Variable-diameter mixing pile machine, its pile-forming construction method, and drill pipe

A technology for mixing pile drivers and drill pipes, applied in the field of mixing piles, which can solve the problems of inability to achieve stepless diameter reduction, poor construction quality, and unopened movable blades, so as to improve mixing efficiency, reduce the time for replacing mixing blades, Solve the effect of bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

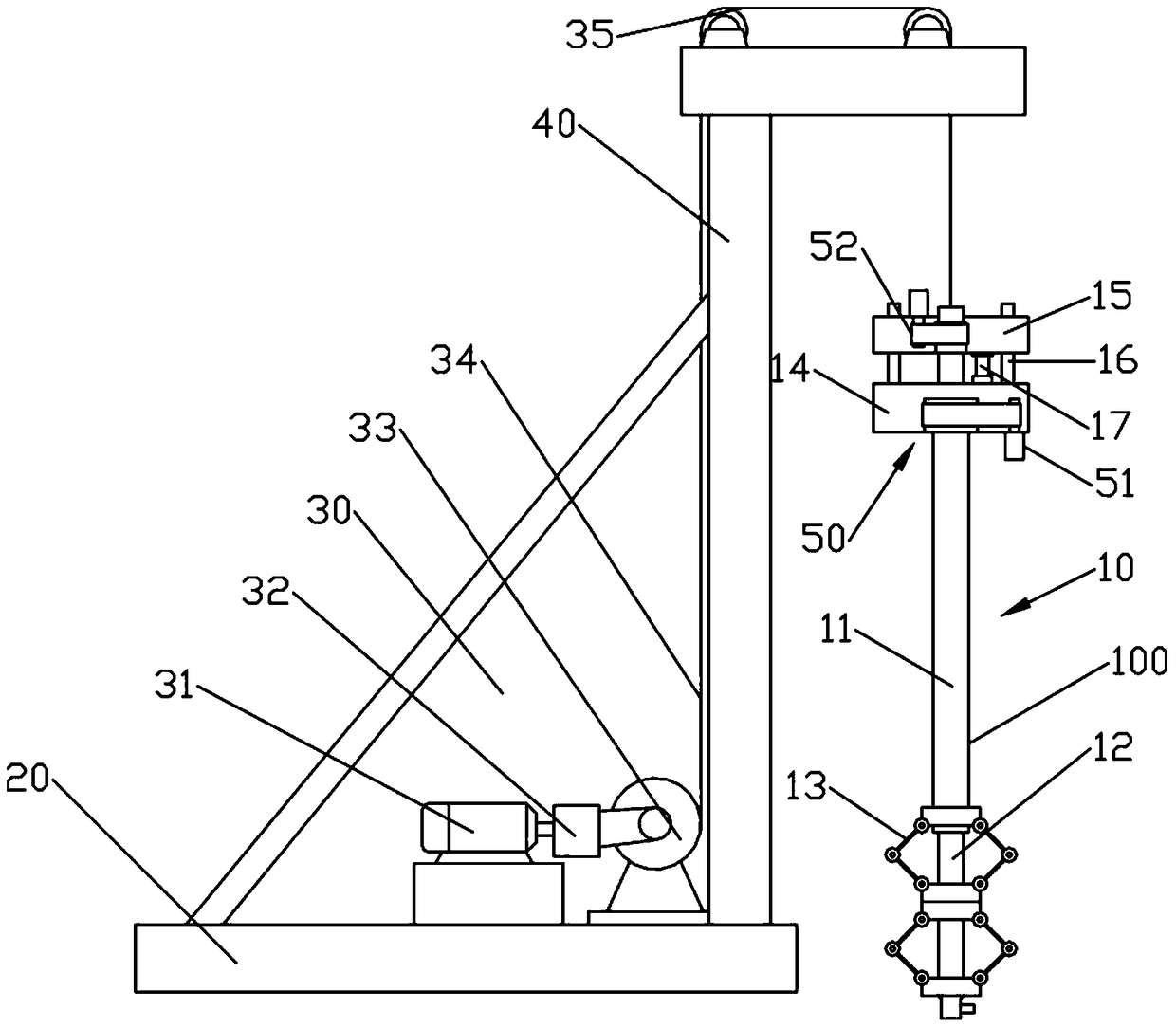

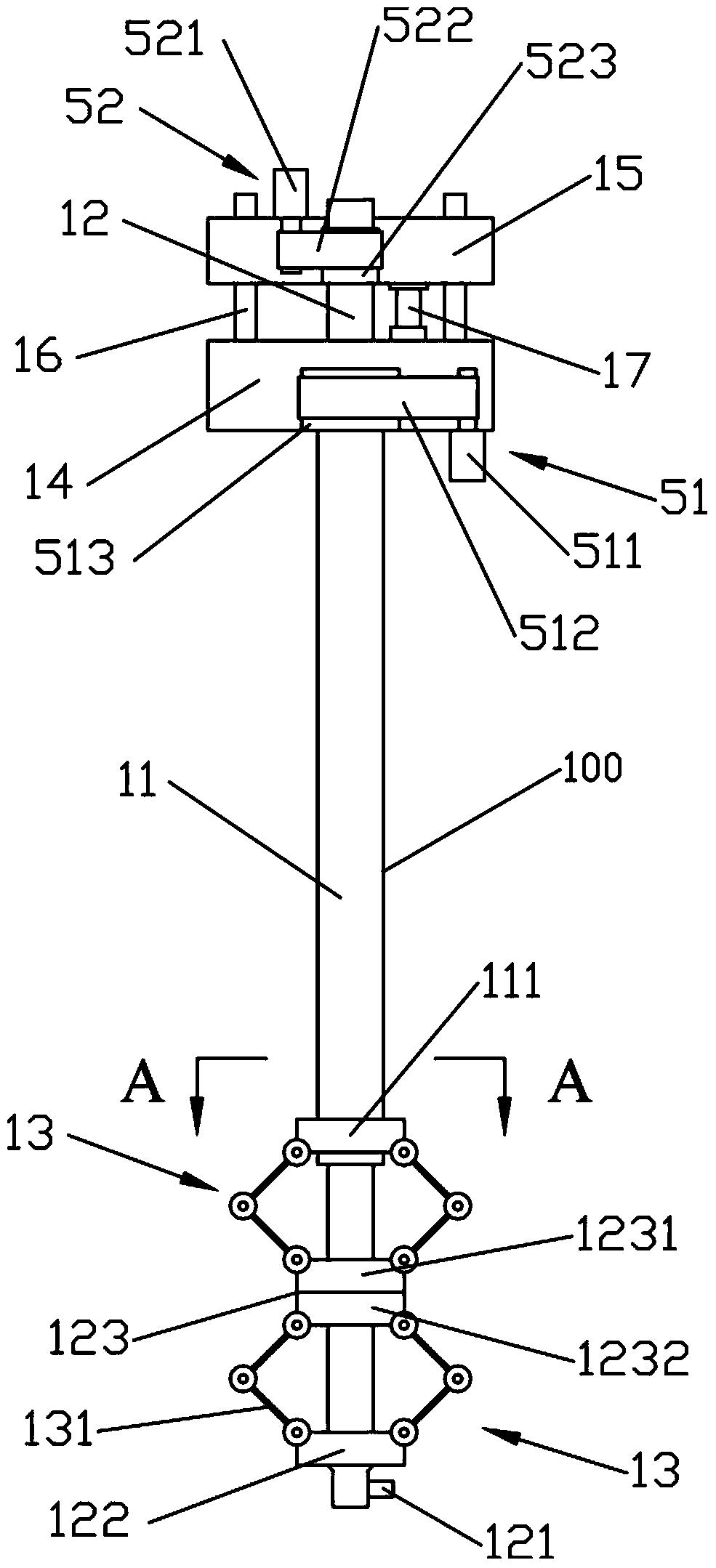

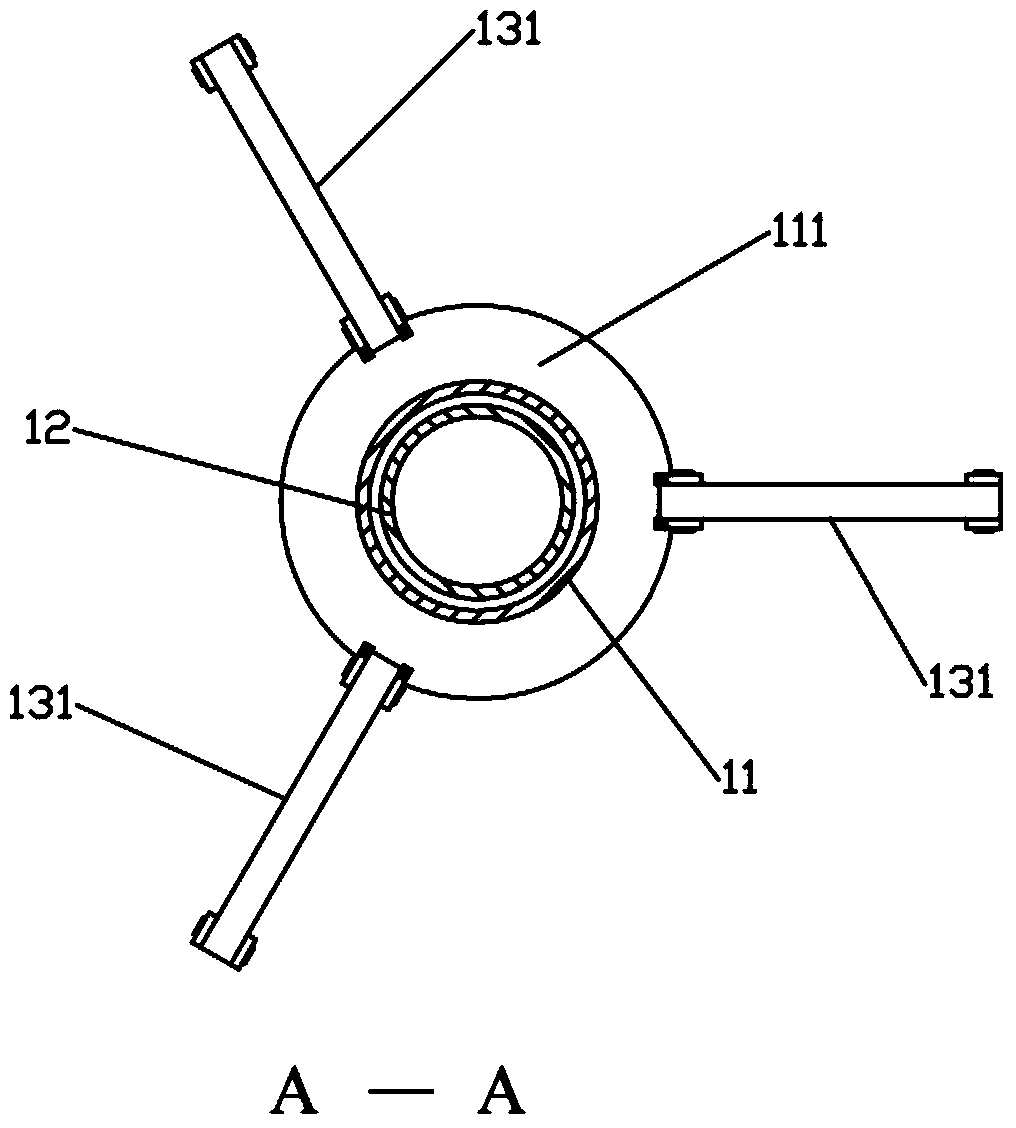

[0048] Such as Figures 1 to 4 As shown, the variable-diameter stirring pile driver of the present invention includes: a machine base 20 , a tower 40 , a stirring head 10 and a lifting mechanism 30 . The tower 40 is fixed on the base 20 . The stirring head 10 is hoisted on the tower 40 through the lifting mechanism 30, and the lifting mechanism 30 drives the stirring head 10 to move up and down. Lifting mechanism 30 has multiple structures such as rope rower formula, electric hoist formula or lifting slide rail formula, all are prior art. refer to figure 1 As shown, in the present embodiment, the rope rower type is adopted, and the lifting mechanism 30 includes a lifting motor 31, a lifting reducer 32, a steel wire rope 34, a lifting roller 35 and a lifting reel 33, and the lifting motor 31 is installed on the base 20. Speed reducer 32 is connected with lifting reel 33, drives lifting reel 33 to rotate, and lifting roller 35 is installed on the tower frame 40. One end of...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, the difference is: refer to Figure 8As shown, two groups of stirring blade groups 13 are hingedly installed between the outer tube spokes 111 and the upper spokes 1231, and the adjacent two groups of stirring blades 13 are hinged through an upper sliding spoke 124, and the upper sliding spokes 124 is slidably mounted on the outer wall of the inner tube 12 and is located between the outer tube spoke 111 and the upper spoke 1231 . Two sets of stirring blade groups 13 are hingedly installed between the inner tube spoke 122 and the lower spoke 1232, and the adjacent two sets of stirring blades 13 are hinged through a lower sliding spoke 125, and the lower sliding spoke 125 can slide It is installed on the outer wall of the inner tube 12, between the inner tube spoke 122 and the lower spoke 1232. In order to ensure better grout pressure during the process of stirring into piles and avoid the generation of grout, the nu...

Embodiment 3

[0058] This embodiment is basically the same as Embodiment 1 and 2, the difference is that: with reference to Figure 9 As shown, the steel wire rope 34 is connected with the outer pipe head seat 14, the outer pipe head seat 14 is provided with a guide rod 16, the inner pipe head seat 15 is provided with a guide hole matched with the guide rod 16, and the inner pipe head seat 15 and the guide rod 16 Slidably socketed, and the upper end of the guide rod 16 passes through the inner pipe head seat 15; The rod 16 moves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com