Single-component air-drying water-based sealing agent for woodware and preparation method thereof

A water-based sealant, one-component technology, used in coatings, polyurea/polyurethane coatings, etc., can solve problems such as damage to wood and paint film, color bleeding and migration of wood swells, and inability to prevent wood swells, etc. Damage and oil seepage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

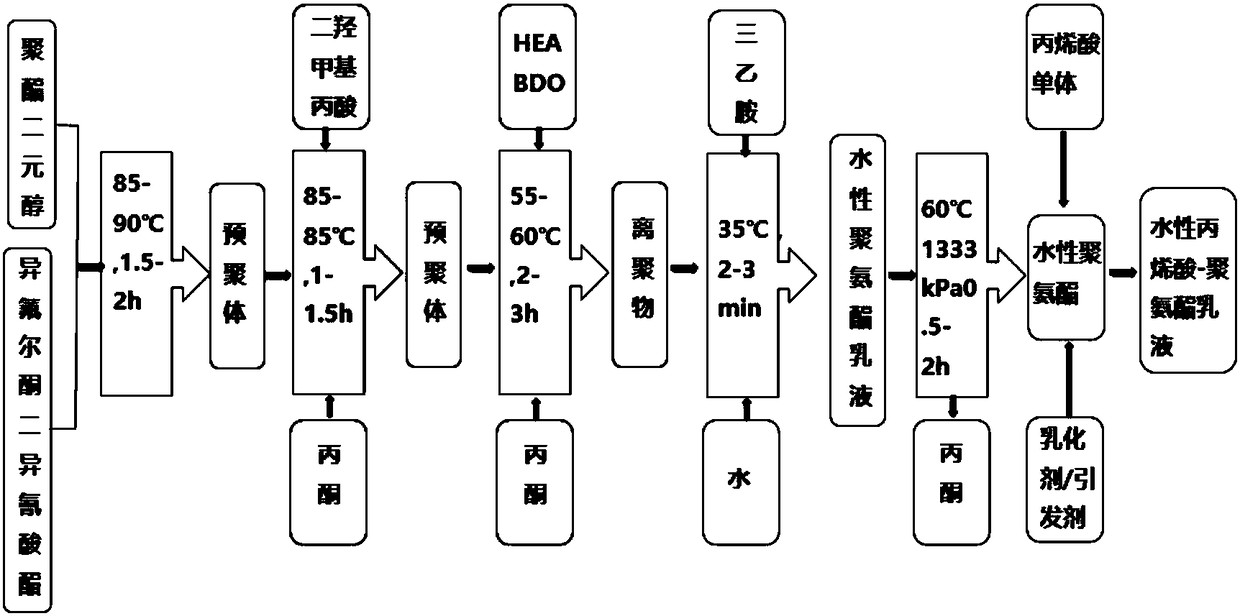

[0039] Mix polyols and isocyanate monomers to control the reaction temperature at 85°C, react for 1.5h, add acetone and dimethylol propionic acid and continue to react at 80°C for 1h, add BDO and HEA at 70°C for 1.5h, cool down to 35°C, add Neutralize with triethylamine, add water to disperse, remove acetone at 60°C and 1333KPa, and copolymerize this aqueous polyurethane dispersion with acrylic monomer to obtain the acrylic-polyurethane mixed emulsion, that is, self-drying water-based sealant.

Embodiment 2

[0041] Mix polyols and isocyanate monomers to control the reaction temperature at 90°C, react for 2 hours, add acetone and dimethylol propionic acid and continue to react at 85°C for 1.5 hours, add BDO and HEA at 75°C for 1.5 hours, cool down to 35°C, add Neutralize with triethylamine, add water to disperse, remove acetone at 60°C and 1333KPa, and copolymerize the aqueous polyurethane dispersion with acrylic monomer to obtain the acrylic-polyurethane mixed emulsion.

Embodiment 3

[0043] Mix polyols and isocyanate monomers to control the reaction temperature at 85°C, react for 2 hours, add acetone and dimethylol propionic acid and continue to react at 85°C for 1.5 hours, add BDO and HEA at 75°C for 1.5 hours, cool down to 35°C, add Neutralize with triethylamine, add water to disperse, remove acetone at 60°C and 1333KPa, and copolymerize the aqueous polyurethane dispersion with acrylic monomer to obtain the acrylic-polyurethane mixed emulsion.

[0044] The present invention also provides a single-component self-drying water-based sealant for wood prepared by the above method. The mass fraction of PUA is 85-95%, the mass fraction of dipropylene glycol methyl ether is 2-4%, the mass fraction of dipropylene glycol butyl ether is 2-4%, the mass fraction of leveling agent is 0.2-0.4%, and the mass fraction of wetting agent The fraction is 0.3-0.5%, the defoamer mass fraction is 0.2-0.4%, and the rest is water.

[0045] The single-component self-drying water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com