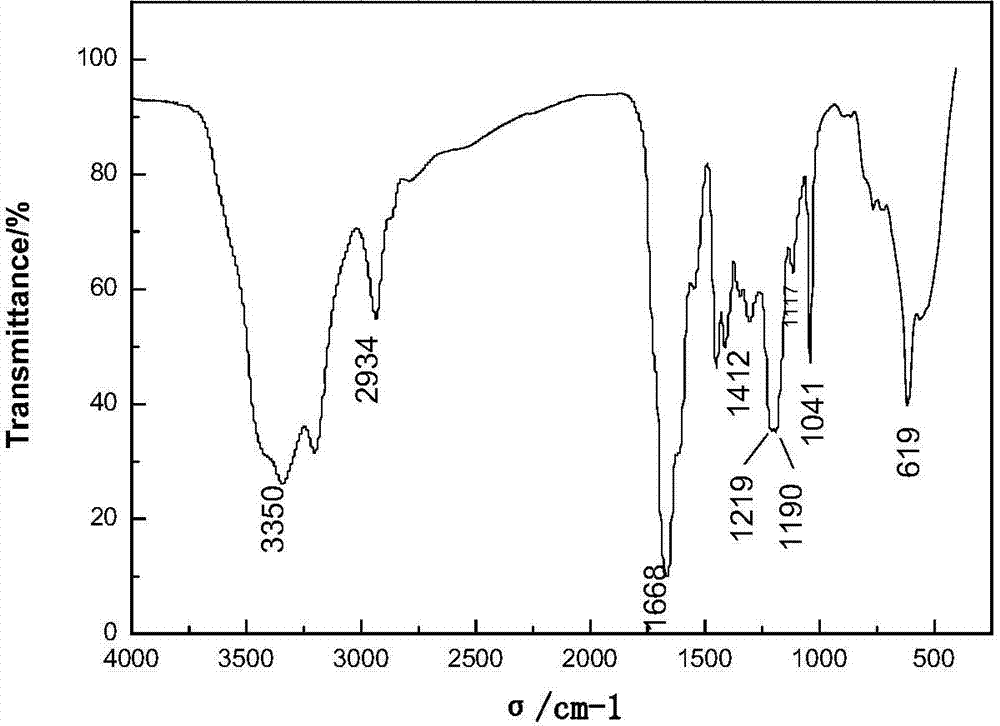

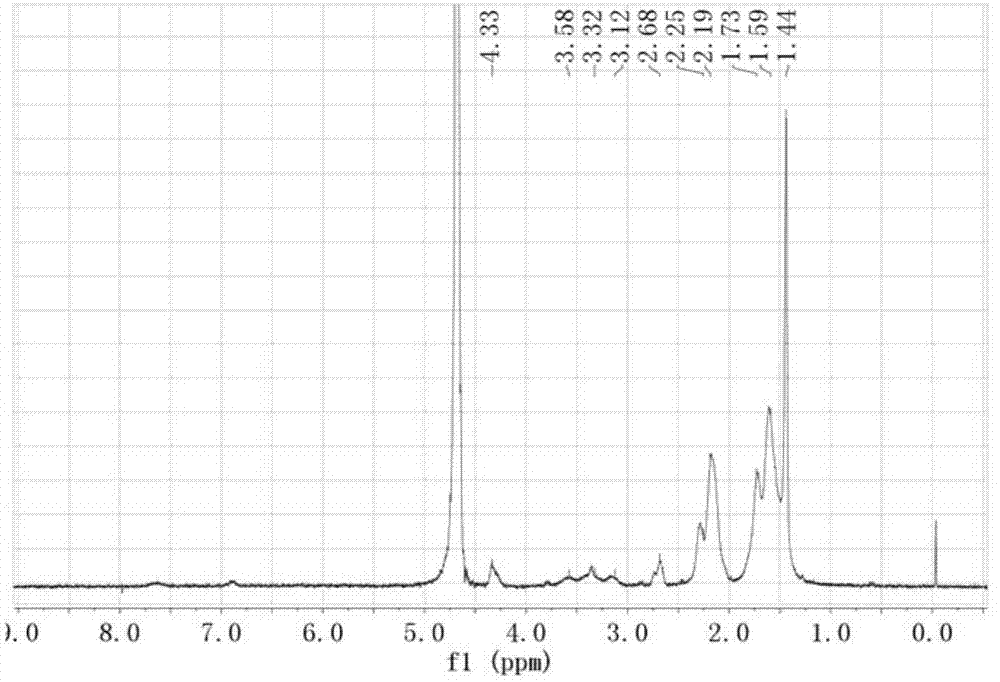

The invention discloses a preparation method of a thickener used for self-compact concrete. The method comprises the following steps: 1, weighing 2-acrylamide-2-methylpropanesulfonic acid and acrylic acid in proportion, processing to prepare an aqueous solution, and adjusting the pH value to 6.5-7.0; 2, adding a prepared monomer acrylamide solution with the concentration of 25-35% while stirring, uniformly stirring, dumping the obtained mixed solution into a flask, carrying out constant temperature water bath, and introducing nitrogen for protection; and 3, adding an initiator in a dropwise manner when the reaction temperature rises to 30-40DEG C, carrying out heat insulation at 40DEG C, carrying out a stirring reaction for about 1.5-2h, stopping the introduction of nitrogen when reactants are a viscous liquid, and carrying out constant temperature slaking for a period of time to obtain a white transparent colloid which is the thickener. The thickener obtained in the invention is used for preparing the self-compact concrete, has a good water solubility and a good thickening effect, can effectively improve the plastic viscosity of the self-compact concrete, and solves the water segregation and separation problems of the self-compact concrete.

Owner:CCCC FOURTH HARBOR ENG INST +4

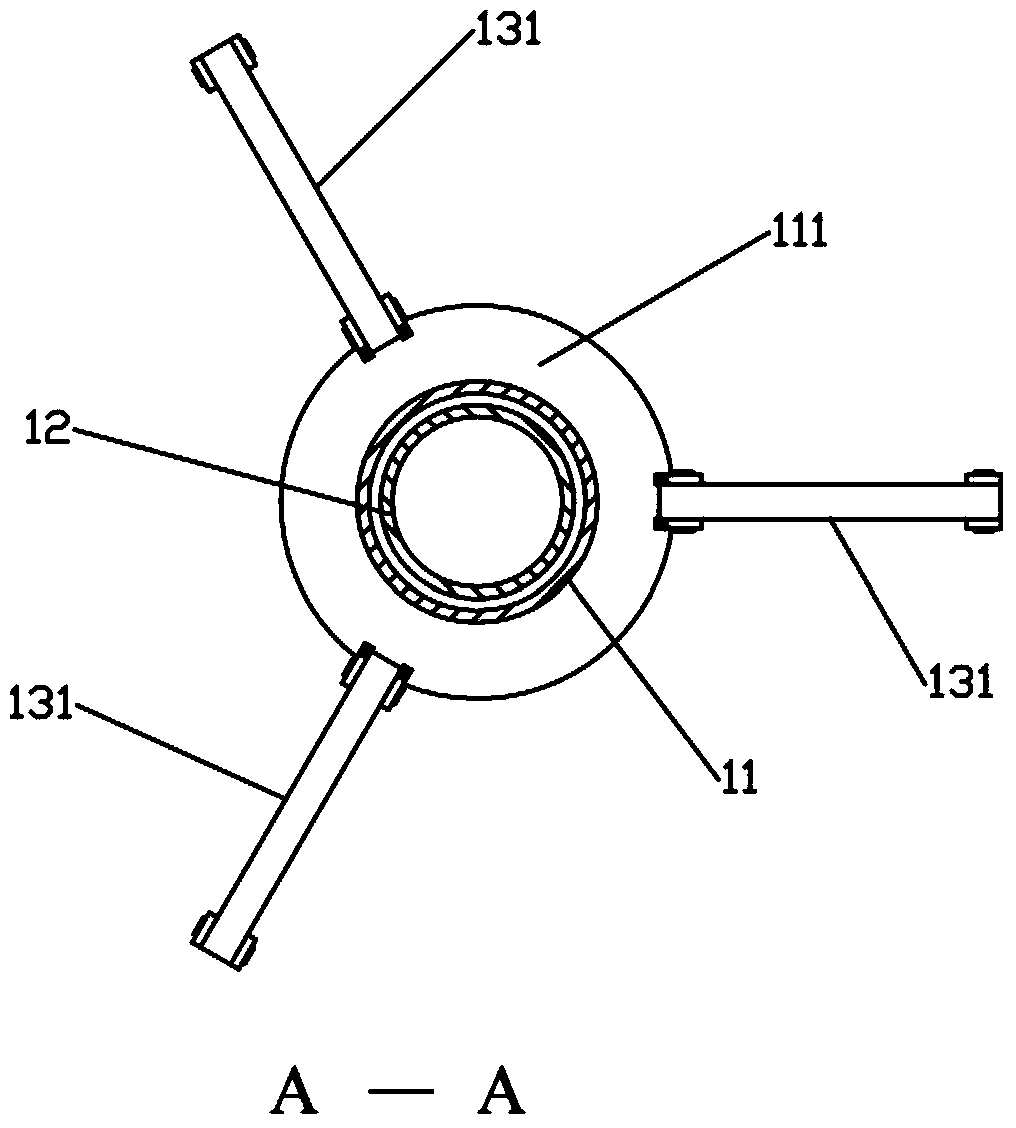

Wet-mixed masonry mortar prepared by adopting aggregate chips

ActiveCN104496327AEasy to get materialsLow priceSolid waste managementCarboxymethyl celluloseSodium Bentonite

The invention discloses wet-mixed masonry mortar prepared by adopting aggregate chips. The wet-mixed masonry mortar comprises the following components in parts by weight: 18-22 parts of cement, 6-8 parts of pulverized fuel ash, 5-7 parts of mineral powder, 22-25 parts of water, 135-145 parts of aggregate chips and 0.5-2.0 parts of a mortar admixture, wherein the particle size of the aggregate chips is not more than 4.75mm; the mountain flour in the aggregate chips accounts for 2-3 percent by weight; the mortar admixture serves as a thickening agent; the thickening agent comprises the following components in parts by weight: 2-4 parts of a sulfonic acid type air entraining agent, 10-20 parts of a melamine water reducing agent, 1-3 parts of soft sugar, 1-3 parts of a water repellent, 4-6 parts of sodium carboxymethyl cellulose and 40-60 parts of sodium bentonite. The machine-made sand and river sand are replaced by residual aggregate chips after stone processing, the aggregate chips are readily available and low in price, the resources are reasonably utilized, the environmental pollution caused by waste aggregate chips is reduced, and the production cost of the mortar is reduced.

Owner:青岛磊鑫混凝土有限公司

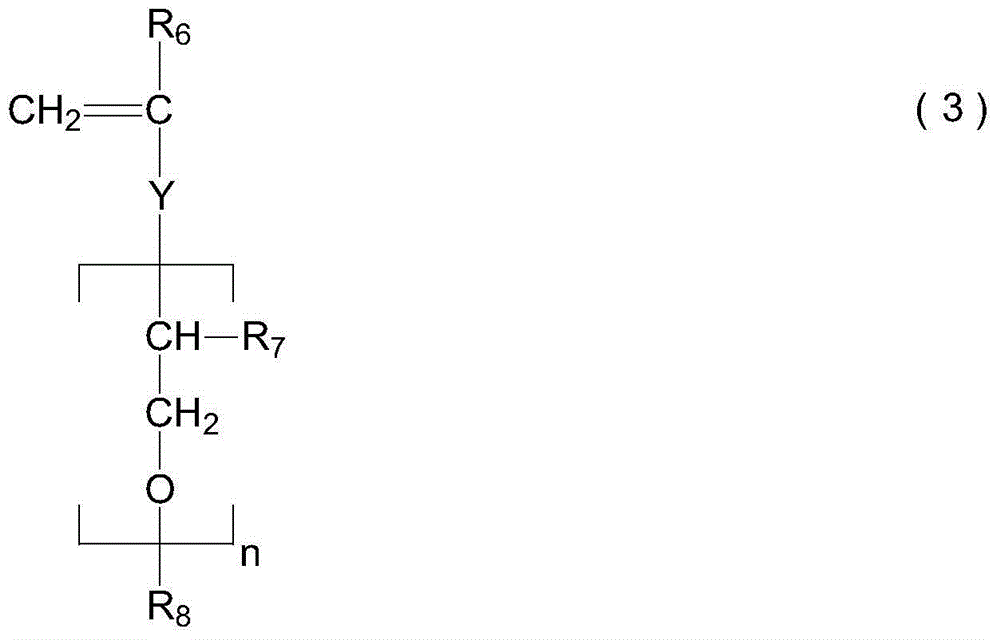

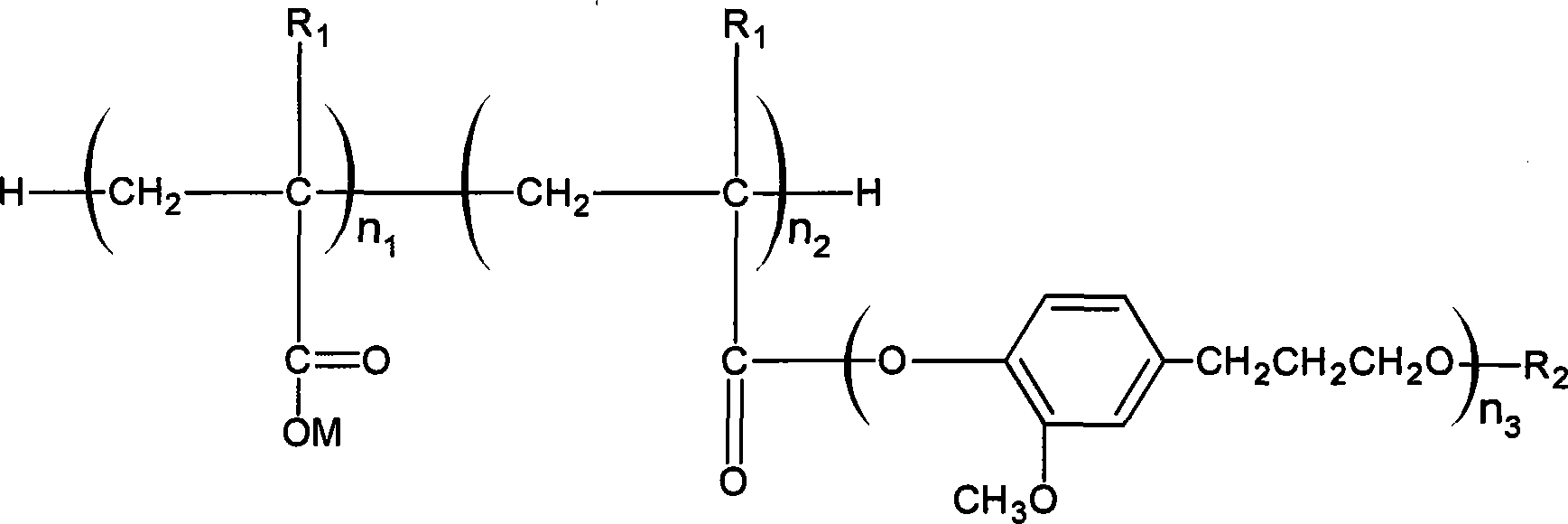

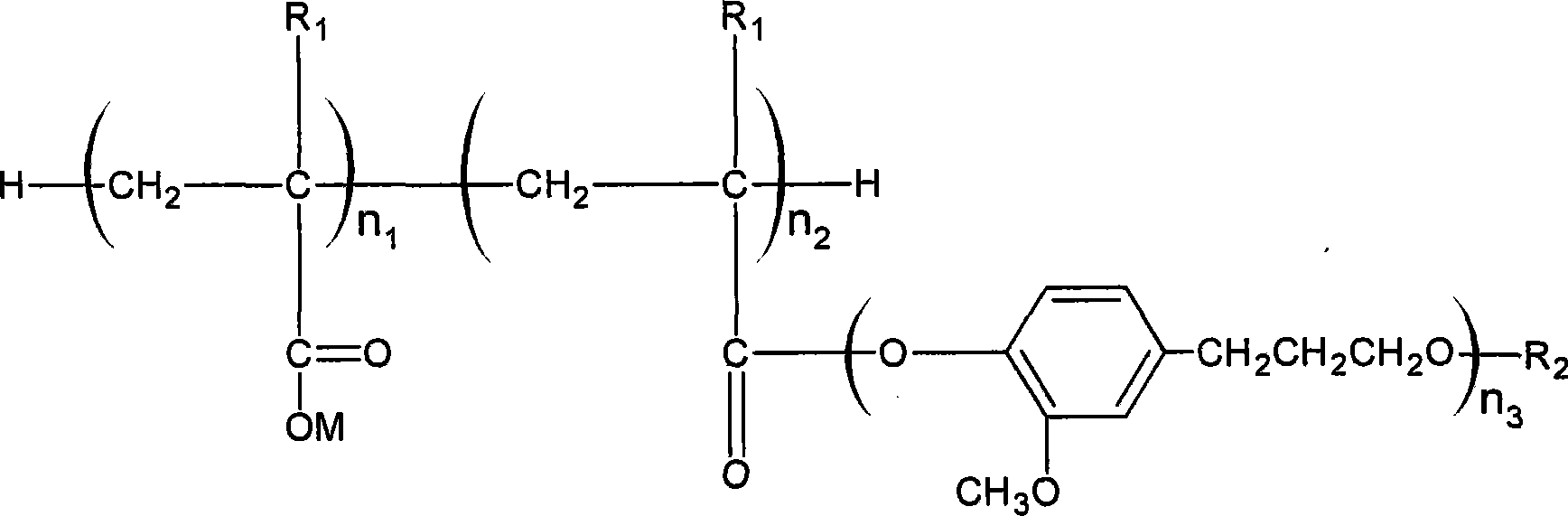

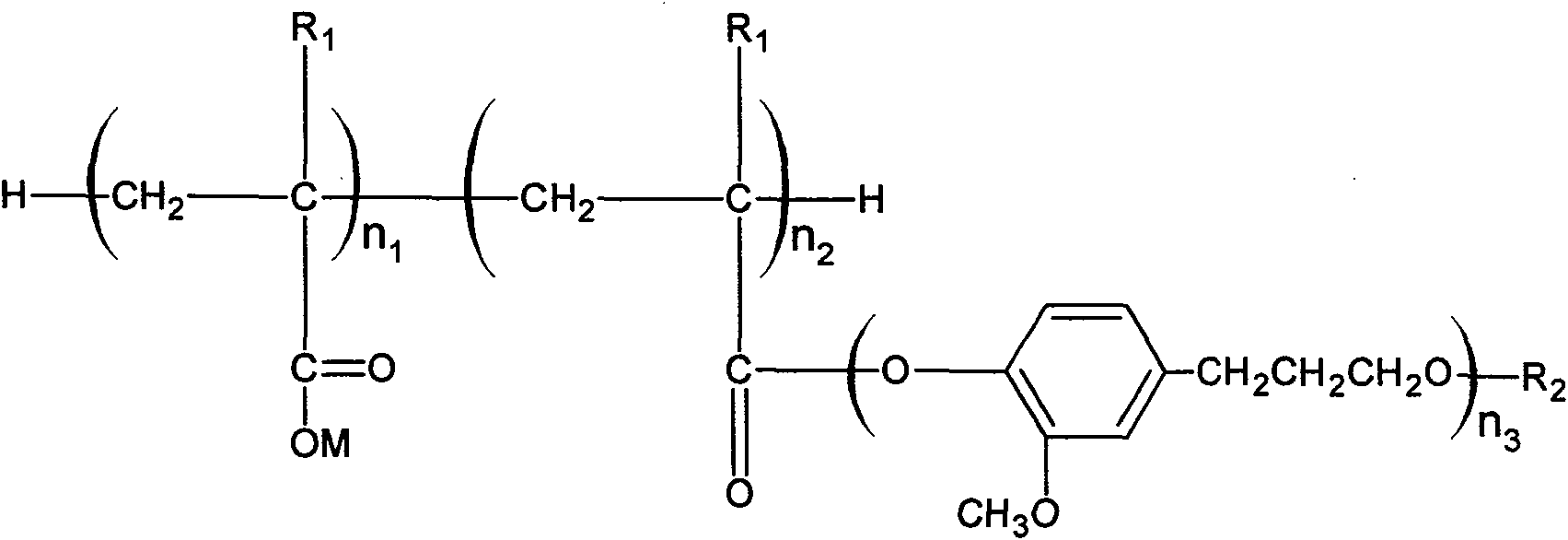

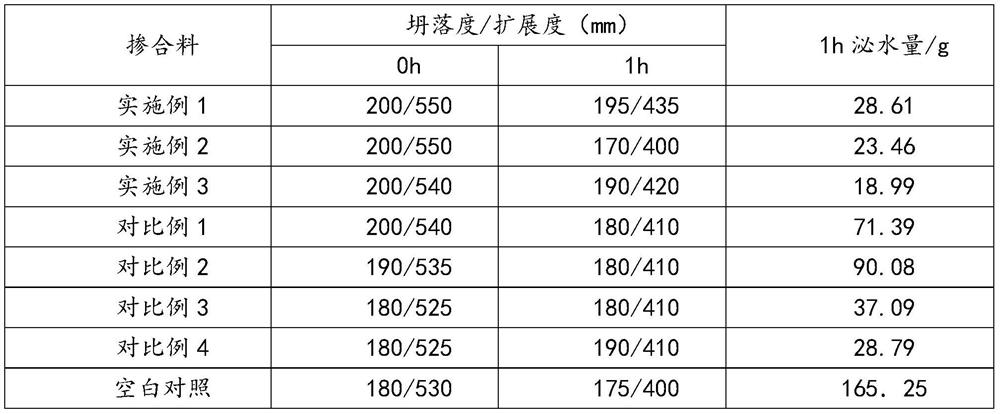

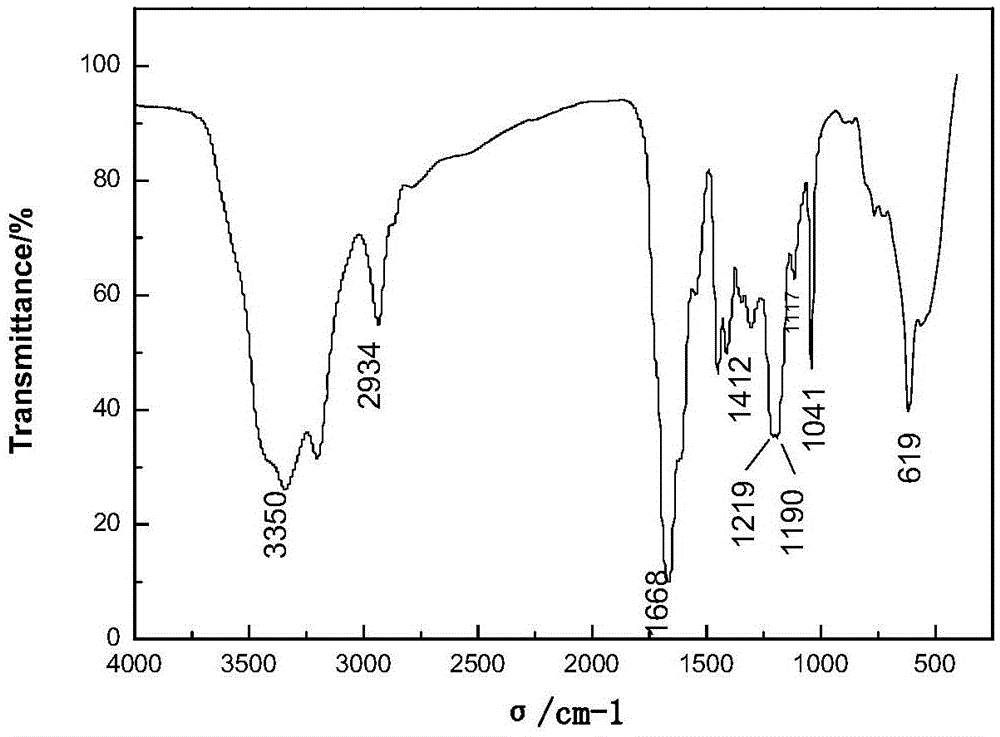

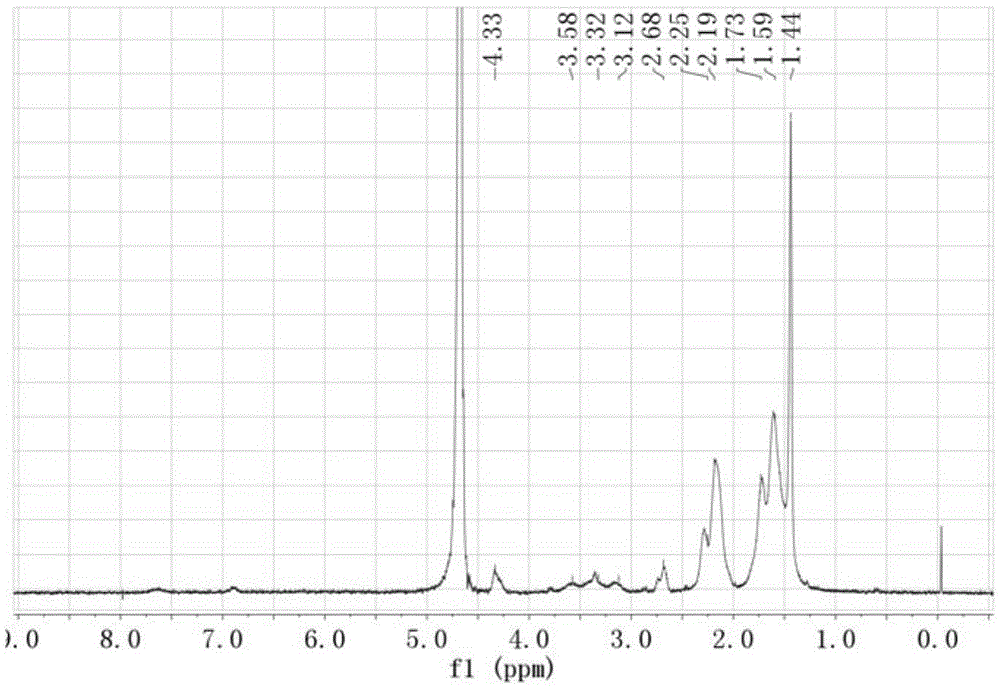

Thickener copolymer as well as preparation method and application thereof

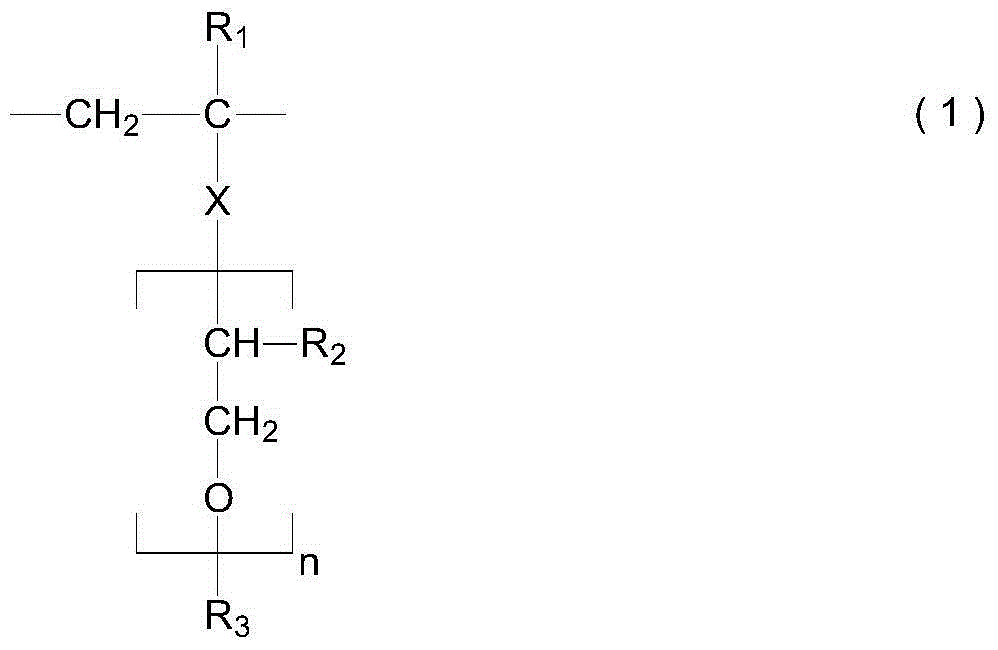

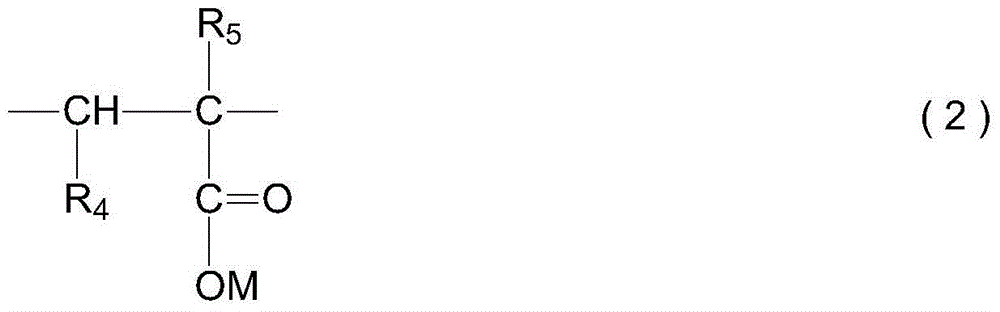

The invention discloses a thickener copolymer as well as a preparation method and an application thereof. The thickener copolymer contains a structural unit I derived from an unsaturated polyether monomer and a structural unit II derived from an unsaturated carboxylic acid monomer. The preparation method comprises the step of copolymerizing the unsaturated polyether monomer (A) shown by the general formula (3) with the unsaturated carboxylic acid monomer (B) shown by the general formula (4) under the existence of an initiator. When the thickener copolymer is used for cement mortar or concrete, the thickener copolymer has the good water-retaining property and simultaneously has the good intermiscibility with a polycarboxylate superplasticizer.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Special modified material for self-compacting concrete of plate-type ballastless track packing layer of high-speed railway

The invention discloses a special modified material for self-compacting concrete of a plate-type ballastless track packing layer of a high-speed railway. The special modified material is formed by mixing the following components in percentage by weight: 40%-70% of coal ash, 20%-30% of calcium carbonate powder, 0%-10% of re-dispersible latex powder, 0%-10% of hydroxypropyl methylcellulose and 0%-30% of magnesium aluminum silicate. The invention provides the special modified material which can be applied to fillingself-compacting concrete to sealed space. The special modified material disclosed by the invention can be used for solving the problems such as segregation, bleeding, surface laitance and the like of the self-compacting concrete on the condition of not changing the construction performances of the self-compacting concrete. More importantly, a problem that a weak connecting layer is formed on the surface of the hardened filling layer concrete can be solved; bonding strength of the filling layer and the upper track board is ensured; and the structural durability is improved.

Owner:CHINA RAILWAY NO 5 ENG GRP +2

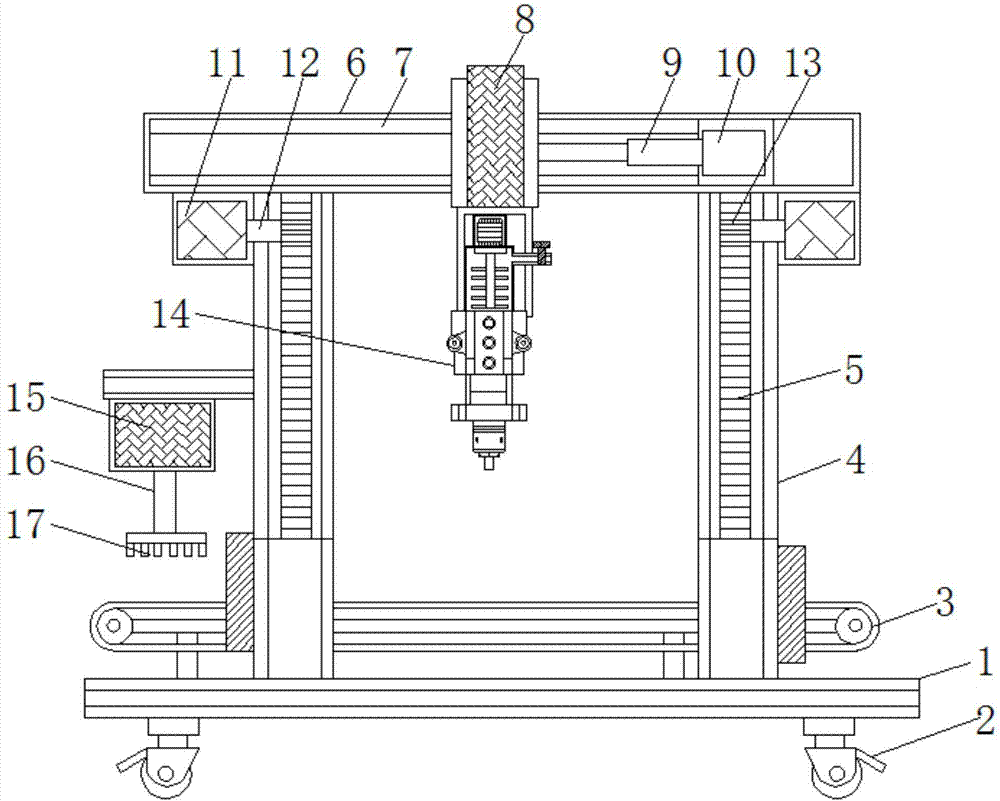

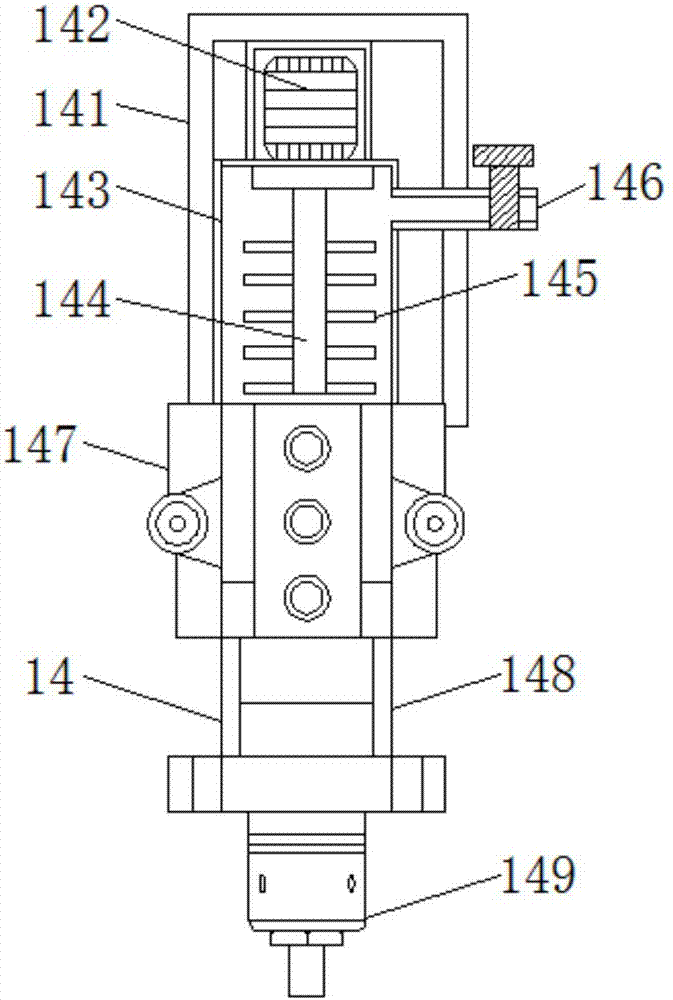

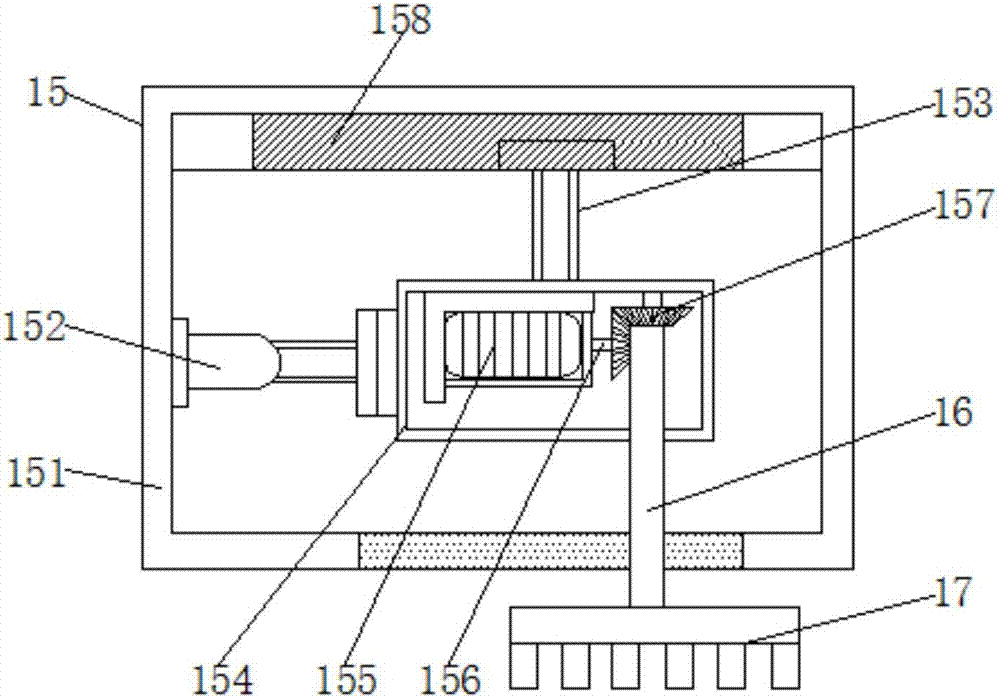

High-efficiency spraying device for automobile fasteners

PendingCN107961929ATo achieve the purpose of lifting adjustmentAchieving stirringSpraying apparatusCleaning using toolsElectric machineGear wheel

The invention relates to the technical field of automobile fastener processing, and discloses a high-efficiency spraying device for automobile fasteners. The high-efficiency spraying device comprisesa baseplate of which the top is fixedly provided with a conveyor and a column of which the surface is fixedly connected to a gear lever, and the surface of the gear lever is engaged with a gear plate;and the center of the gear plate is fixedly connected to a rotating shaft, and one end, far away from the gear plate, of the rotating shaft is fixedly connected to an output shaft of a main motor. According to the high-efficiency spraying device for the automobile fasteners, by arranging a dust removal device and a dust removal brush, a bevel gear is driven to rotate by an auxiliary motor, so that the dust removal brush at the bottom of a telescopic sleeve rod is driven to rotate; the dust removal of fasteners on the conveyer is achieved through the dust removal brush, and meanwhile a mounting plate is driven by an electric linear actuator to move right and left in a sliding chute, so that the dust removal brush is moved back and forth on the surface of the fasteners, and the dust removaleffect is achieved; dust and chippings on the fasteners are removed, so that uniform spraying is ensured, and the machining quality of the automobile fasteners is guaranteed.

Owner:苏州东吾丰机械科技有限公司

Tackifier of cement-base material and its preparation method and application

InactiveCN101239794AGood viscosity increasing effectSolving Segregation ProblemsCarboxylic acidPhenol

The present invention discloses an adhesion promoter of a cement-based material and the preparing method and the use thereof, the invention is the adhesion promoter of the cement-based material which is obtained using the papermaking waste liquor, extracting the methyphenylpropane of the phenol-containing hydroxyl group, generating esterifying reaction with the carboxyl monomer under the function of the catalyst and then copolymerizing with the carboxyl acid, or graft-copolymerizing with the acidamide substance and ahs a comb-shaped structure. When the adhesion promoter is mixed into the cement-based material the appropriate thickness and workability can be endowed to the cement-based material, the mixed water is leaded to be uniformly distributed in the cement-based material and can be kept stable for a long time without discharging out, at the same time the adhesion promoter of the invention increases the viscosity of the paste and leads to that the particles of aggregate is not easily moved thereby effectively preventing the disengagement and facilitating that the cement-based material always keeps better homogeneity.

Owner:HOHAI UNIV

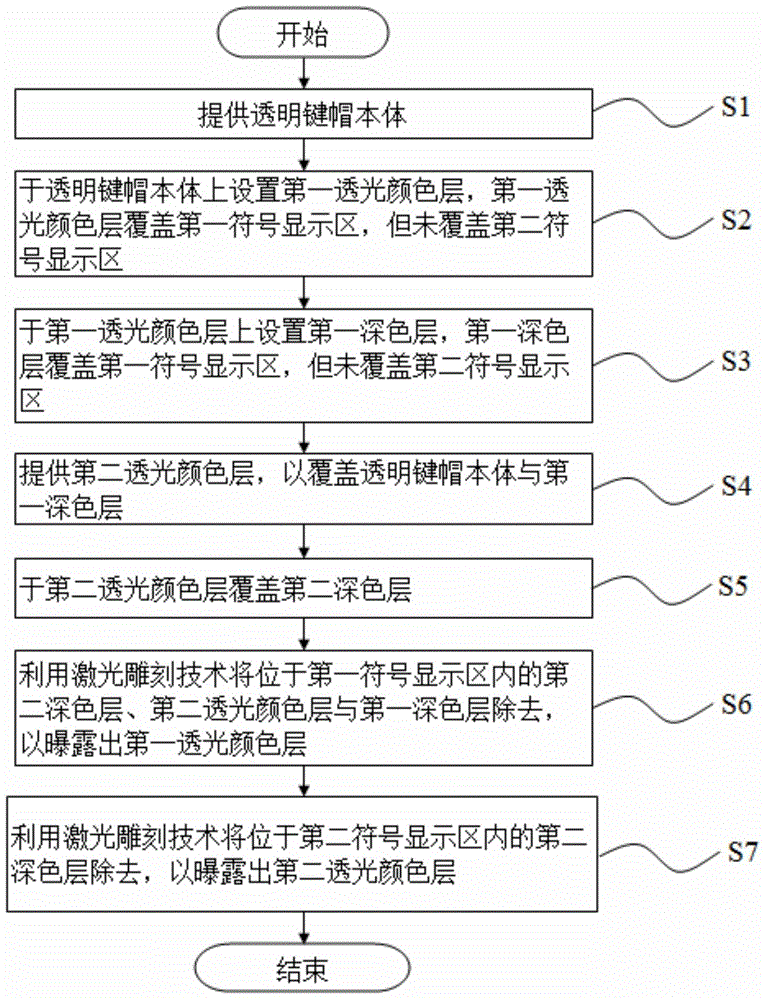

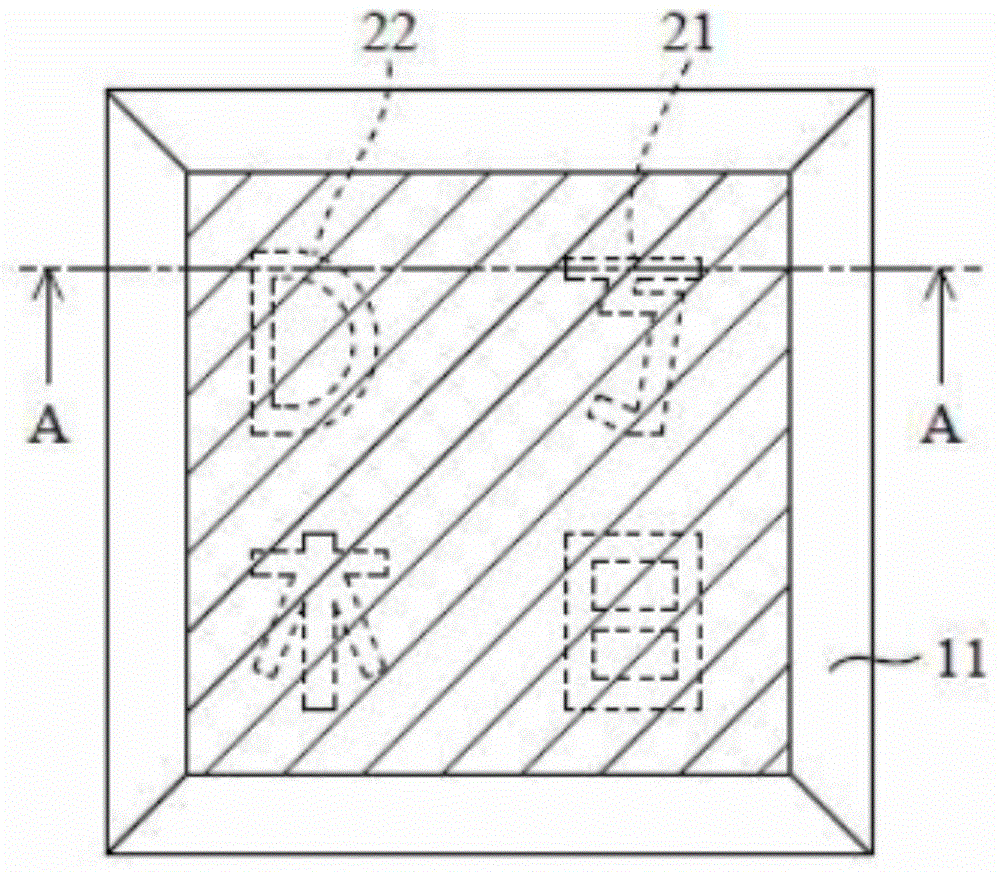

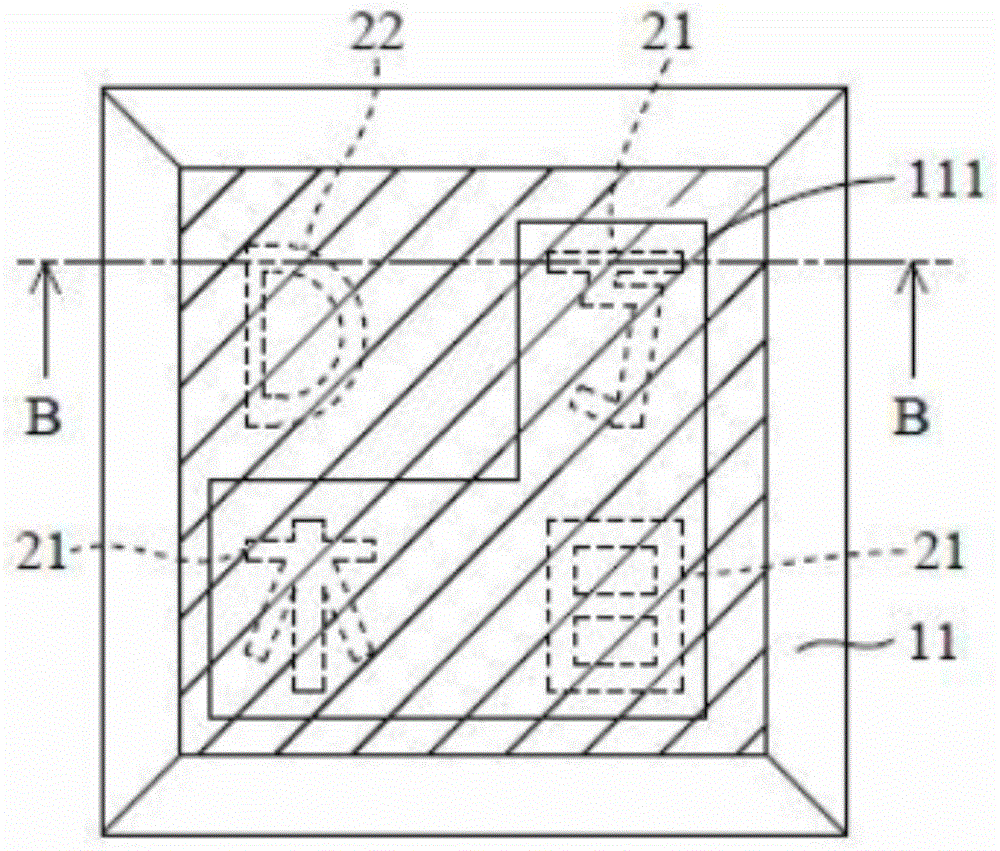

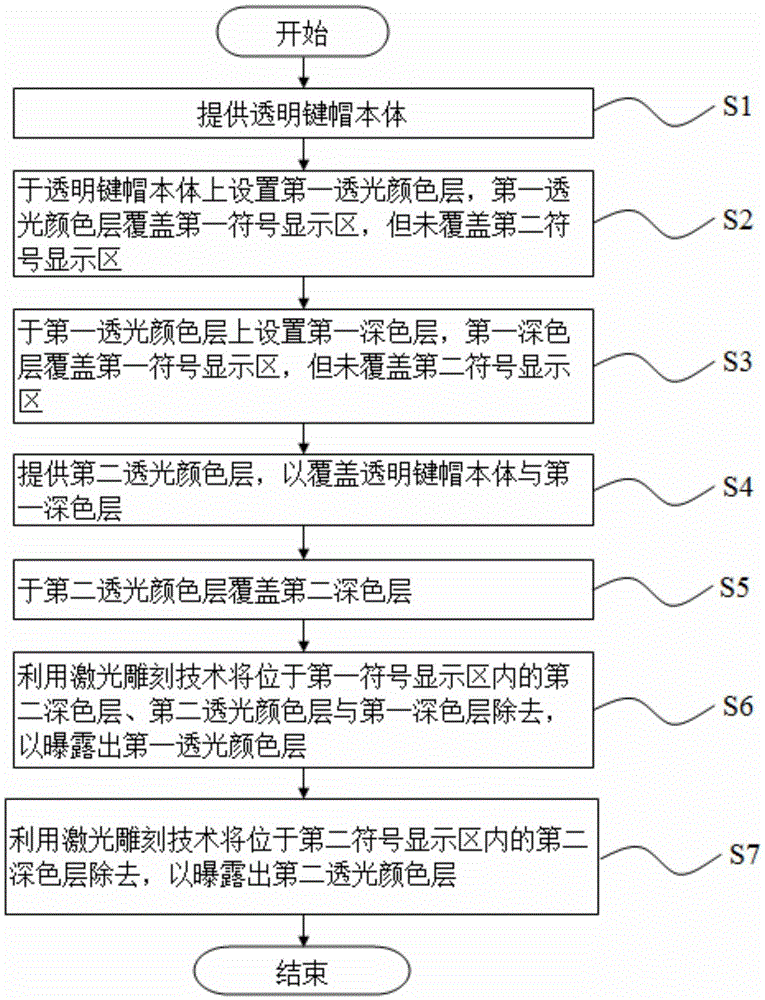

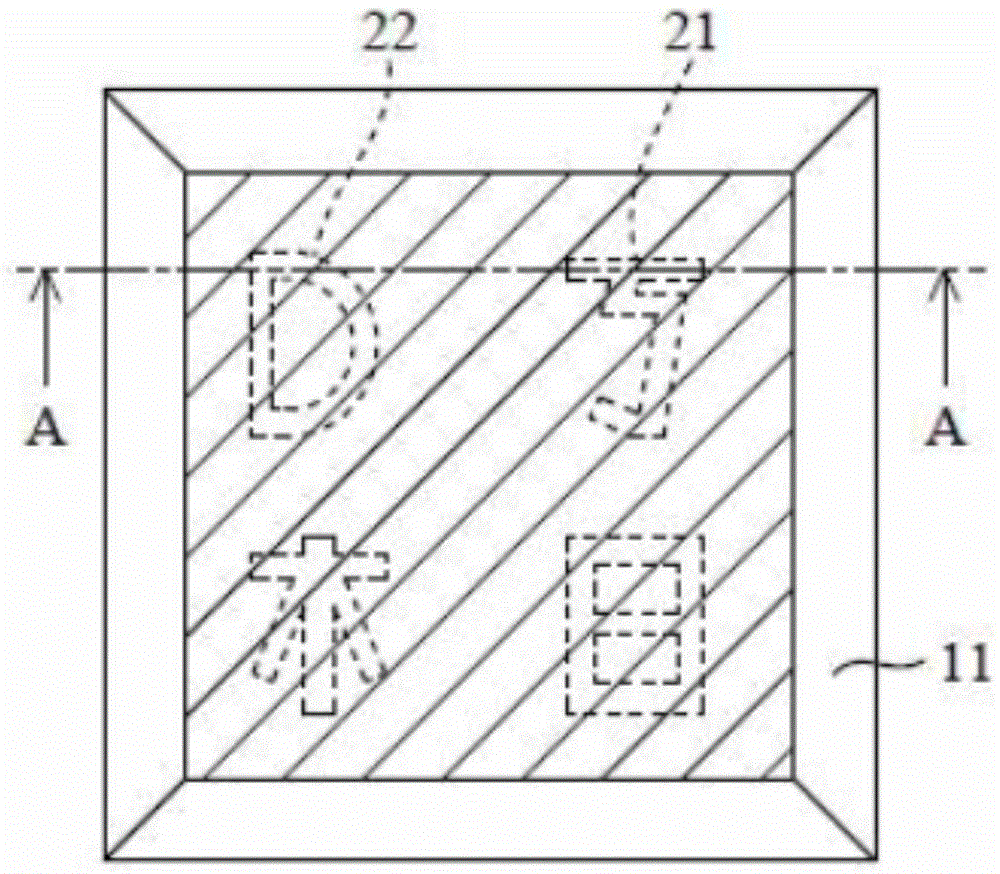

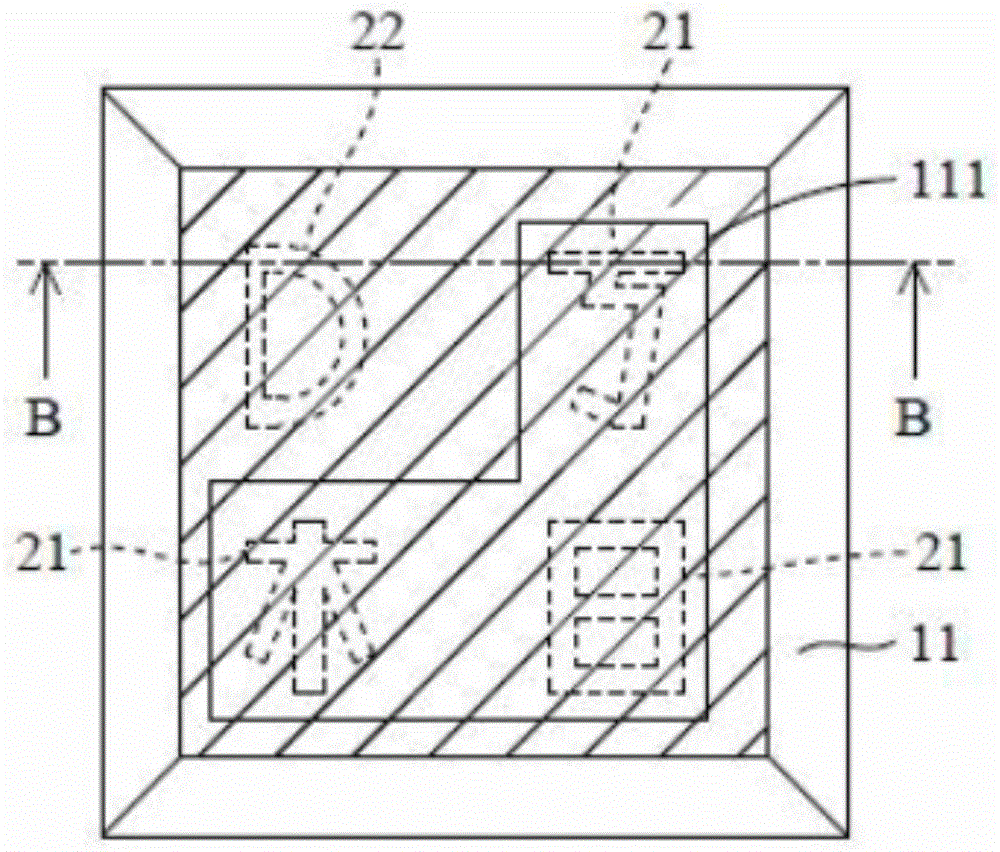

Multicolor light-previous keycap and manufacturing method thereof

ActiveCN104377066ASolve Bleeding ProblemsSolve bleedingLegendsElectric switchesLight sourceComputer graphics (images)

The invention relates to a multicolor light-previous keycap and a manufacturing method of the multicolor light-previous keycap. The manufactured multicolor light-previous keycap is provided with a plurality of symbol display regions, characters are arranged in all the symbol display regions, and each symbol display region is only covered with a single light-previous color layer. Thus, when a backlight source below the keycap emits light, light form the light source will only penetrate through the single light-previous color layer covering one symbol display region and will not penetrate through the other light-previous color layers covering the other symbol display regions, and in this way, the problem of color bleeding caused due to the fact that each symbol display region is covered with multiple light-previous color layers in the prior art can be solved.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

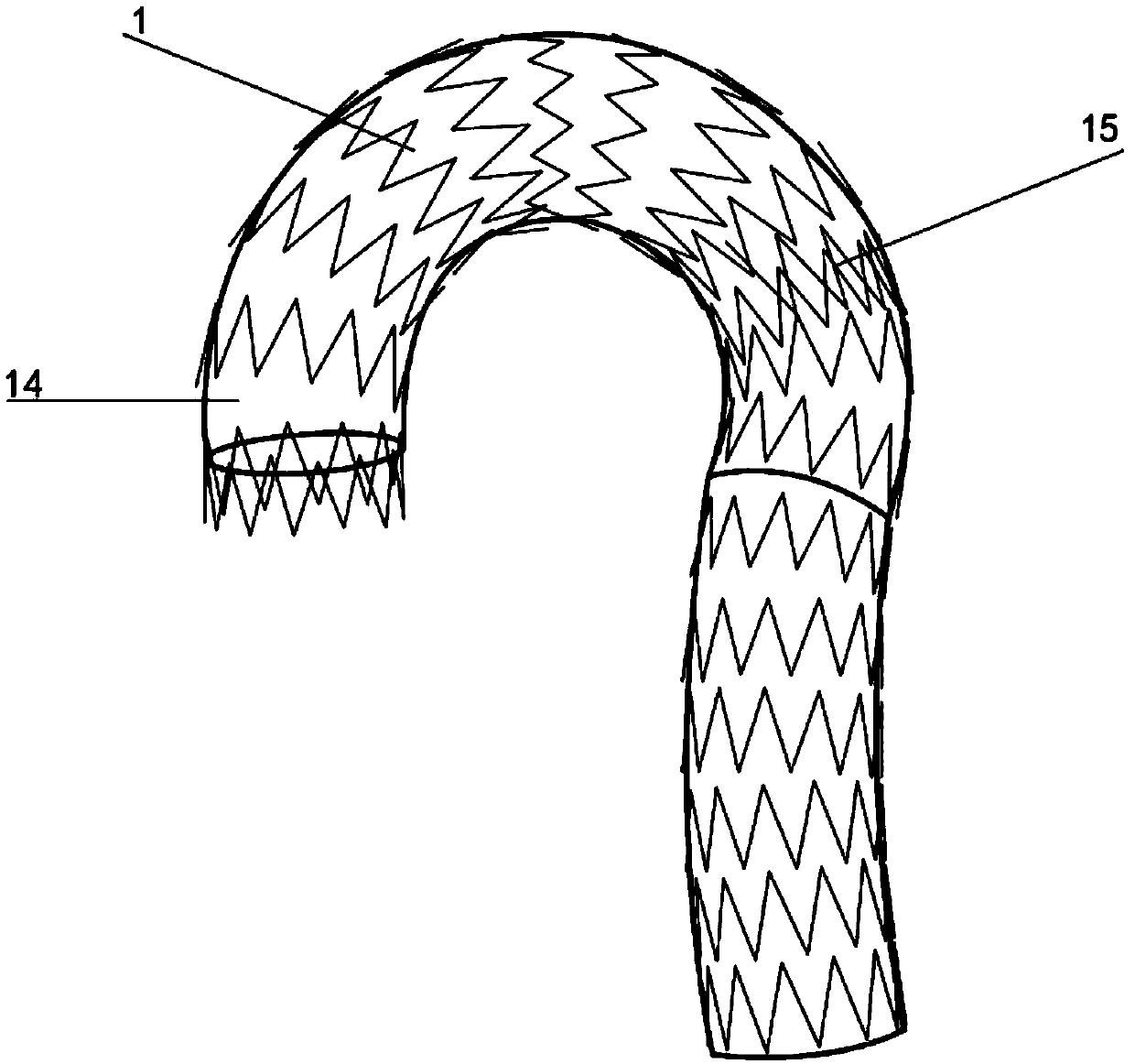

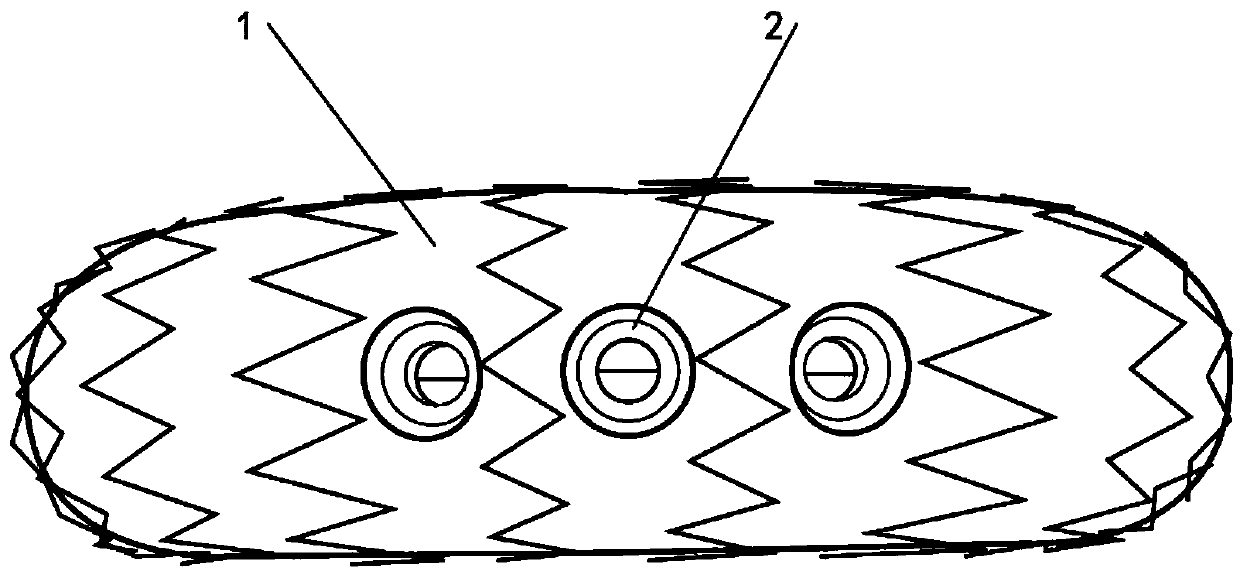

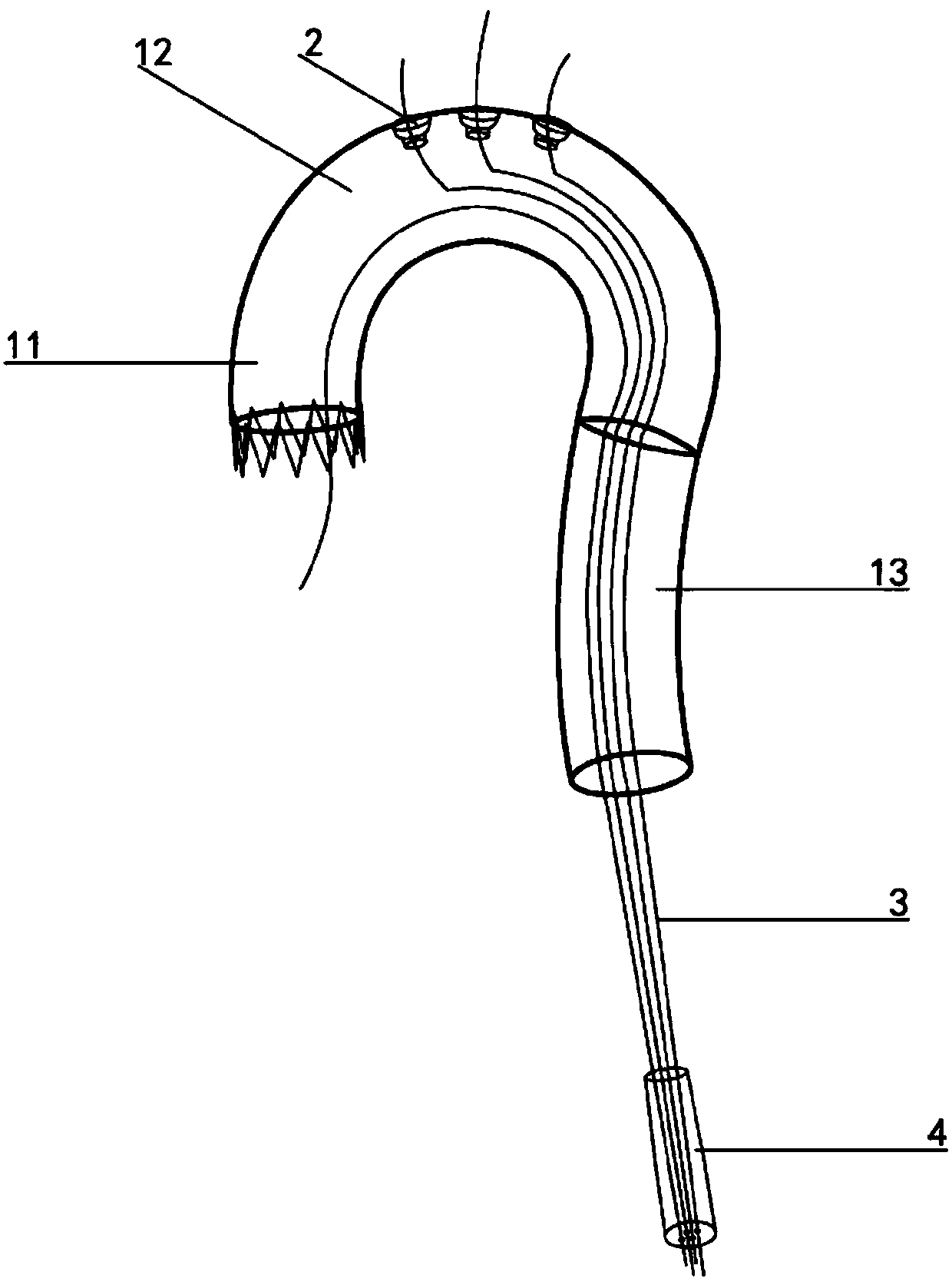

Novel aorta inner branch type covered stent

The invention aims at providing a novel aorta inner branch type covered stent. The novel aorta inner branch type covered stent is composed of a metal frame and a covering film. The novel aorta inner branch type covered stent comprises an anterior arch area, an arch area and a posterior arch area. Multiple inner branch stents are arranged on the big bend side of the arch area, a round open hole located in the big bend side is formed in the top of any inner branch stent, any inner branch stent can comprise an upper part and a lower part, the upper part of any inner branch stent is of a bowl-shaped structure, the diameter of the top section of the upper part is larger than that of the bottom section of the upper part, the lower part of any inner branch stent is of a cylindrical structure, andthe diameter of the cross section of the cylindrical structure of the lower part of any inner branch stent is not larger than that of the bottom section of the bowl-shaped structure of the upper partof any inner branch stent. The novel aorta inner branch type covered stent in the design has the effect that the open holes in the tops of the inner branch stents can correspond to branch arteries ofthe top end of an arch artery. The novel aorta inner branch type covered stent has the advantages that the problem of blood leakage between the aorta covered stent and branch covered stents can be effectively solved, the structures of the inner branch stents adapt to most blood vessel anatomical structures, and alignment with branch artery blood vessels is convenient.

Owner:戴向晨

Machine-made sand conditioning agent

InactiveCN110950571AImprove adaptabilityAvoid slag and other phenomenaFirming agentStructural engineering

The invention relates to the technical field of buildings, and discloses a machine-made sand conditioning agent which can be freely prepared by a user according to requirements by separately preparingmultiple conditioning agents and then combining the multiple conditioning agents, so that the machine-made sand conditioning agent adapting to the environment is prepared, and the machine-made sand conditioning agent has good adaptability and practicability; coal tar, furfural, a curing agent and other materials are added into epoxy resin, so that the phenomenon that the whole concrete binder isdried and the binding degree of the concrete binder is reduced after the cement is dried along with time due to addition of the cement is avoided, the phenomena of concrete slag falling and the like are avoided, and meanwhile, when new concrete and old concrete are bound, the binding strength of the concrete binder is improved. A thickening agent is arranged, so that when self-compacting concreteis prepared, the water solubility of the self-compacting concrete is good, the thickening effect of the self-compacting concrete is good, the plastic viscosity of the self-compacting concrete can be effectively improved, and the problems of bleeding and segregation of the self-compacting concrete are solved.

Owner:深圳市君辰装饰设计工程有限公司

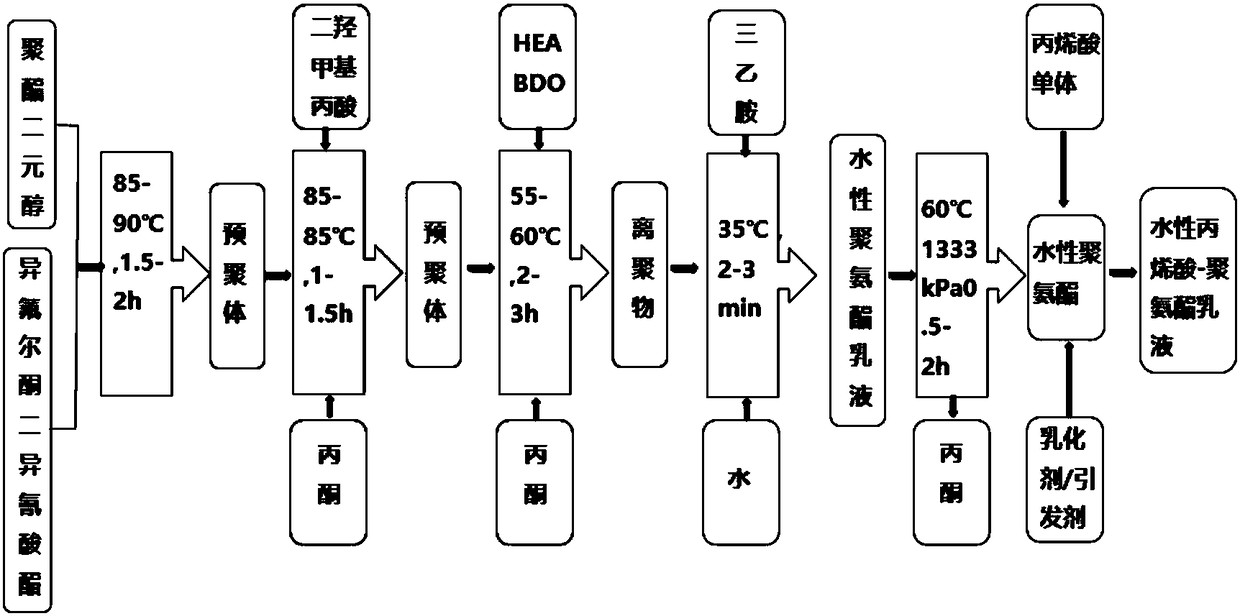

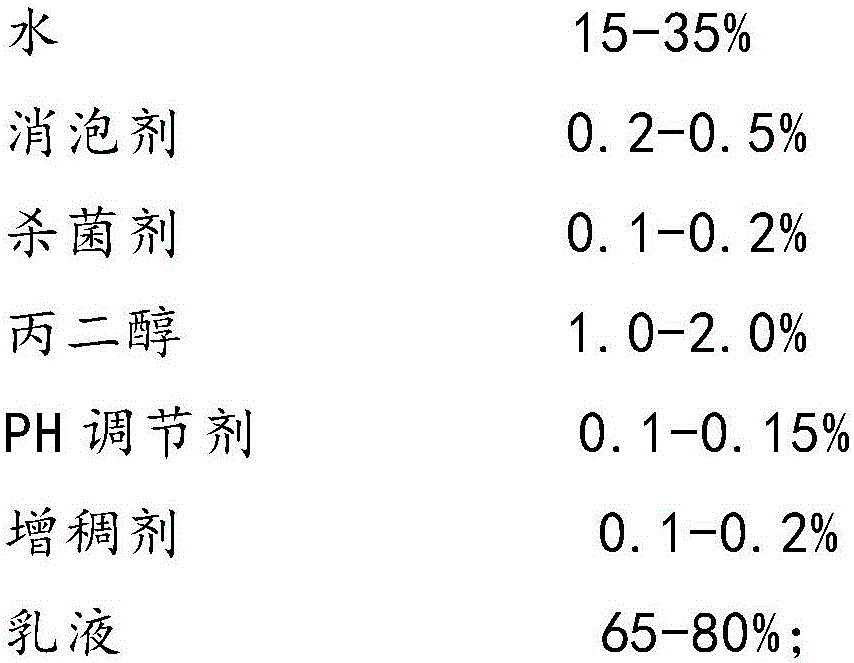

Single-component air-drying water-based sealing agent for woodware and preparation method thereof

InactiveCN108485510ASolve muscle tensionSolve bleedingPolyurea/polyurethane coatingsWater basedAcrylic monomers

The invention discloses a single-component air-drying water-based sealing agent for woodware. Polyhydric alcohols and an isocyanate monomer are mixed for a reaction for a period of time, a certain amount of acetone and dimethylolpropionic acid are added for a continuous reaction for a period of time; BDO and HEA are added for a reaction for a period of time, and then cooling is performed; triethylamine is added for neutralization, water is added for dispersion, acetone is removed, and a waterborne polyurethane dispersion is obtained; the waterborne polyurethane dispersion and an acrylic monomer are copolymerized to obtain acrylic acid-polyurethane mixed emulsion. The acrylic acid-polyurethane mixed emulsion prepared through the method has the dense film formation effect, the surface of wood can be well wrapped, and the phenomenon that the surface of a paint film is damaged due to the fact that much water in water paint is absorbed and serious base material rib expansion is caused is avoided. Meanwhile, on the basis of reasonable auxiliaries, finally, when paint is used on the surface of wood, the problems that wood rib expansion damage is caused and oil leakage and color changing are caused can be effectively avoided.

Owner:广东海顺新材料科技有限公司

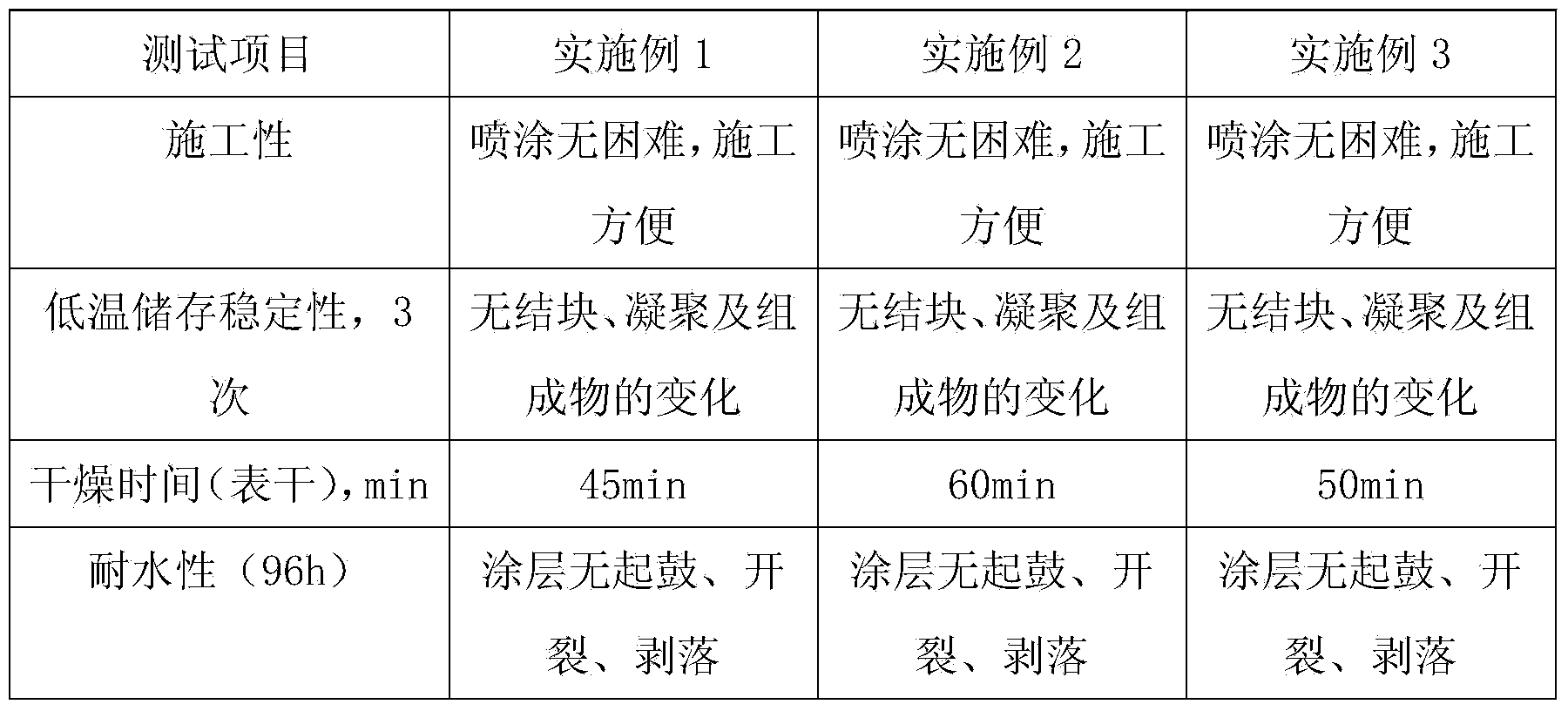

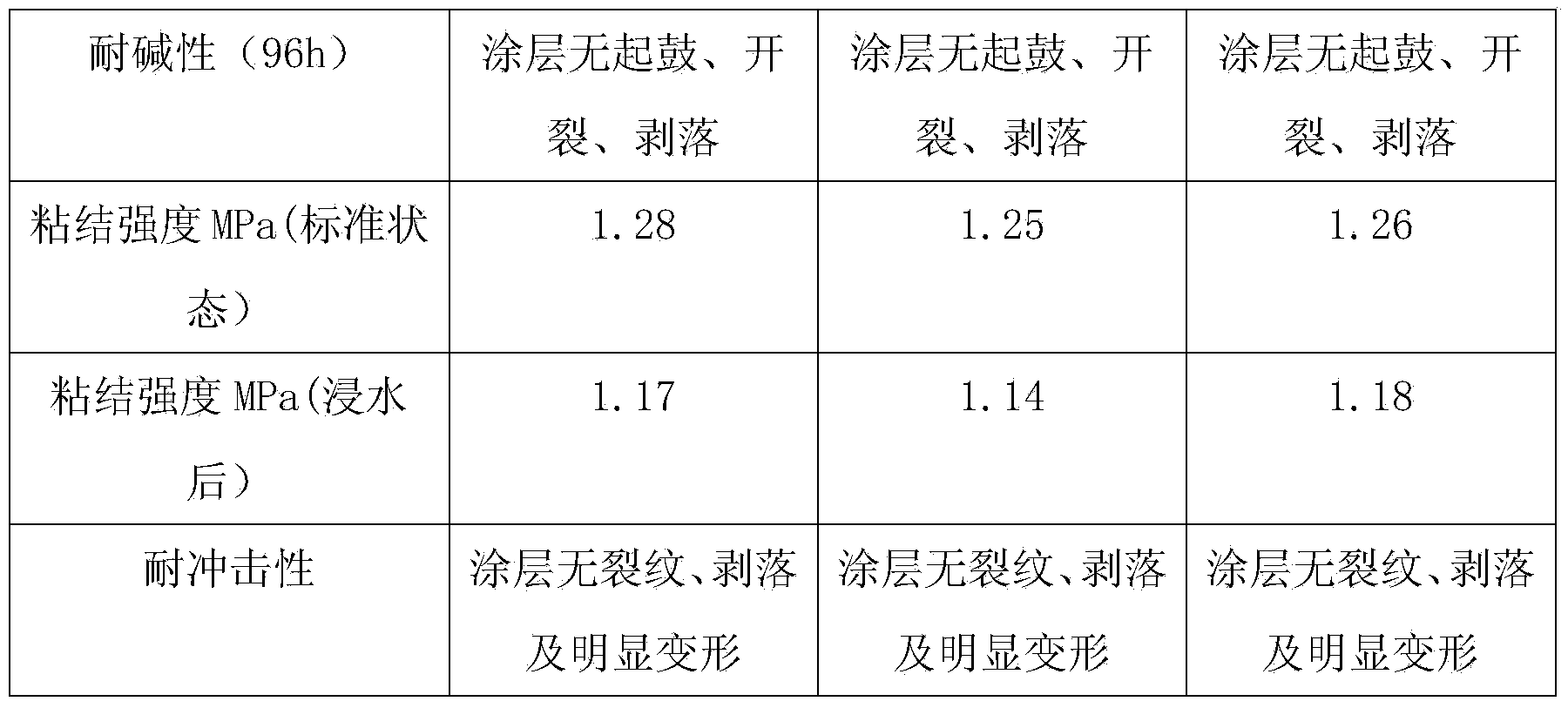

Aqueous slice multi-color paint

The invention discloses an aqueous slice multi-color paint, which comprises the following raw materials by weight: 30-40 parts of silicone acrylic emulsion, 0.03-0.05 part of a wetting agent, 1-3 parts of an antiseptic, 0.02-0.04 part of a defoaming agent, 1-2 parts of neopentyl glycol, 0.03-0.05 part of carboxymethyl cellulose, 0.03-0.05 part of a pH regulator, 1-2 parts of propylene glycol, 1.2-2 parts of a coalescent, 0.3-0.8 part of a thickening agent, 1.5-2.5 parts of polyamide wax, 15-20 parts of multi-color slice, 2-3 parts of costus oil, 1-2 parts of inositol hexaphosphate and 5-10 parts of nano composite powder. The invention adopts the combination of silicone acrylic emulsion and nano composite powder to effectively improve the gloss, weatherability and durability of the paint; usage of multi-color slice provides same decorative effect as a traditional multi-color paint, at the same time is very convenient for the production process, so as to reduce the production cost; and the optimization of the production formula fundamentally solves the problems of floating layer and color bleeding of a traditional aqueous multi-color paint; in addition, the construction is convenient, and does not require special construction equipment.

Owner:ORIGIN DONBON PAINT DONGGUAN CO LTD

Green environment-friendly building mortar and preparation method thereof

The invention provides a green environment-friendly building mortar and a preparation method thereof, and relates to the technical field of building materials, wherein the building mortar is preparedfrom the following raw materials in parts by weight: 30-45 parts of building waste, 40-50 parts of Portland cement, 20-30 parts of a steel slag micro-powder, 15-20 parts of a water slag micro-powder,1-1.3 parts of aminosulfonate, 1-3 parts of calcium chloride, 1-2 parts of aluminum oxide clinker, 1.5-2 parts of cellulose ether, 0.5-1 part of emulsified silicone oil, 0.3-0.5 part of modified waterborne epoxy resin, 1-1.5 parts of polypropylene fibers, 1-1.3 parts of regenerated rubber, 1-2 parts of zinc stearate, 0.5-1 part of aluminum hydroxide, 1.5-4 parts of glass microbeads, 2-3 parts of alkali lime, 0.2-0.4 part of higher fatty acid, 0.1-0.3 part of rosin resin, 1-2 parts of an admixture, and 8-10 parts of water. The preparation method of the green environment-friendly building mortarincludes four steps; the green environment-friendly building mortar has the properties of heat preservation, heat insulation, noise reduction, sound insulation, fire prevention, water prevention, lowenergy consumption and moisture prevention, has good durability, mechanical properties and mechanical strength, and has better economic benefits and environment-friendly functions.

Owner:李修来

3D printing mortar with high bonding strength

InactiveCN108069659AAvoid wastingHigh strengthAdditive manufacturing apparatusSodium BentoniteFlax fiber

The invention discloses 3D printing mortar with high bonding strength. The 3D printing mortar comprises the following raw materials in parts by weight: 50-65 parts of ordinary portland cement, 60-80 parts of weathered coal, 15-24 parts of bentonite, 8-14 parts of mica powder, 10-16 parts of zeolite powder, 4-10 parts of flax fiber, 2-6 parts of calcium sulfate whisker, 4-8 parts of asphalt micro-powder, 1-3 parts of sodium carbonate, 0.5-1.5 parts of a water reducing agent, 0.8-1.6 parts of soft sugar, 0.1-0.8 part of an air entraining agent and 0.5-1.45 parts of sodium carboxymethyl cellulose. The 3D printing mortar provided by the invention not only has convenient material drawing and a low price and realizes reasonable utilization of resources, but also enables a product to have a function of keeping the plasticity of mortar, solves a bleeding problem easily caused by weathered coal and bentonite as raw materials, and ensures the fluidity and adhesive force of the product.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

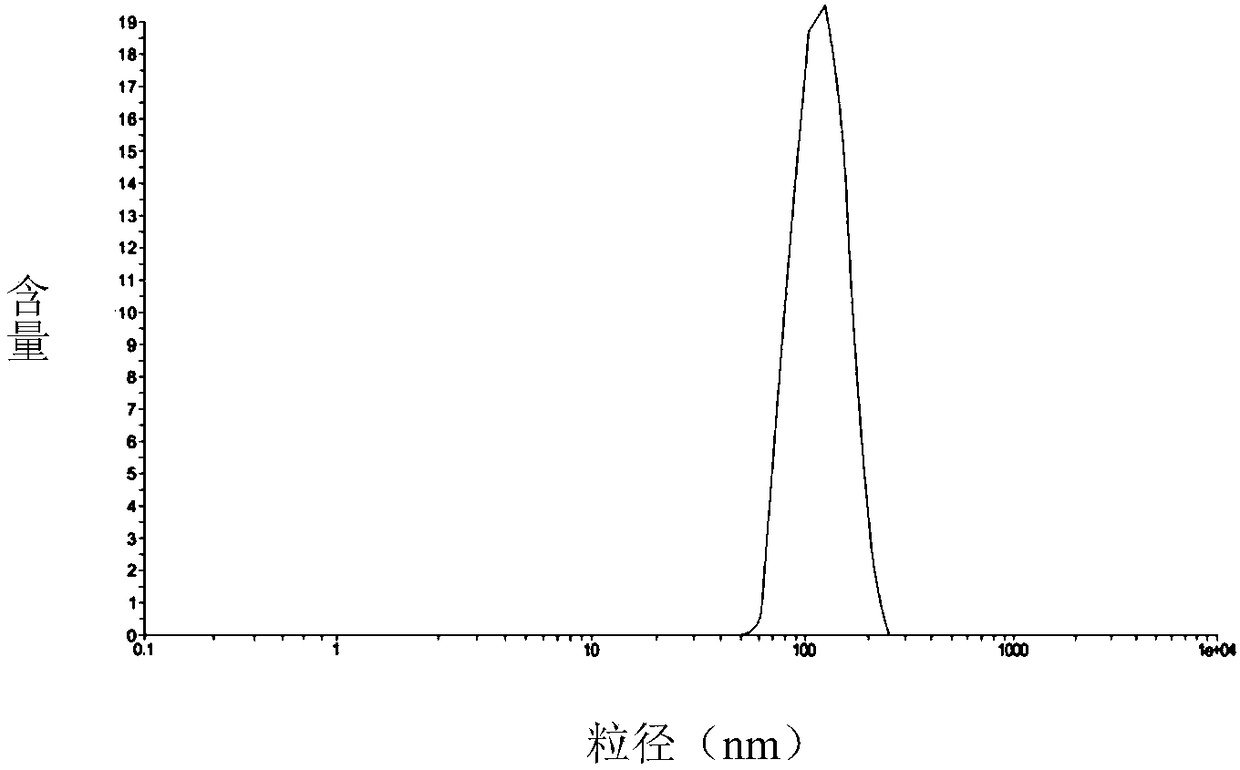

Base paint of water-based stone-like coating and preparation method thereof

Embodiments of the invention disclose a base paint of a water-based stone-like coating, belonging to the technical field of coatings. The base paint of the water-based stone-like coating consists of the following components in percentage by mass: 42.7% of filler slurry, 31% of dispersed organic modified bentonite, 25.0% of a hydroxyl acrylic emulsion, 0.7% of a defoaming agent, 0.3% of a thickening agent and 0.3% of a sterilizing agent. The invention also discloses a preparation method of the base paint of the water-based stone-like coating. The base paint of the water-based stone-like coatingand the preparation method thereof can solve the problems of poor storage stability such as bleeding, water diversion, gelatinization and the like of existing stone-like coatings, and the shapes of particles can be controlled, so the stone-like effect of a coated article is better and more vivid.

Owner:广西瑞顺建材有限公司

Gradient release type long-acting slump-retaining polycarboxylic water reducer, and preparation method and application thereof

The invention provides a gradient release type long-acting slump-retaining polycarboxylic water reducer, and belongs to the technical field of building materials. The water reducer is prepared by freeradical polymerization of raw materials including an unsaturated polyether macromonomer A, an unsaturated carboxylic acid monomer B, a hydrolyzed ester monomer C and a crosslinking monomer D containing unsaturated carboxylic acid cellulose ester. The invention also provides a preparation method and an application of the water reducer. According to the water reducer disclosed by the invention, theester group hydrolysis release capacity on a molecular chain of the polycarboxylic reducer in an alkaline environment is effectively adjusted, carboxylate ions can be stably released in a graded manner along with time, the introduced cellulose micromolecules can enable the polymer to be slightly cross-linked and reduce the temperature sensitivity of hydrolysis and release, 0-4 h of staged whole-process stable supplement of admixture consumption in concrete is realized, different fluidity retention time requirements are met, the workability of the concrete is improved, and the problems of slump loss, segregation and bleeding of the concrete are obviously solved.

Owner:湖北西建新材料科技有限公司 +2

Machine-made sand fair-faced concrete using limestone powder and preparation method thereof

The invention discloses machine-made sand fair-faced concrete using limestone powder and a preparation method thereof. The concrete comprises the following components in percentage by mass: 12-15% ofcement; 0.7-2.6% of limestone powder; 0-1% of phosphorus slag powder; 33-38% of machine-made sand; 36-40% of broken stone; 0.03-0.04% of an additive; and 6-7% of water. The limestone powder is used for partially replacing cement, the cement consumption of the same-grade machine-made sand fair-faced concrete can be reduced, the risk of concrete cracking is reduced, meanwhile, the concrete cost is reduced, good economic benefits and social benefits are achieved, the inherent advantages of the machine-made sand are brought into full play, and the problem of natural sand resource shortage is effectively relieved.

Owner:中建西部建设贵州有限公司 +1

Multi-color light-transmitting keycap and manufacturing method thereof

The invention relates to a multicolor light-previous keycap and a manufacturing method of the multicolor light-previous keycap. The manufactured multicolor light-previous keycap is provided with a plurality of symbol display regions, characters are arranged in all the symbol display regions, and each symbol display region is only covered with a single light-previous color layer. Thus, when a backlight source below the keycap emits light, light form the light source will only penetrate through the single light-previous color layer covering one symbol display region and will not penetrate through the other light-previous color layers covering the other symbol display regions, and in this way, the problem of color bleeding caused due to the fact that each symbol display region is covered with multiple light-previous color layers in the prior art can be solved.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

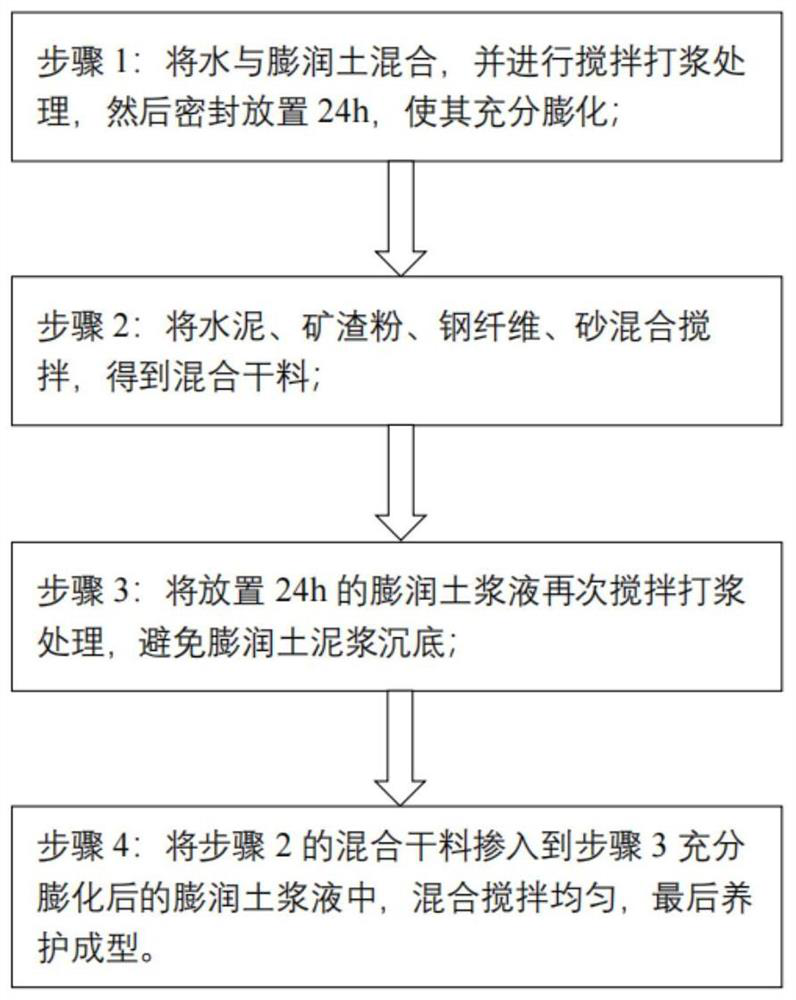

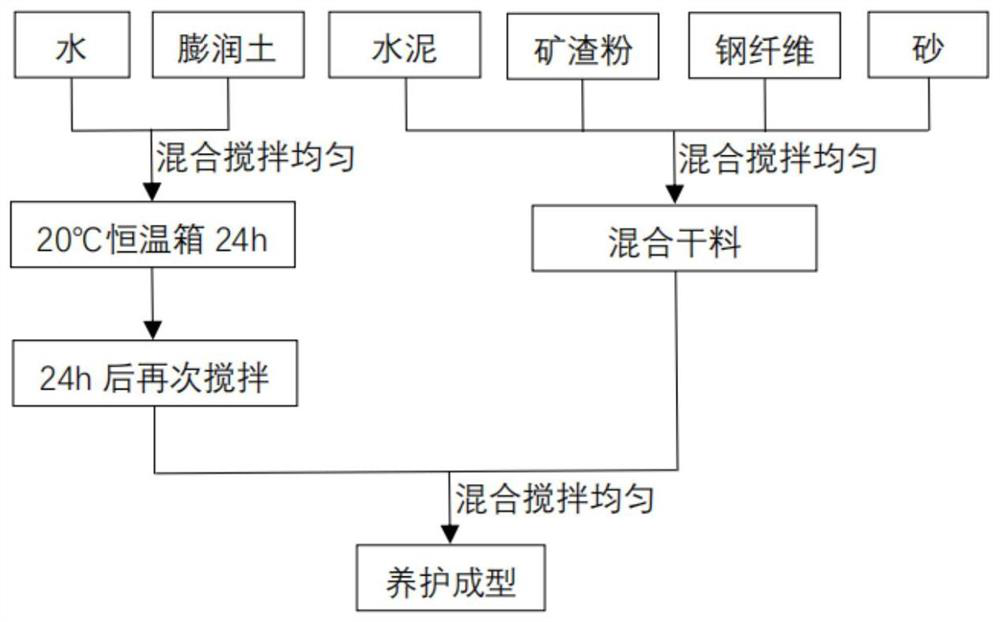

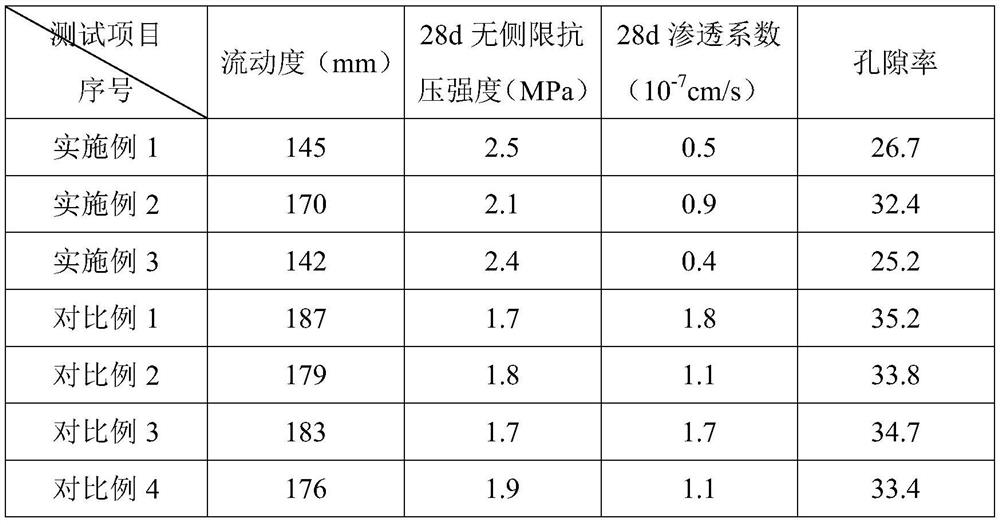

Preparation method of plastic concrete with high water-binder ratio

InactiveCN114349417ASolve bleedingSolve the phenomenon of segregationSolid waste managementCompressive resistanceSlurry

The invention discloses a preparation method of plastic concrete with a high water-binder ratio. Belongs to the technical field of plastic concrete preparation. The preparation method comprises the following specific steps: 1, mixing water and bentonite, uniformly stirring, and sealing and placing in a thermotank at the temperature of 20 DEG C for 24 hours to obtain bentonite slurry; 2, cement, slag powder, steel fibers and sand are mixed and evenly mixed in a dry mode, and a mixed dry material is obtained; 3, stirring the bentonite slurry placed for 24 hours in the step 1 again to obtain fully expanded bentonite slurry; and 4, doping the mixed dry material prepared in the step 2 into the bentonite slurry fully puffed in the step 3, uniformly mixing and stirring, curing and forming, and finally preparing the plastic concrete with the high water-binder ratio. The plastic concrete prepared by the invention can increase the water-binder ratio and reduce the cement consumption, avoids the bleeding and segregation phenomena of the plastic concrete under the condition of not adding a water reducer, and has the advantages of small porosity, low permeability coefficient, high compressive strength, low price and the like.

Owner:JIANGSU UNIV OF SCI & TECH

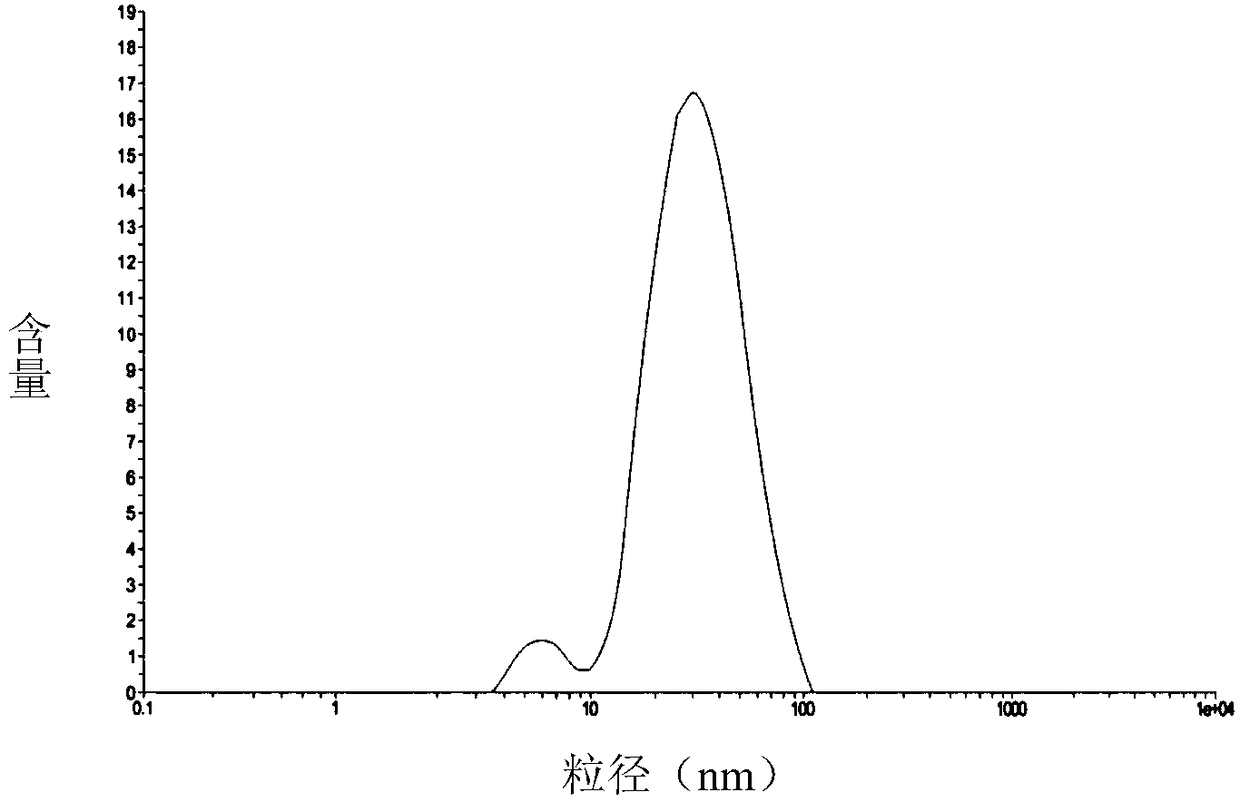

Water-in-water multi-color coating applicable to production line construction and preparation method of water-in-water multi-color coating

ActiveCN106752570AGood transportation and storage capacityEasy to spreadAntifouling/underwater paintsPaints with biocidesCelluloseEngineering

The invention provides a water-in-water multi-color coating applicable to production line construction and a preparation method of the water-in-water multi-color coating. The water-in-water multi-color coating comprises a basic coating, continuous-phase emulsion composition and protection glue, wherein with adoption of composite emulsion formed by the silicone-acrylic emulsion and pure acrylic emulsion, spreading of multi-color particles is better facilitated; xanthan gum capable of improving viscosity and stability of the finished coating is added; large-molecular-weight cellulose and small-molecular-weight cellulose coordinate for use and are compounded with the xanthan gum, so that all natural biological glue with high strength is formed, and the particle intensity is improved. 4000-mesh kaolin and rutile titania are taken as pigments. Therefore, the water-in-water multi-color coating is low in consumption and reduces cost; stability of batches can be controlled during construction; the intensity of the multi-color particles is improved, and the coating has better transportation and storage capacity. The coating can be applied to production line construction and construction on production boards, so that problems caused by poor construction in the prior art are solved, and the construction cost is reduced.

Owner:ASIA PAINT SHANGHAI

Tackifier of cement-base material and its preparation method and application

InactiveCN101239794BGood viscosity increasing effectSolving Segregation ProblemsPolymer scienceMeth-

The present invention discloses an adhesion promoter of a cement-based material and the preparing method and the use thereof, the invention is the adhesion promoter of the cement-based material which is obtained using the papermaking waste liquor, extracting the methyphenylpropane of the phenol-containing hydroxyl group, generating esterifying reaction with the carboxyl monomer under the functionof the catalyst and then copolymerizing with the carboxyl acid, or graft-copolymerizing with the acidamide substance and ahs a comb-shaped structure. When the adhesion promoter is mixed into the cement-based material the appropriate thickness and workability can be endowed to the cement-based material, the mixed water is leaded to be uniformly distributed in the cement-based material and can be kept stable for a long time without discharging out, at the same time the adhesion promoter of the invention increases the viscosity of the paste and leads to that the particles of aggregate is not easily moved thereby effectively preventing the disengagement and facilitating that the cement-based material always keeps better homogeneity.

Owner:HOHAI UNIV

A kind of bleeding-reducing concrete admixture and preparation method thereof

The invention relates to the technical field of building materials, in particular to a bleeding-reducing concrete admixture and a preparation method thereof, wherein the preparation method includes the following preparation steps: adding quicklime to the original ready-mixed concrete waste slurry to perform pressure filtration treatment to obtain a pre-mixed concrete admixture. Mixing waste concrete slurry press filter residue; adding the ready-mix waste concrete slurry filter residue and grinding aid into a ball mill for ball milling to obtain ready-mix waste concrete slurry powder; mixing the ready-mix waste concrete slurry powder and pulverized coal The ash is mixed and stirred to prepare the bleeding-reducing concrete admixture. The invention uses the waste cement slurry produced by the ready-mixed concrete in the concrete mixing plant, and uses it as a raw material to prepare an admixture with reduced bleeding performance, which reduces the amount of other admixtures such as silica fume and mineral powder, and reduces the cost of concrete ; At the same time, high-value reuse of waste slurry from mixing plants has good economic and environmental effects, and is in line with the concept of sustainable development.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Thickener for self-compacting concrete, preparation method thereof and self-compacting concrete using the thickener

The invention discloses a preparation method of a thickener used for self-compact concrete. The method comprises the following steps: 1, weighing 2-acrylamide-2-methylpropanesulfonic acid and acrylic acid in proportion, processing to prepare an aqueous solution, and adjusting the pH value to 6.5-7.0; 2, adding a prepared monomer acrylamide solution with the concentration of 25-35% while stirring, uniformly stirring, dumping the obtained mixed solution into a flask, carrying out constant temperature water bath, and introducing nitrogen for protection; and 3, adding an initiator in a dropwise manner when the reaction temperature rises to 30-40DEG C, carrying out heat insulation at 40DEG C, carrying out a stirring reaction for about 1.5-2h, stopping the introduction of nitrogen when reactants are a viscous liquid, and carrying out constant temperature slaking for a period of time to obtain a white transparent colloid which is the thickener. The thickener obtained in the invention is used for preparing the self-compact concrete, has a good water solubility and a good thickening effect, can effectively improve the plastic viscosity of the self-compact concrete, and solves the water segregation and separation problems of the self-compact concrete.

Owner:CCCC FOURTH HARBOR ENG INST +4

Wet-mix plastering mortars prepared from stone chips and tailings sand

ActiveCN104556875BRealize rational utilizationReduce pollutionSolid waste managementFiberSodium Bentonite

The invention discloses wet-mixed plastering mortar prepared from stone chips and tailing sand. The wet-mixed plastering mortar comprises the following components in parts by weight: 18-22 parts of cement, 6-8 parts of coal ash, 5-7 parts of mineral powder, 22-25 parts of water, 100-125 parts of the stone chips, 20-35 parts of the tailing sand and 0.5-1.5 parts of a mortar additive, wherein the particle sizes of the stone chips are not greater than 4.75 mm and the stone chips comprise 2-3% of stone powder; the particle size of the tailing sand is not greater than 2.36 mm and the tailing sand comprises 5-10% of mud; the mortar additive is a thickener and comprises the following components in parts by weight: 2-4 parts of a sulfonic acid air entraining agent, 20-40 parts of a naphthalene water reducer, 2-6 parts of sodium gluconate, 0.5-2 parts of polypropylene staple fibers, 5-10 parts of latex powder and 20-40 parts of sodium bentonite. The stone chips and the tailing sand are adopted for replacing machine-made sand and river sand, so that the environmental pollution caused by waste stone chips and tailing sand is alleviated and the production cost of the mortar is reduced.

Owner:青岛磊鑫混凝土有限公司

A kind of LC30 light-weight high-strength pumping ceramsite concrete and its preparation method

ActiveCN113135717BImprove water retentionSavings on saturated pre-wetting processExpanded clay aggregateMechanical engineering

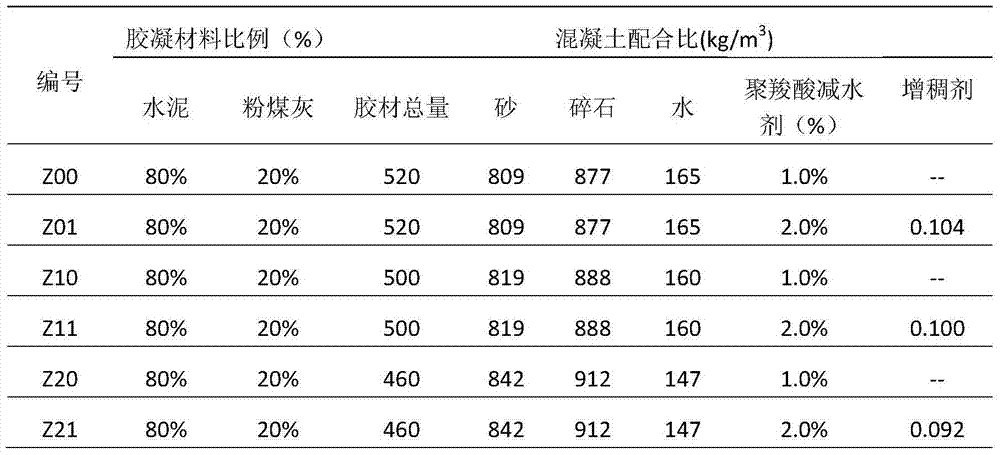

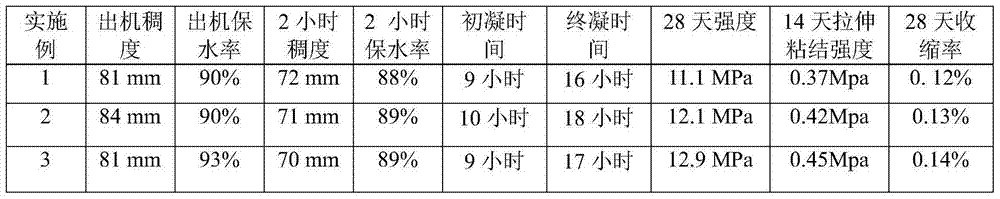

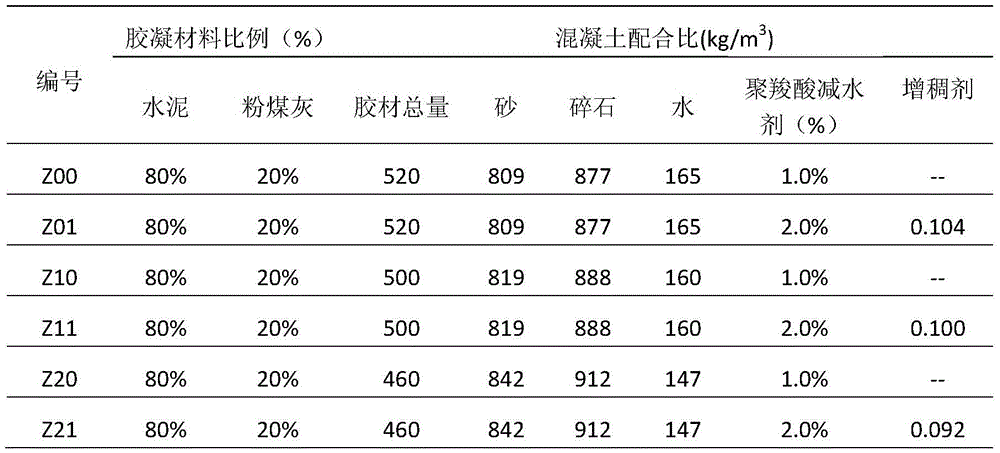

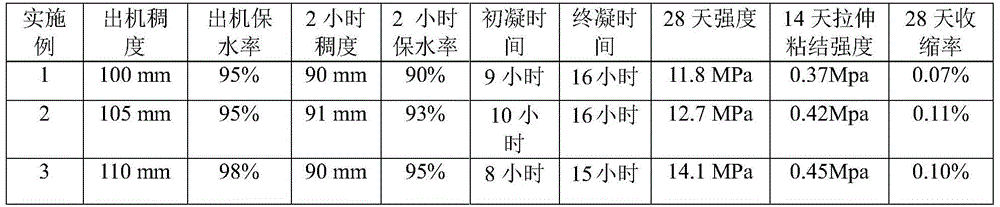

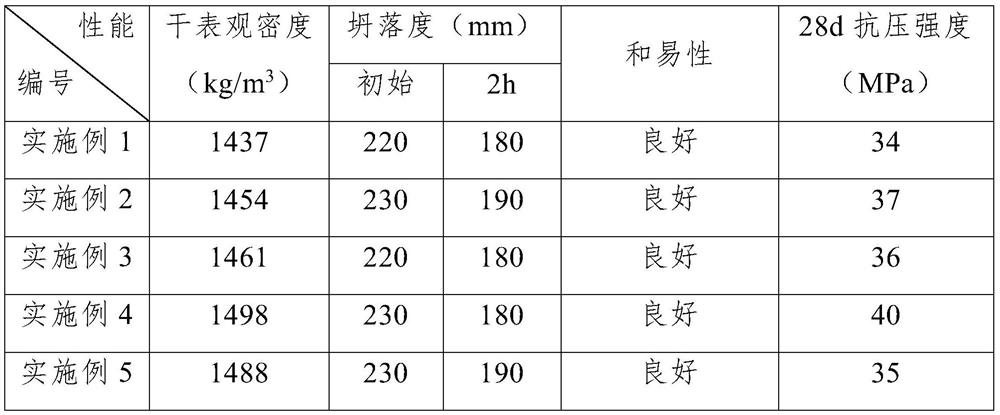

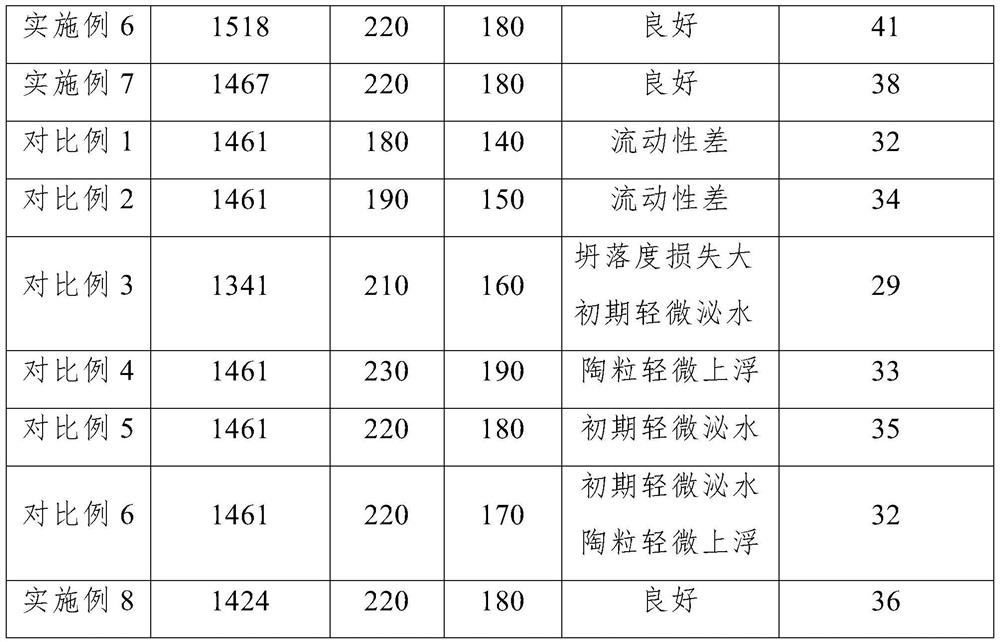

The invention discloses a LC30 light-weight high-strength pumping ceramsite concrete, which consists of the following components in parts by mass: 340-360 parts of cement, 120-130 parts of fly ash, 274-329 parts of ceramsite and 340 parts of ceramsite ~360 parts, 90~100 parts of natural medium sand, 90~100 parts of machine-made medium sand, 70~80 parts of natural fine sand, 8~9 parts of water reducer, 180~200 parts of mixing water, 15~25 parts of additional water parts, 0.096-0.106 parts of water-soluble organic tackifier; the invention also discloses a method for preparing LC30 light-weight high-strength pumping ceramsite concrete. The ceramsite concrete of the present invention saves the saturated pre-wetting process of ceramsite by rationally designing the mixing ratio, avoids layered segregation, and realizes the effect of light weight and high strength of lightweight aggregate concrete, making it suitable for pumping; the present invention The preparation method improves the production efficiency and reduces the preparation cost.

Owner:陕西建工集团混凝土有限公司

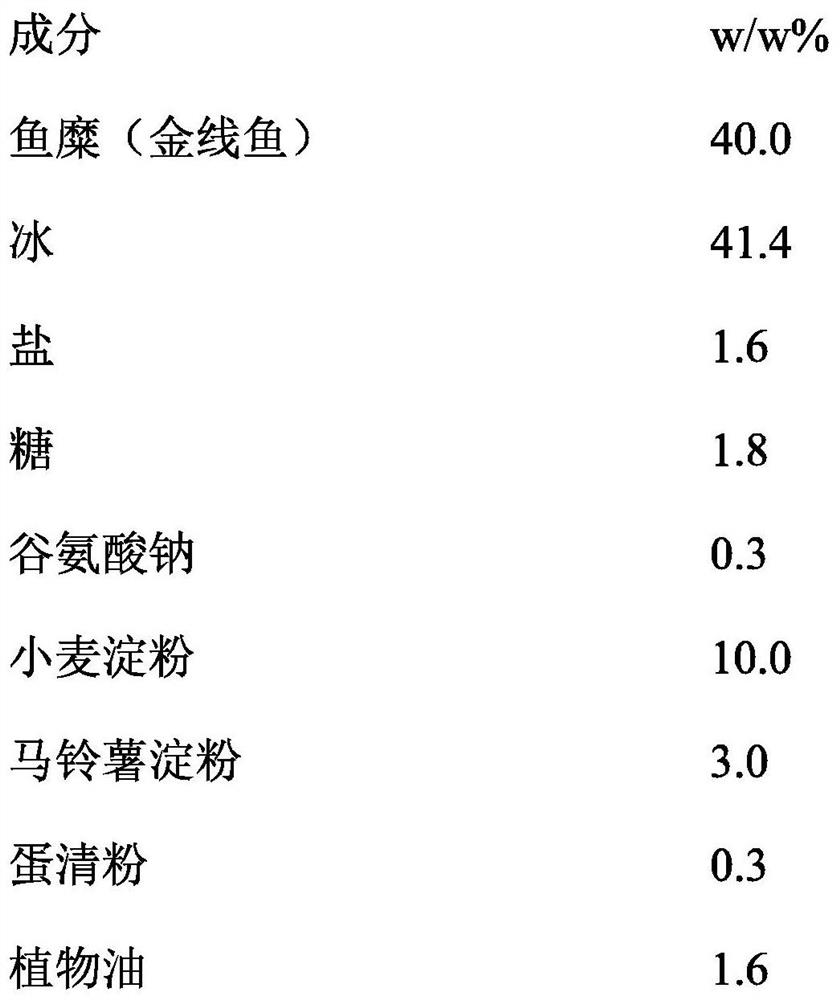

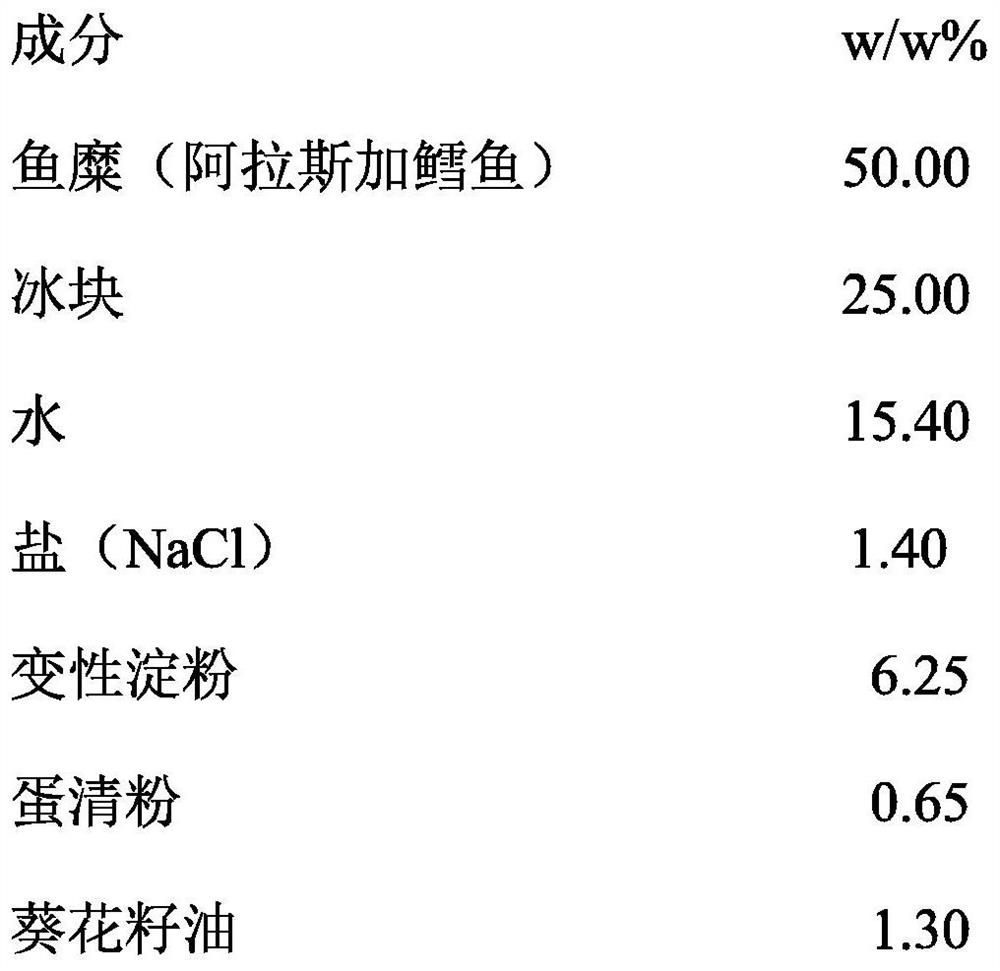

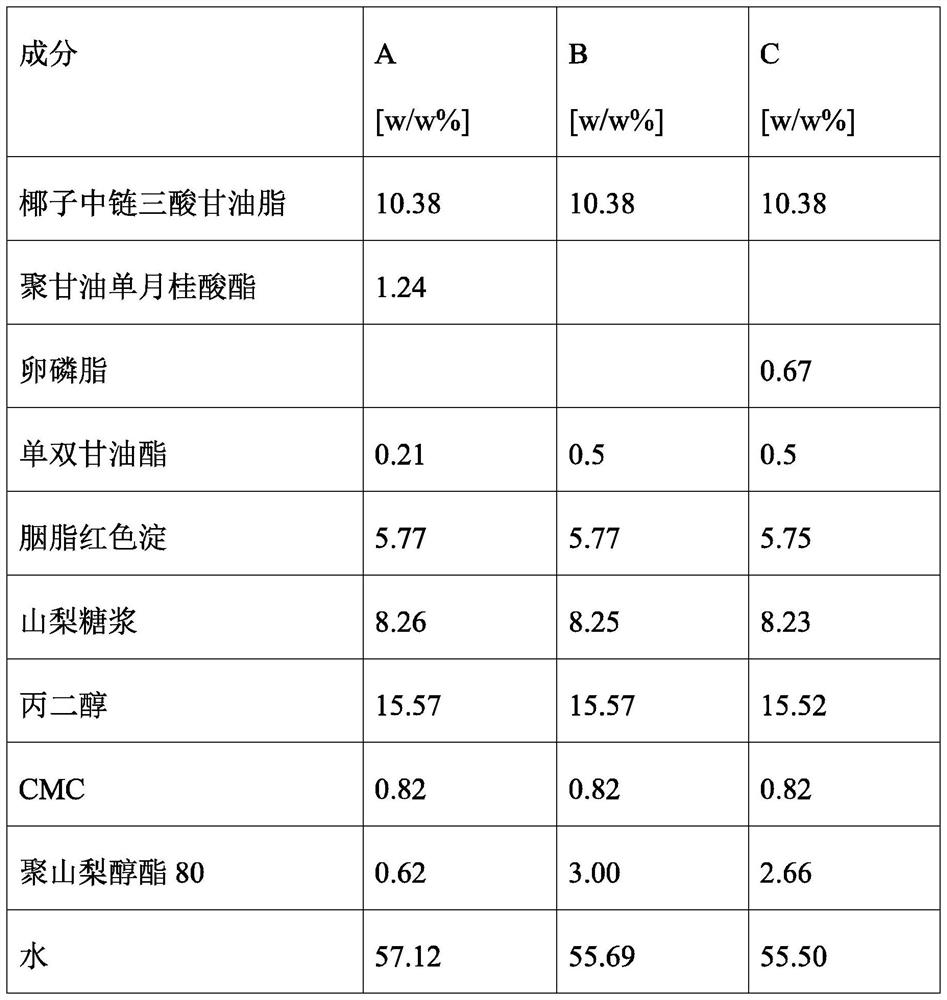

Formulation for coloring surimi products

Owner:OTERRA AS

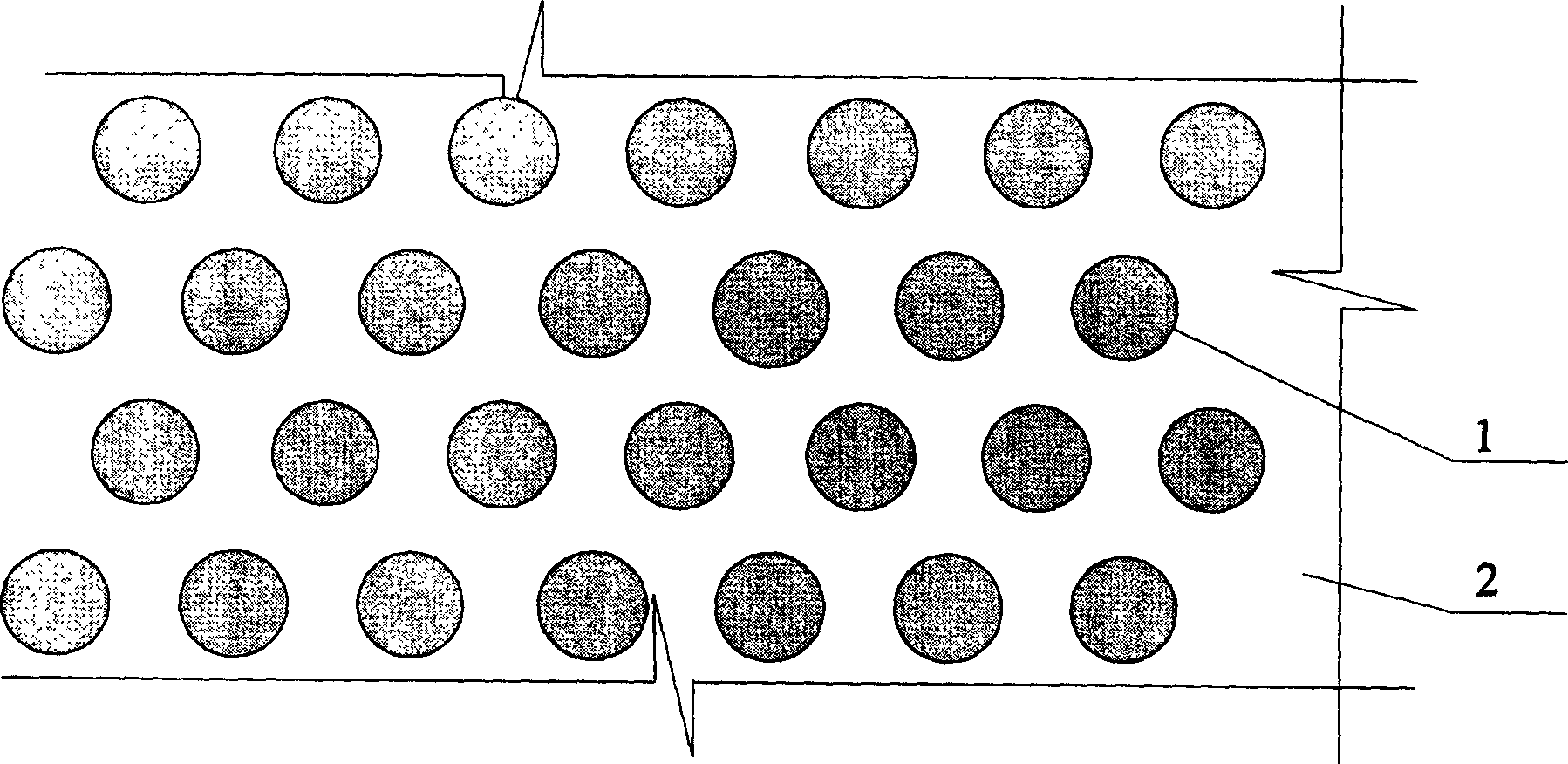

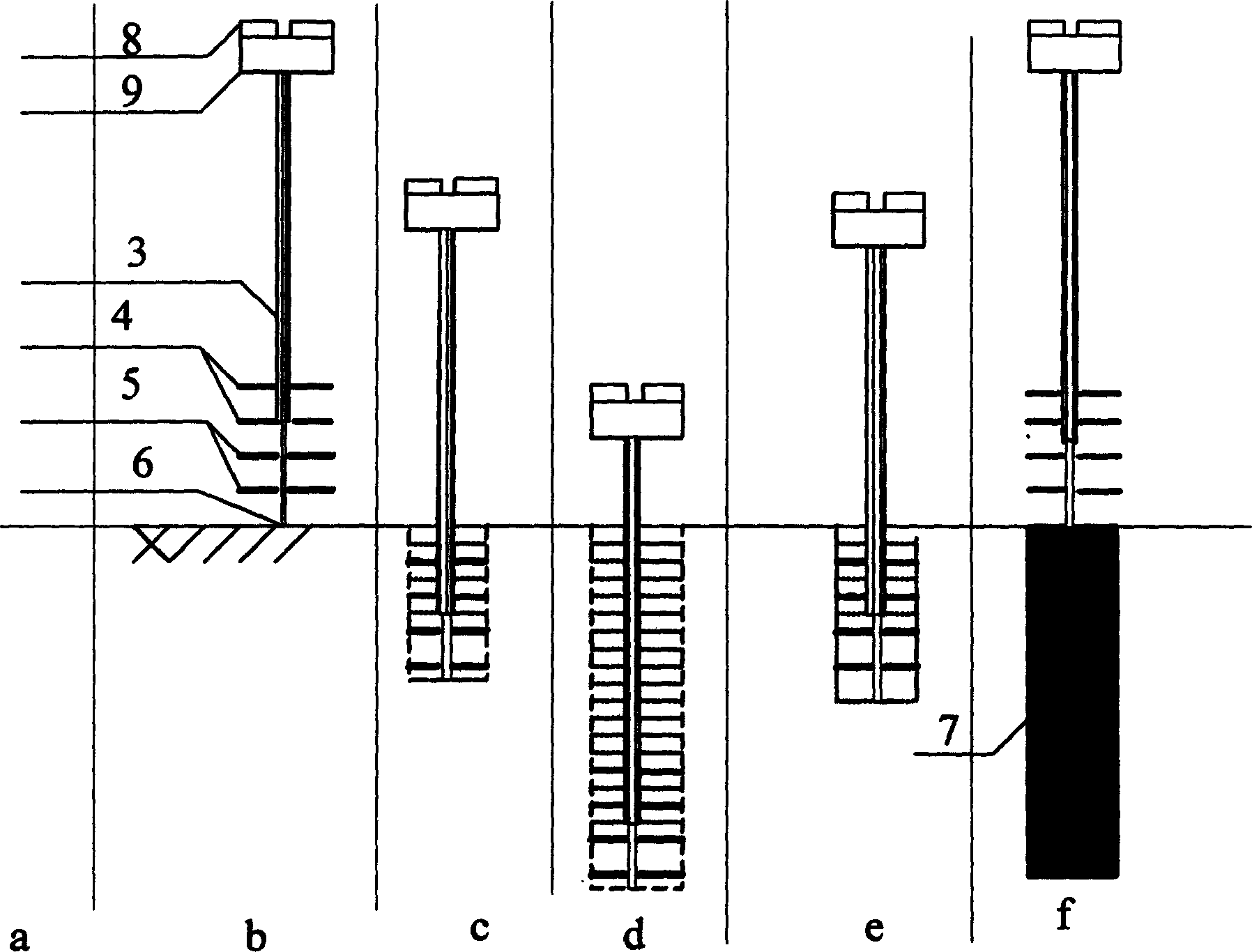

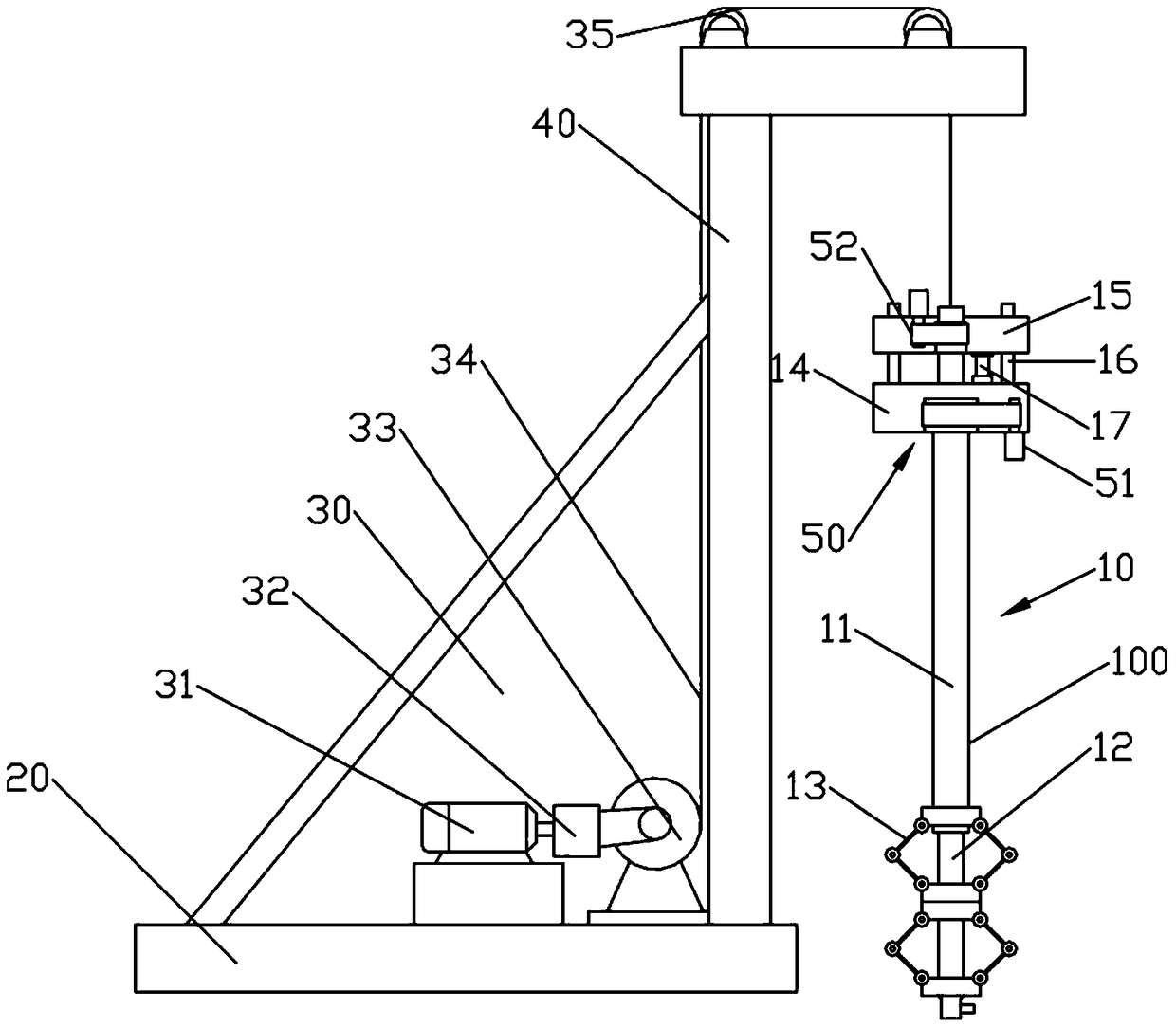

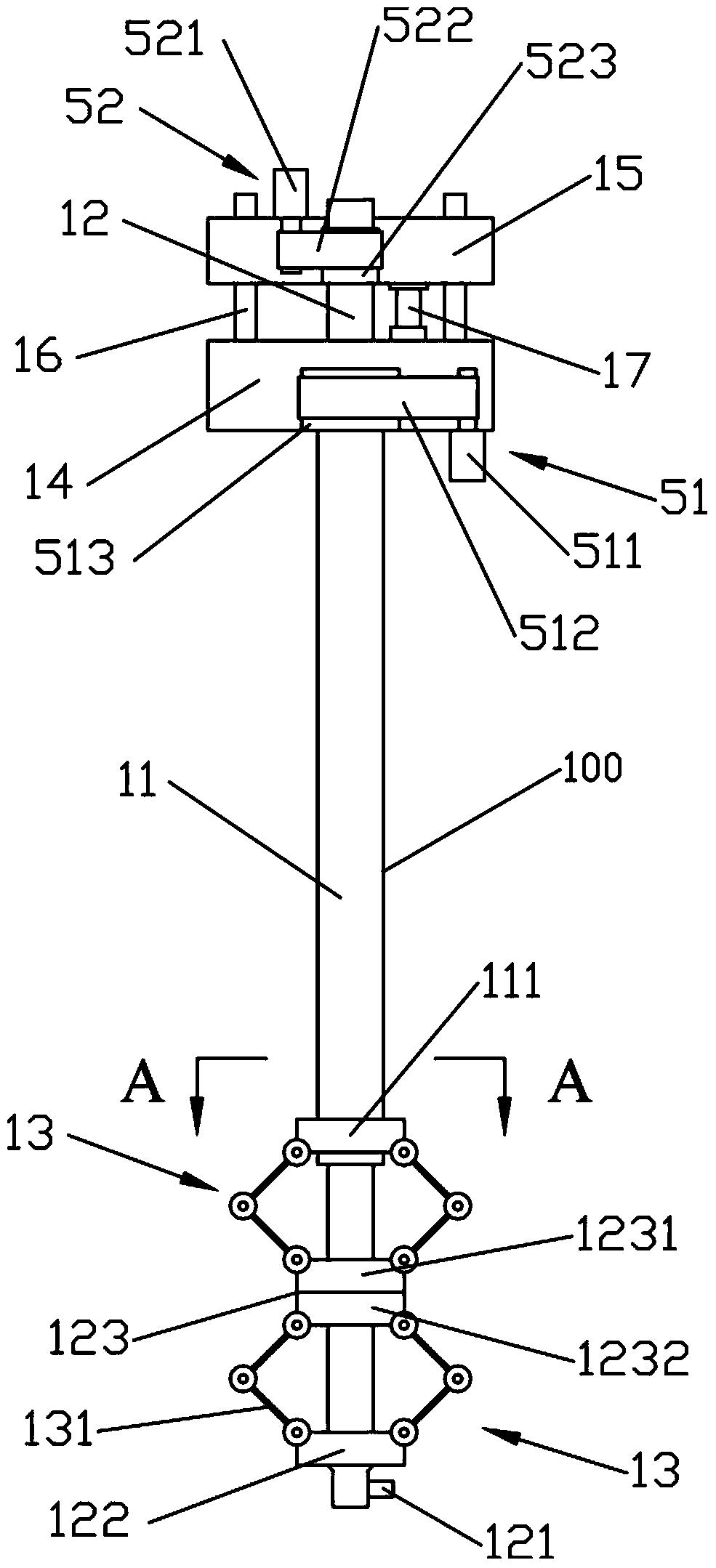

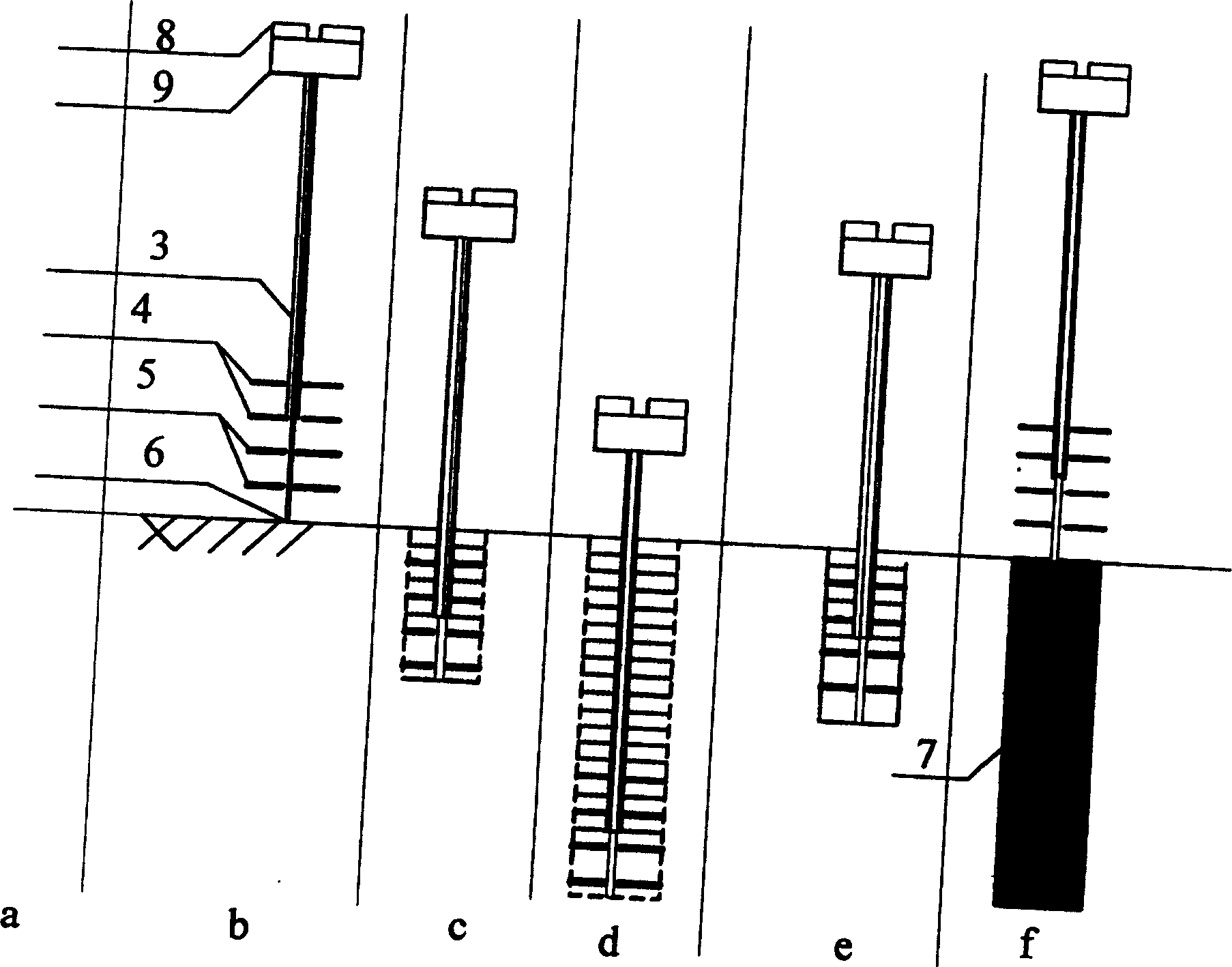

Variable-diameter mixing pile machine, its pile-forming construction method, and drill pipe

ActiveCN105714774BImprove reinforcement qualityShorten the timeDrilling rodsDrilling casingsEngineeringTower

Owner:江苏路鼎智能科技有限公司

Preparation method of cellulose ether with high suspension, strong rheology and bleeding prevention

ActiveCN111040081AGood dispersionImprove solubilityBulk chemical productionPolymer sciencePtru catalyst

The invention belongs to the technical field of modified synthesis of cellulose ether, and particularly discloses a preparation method of high-suspension, strong-rheology and anti-bleeding cellulose ether. The method comprises the following steps: synthesizing and preparing cellulose ether by a universal process flow; during subsequent synthesis, adding a water-soluble rheological polymerization modification monomer with a proper concentration ratio; and carrying out substitution treatment under the conditions of a proper catalyst and a water bath temperature to finally obtain the modified cellulose ether. According to the invention, the cellulose ether has the advantages of high water-retaining property, low viscosity, high suspension, strong rheology, sedimentation resistance and the like, is used in self-leveling mortar, grouting materials, grouting agents, high-performance concrete and other mortars, can ensure high fluidity and pumpability, avoid the phenomena of sand setting, bleeding, layering, segregation and the like during construction, maintain the cohesive viscosity of pouring self-leveling, grouting materials and concrete and ensure the uniformity and the stability ofhardened mortar, and avoids the quality problem.

Owner:广州建涂堡建材有限公司

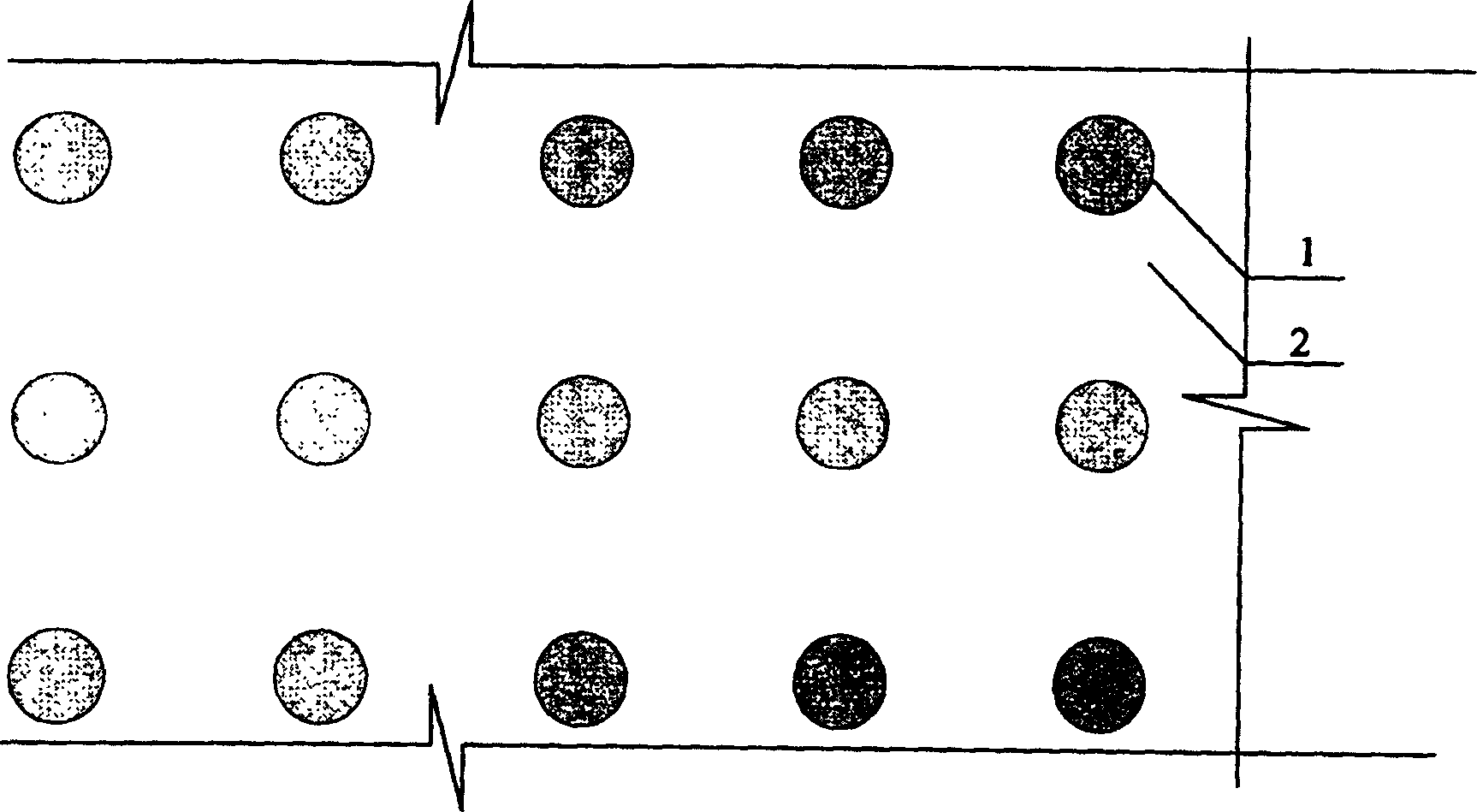

Pile forming operation method for bi-directional stirring piles

ActiveCN1274912CGuaranteed dosageThere will be no bleeding phenomenonBulkheads/pilesCement slurryEarth surface

A pile forming operation method for bidirectional stirring piles is a ground foundation processing method and is adapted for soft ground foundation treatment. The operation method is that: a: leveling ground; b: the position of a bidirectional stirring pile machine: a hoisting machine suspends the stirring pile machine to a defined pile position and moves it to the center; c: stirring sinkage: starting the bidirectional stirring pile machine to make the drill rod cut soil from up to down along a guide frame, starting a slurry feeding pump to inject cement slurry to the ground, the vanes that rotate in normal and reverse directions on the drill rod of the bidirectional stirring pile machine are rotating together to stir the cement soil; d: the drill rod of the bidirectional stirring pile machine will continue moving down and stirring cement soil till to a designed depth; e: the vanes that rotate in normal and reverse directions on the drill rod of the bidirectional stirring pile machine will continue stirring the cement soil while stirring and hoisting ; f: hoisting and stirring to ground surface or designed elevation more than 50 cm to complete the construction of the bidirectional stirring cement soil stirring pile (1). The cement soil stirring piles (1) are disposed in the form of quincunx or square shape in order to ensure the pile quality and pile body quality.

Owner:南京路鼎搅拌桩特种技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com