Patents

Literature

39results about How to "Won't bounce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

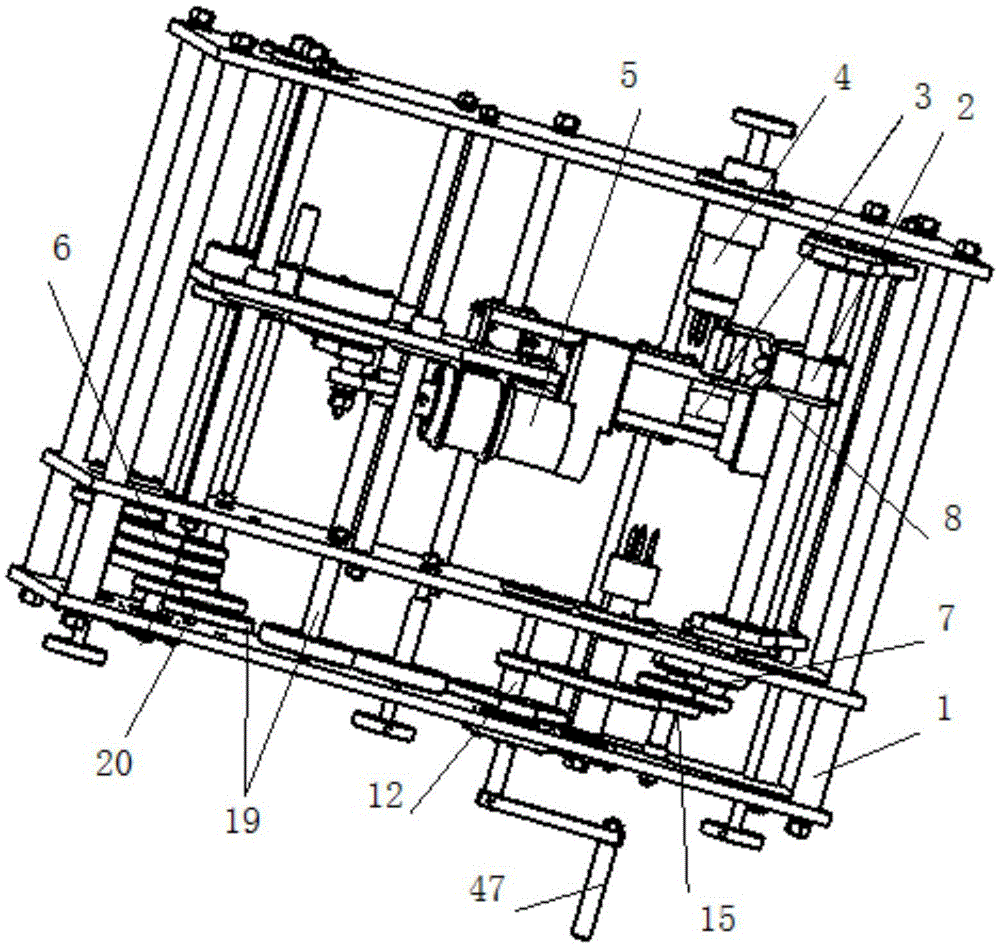

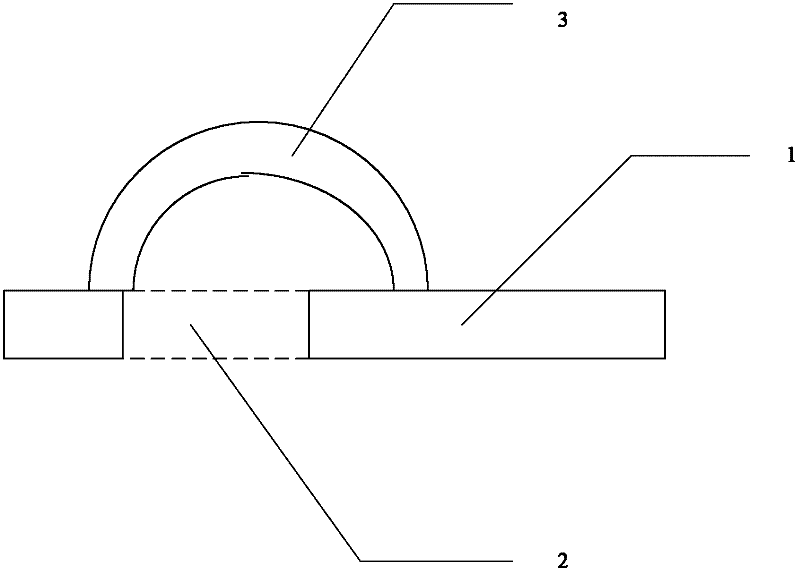

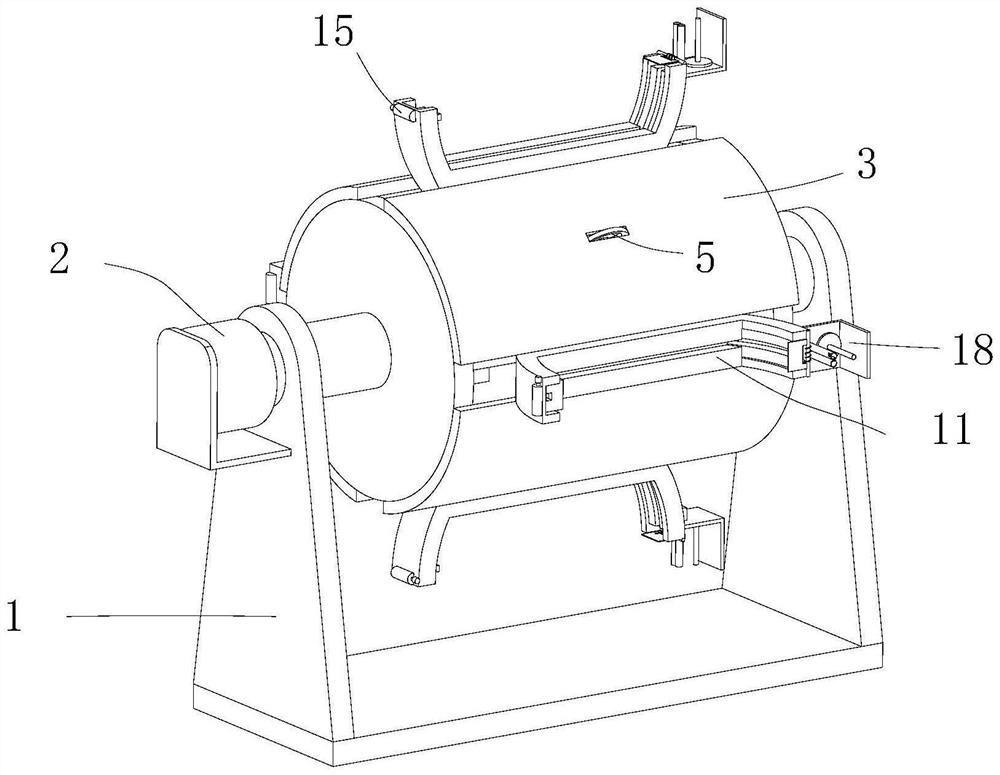

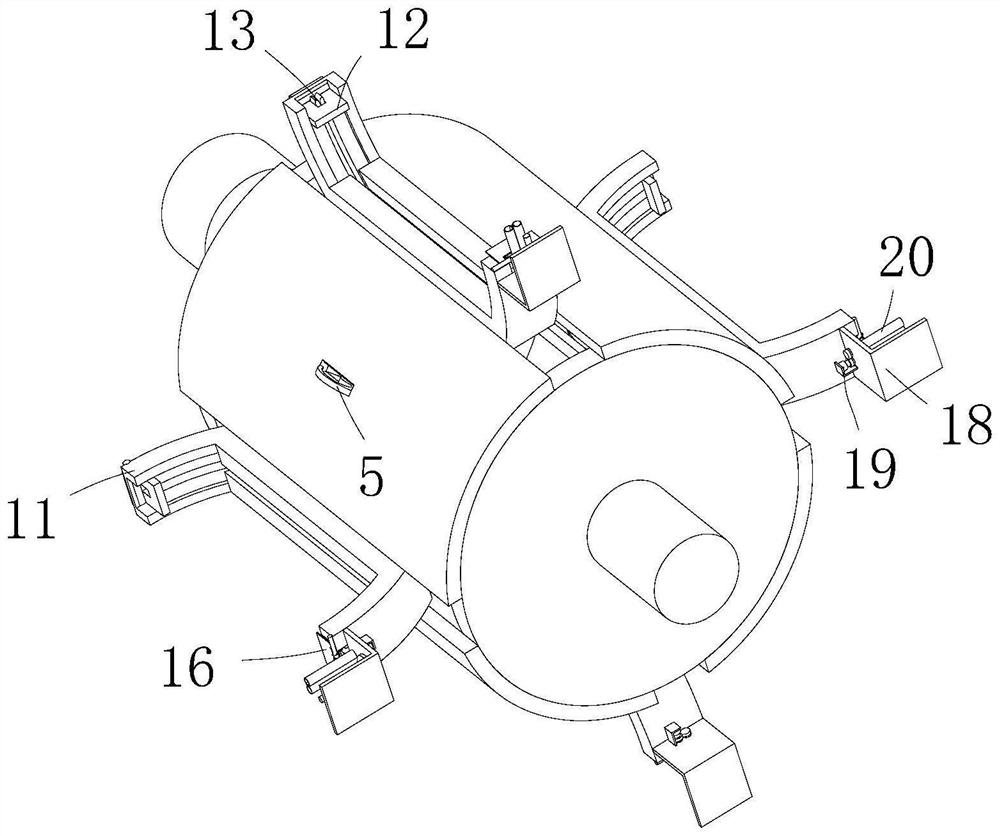

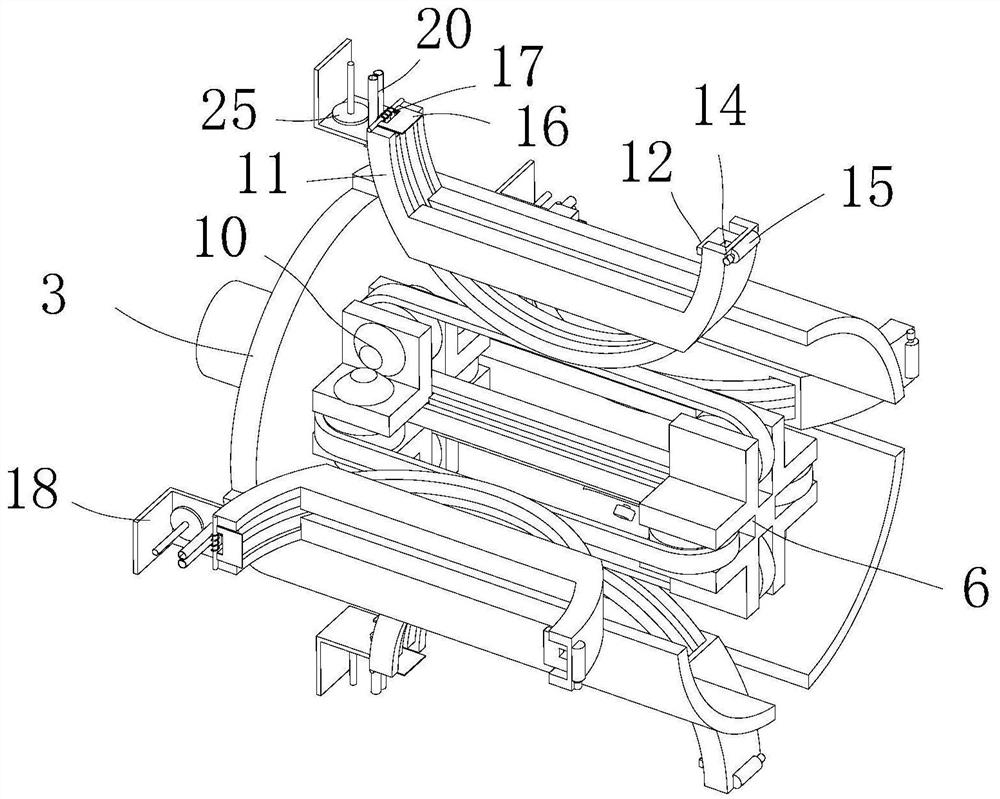

Mechanical pineapple peeling machine

InactiveCN105581621AImprove peeling efficiencyFor precise clampingFruit coringPeelersEngineeringElectrical and Electronics engineering

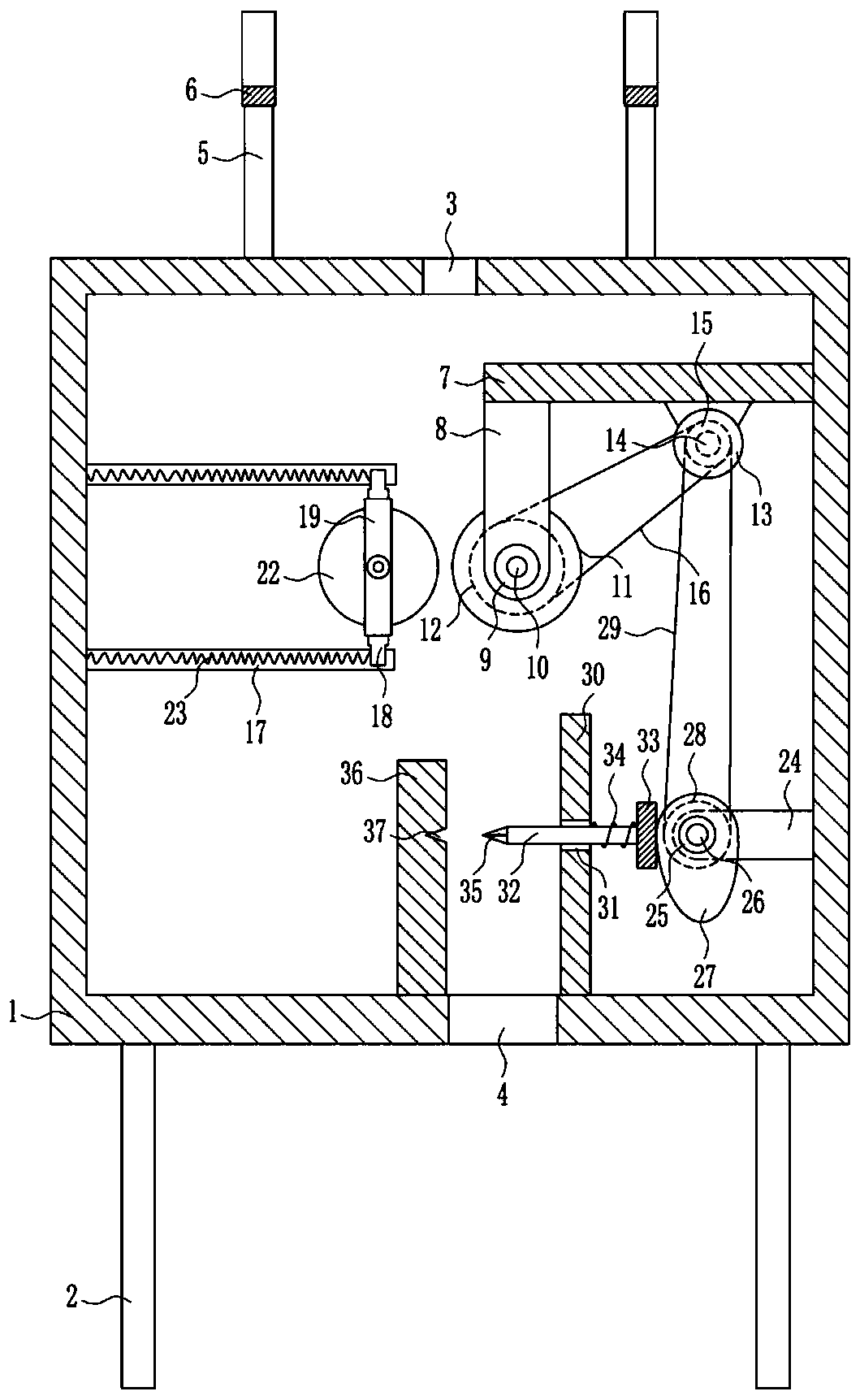

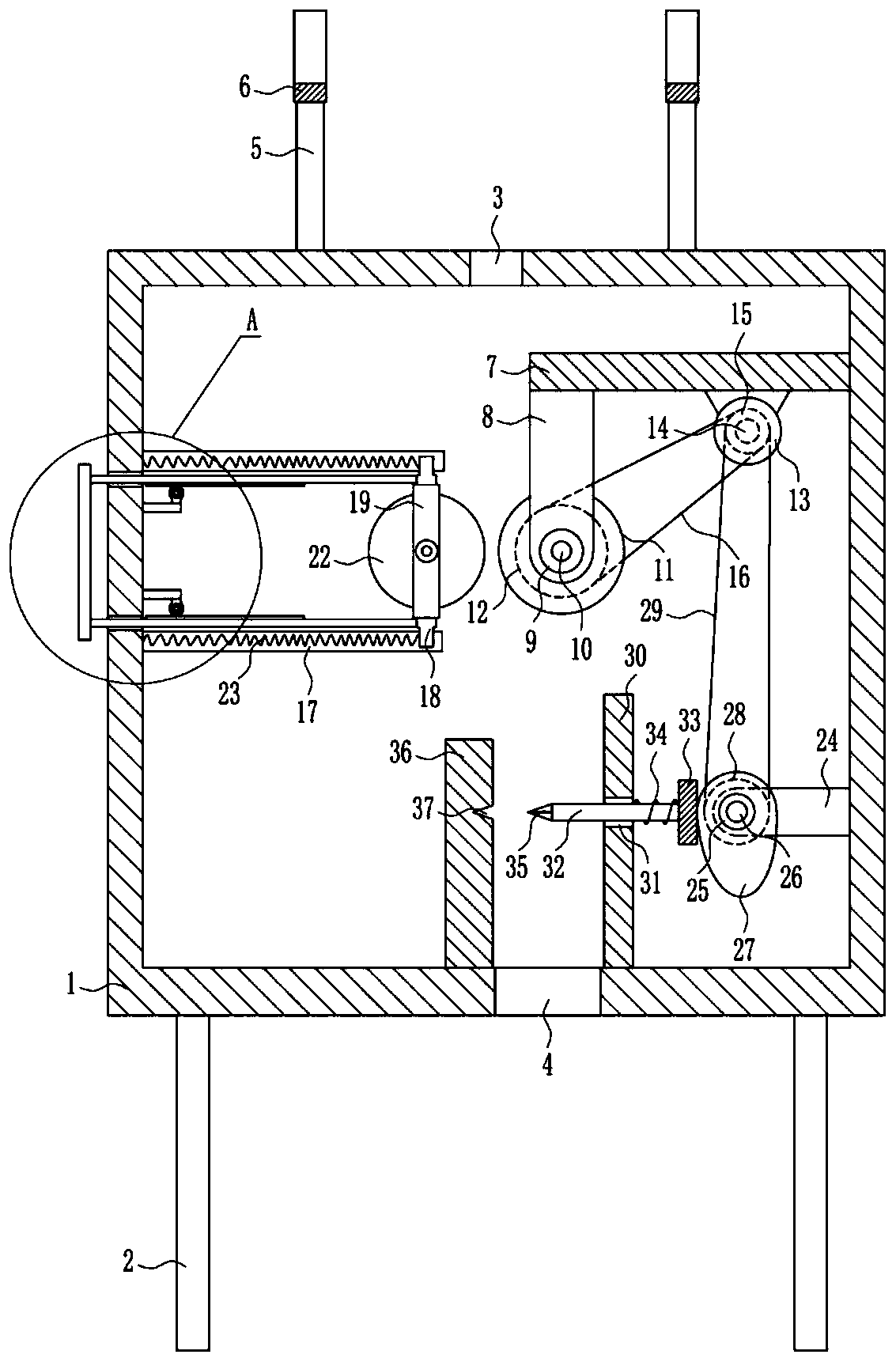

The invention discloses a mechanical pineapple peeling machine which comprises a machine frame. A positioning clamp and a black core removing structure are arranged on the machine frame. Two opposite pineapple insertion tables are arranged on the opposite sides of the machine frame. One pineapple insertion table is telescopic and is connected with a gear shifting mechanism through a main transmission mechanism, the gear shifting mechanism is connected with a handle and a black core removal transmission mechanism, the main transmission mechanism is connected with a peeling transmission mechanism, the peeling transmission mechanism is connected with a lead screw a, the lead screw a is connected with a peeling adjustable cutter, the positioning clamp and the peeling adjustable cutter are located between the two opposite pineapple insertion tables, the black core removal transmission mechanism is connected with the black core removing structure, and the black core removing structure is opposite to the peeling adjustable cutter. The mechanical pineapple peeling machine completes the peeling step and the black core removing step through one-time clamping, and pineapple peeling efficiency is greatly improved.

Owner:XIAN UNIV OF TECH

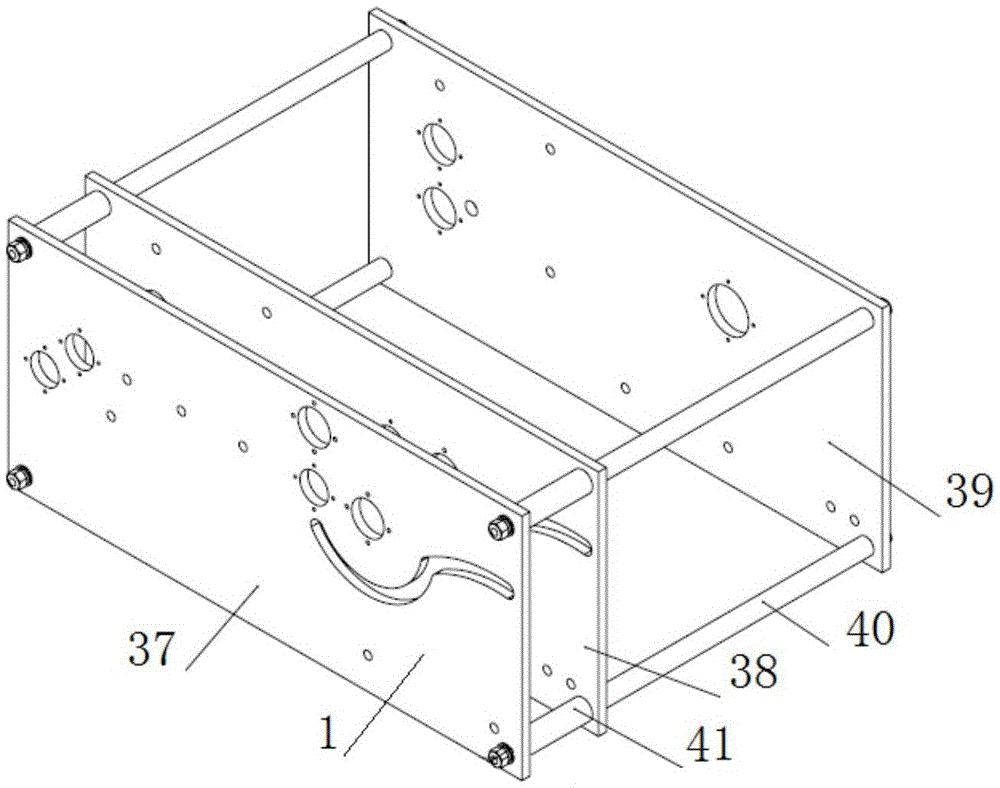

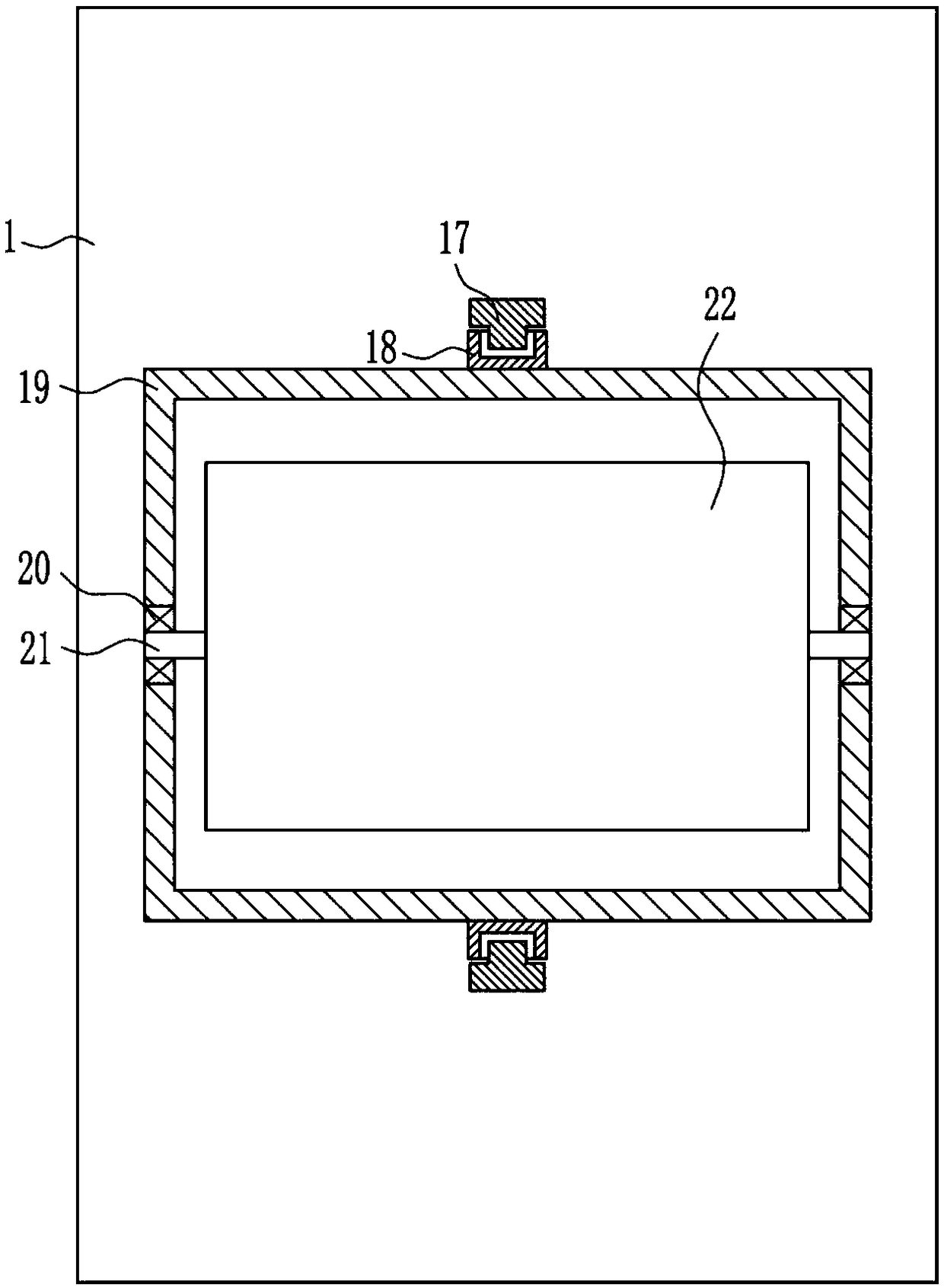

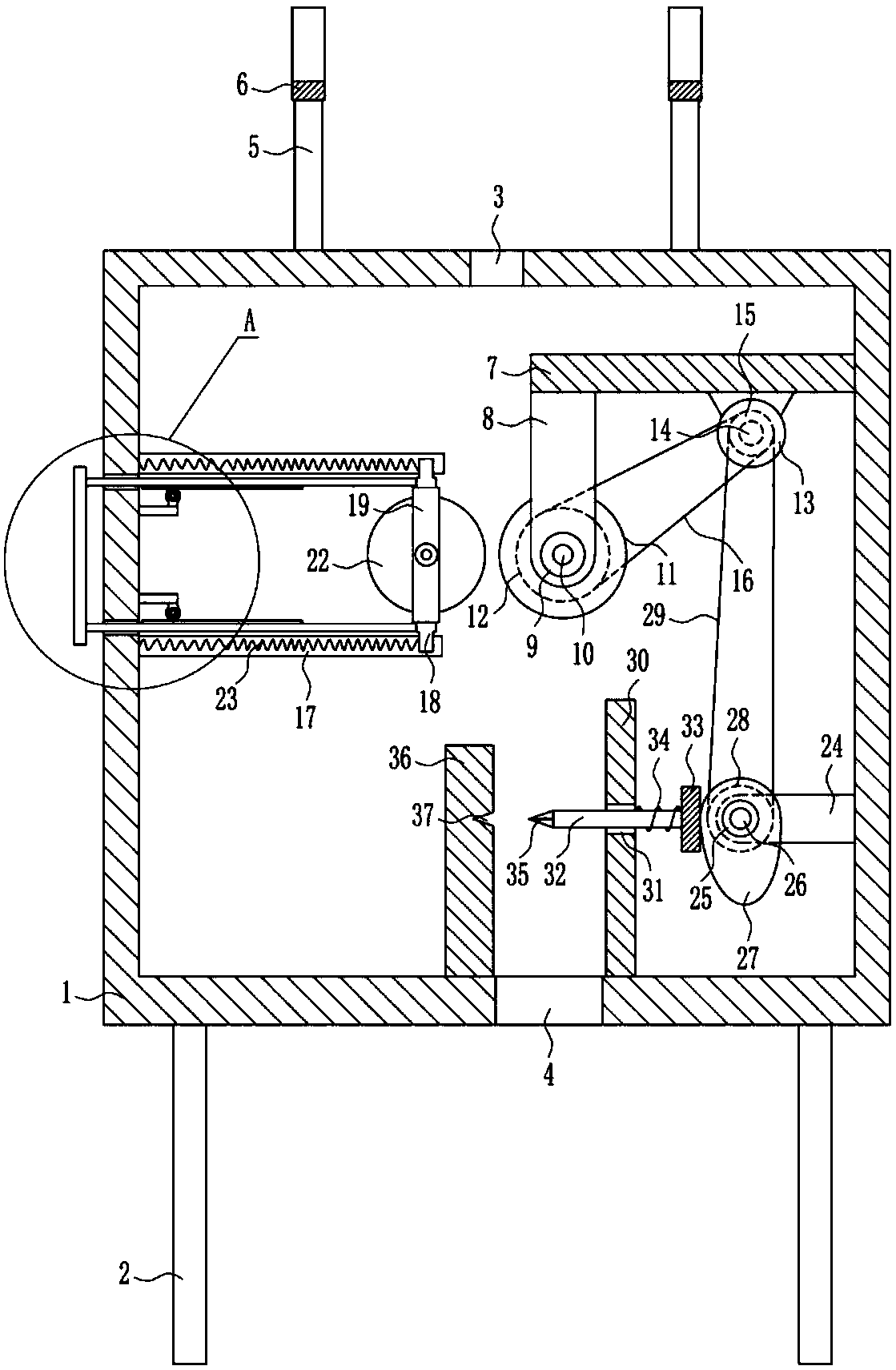

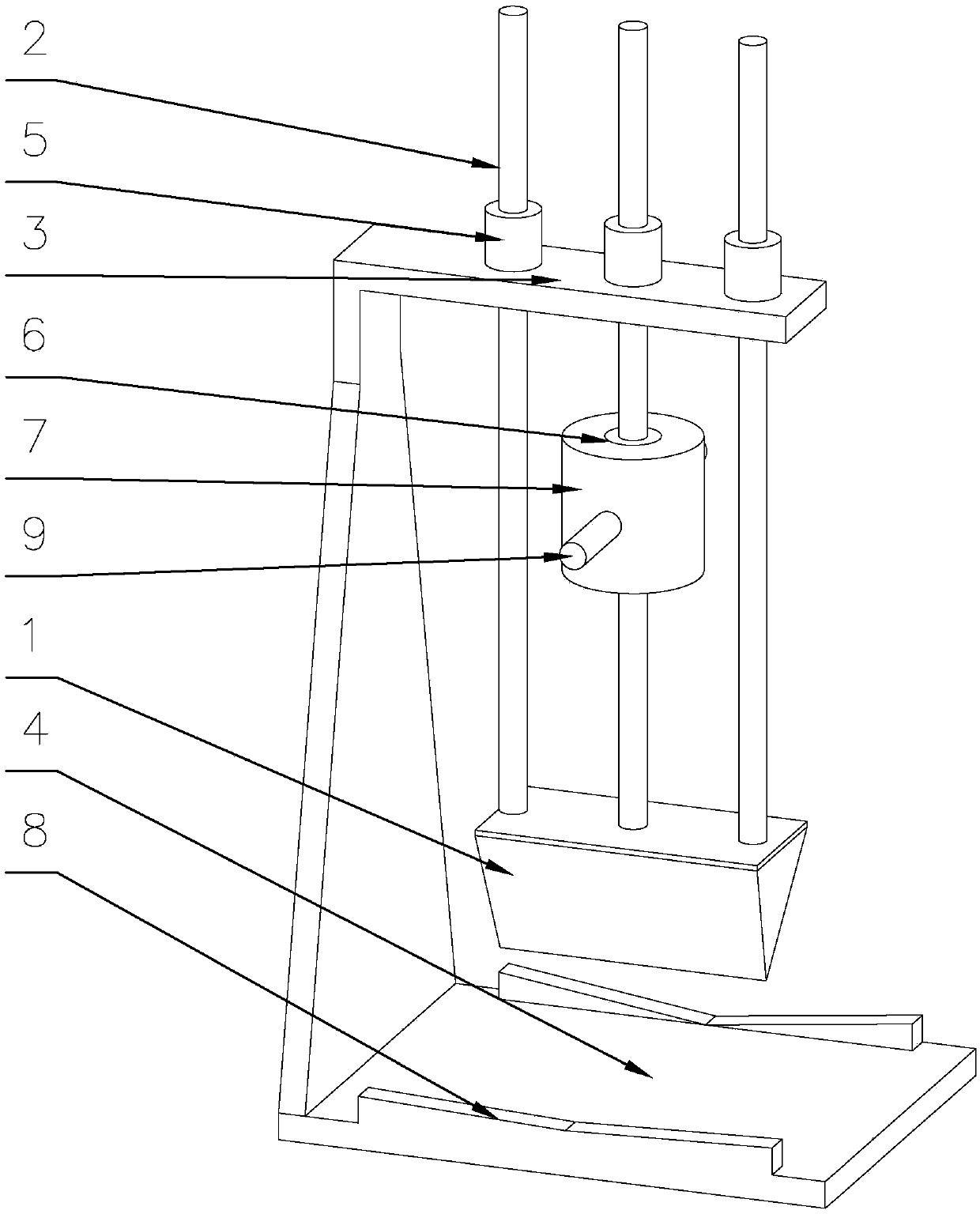

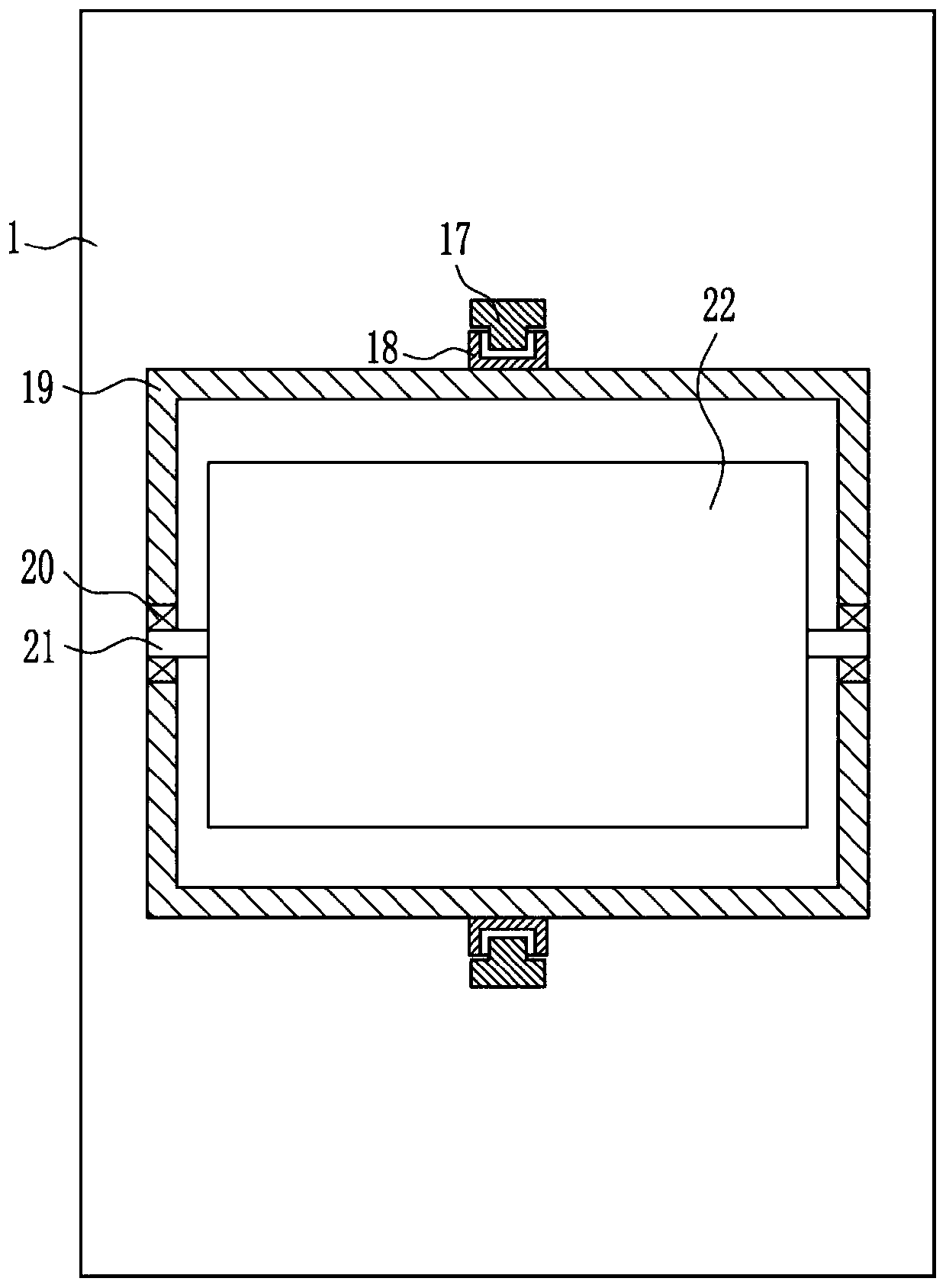

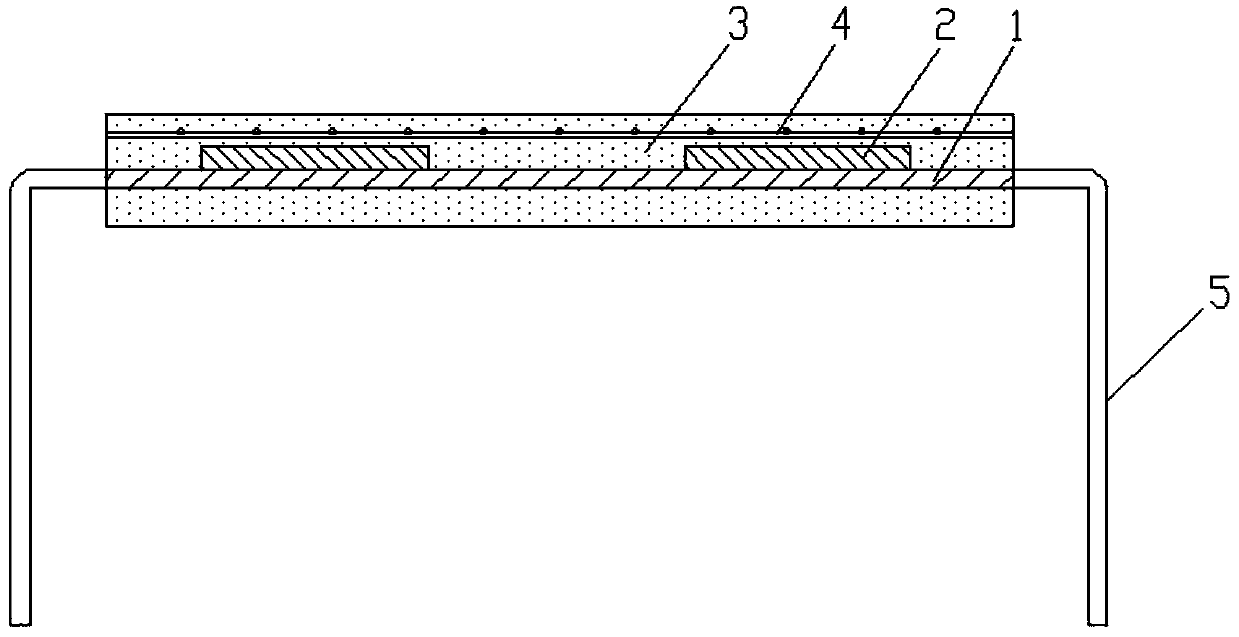

Wire harness cutting-off equipment for instrument production

The invention relates to cutting-off equipment, in particular to wire hardness cutting-off equipment for instrument production. According to the technical aims, the wire hardness cutting-off equipmentfor instrument production is high in cutting-off speed and uniform in cutting-off. The wire hardness cutting-off equipment for instrument production comprises a tank, supporting legs, supporting boards, arc-shaped boards, a first transverse board, a first vertical board, a first bearing pedestal, a first rotary shaft, a first roller, a first belt wheel and the like. The supporting legs are installed at four corners of the bottom of the tank; a feeding inlet is formed in the middle of the top of the tank; a discharging outlet is formed in the middle of the bottom of the tank; the two supporting boards are installed on the top of the exterior of the tank; and the feeding inlet is located between the two supporting boards. A first motor is used as a driver to drive the first roller to rotate, so that wire harnesses are driven to move downwards; and a cam drives a cutter to cut off the wire harnesses, a movable plate and a fourth spring are also arranged, so that the cut-off wire harnesses are not stacked, and the effects that the wire harnesses are cut off fast and uniformly are achieved accordingly.

Owner:常州中端电器有限公司

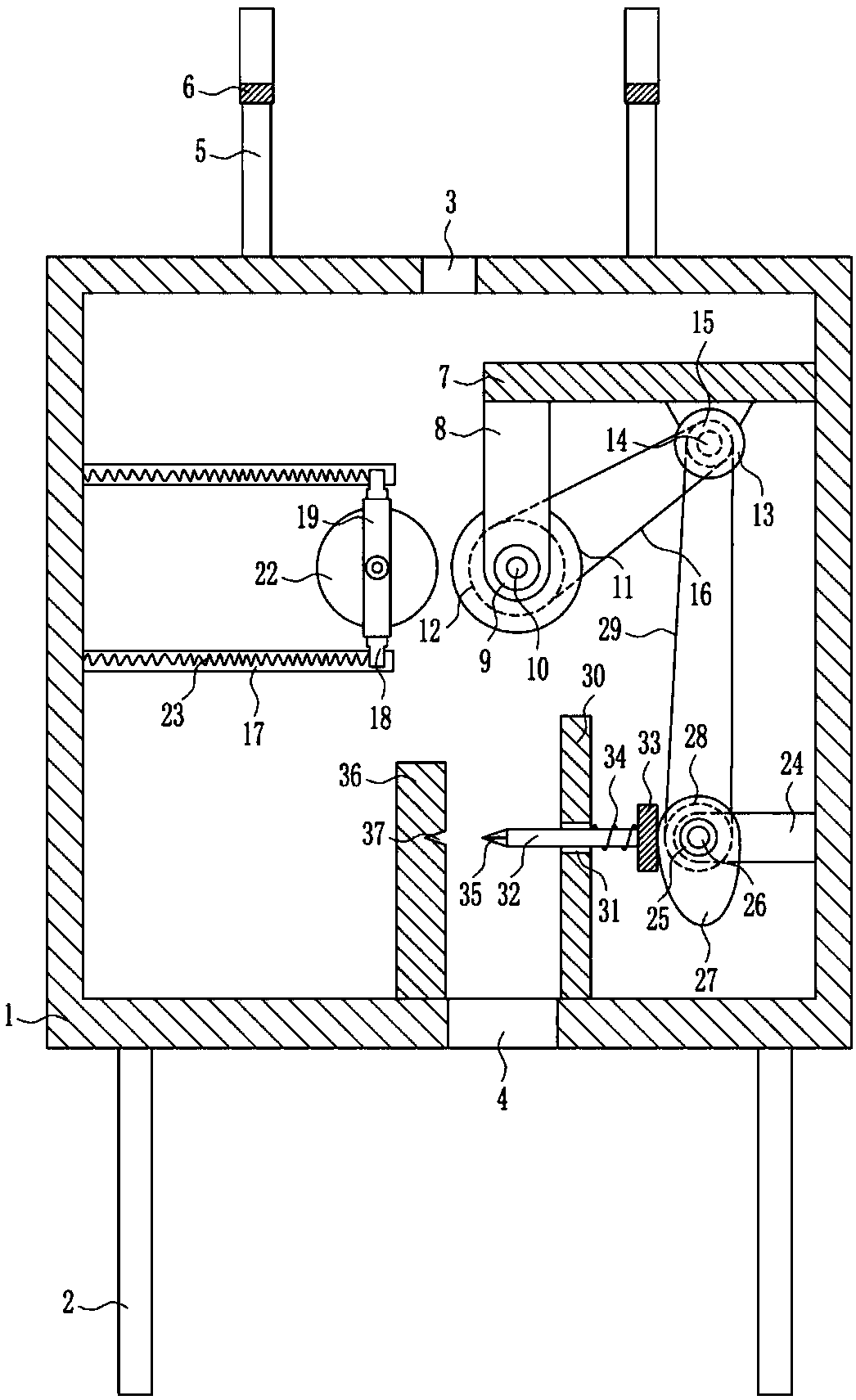

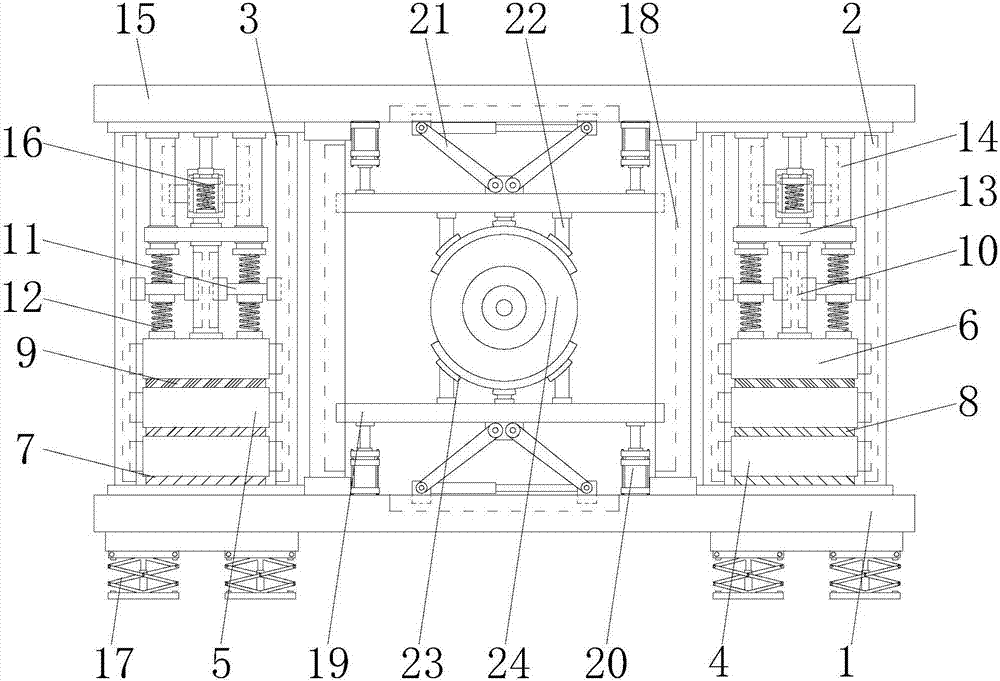

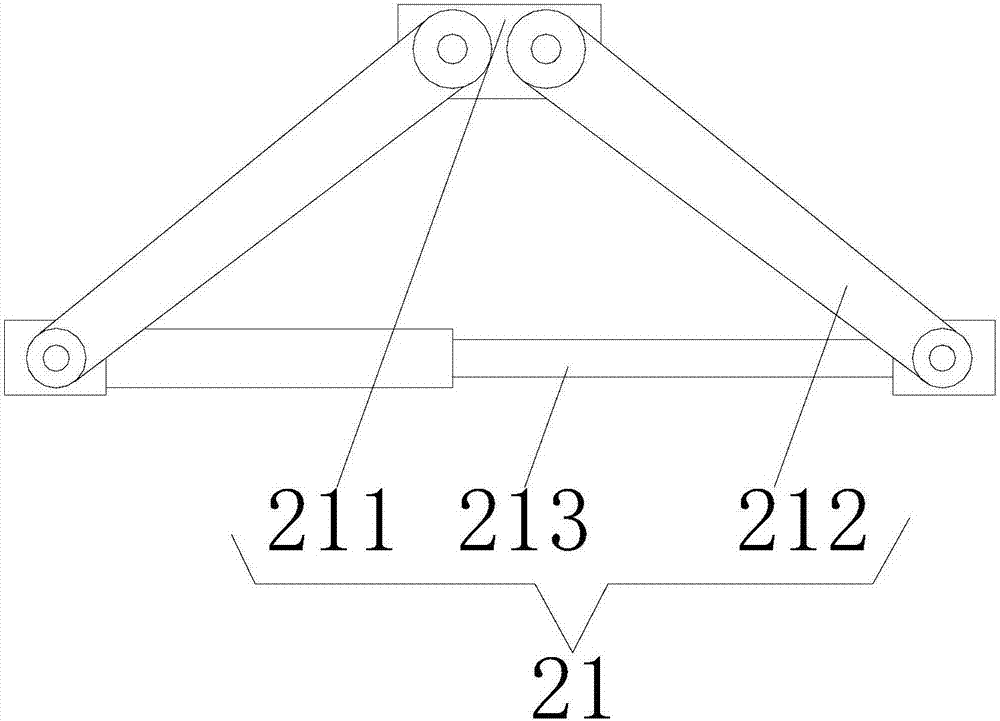

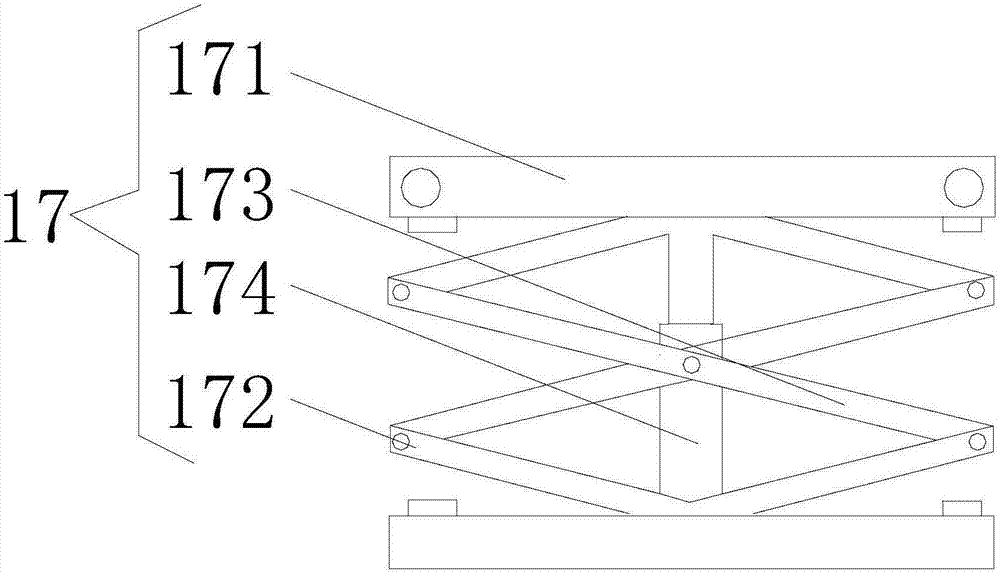

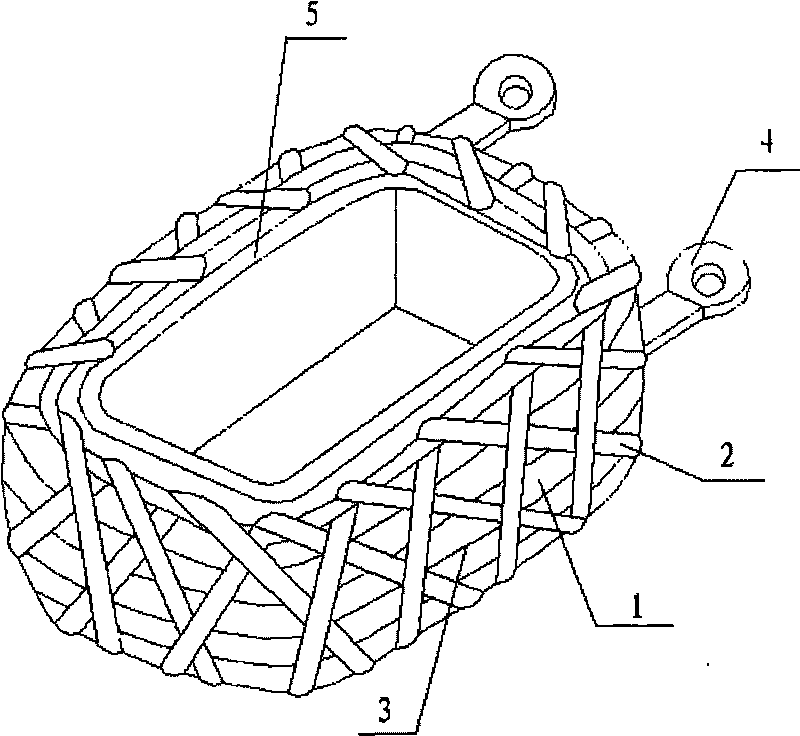

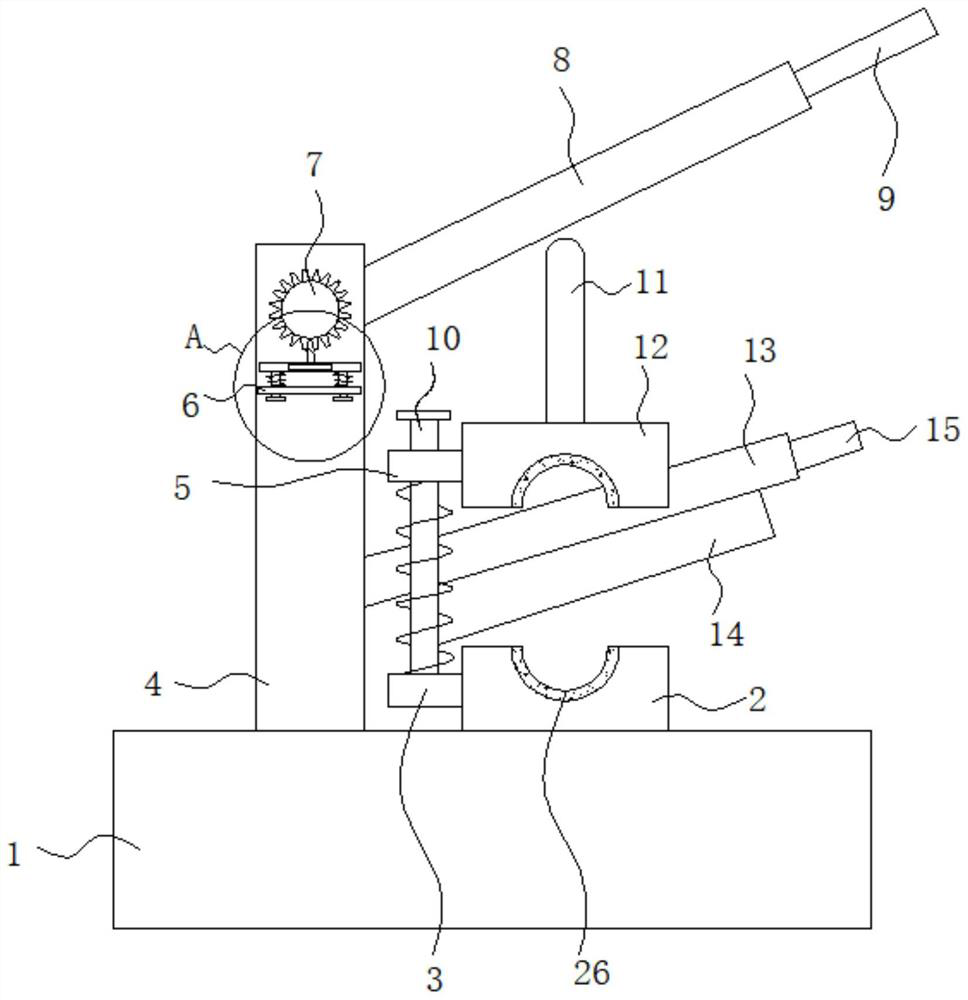

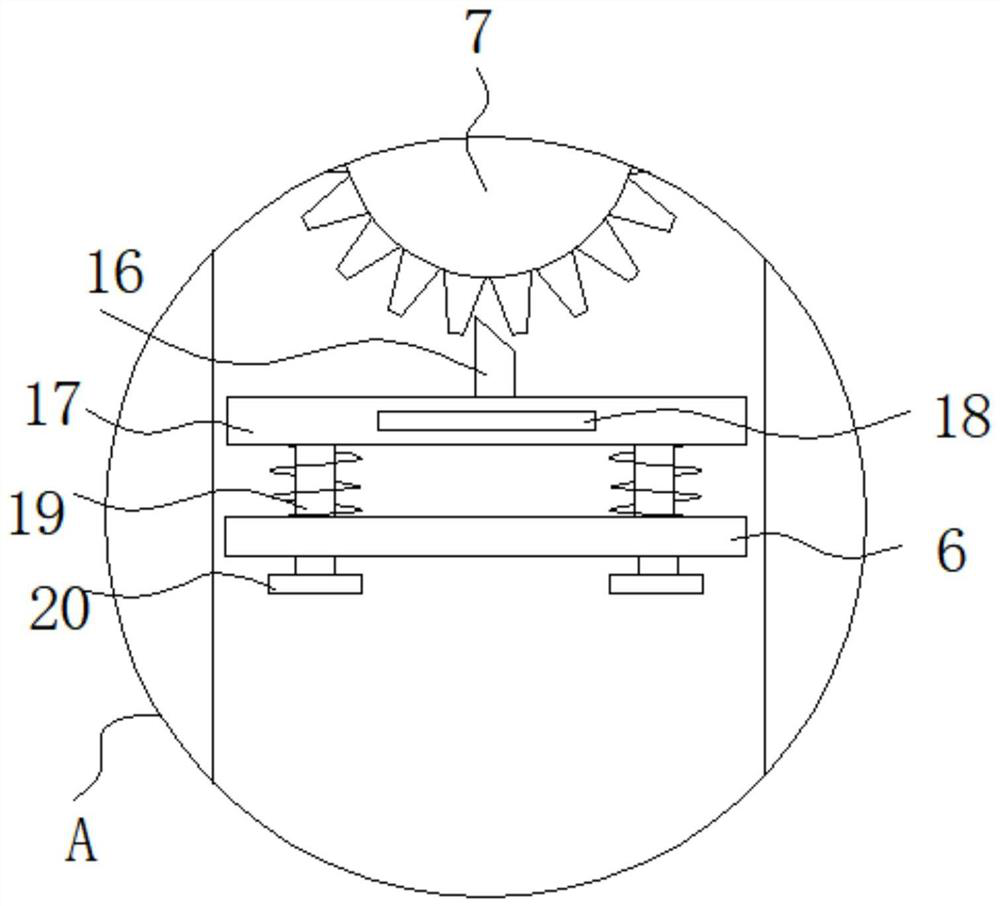

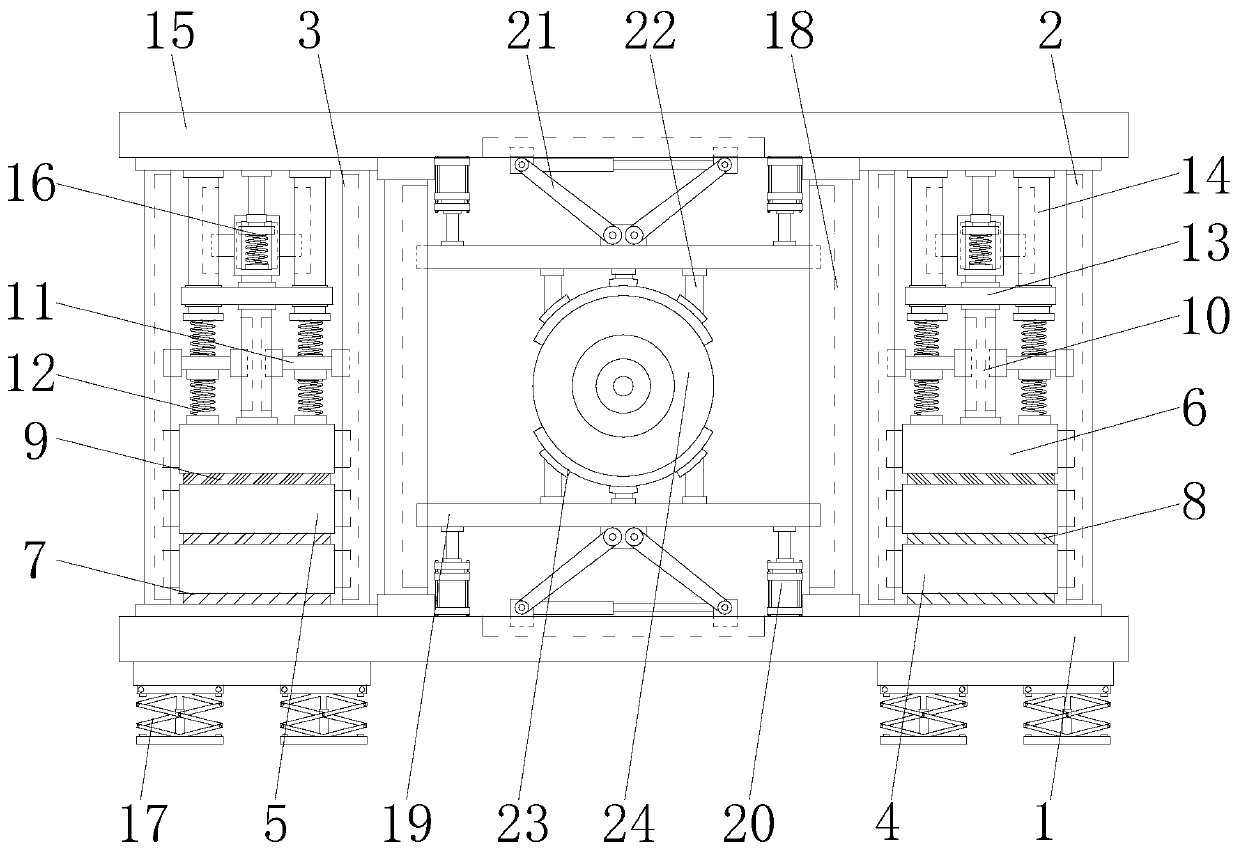

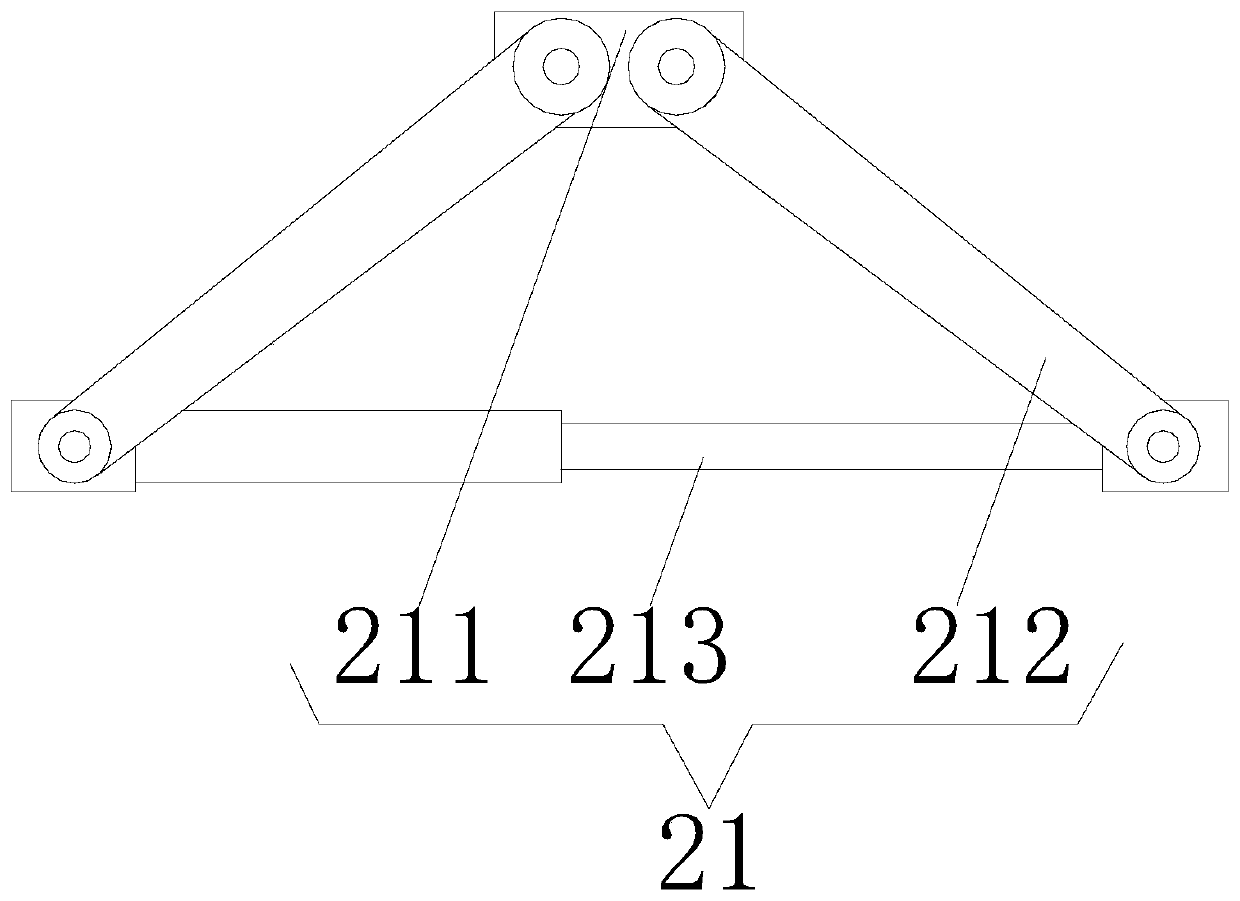

Power generator base with protection function

ActiveCN107959373AWith protective functionWon't bounceSupports/enclosures/casingsEngineeringElectric generator

The invention discloses a power generator base with a protection function. The power generator base comprises a bottom plate. Two sides of the top of the bottom plate are fixedly connected to first support rods. One side of each of the first support rods is fixedly connected to a second support rod at the top of the bottom plate. The bottoms of second damper blocks are fixedly connected to secondary buffer boards. The invention relates to the technical field of a power generator protection base. According to the power generator base with a protection function, two sides of the top of the bottom plate are fixedly connected to the first support rods, a condition that a power generator does not pop up when the power generator falls to the ground is ensured, the protection of the power generator is stronger, thus the power generator is not damaged after falling to the ground, the damage in falling is reduced, the safety of the power generator is greatly protected, thus the service life ofthe power generator is longer, and the problem that an existing power generator base with a protection function can not maintain the stability of the power generator when the power generator falls tothe ground and can not prevent the popup of the power generator is solved.

Owner:江西省一互电气有限公司

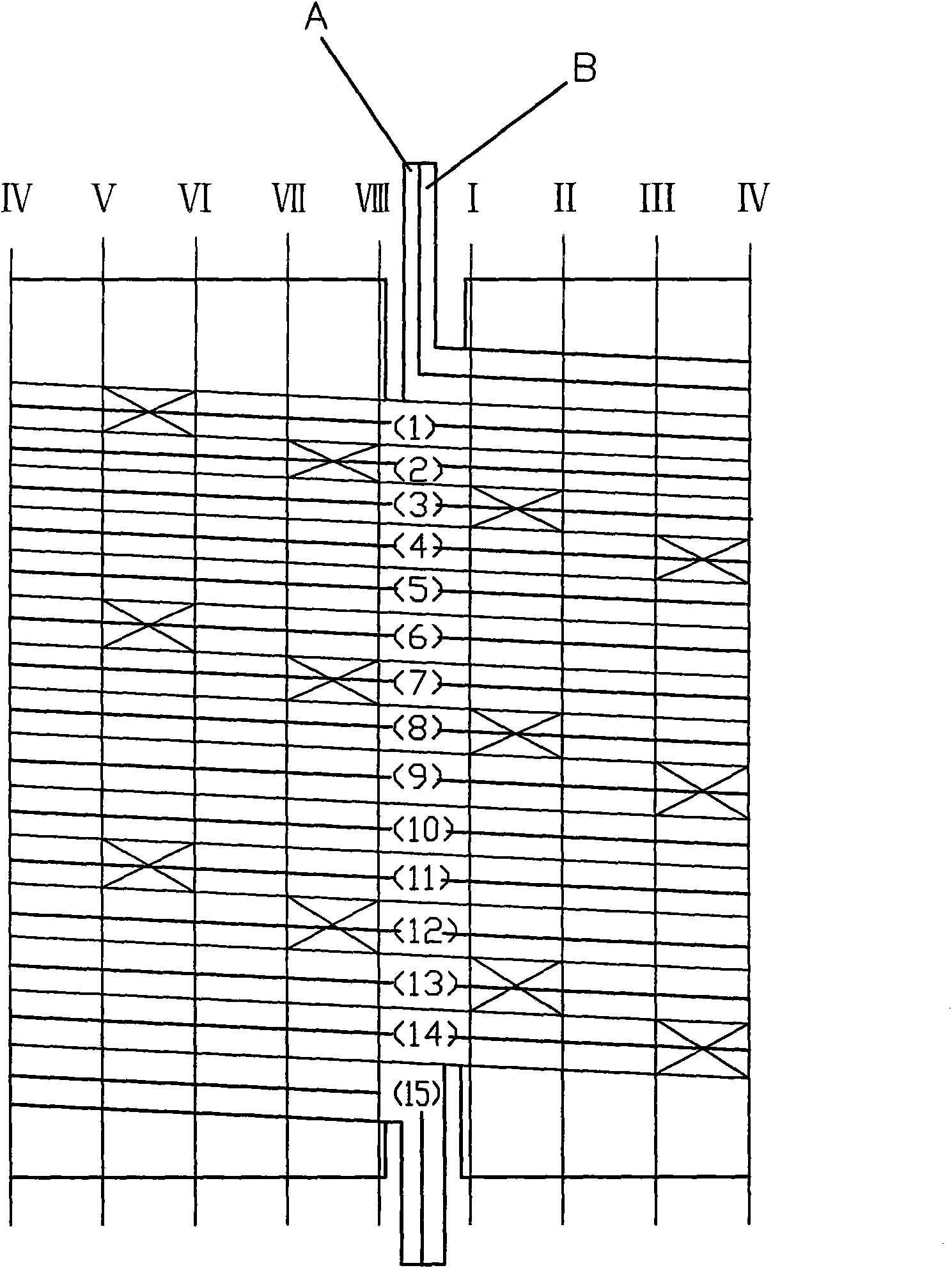

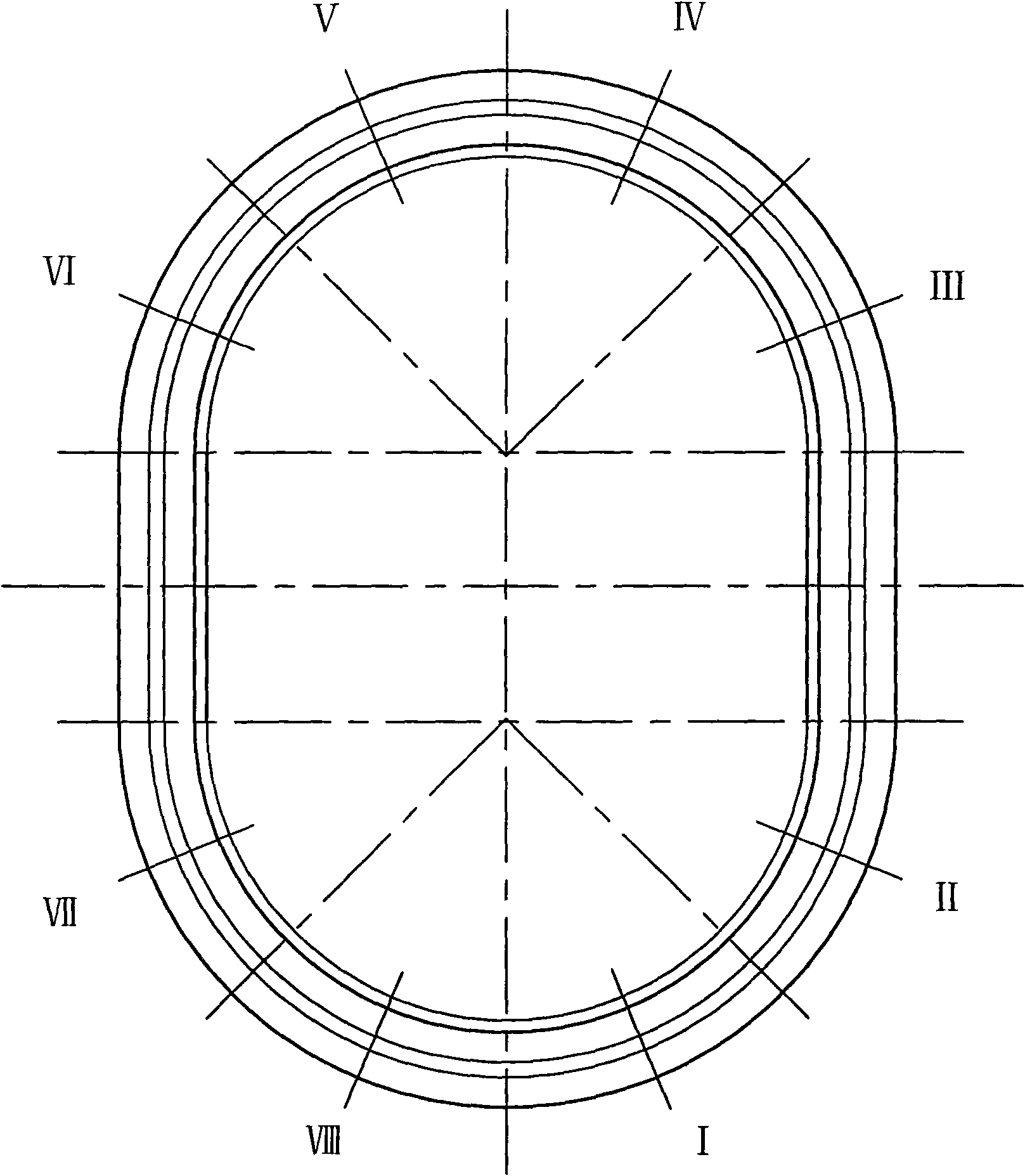

Method for replacing double/quadruple helix coil of transformer with long-circle section

ActiveCN101620923AWon't bounceAdditional lossTransformers/inductances coils/windings/connectionsCoils manufactureCirculating currentElectrical and Electronics engineering

The invention discloses a method for replacing a double / quadruple helix coil of a transformer with a long-circle section, comprising a double helix and a quadruple helix. The replacing method of the double helix comprises the following steps: (1) a plurality of leads wound in parallel are axially divided into two groups of line cakes, and the leads of each group of the line cake are overlapped together to wind along an iron core with the long-circle section; (2) the leads of two groups of line cakes replace once when winding at least one circle, and the replacement is evenly carried out on two semi-circular parts at the section of the coil at interval; and (3) the arrangement position of the leads of each group of the line cake is same as the original arrangement position after the times of the replacement same as the total number of the parallel wound leads are carried out so as to axially lead out two groups of the line cakes. The replacing method of the quadruple helix comprises a step of replacing according to the replacing method of the double helix. A crosswise size in a direction of a short axle of the coil can be completely controlled without bouncing so as to completely replace, the lengths of the parallel-connected leads are same in the same magnetic field, no circulating current is generated among the leads, and the coil has no additional loss due to the replacement, thereby the invention ensures favorable electric performance of the transformer.

Owner:NINGBO TIANAN GRP CO LTD

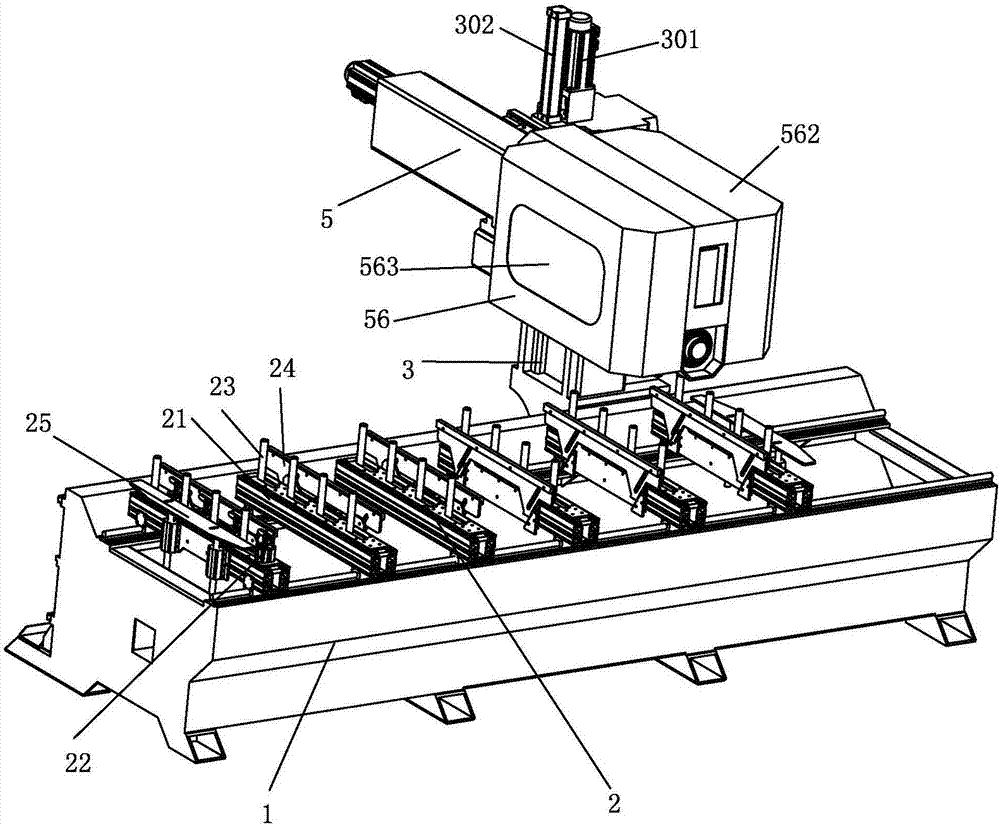

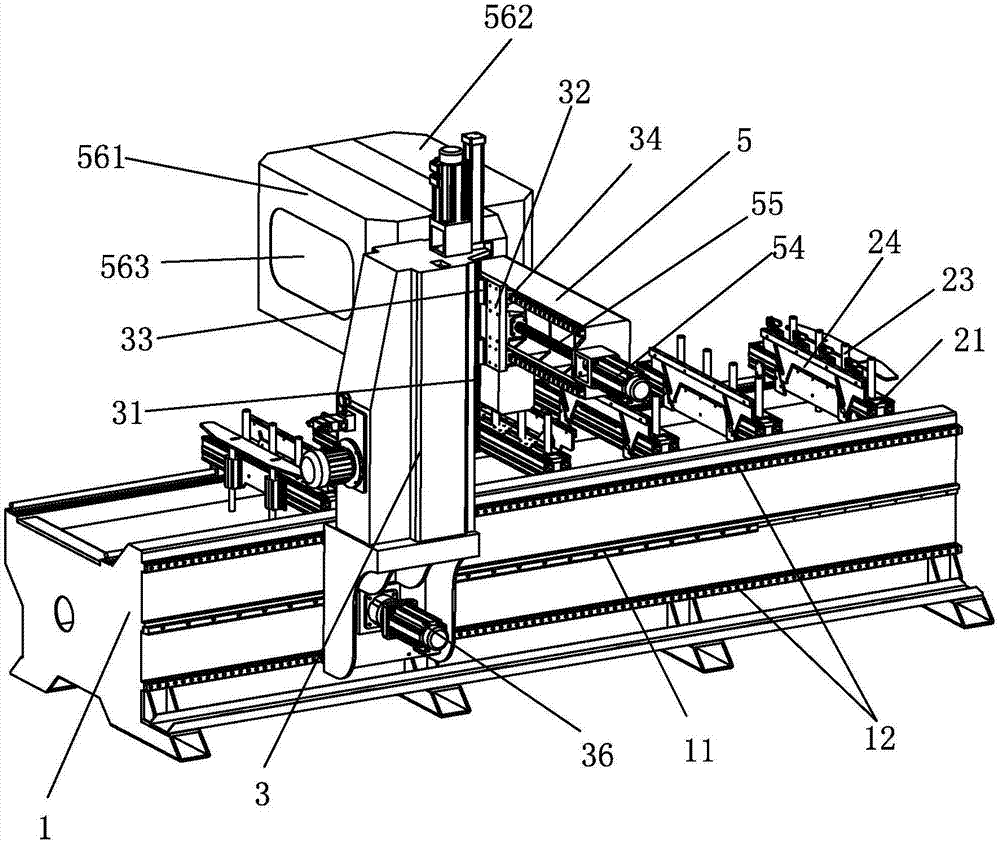

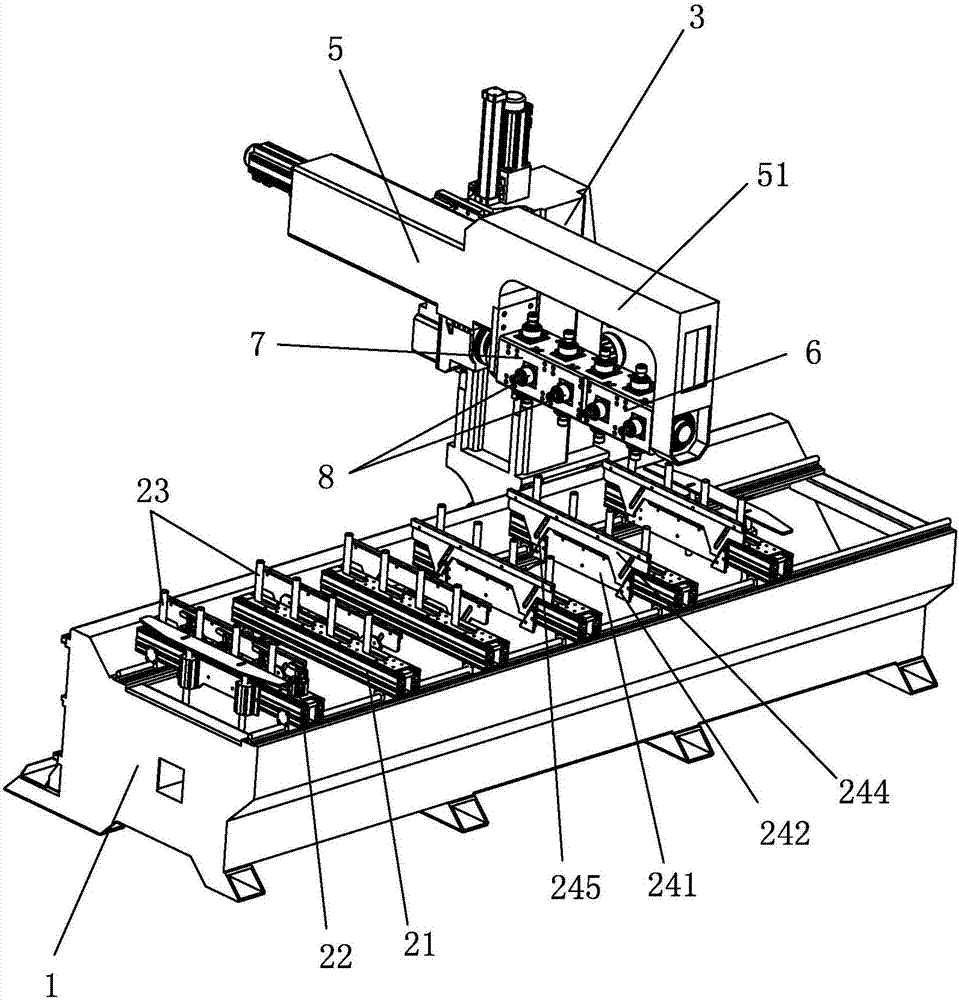

Wood processing machine

PendingCN107053363AEasy to processVariety of processing texturesMulti-purpose machinesEngineeringMachine tool

The invention discloses a wood processing machine. The wood processing machine comprises a machine tool; the machine tool is provided with a fixing mechanism for fixing the wood; a vertical shaft seat capable of sliding on the machine tool is also arranged at one side of the machine tool; a horizontal shaft seat capable of sliding forwards, backwards, upwards and downwards on the vertical shaft seat is arranged on the vertical shaft seat; a rotating main shaft assembly is arranged on the horizontal shaft seat; the rotating main shaft assembly comprises a rotating motor seat; and the rotating motor seat is provided with tool bit components in a plurality of directions. According to the wood processing machine disclosed by the invention, the horizontal shaft seat can be driven by the vertical shaft seat to slide leftwards and rightwards on the machine tool; the rotating main shaft assembly can be driven by the horizontal shaft seat to move forwards, backwards, upwards and downwards so that the tool bit components can be driven to move in directions of axis X, axis Y and axis Z, so the wood can be conveniently processed in all directions and totally along the grain direction of the wood, no cracks are generated and the wood is not damaged. The wood processing machine is high in automation degree, convenient in processing, accurate and varied in processing and capable of shortening the processing time and lowering the processing cost.

Owner:ZHONGSHAN CITY SHAXI TOWN JIANENG WOODEN MACHINERY FACTORY

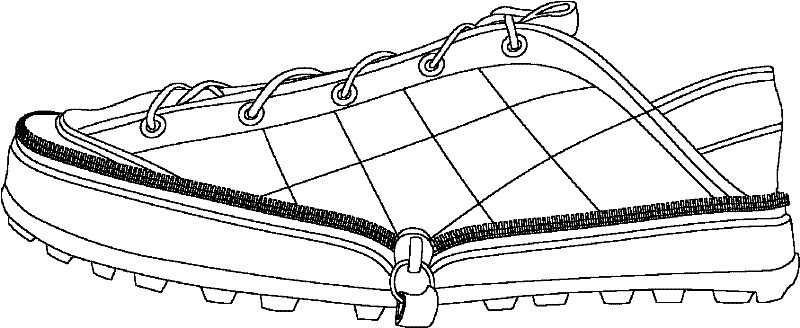

Foldable accommodation shoe

The invention relates to a foldable accommodation shoe, in particular to a foldable accommodation shoe which can be zipped up by a zipper after being folded. By the foldable accommodation shoe, the problem that the folding state is difficult to well keep when an upper of the conventional foldable shoe is high and / or hard is solved. The foldable accommodation shoe comprises a foldable upper and a sole, and is characterized by also comprising a zipper which is arranged around a front upper and a rear upper, wherein stops on two end heads of the zipper are correspondingly arranged on two lateralsurfaces of the shoe; and two tooth chain belts, which occlude mutually, of the zipper encircle the front upper and the rear upper respectively. The foldable accommodation shoe is convenient to storeand / or carry.

Owner:MAOTAI FUJIAN SOLES CO LTD

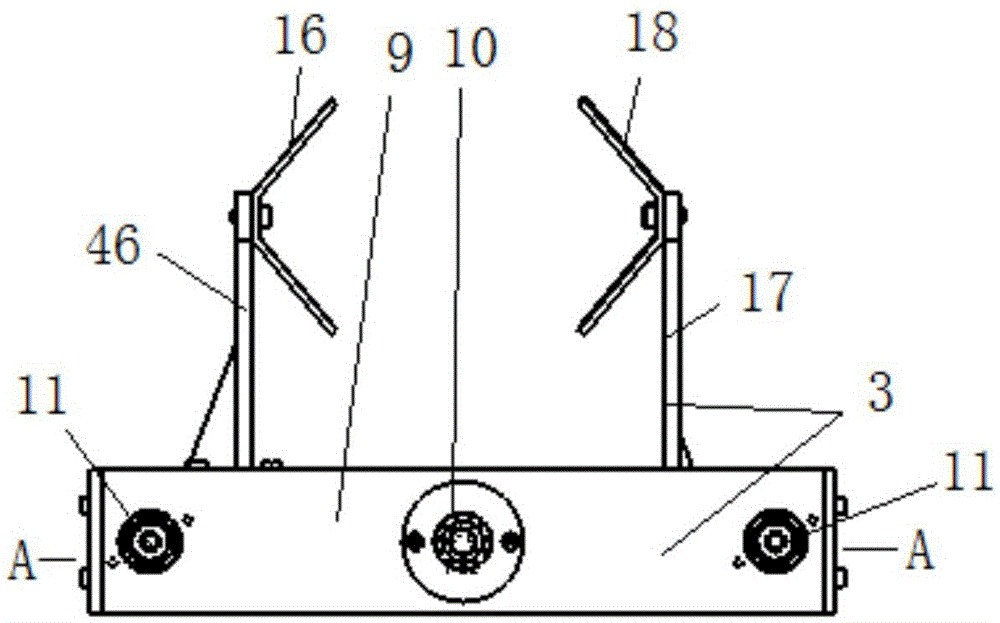

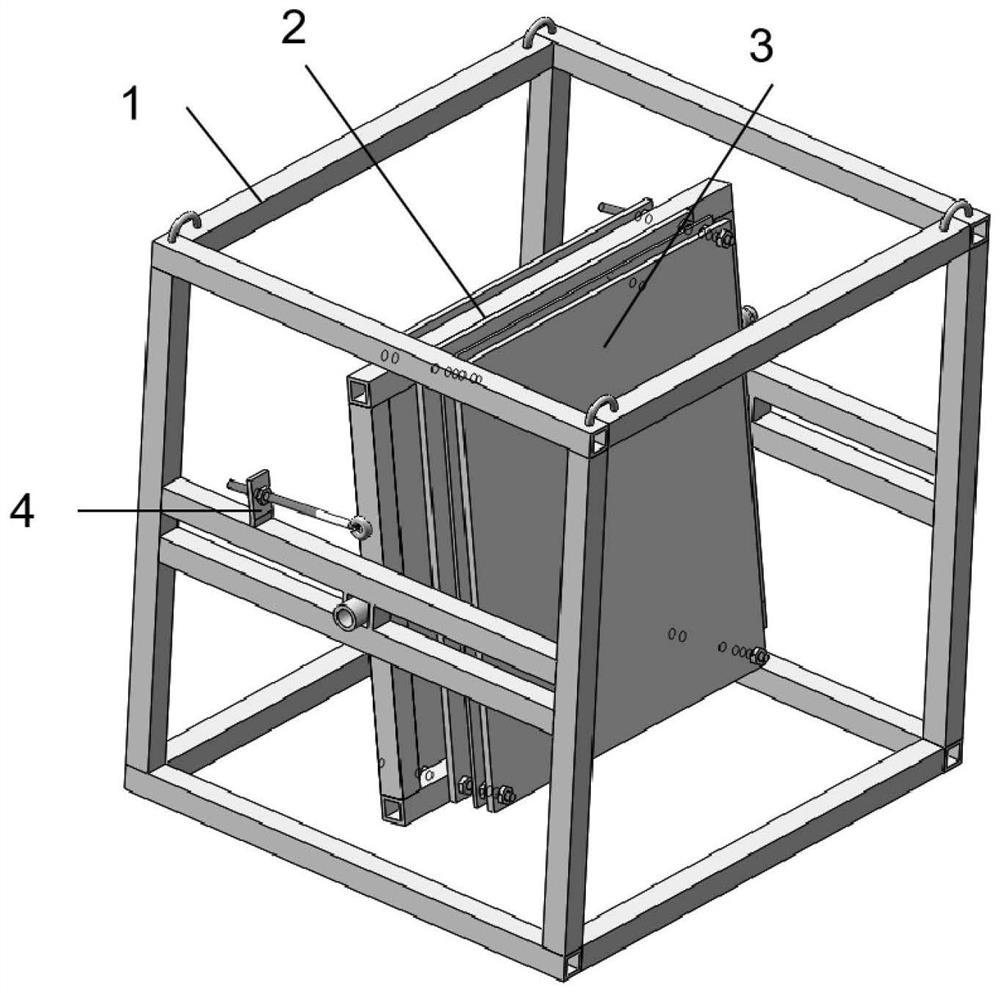

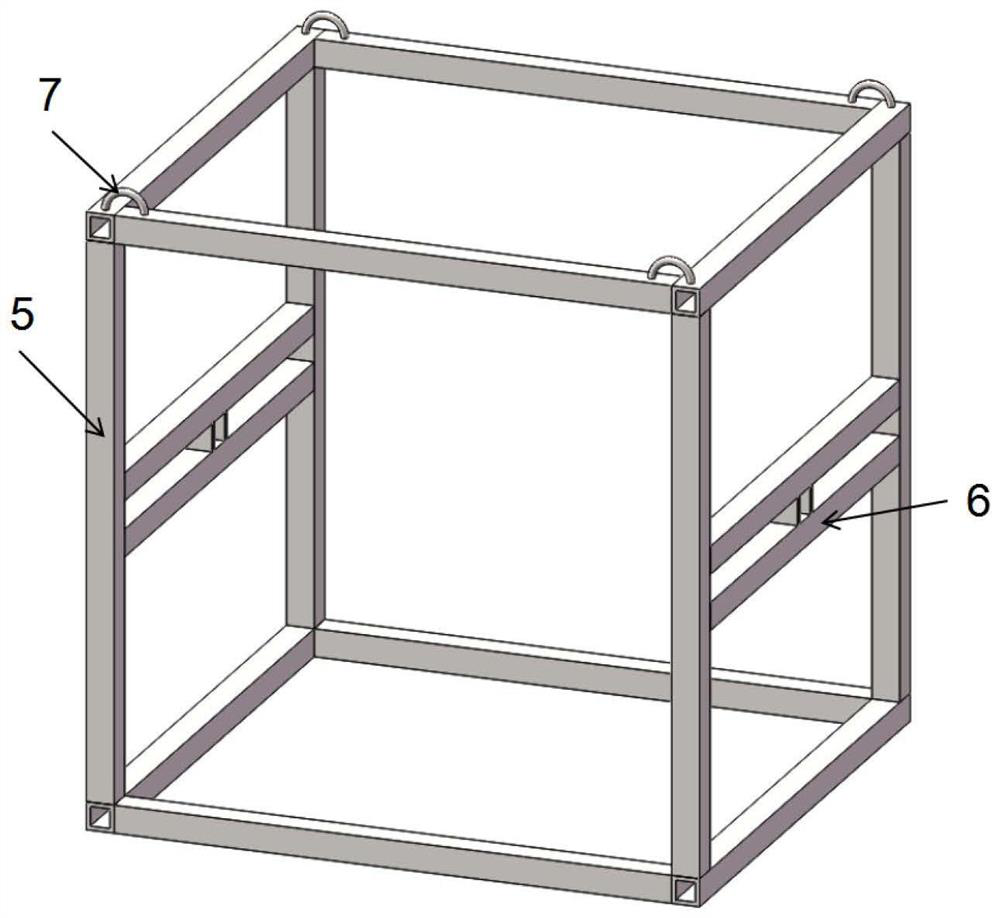

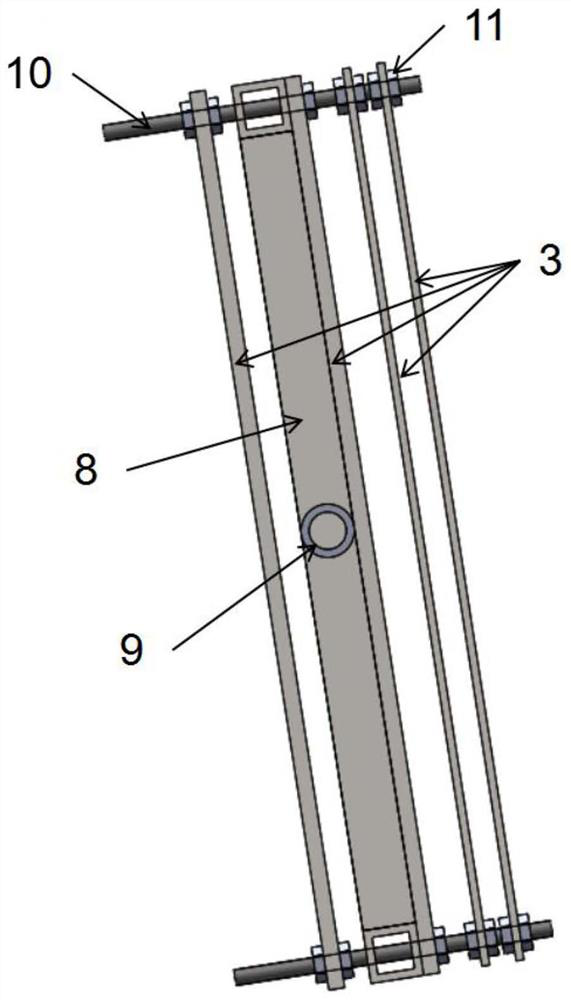

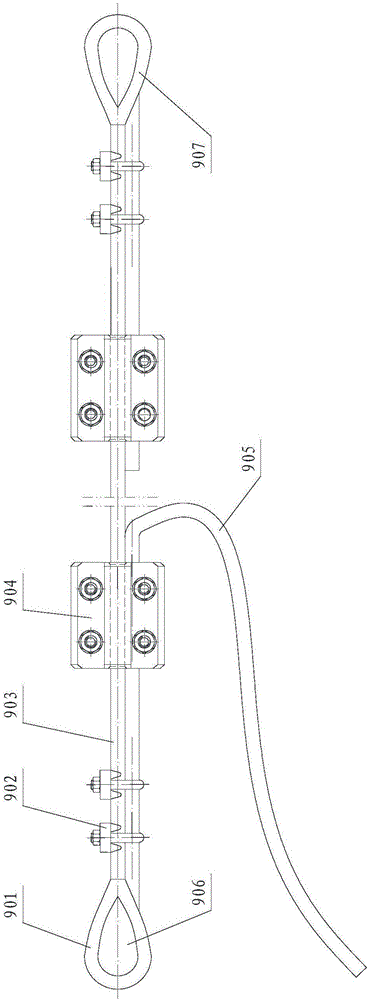

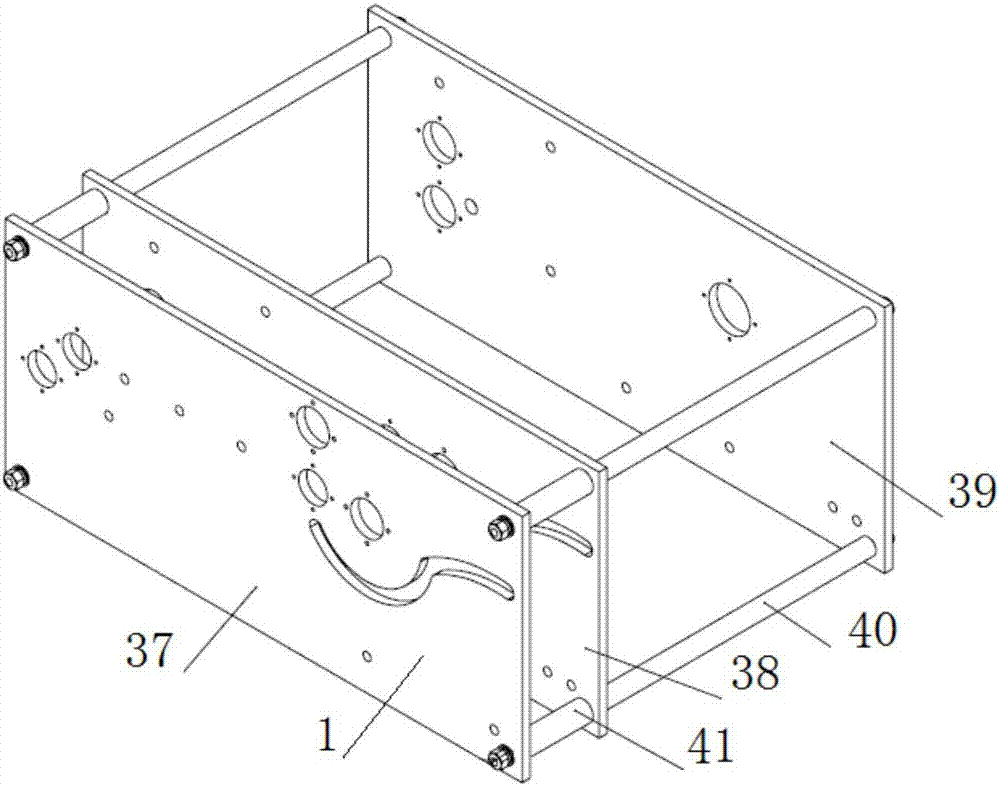

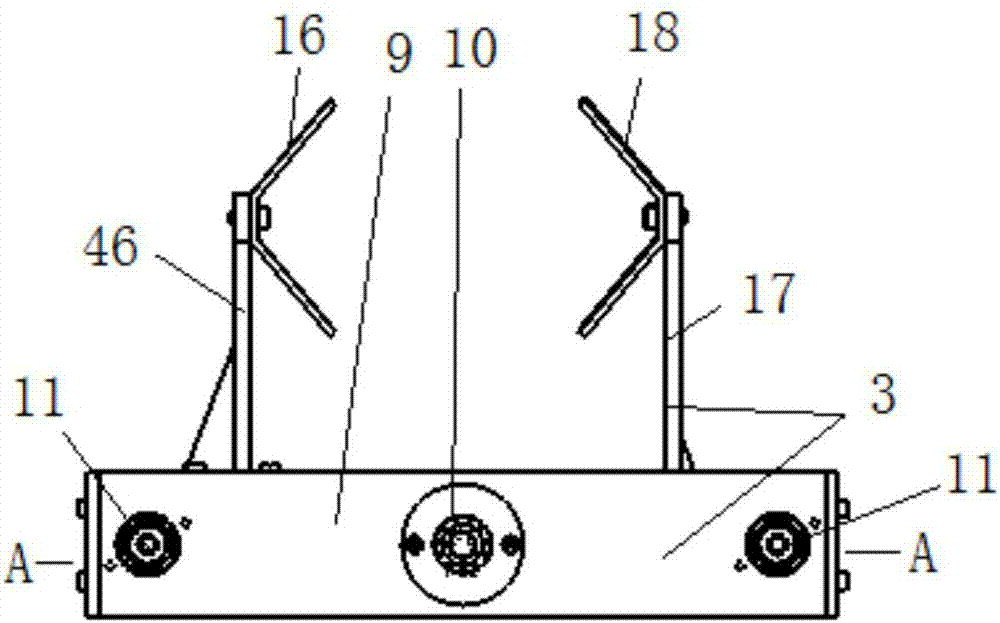

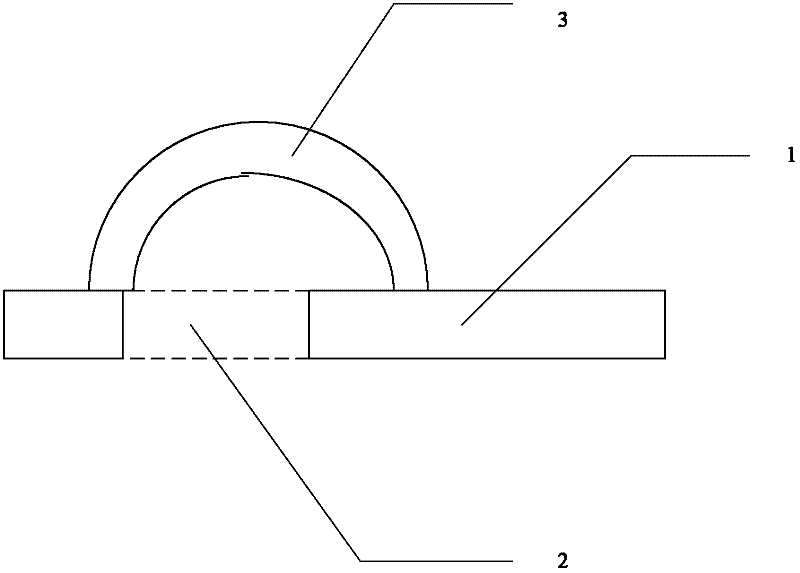

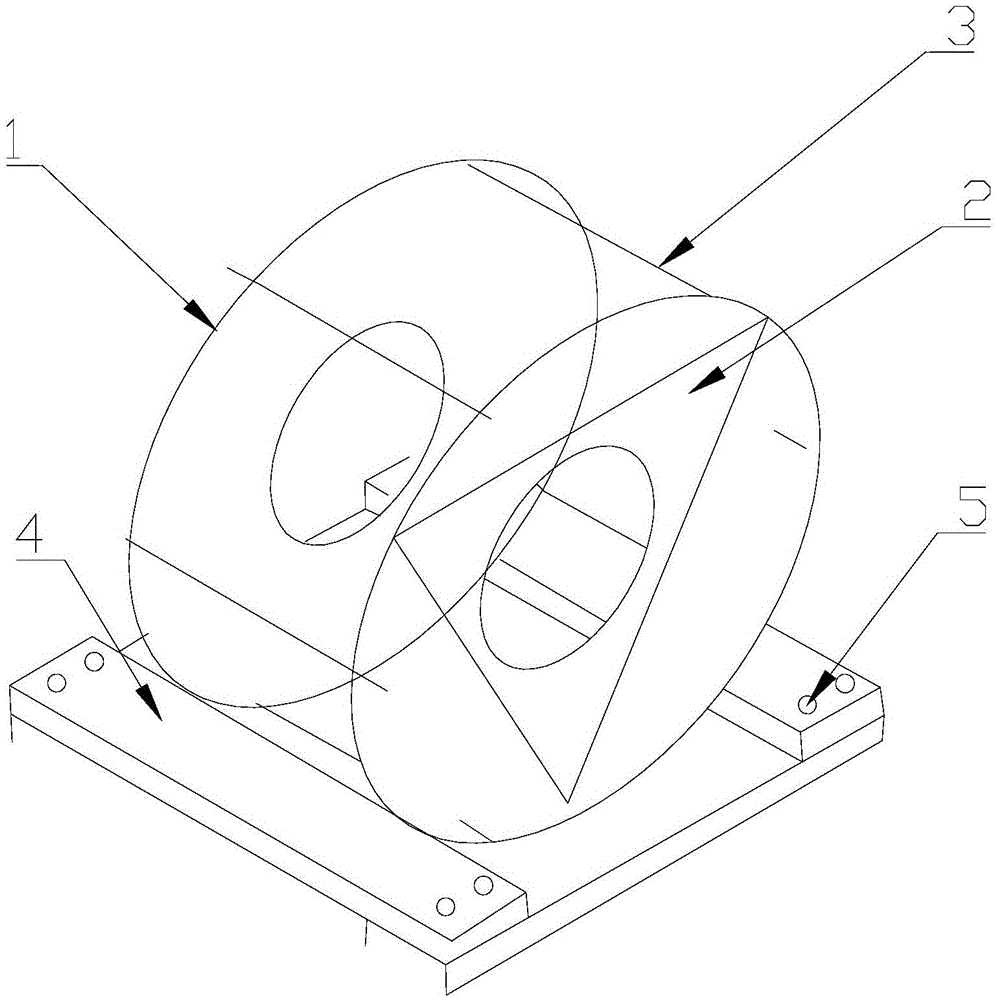

Intercepting and recycling device for high-speed water entry model test

PendingCN114112294AReduce shock loadEasy to take outHydrodynamic testingWater entryUnderwater vehicle

The invention discloses an intercepting and recycling device for a high-speed water entry model test, and belongs to the technical field of high-speed water entry tests of underwater vehicles. Comprising an intercepting frame, an intercepting plate frame, an intercepting plate and an intercepting plate angle adjusting device. The intercepting frame is of a frame structure, the intercepting plate frame is a rectangular frame, the two ends of the intercepting plate frame are connected into the intercepting frame through intercepting plate angle adjusting devices and rotating round pipes and can rotate relatively, an intercepting plate is embedded in the intercepting plate frame, two layers of intercepting plates are fixed right in front of the front side end face of the intercepting plate frame in parallel, and a layer of intercepting plate is fixed right behind the rear side end face of the intercepting plate frame in parallel. The two rotating circular pipes are vertically fixed to the middles of the two sides of the intercepting plate frame correspondingly; the angle of the intercepting frame is adjusted by adjusting the screwing-in length of an angle adjusting rod in the intercepting plate angle adjusting device. According to the device, the underwater model can be effectively intercepted and recycled, it is guaranteed that the main body structure of the model is not damaged, and the device is simple in structure and easy to use.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

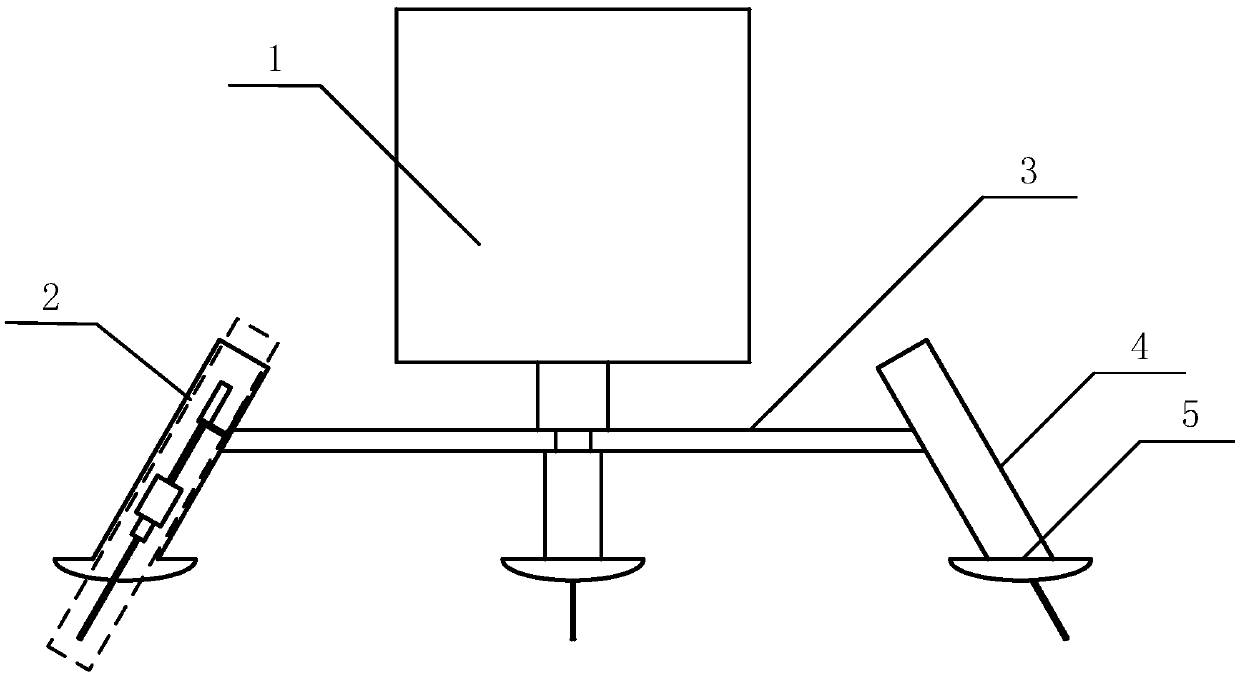

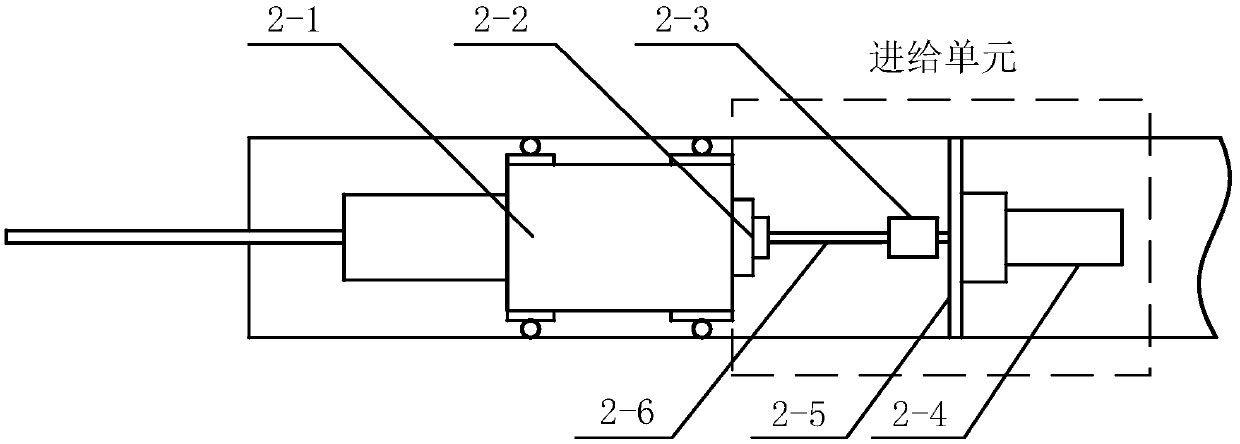

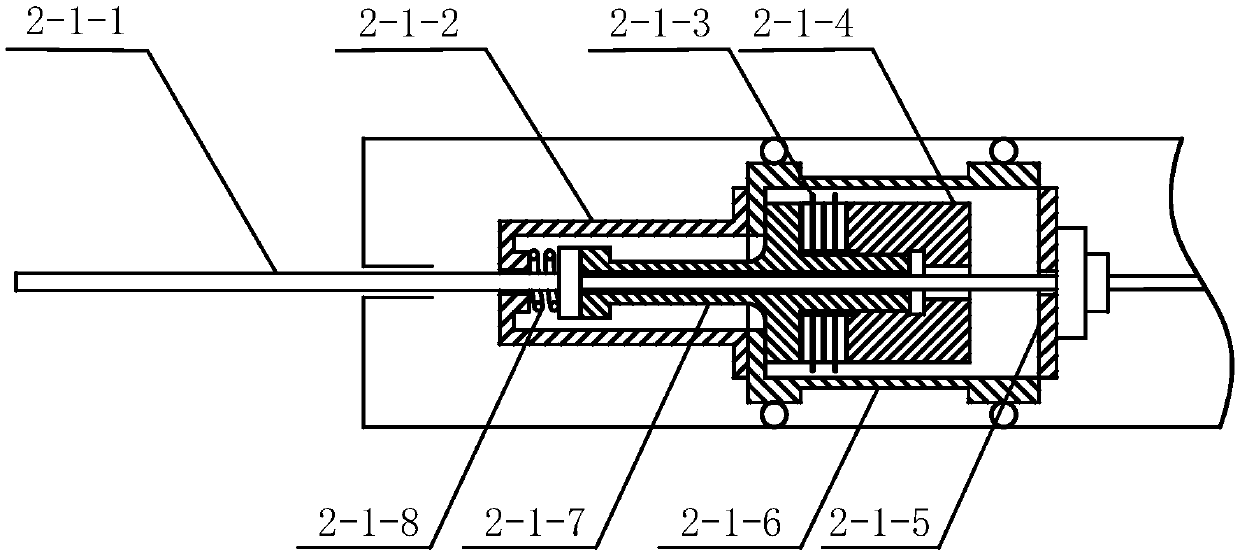

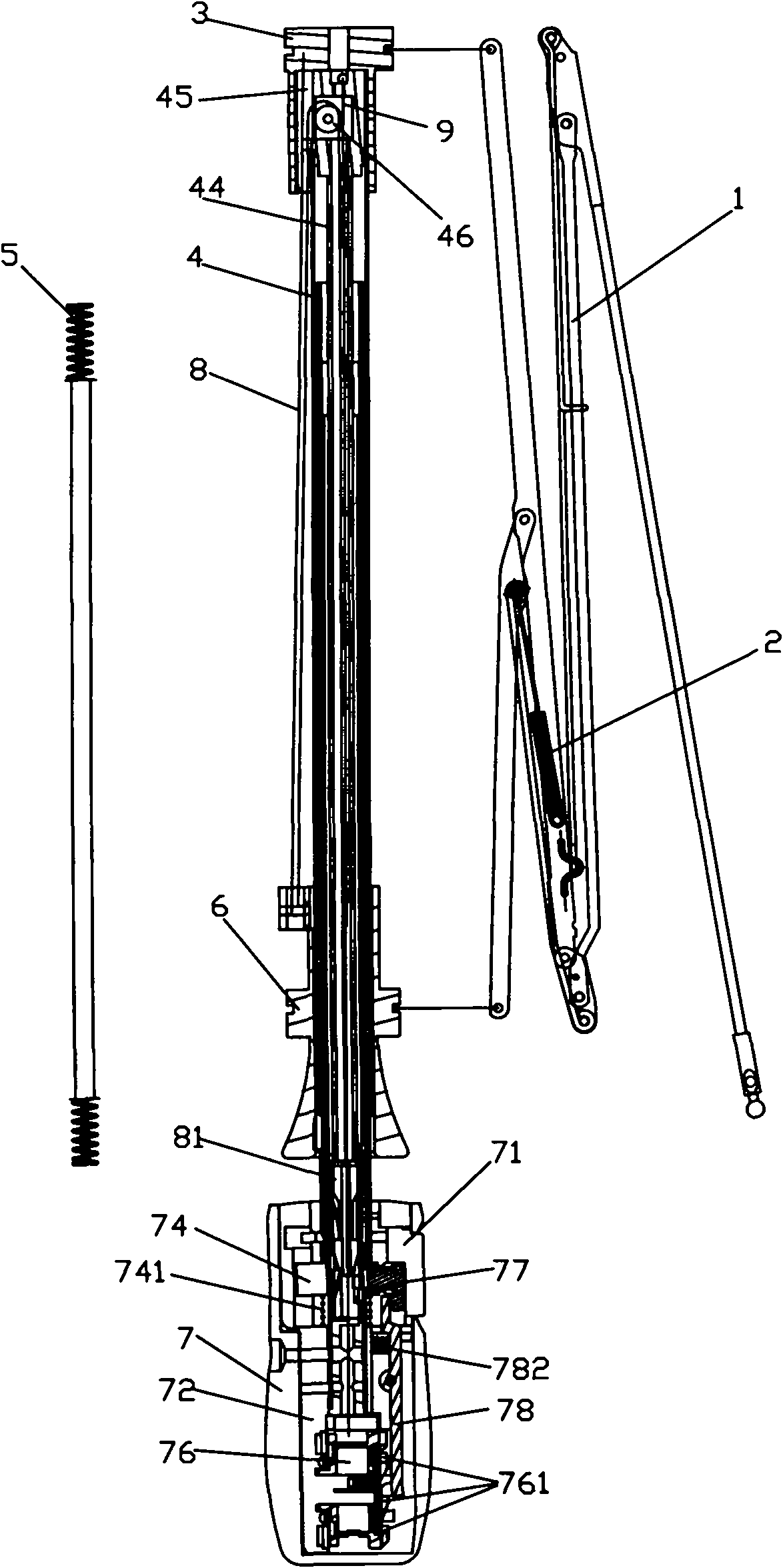

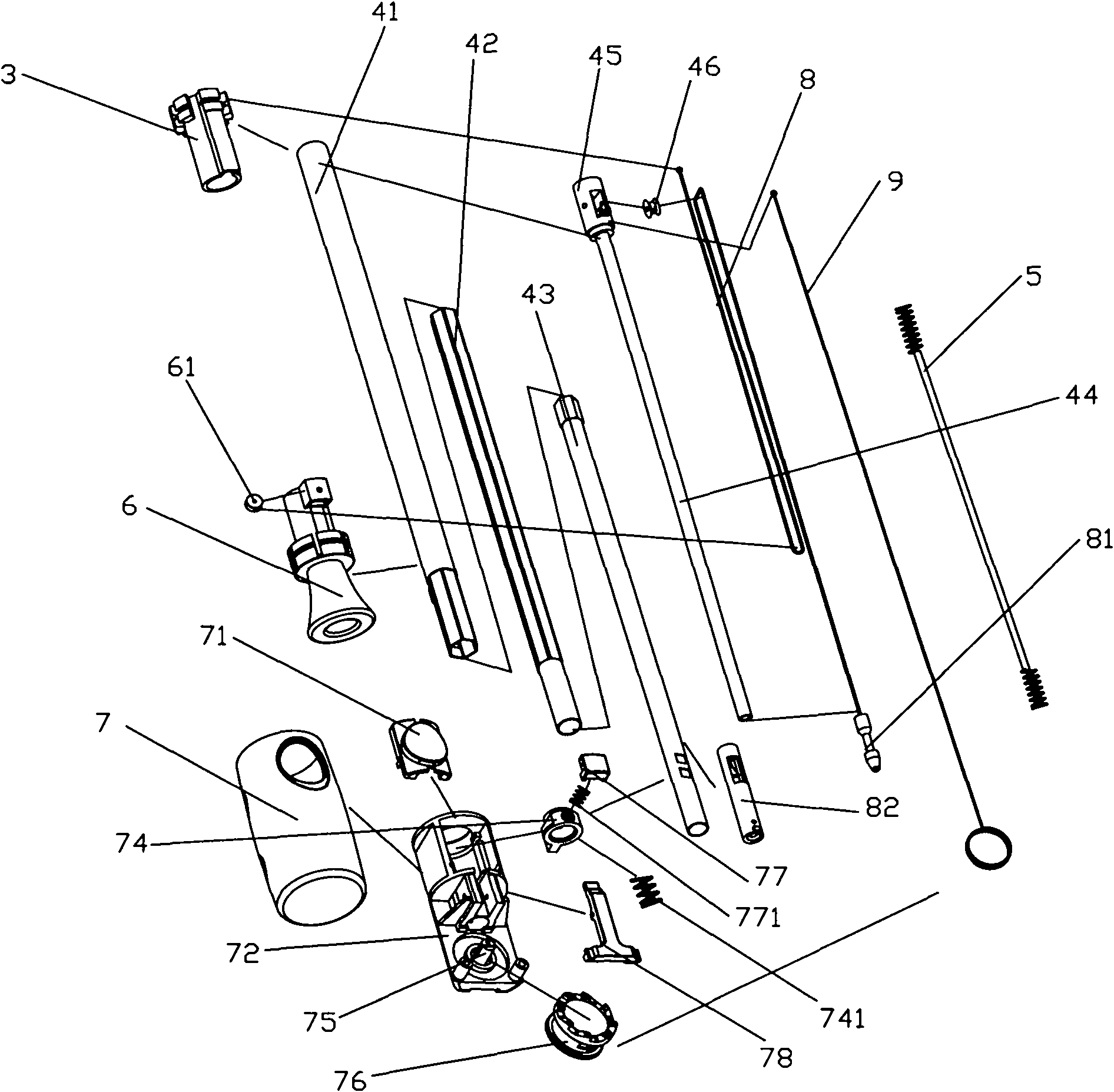

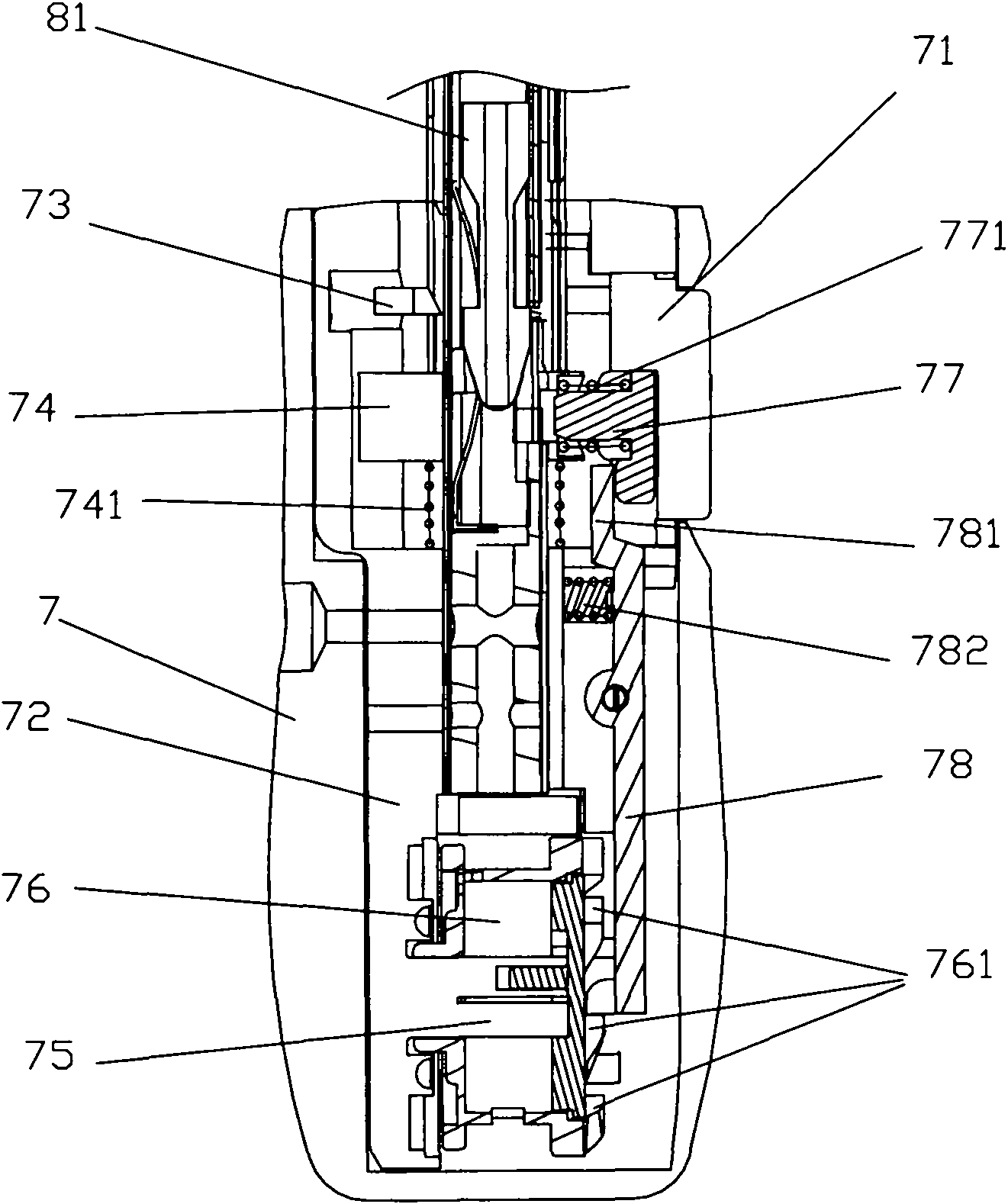

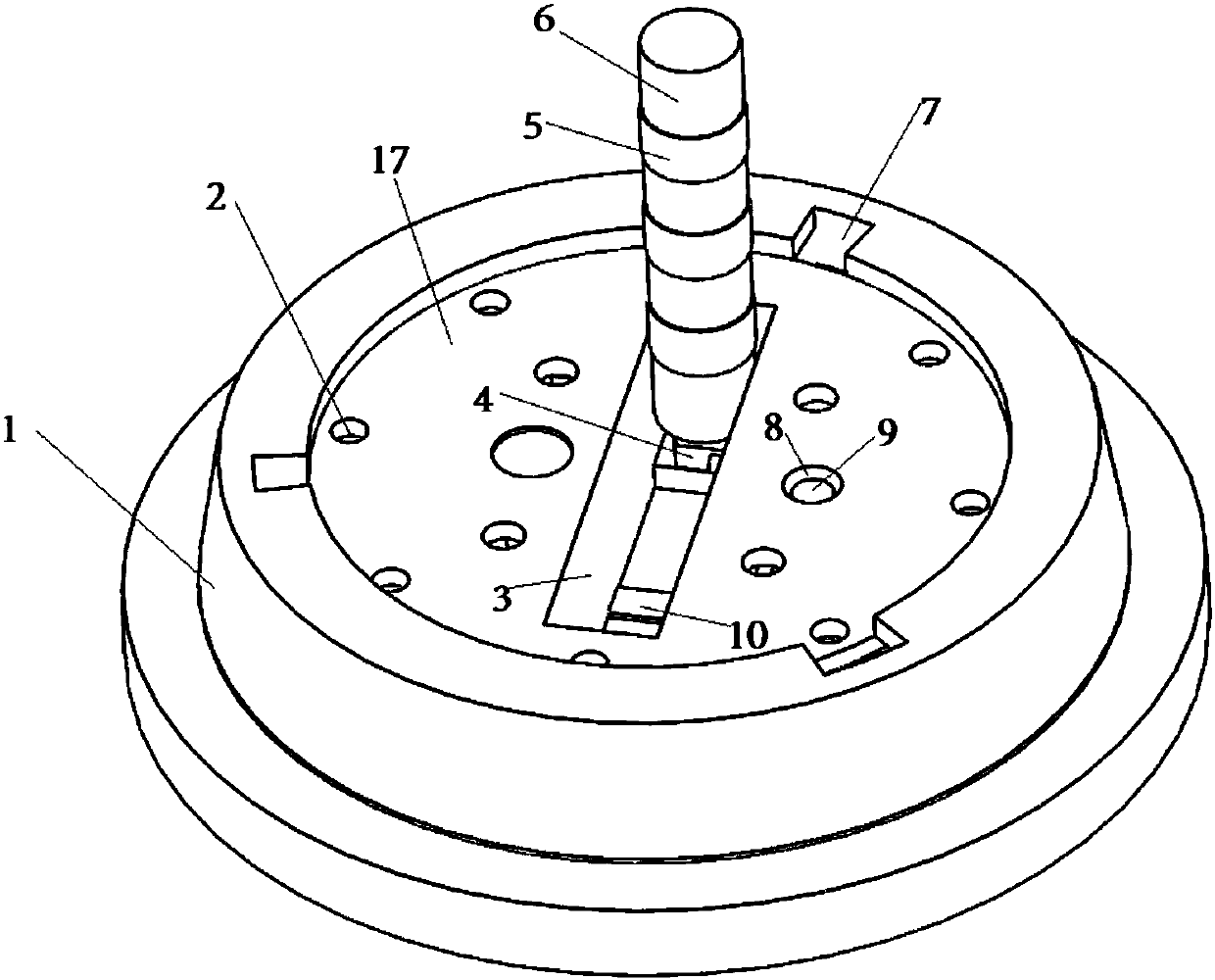

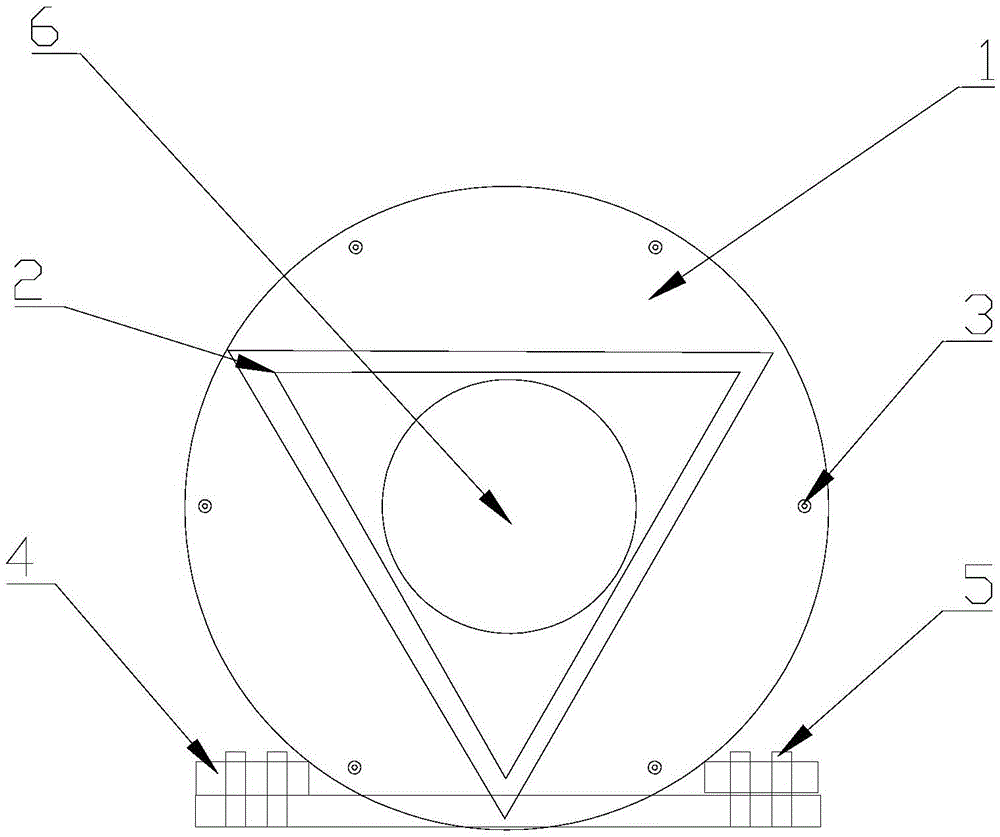

Three-leg supporting asteroid surface anchoring device based on impact type ultrasonic drill

The invention provides a three-leg supporting asteroid surface anchoring device based on an impact type ultrasonic drill. A support of the anchoring device is installed at the bottom of a detector, wherein the three branches of the support are evenly arranged at intervals of 120 degrees, the supporting legs are installed at the tail end of each branch of the support, a supporting foot pad is arranged at the bottom of each supporting leg and used for improving the landing stability of the supporting leg, the interior of each supporting leg is of a hollow structure, a drilling anchoring mechanism is installed in each supporting leg, and one end of the drilling anchoring mechanism penetrates out of the supporting foot pad. The problem is solved that an asteroid detector in the prior art cannot be stably fixed on the surface of an asteroid after landing, and because the attractive force on the surface of the asteroid is very small, the detector is easy to bounce during landing and samplingwork. The three-leg type supporting asteroid surface anchoring device based on the impact type ultrasonic drill is provided, the three anchoring supporting legs are evenly arranged at intervals of 120 degrees to form a force closed structure, stability is high, the reaction force of the impact type ultrasonic drill is small, and the detector is not prone to bounce.

Owner:HARBIN INST OF TECH

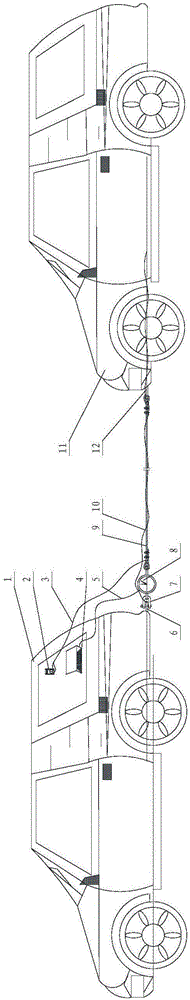

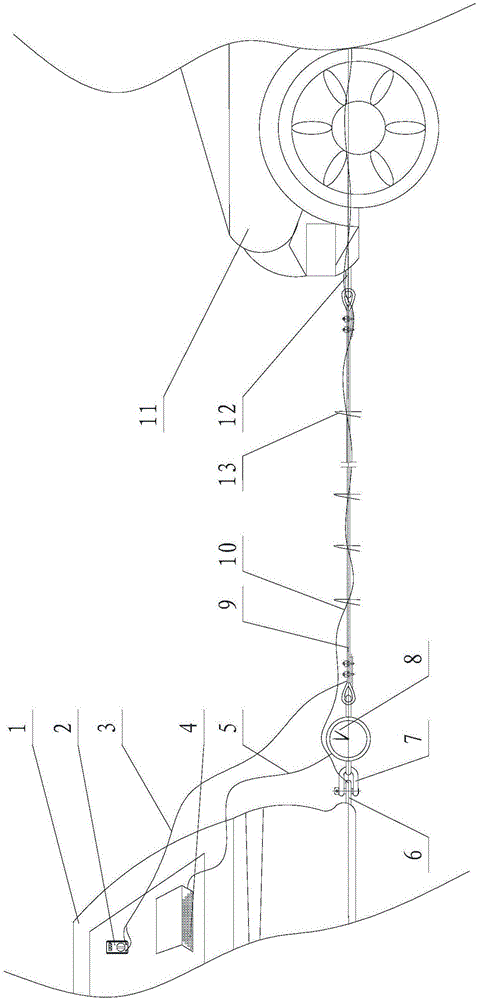

Testing device for instant tension of cable and testing method of testing device

InactiveCN106769454AEasy to manufactureEasy to implementMaterial strength using tensile/compressive forcesTester deviceEngineering

The invention belongs to the field of mechanical testing, and particularly relates to a testing device for instant tension of a cable and a testing method of the testing device. The testing device is characterized in that a front buckle and a rear buckle are arranged at the two ends of the testing cable by capels, cable binding heads and cable clamping devices; a testing connection line is reserved at the front buckle; one end of a tension meter is connected with a rear trailer hook of a front vehicle by a shackle; the other end of the tension meter is connected with the front buckle of the testing cable; the tension meter is connected with a computer by a communication line; the testing connection line of the testing cable is connected with a cable communication tester; a safety rope is longer than the testing cable, and bound on the testing cable by binding tapes; and the two ends of the safety rope are tightened on a front trailer hook and the rear trailer hook of the front vehicle and a rear vehicle. The testing method comprises the steps that different braking degrees are selected for the rear vehicle; the front vehicle instantly pulls the rear vehicle to accelerate forwards at different speeds by the testing cable; tension testing data of the tension meter is recorded by the computer; and on-off of the cable is recorded by the cable communication tester. The testing device has the advantage of simple structure. The testing method has the advantages of easiness in realization, testing safety and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

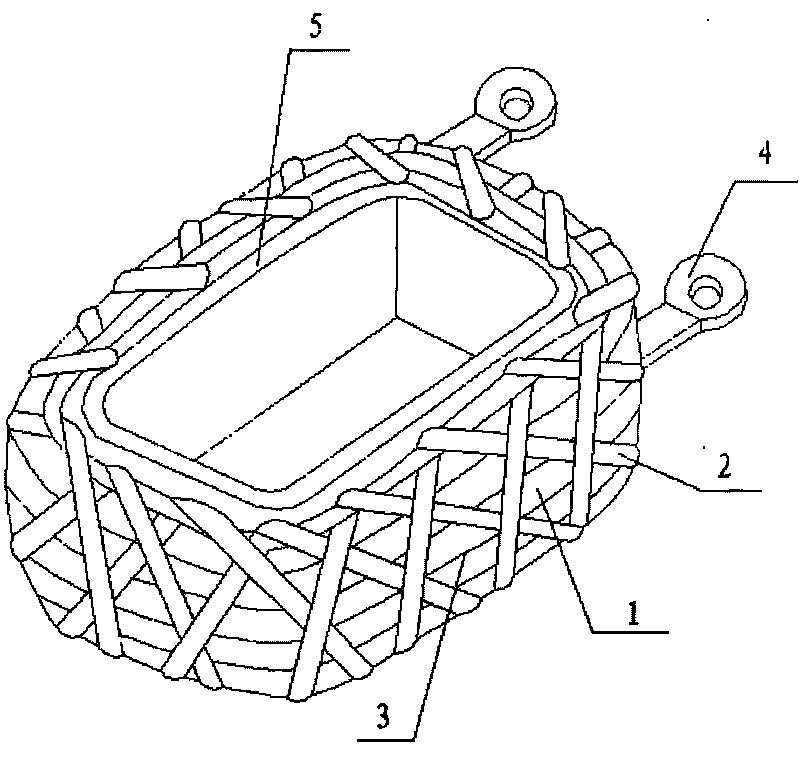

Manufacturing method of motor stator coils

InactiveCN101694957AImprove overload capacityAvoid bruisesManufacturing dynamo-electric machinesStator coilThermal diffusivity

The invention relates to a manufacturing method of motor stator coils, in particular to a manufacturing method of maintenance DC motor stator coils. The motor stator coils comprises coils, a netted insulator, an insulated paint layer, a wire connecting nose and a coil inner lining frame; the coils are wound outside the coil inner lining frame, are shaped through winding and are wound into the netted insulator along a coil winding direction and a coil axial direction in certain angles by binding insulated tapes; the coils are sequentially soaked and dried for 2-3 times with insulated paint to form an insulated layer; the wire connecting nose is fixedly connected with both ends of the coils; and the motor stator coils can prevent powdered carbon oil stains from entering, have good thermal diffusivity and enhanced motor overload capacity, and effectively prevent coil damage.

Owner:杨存高

Firewood splitting device

The invention discloses a firewood splitting device. The firewood splitting device comprises a support and an axe, and is characterized in that a linear guide rail is arranged on the upper portion ofthe axe; the supporting comprises an upper plate and a lower plate; a sliding block I is fixedly mounted on the upper plate; the linear guide rail is matched with the sliding block I, and thus the axecan only move up and down along the linear guide rail; a sliding block II is arranged on the linear guide rail; and a stress application hammer is fixedly connected with the sliding block II. The stress application hammer is arranged on the axe of the firewood splitting device, the effect of effort saving is achieved by smashing the axe with the stress application hammer, and wood blocks do not bounce; and the axe can only move up and down and is not deviated in the downwards-splitting process.

Owner:桂林市逸仙中学

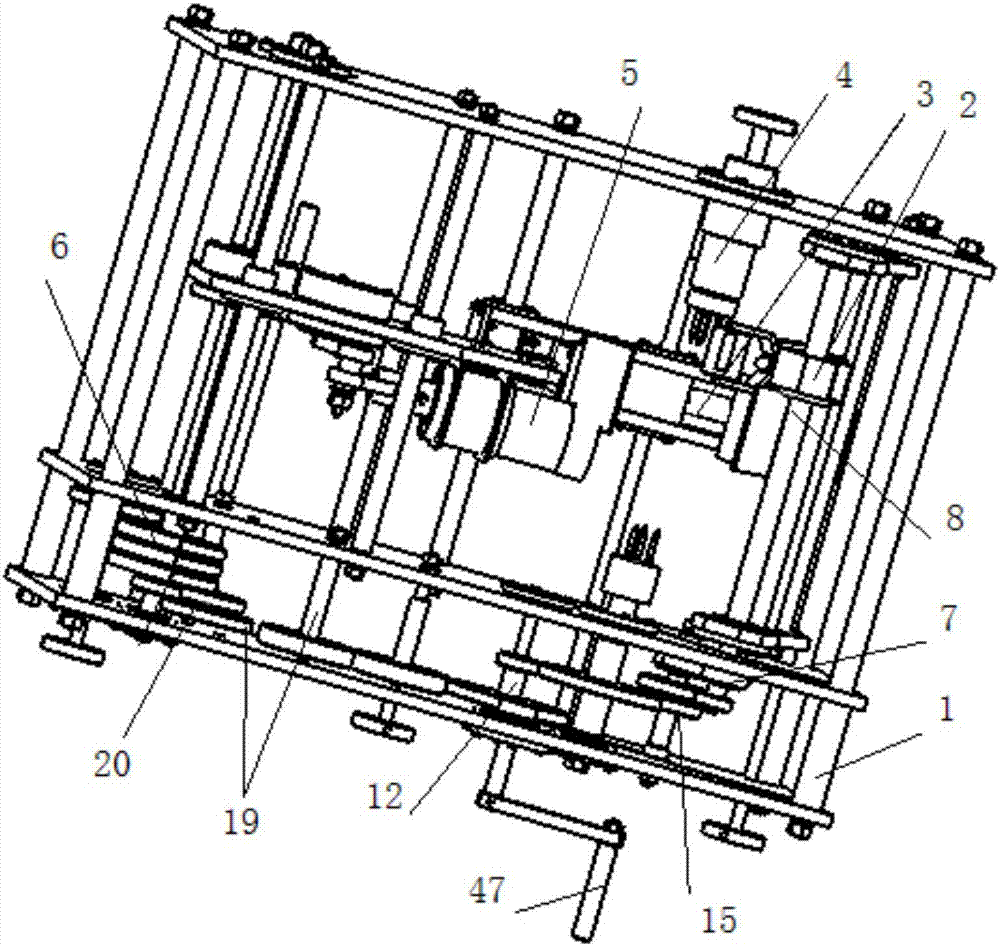

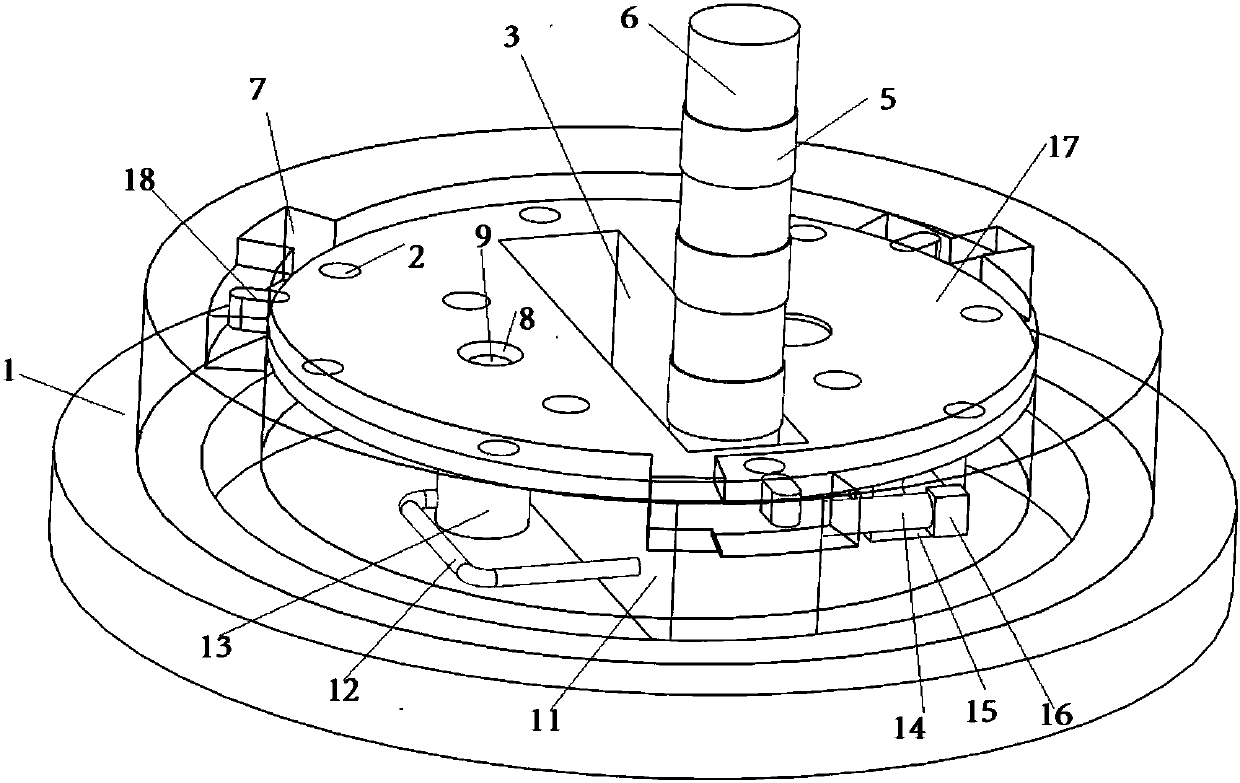

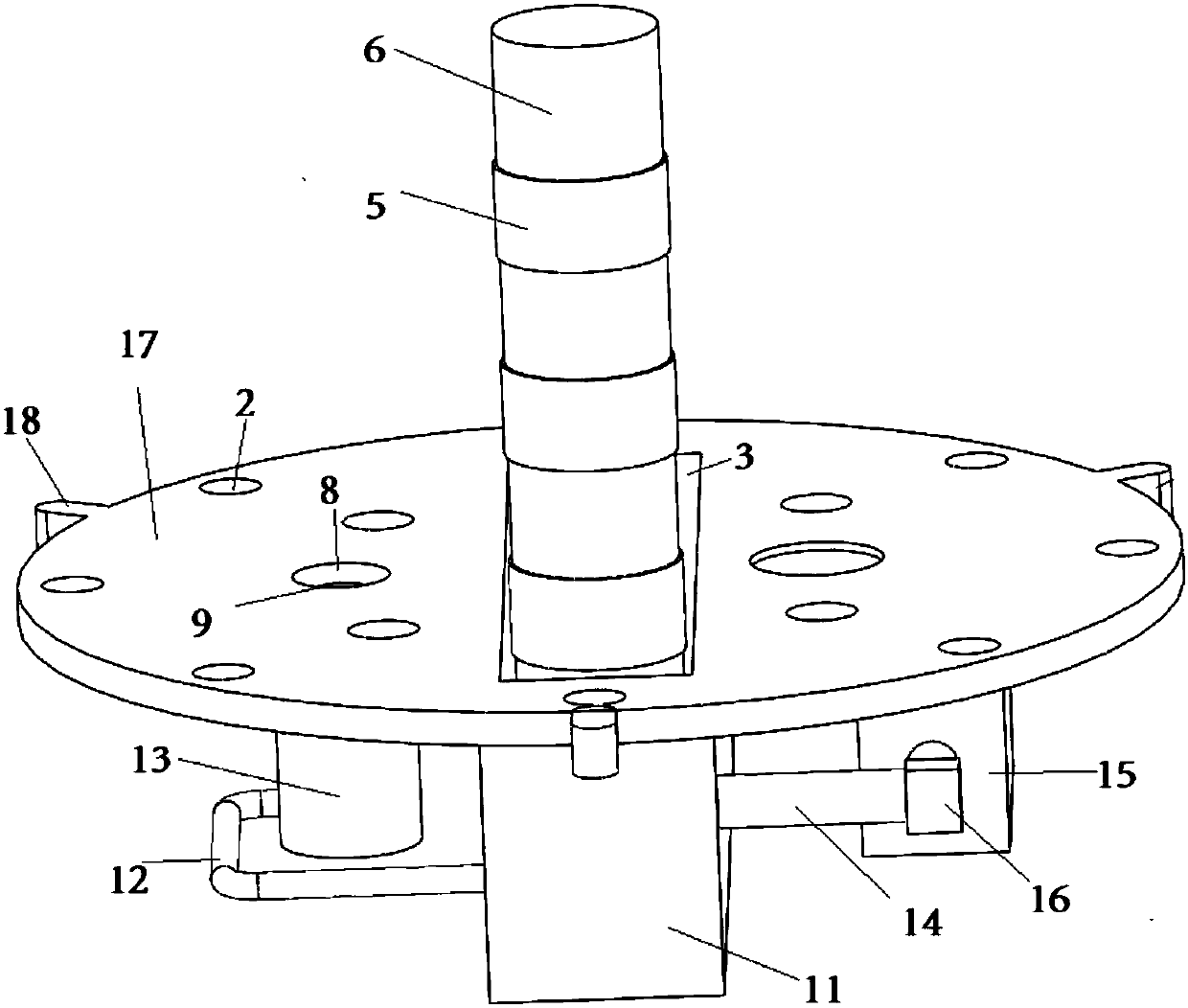

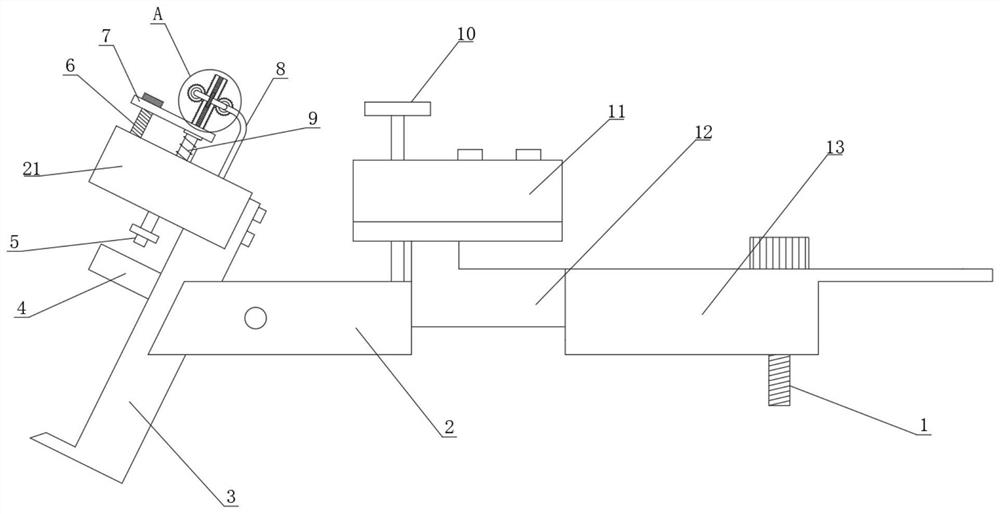

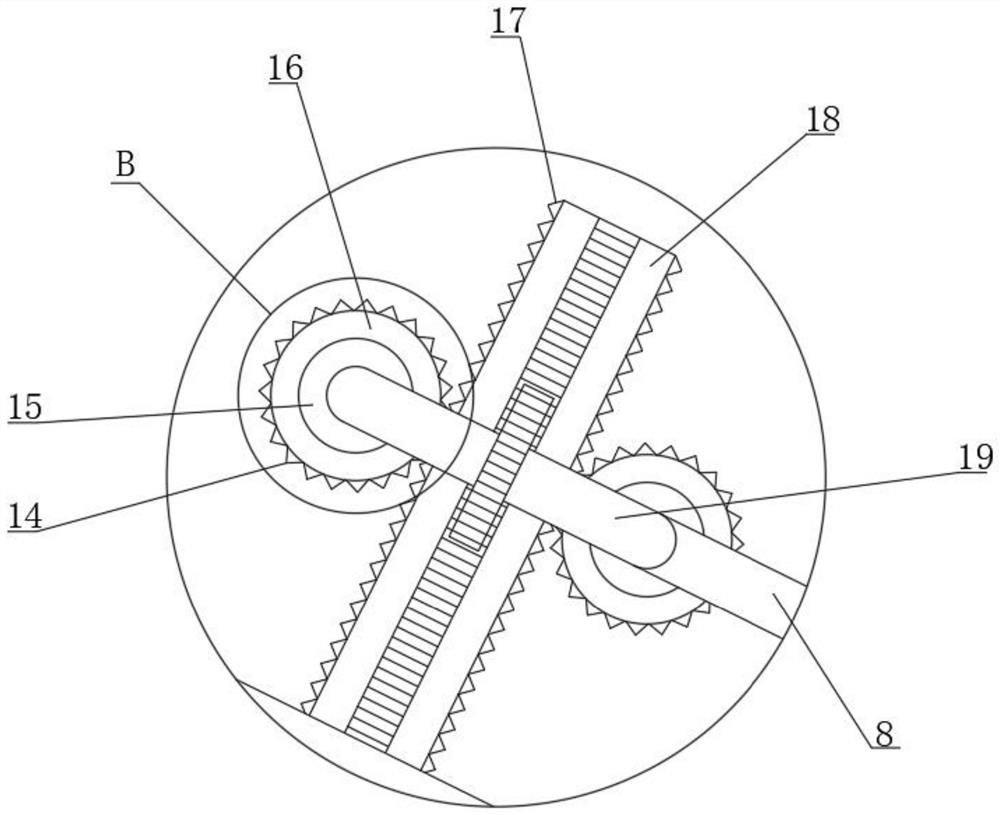

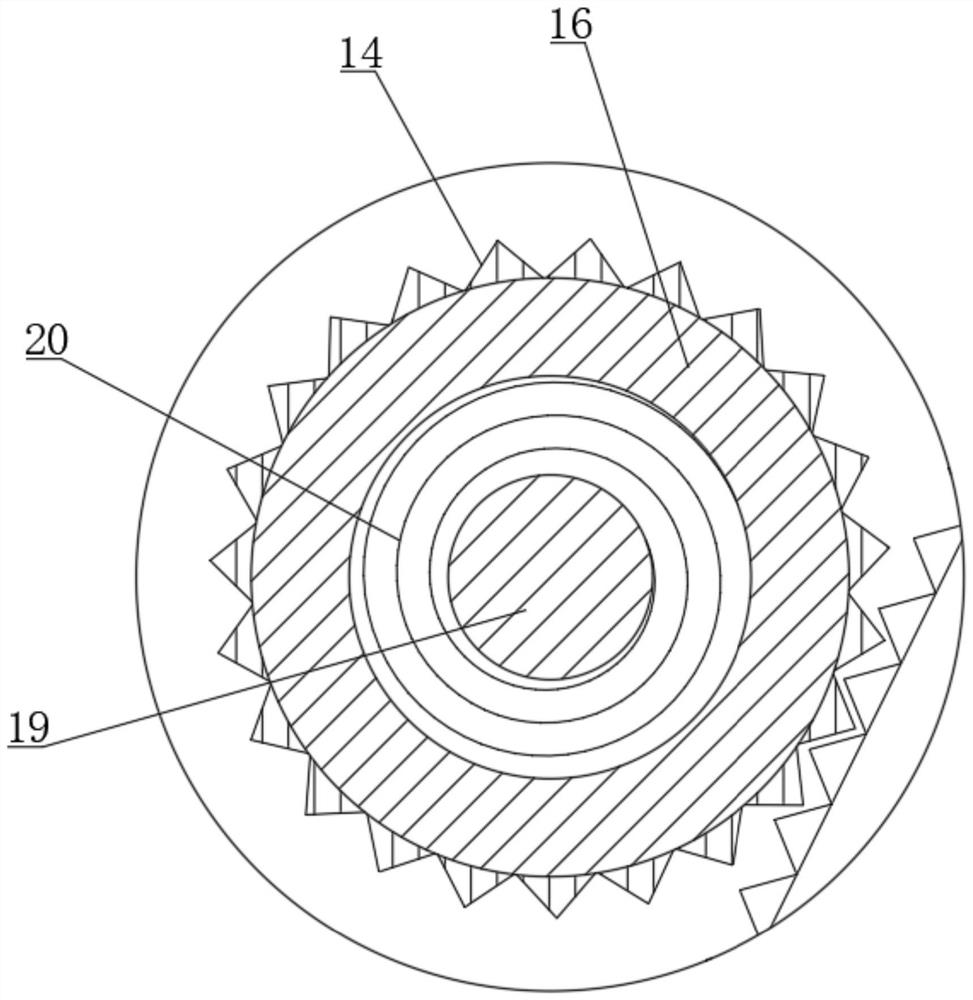

A mechanical pineapple peeling machine

InactiveCN105581621BImprove peeling efficiencyAchieve alignmentFruit coringPeelersEngineeringElectrical and Electronics engineering

The invention discloses a mechanical pineapple peeling machine which comprises a machine frame. A positioning clamp and a black core removing structure are arranged on the machine frame. Two opposite pineapple insertion tables are arranged on the opposite sides of the machine frame. One pineapple insertion table is telescopic and is connected with a gear shifting mechanism through a main transmission mechanism, the gear shifting mechanism is connected with a handle and a black core removal transmission mechanism, the main transmission mechanism is connected with a peeling transmission mechanism, the peeling transmission mechanism is connected with a lead screw a, the lead screw a is connected with a peeling adjustable cutter, the positioning clamp and the peeling adjustable cutter are located between the two opposite pineapple insertion tables, the black core removal transmission mechanism is connected with the black core removing structure, and the black core removing structure is opposite to the peeling adjustable cutter. The mechanical pineapple peeling machine completes the peeling step and the black core removing step through one-time clamping, and pineapple peeling efficiency is greatly improved.

Owner:XIAN UNIV OF TECH

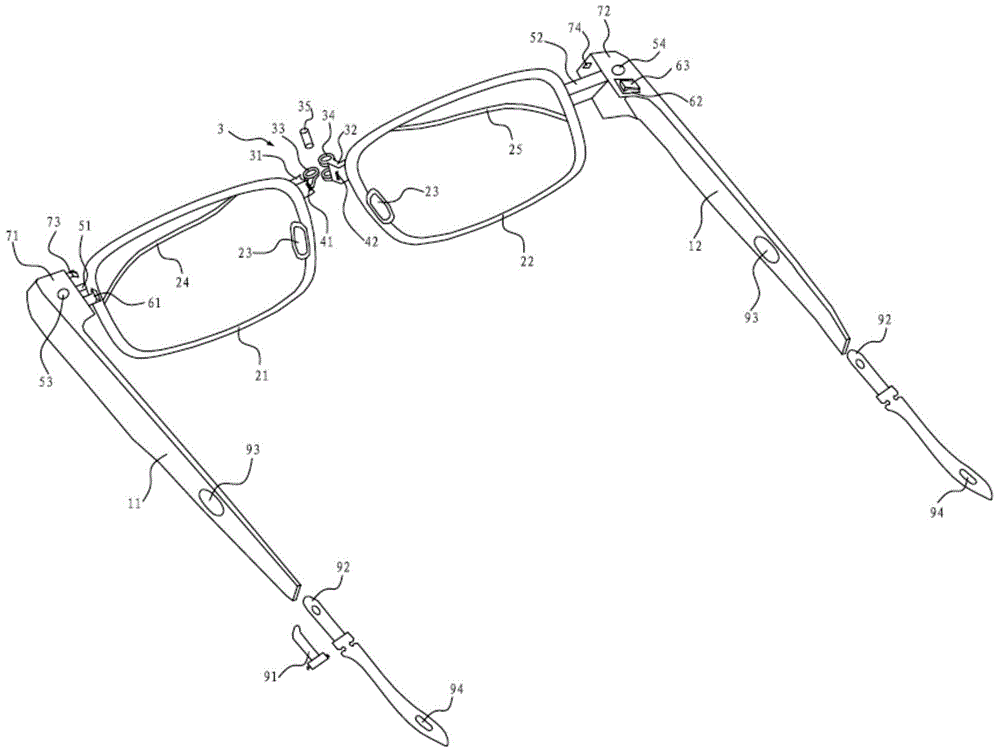

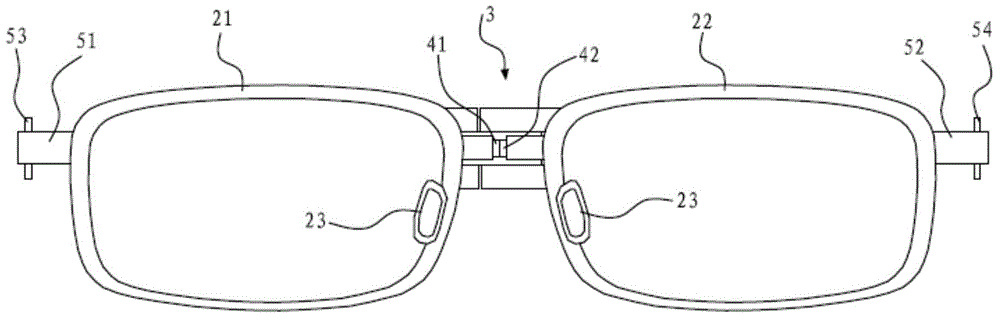

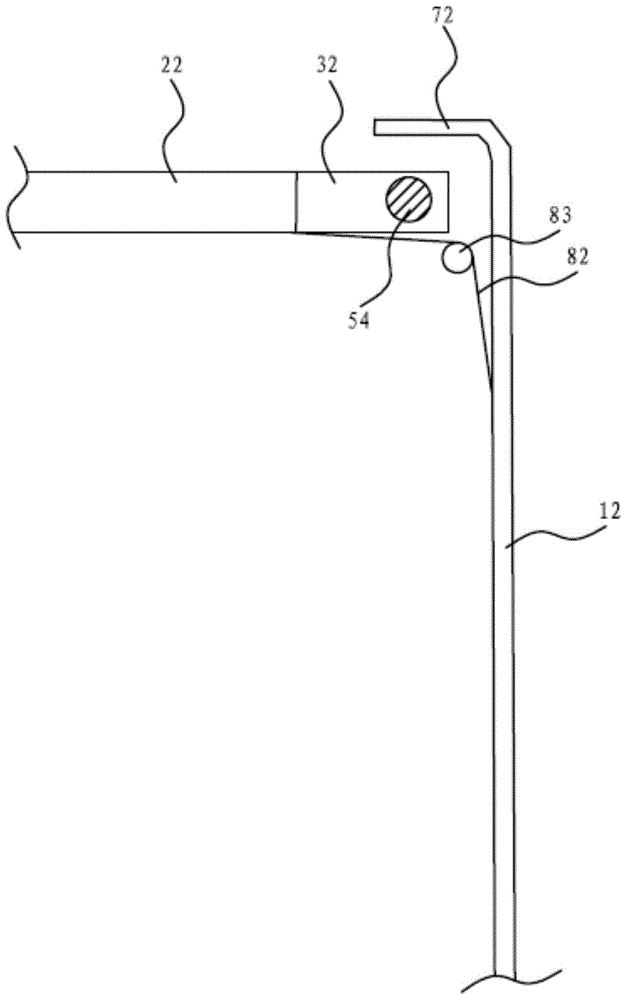

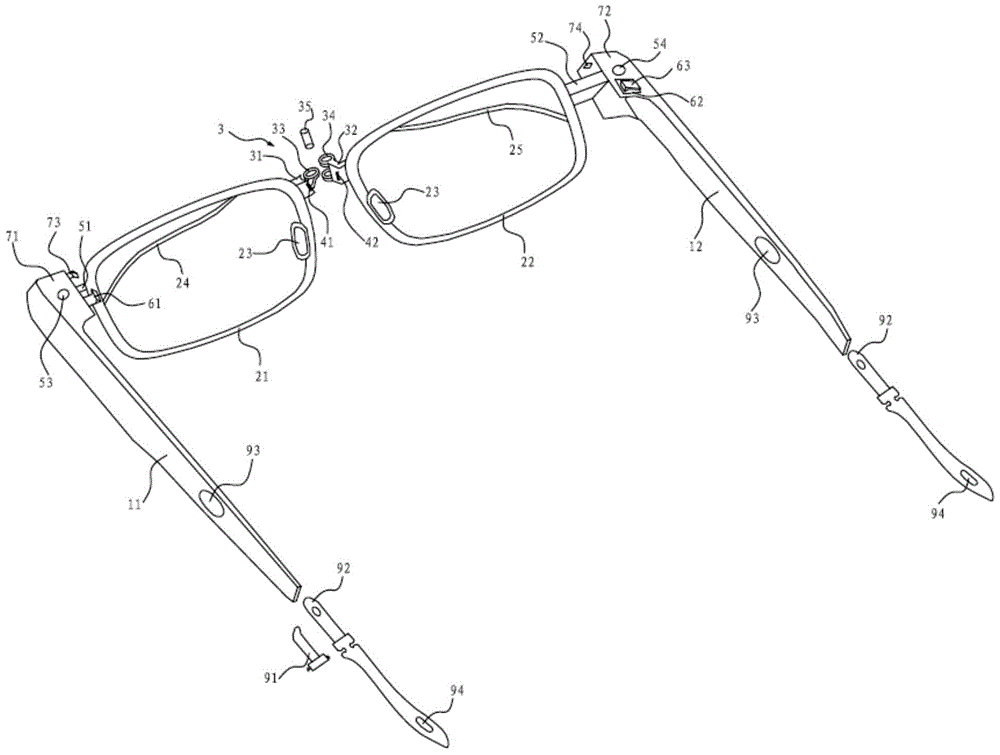

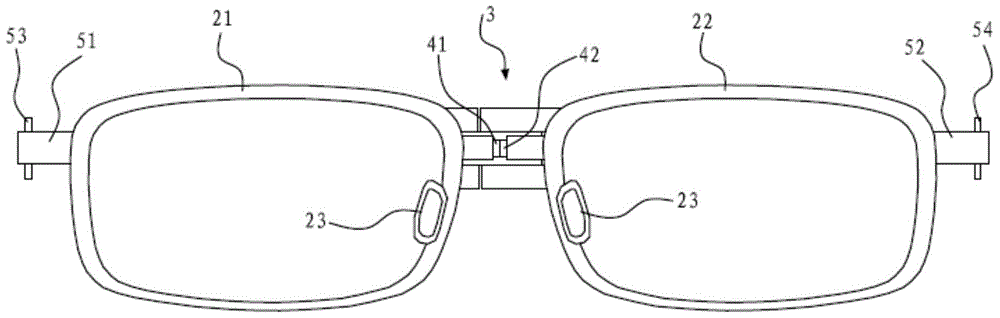

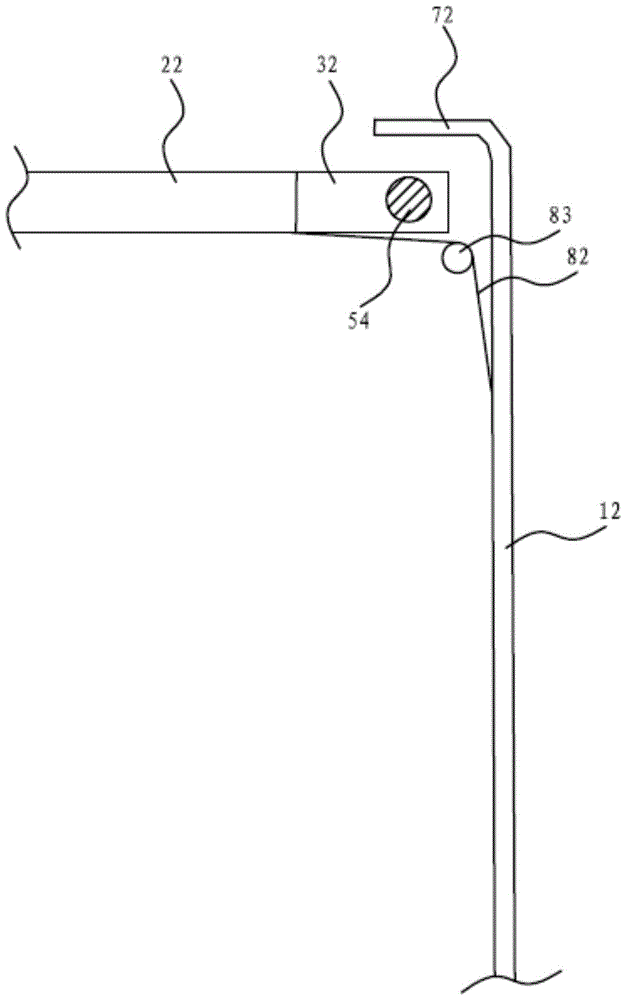

Folding type glasses

InactiveCN104678563AFolded state is stableImprove satisfactionNon-optical partsUses eyeglassesEngineering

The invention discloses a pair of folding type glasses which comprise a first glasses leg, a second glasses leg, a first glasses body, a second glasses body and a middle beam mechanism for connecting two glasses frames, wherein the middle beam mechanism comprises a first connecting piece and a second connecting piece; the first glasses body and the second glasses body can rotate by taking a first pin shaft as a support point, so that the glasses can be folded; a third connecting piece capable of containing the width of a finger is arranged at the outer side of the first glasses body; a fourth connecting piece capable of containing the width of the finger is arranged at the outer side of the second glasses body; two first drag hooks are respectively arranged at the upper side and the lower side of the head of the first glasses leg; two first buckling positions are respectively arranged at the upper side and the lower side of the head of the second glasses leg; and the first drag hooks are matched with the first buckling positions. Therefore, the glasses frames are wider than the glasses legs when the glasses are folded, namely, the first glasses body and the second glasses body are locked by the first glasses leg and the second glasses leg, so that the reasonable proportion of the glasses legs and the glasses frames can be guaranteed.

Owner:苏州高仓健康科技有限公司

Safe wine bottle opener

The invention discloses a safe wine bottle opener which comprises a handle and a bayonet, wherein a round shield is arranged above the bayonet and is stuck on the handle. During practical operation, a used beer bottle cover is ensured to be left in the round shield and is free from being casually bounced, therefore, the safety of the wine bottle opener is greatly improved.

Owner:郭正荣

Cutting mechanism for electronic wire harness processing

InactiveCN112309641ASolve the problem that the wire harness needs to be held down by hand all the timeSolve the pressing problemManufacturing wire harnessesGear wheelEngineering

The invention relates to the technical field of wire harness processing devices, in particular to a cutting-off mechanism for electronic wire harness processing, and provides the following scheme forsolving the problem that in the prior art, when an electronic wire harness cutting-off mechanism cuts, a wire harness needs to be pressed by hands all the time: the cutting-off mechanism comprises a base, a placing plate fixed at the top of the base and a cutter mounted at the top of the base; two side plates are fixed to the top of the base and located on the same side of the containing plate, arotating shaft is rotatably connected between the two side plates, a pressing plate is fixed to the outer portion of the rotating shaft, one end of the rotating shaft extends to the outer side of oneside plate, and a gear is fixed to the end, located on the outer side of the side plate, of the rotating shaft. The mechanism is reasonable in structure and easy to operate, an electronic wire harnesscan be conveniently pressed when cut off, the hand can be loosened after the wire harness is pressed, then the hand can be freed to operate other components, and the mechanism is convenient for an operator to use.

Owner:CHANGSHU DACHUAN ELECTRONIC CO LTD

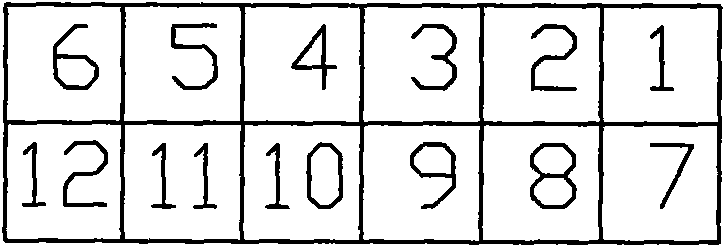

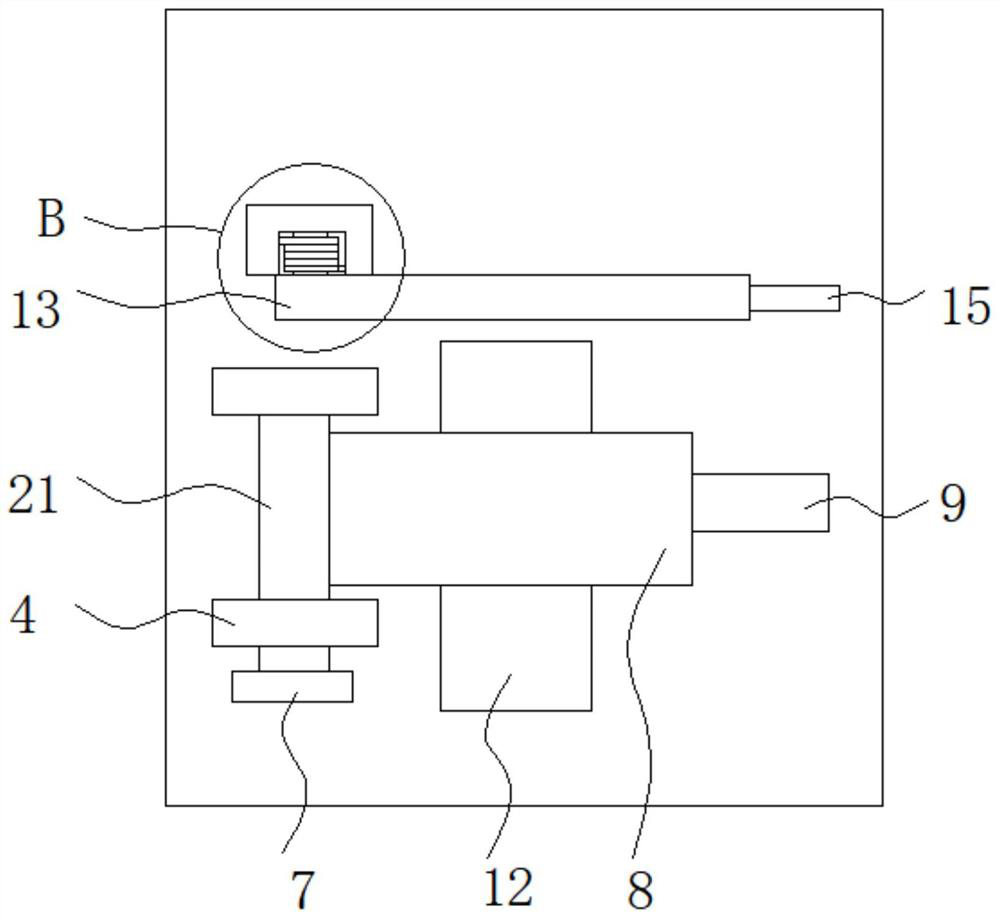

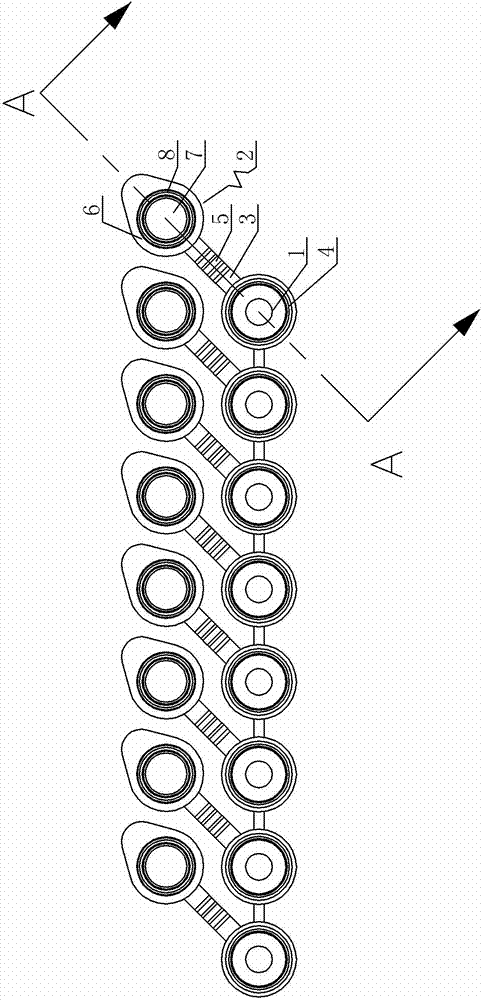

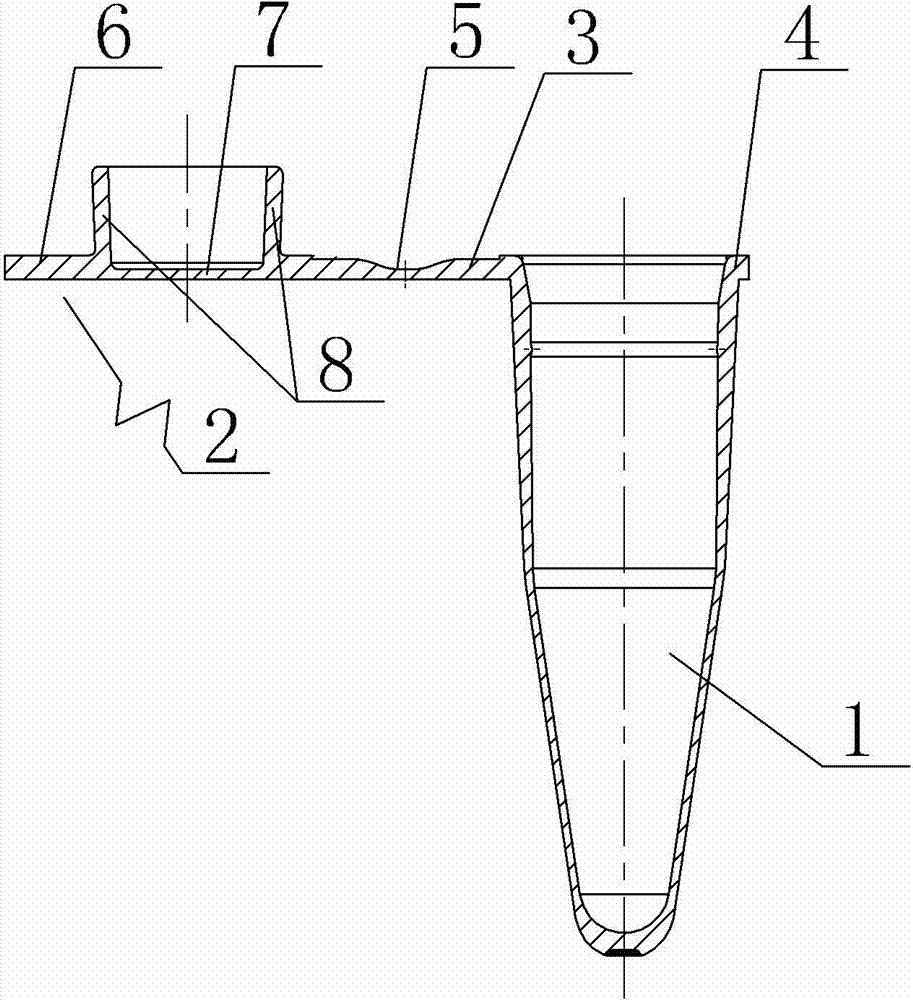

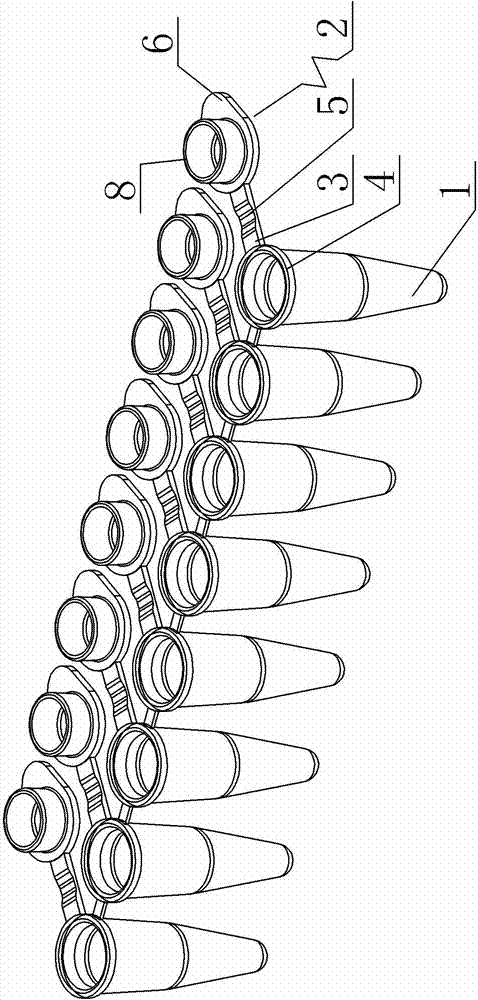

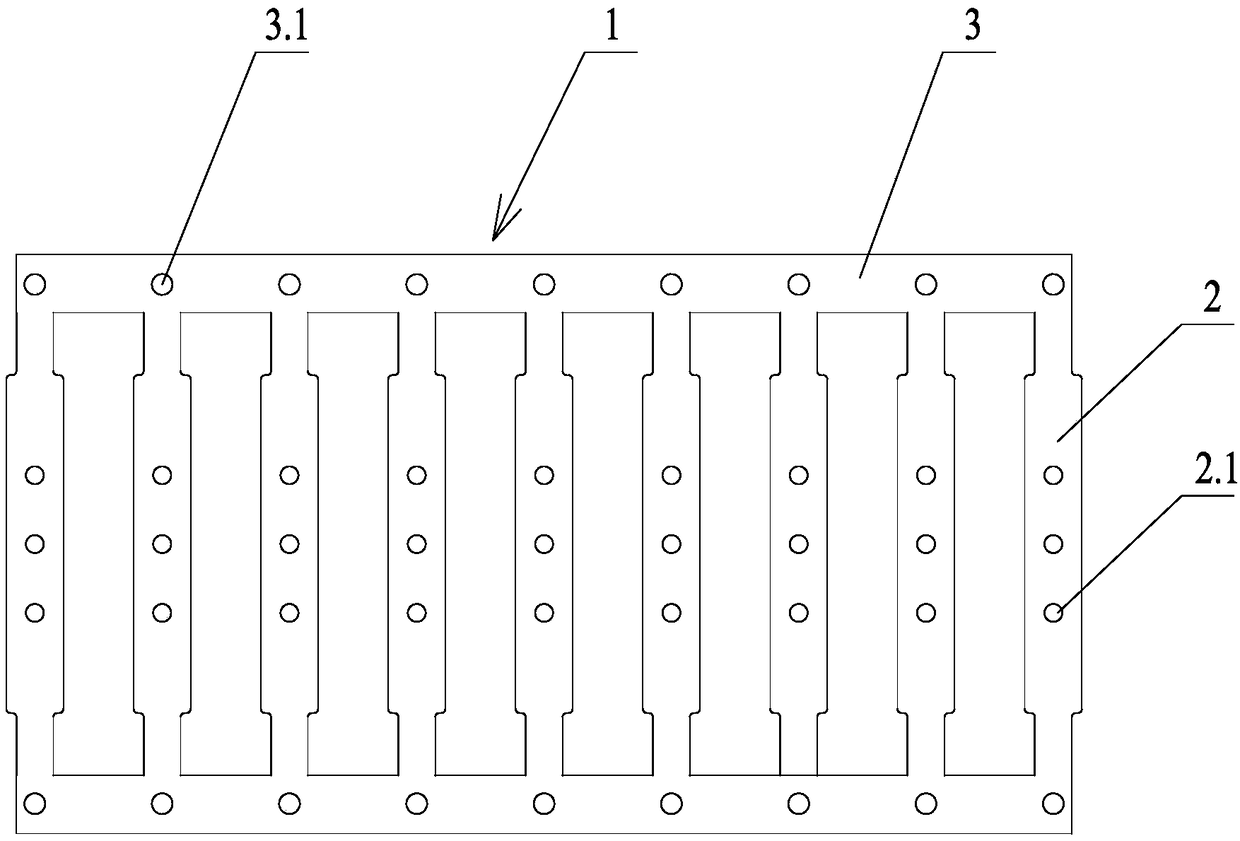

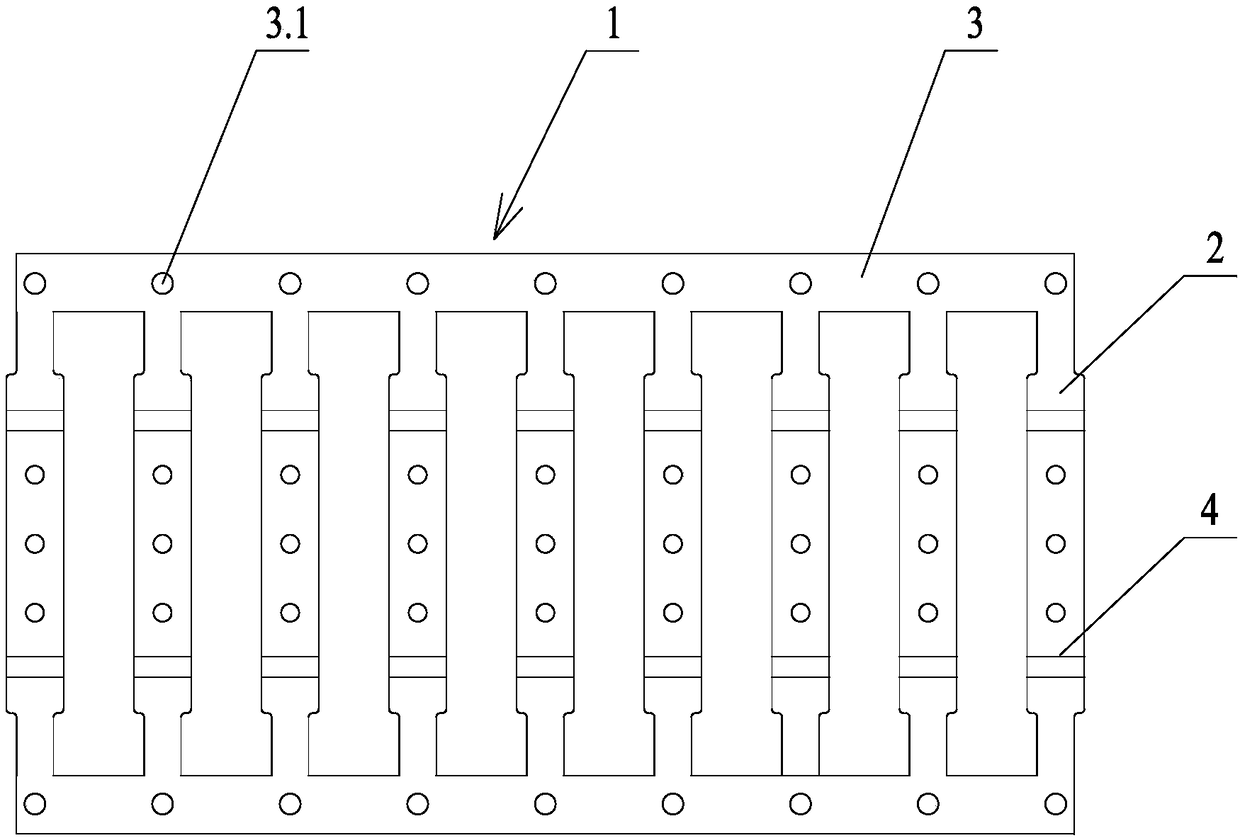

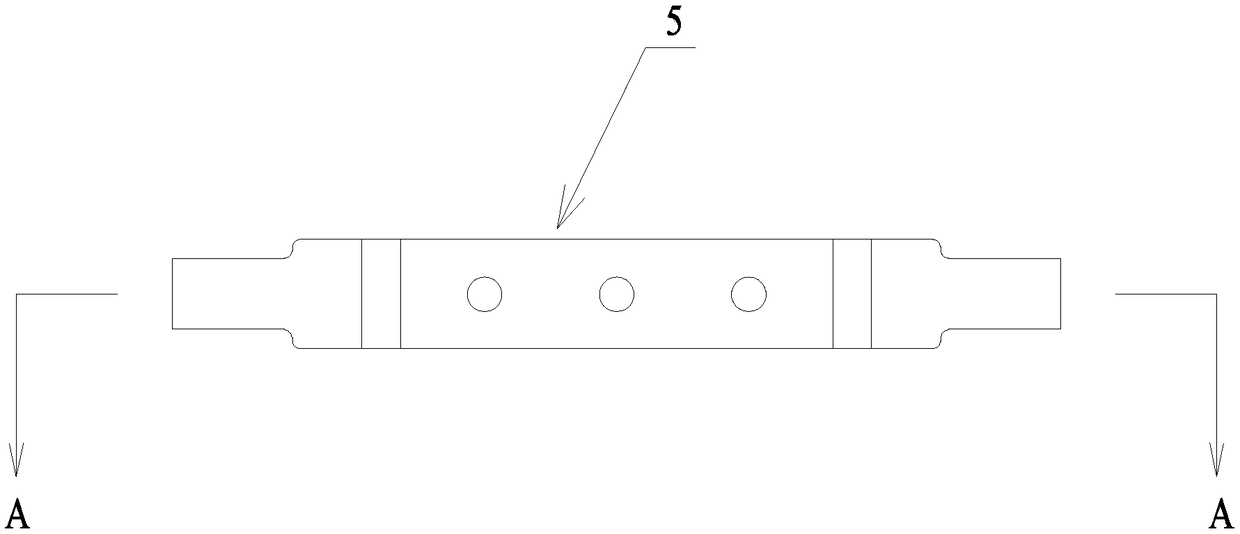

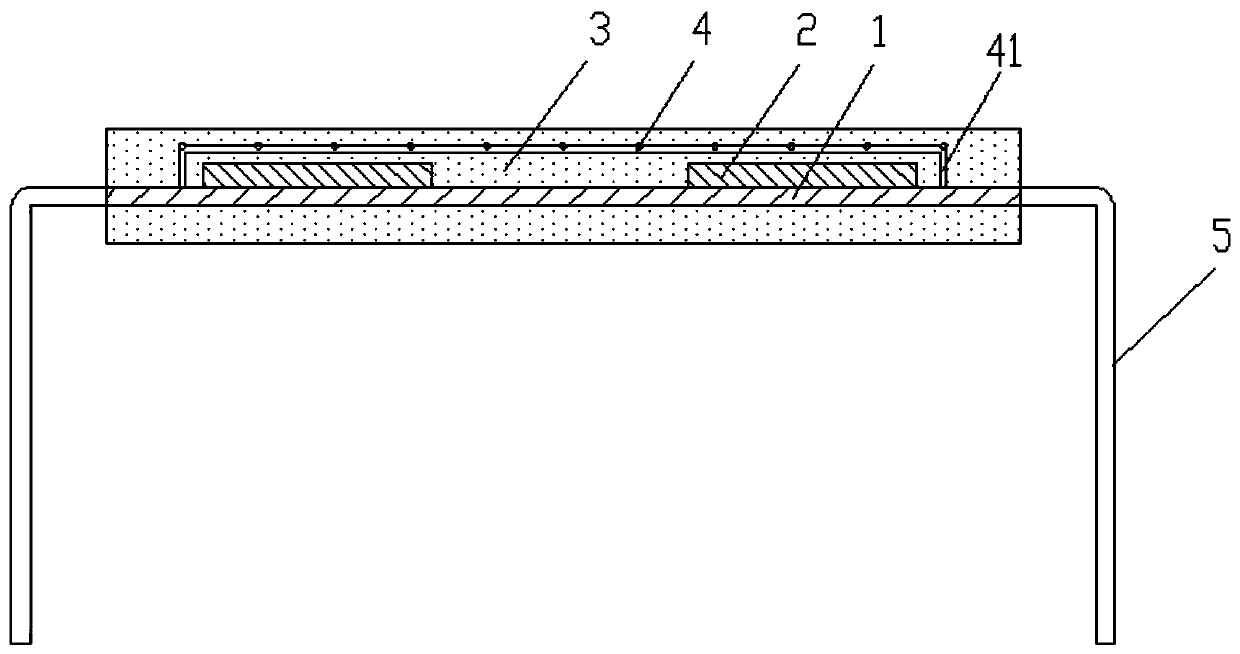

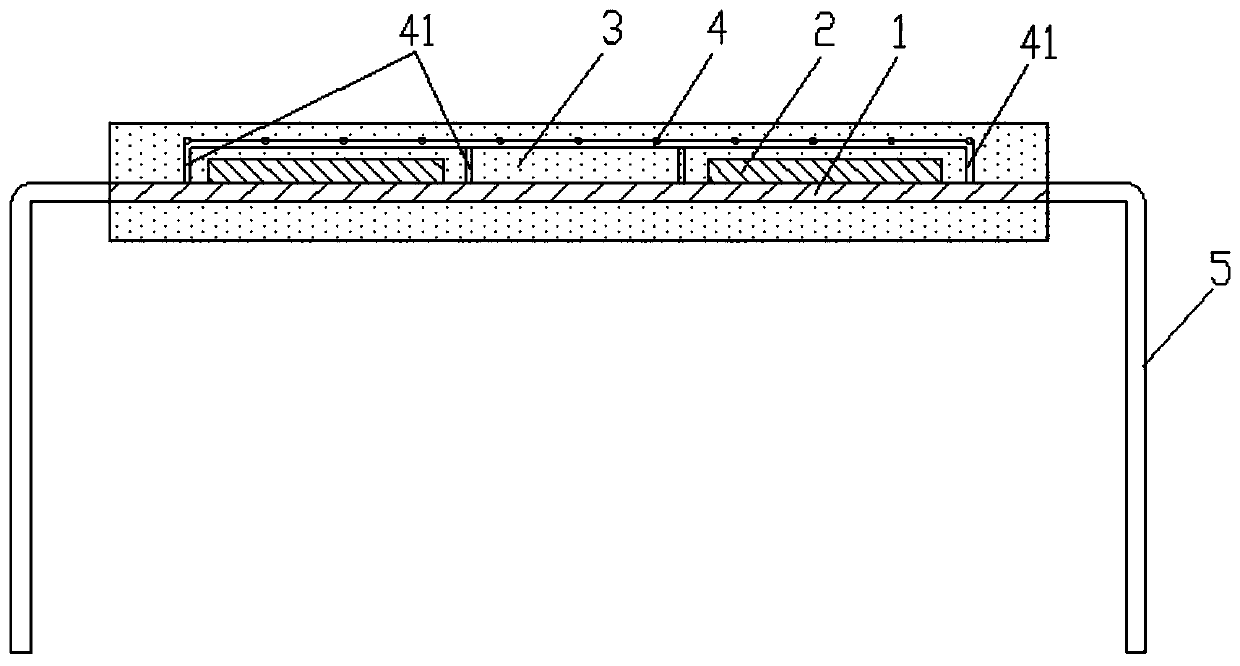

Polymerase chain reaction eight-cascade calandria structure with cover

InactiveCN102925343AEasy to openWon't bounceBioreactor/fermenter combinationsBiological substance pretreatmentsInterference fitEngineering

The invention provides a polymerase chain reaction eight-cascade calandria structure with a cover, which ensures that a test tube occupies small space and is convenient to take and place. The structure comprises tube bodies and a cover and is characterized in that eight tube bodies are connected to form a cascade calandria body through a tube body connecting piece; the orifice of each tube body is connected with the cover through a corresponding hinge structure; the middle joint of the hinge is of a thin-wall structure; the diameter of the round surface of the cover is greater than that of the orifice; the cover covers the orifice, and the part extending out of the orifice is of a brim structure; the central part of the cover is of a thin-wall round-surface structure; and a guide sleeve of the cover after covering is in interference fit with the inner wall of the orifice.

Owner:WUXI NEST BIOTECHNOLOGY CO LTD

folding glasses

The invention discloses a pair of folding type glasses which comprise a first glasses leg, a second glasses leg, a first glasses body, a second glasses body and a middle beam mechanism for connecting two glasses frames, wherein the middle beam mechanism comprises a first connecting piece and a second connecting piece; the first glasses body and the second glasses body can rotate by taking a first pin shaft as a support point, so that the glasses can be folded; a third connecting piece capable of containing the width of a finger is arranged at the outer side of the first glasses body; a fourth connecting piece capable of containing the width of the finger is arranged at the outer side of the second glasses body; two first drag hooks are respectively arranged at the upper side and the lower side of the head of the first glasses leg; two first buckling positions are respectively arranged at the upper side and the lower side of the head of the second glasses leg; and the first drag hooks are matched with the first buckling positions. Therefore, the glasses frames are wider than the glasses legs when the glasses are folded, namely, the first glasses body and the second glasses body are locked by the first glasses leg and the second glasses leg, so that the reasonable proportion of the glasses legs and the glasses frames can be guaranteed.

Owner:苏州高仓健康科技有限公司

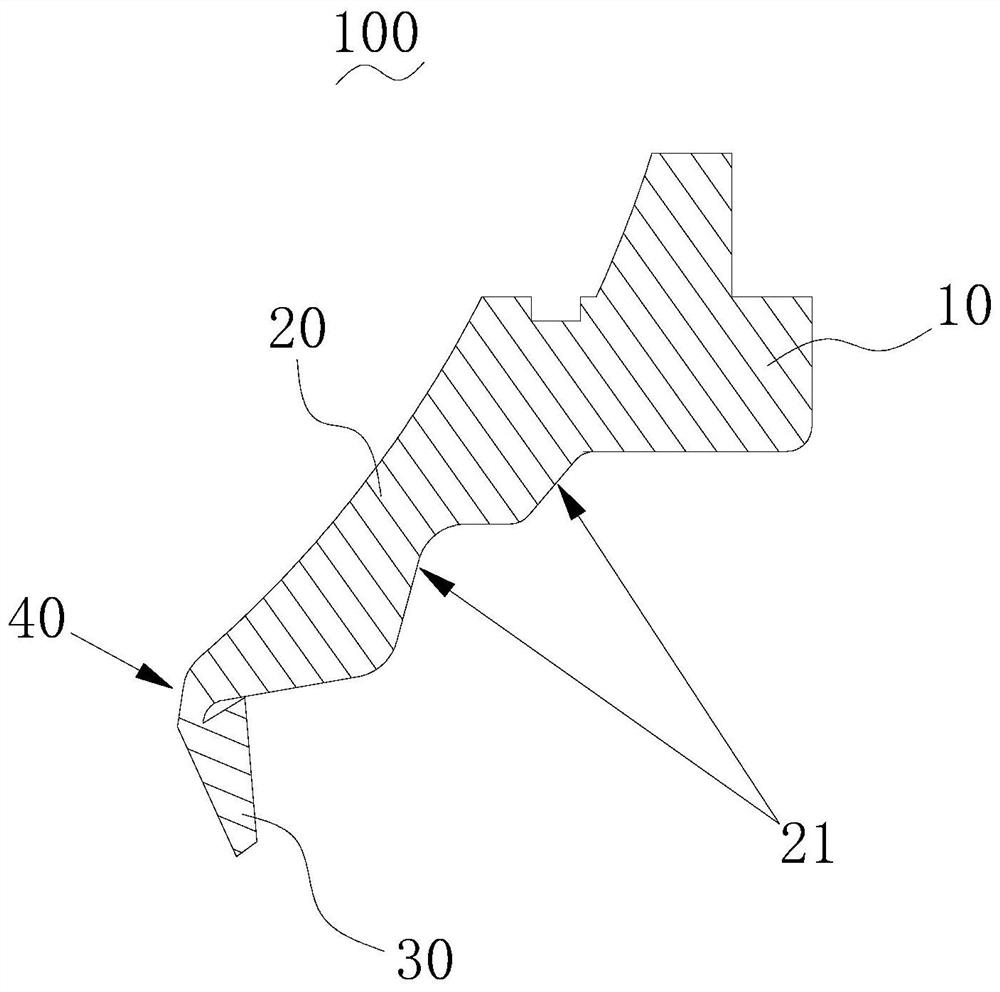

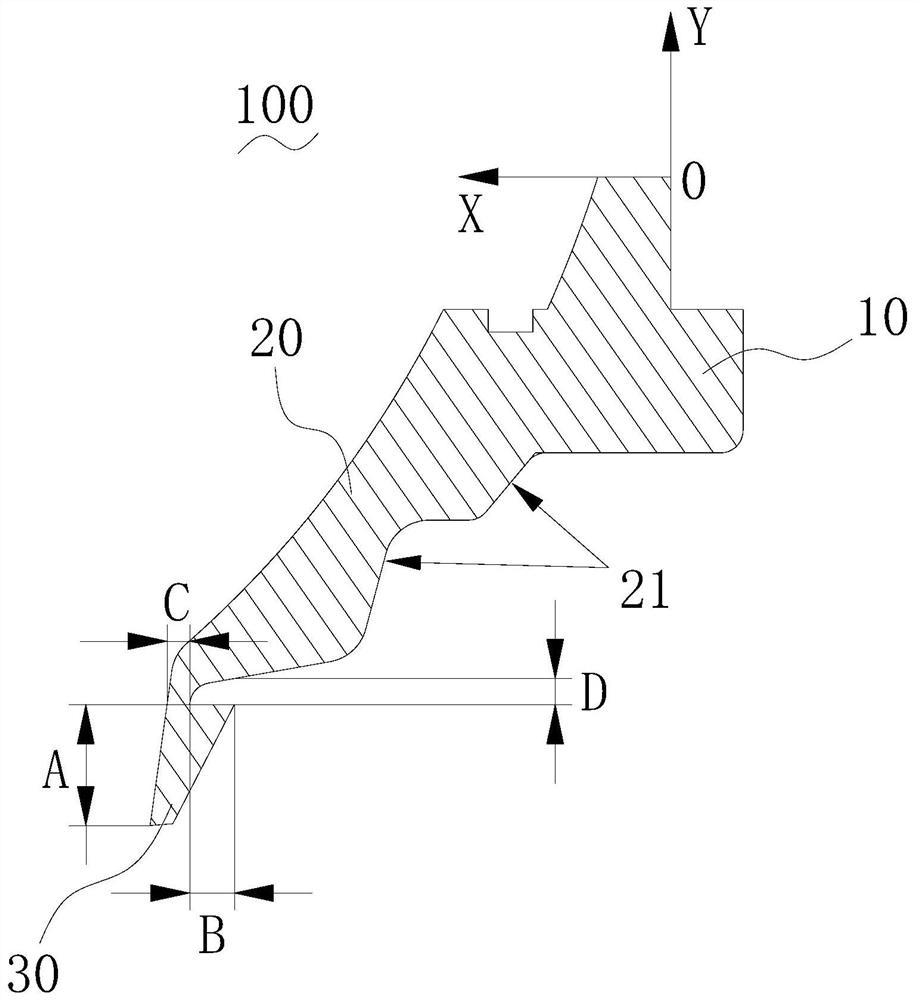

Cleaning scraping strip and cleaning robot

The invention belongs to the technical field of intelligent cleaning equipment, and particularly relates to a cleaning scraping strip and a cleaning robot. The cleaning scraping strip is used for the cleaning robot and comprises: a connecting part, wherein the connecting part is provided with a first end and a second end, and the first end of the connecting part is used for being installed at the bottom of the cleaning robot; and a working part, wherein the working part is provided with a first end and a second end, the first end of the working part is connected with the second end of the connecting part, and the second end of the working part is used for making contact with the ground. A notch is formed in the connecting position of the first end of the working part and the second end of the connecting part and located on the side, away from the advancing direction of the cleaning robot, of the connecting part, and the working part can be bent along the notch, so that at least part of the working part can abut against the connecting part. By applying the technical scheme, the problems that waste water or garbage on the ground cannot be completely scraped by adopting a scraping strip on a cleaning robot in the prior art can be solved.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

Metal hose winding and packaging device

PendingCN114394482ATo achieve a tightly wound effectEasy to removeFilament handlingBinding material applicationElectric machineClassical mechanics

The invention provides a metal hose winding and packaging device, and relates to the field of metal pipelines. The metal hose winding and packaging device comprises a rack, the upper end of the rack is fixedly connected with a winding motor, the output end of the winding motor is fixedly connected with a winding cylinder, the winding cylinder is rotationally connected with the rack, the inner side of the winding cylinder is fixedly connected with a clamping motor, the output end of the clamping motor is fixedly connected with a clamping disc, and the clamping disc is rotationally connected with the winding cylinder. A positioning core is fixedly connected to the inner side of the winding cylinder, a power motor is fixedly connected to the surface of the positioning core, and a transmission wheel is fixedly connected to the output end of the power motor and rotationally connected with the positioning core. According to the metal hose winding and packaging device, a pipeline joint is fixed through rotation of the clamping disc, so that the joint cannot bounce up when a pipeline is wound, the wound pipeline is easier to take down through sliding of the guide frame in an inner groove of the winding barrel, the effect of tight winding of the metal hose is achieved, and the problem that the joint bounces up when the metal hose is wound is solved.

Owner:孙红伟

Safety automatic umbrella folding and unfolding structure

The invention relates to a safety automatic umbrella folding and unfolding structure which comprises ribs, an upper nest, a lower nest, a middle bar and an umbrella head, wherein the middle bar is provided with a plurality of sections of telescopic joint pipes and is internally provided with an umbrella unfolding spring; the ribs are provided with umbrella folding springs; the umbrella head is internally provided with a bullet for controlling automatic folding and unfolding and the bullet is connected with an umbrella unfolding line; the umbrella unfolding line is led out of the middle bar, and then goes around the lower nest and finally is connected to the upper nest or the joint pipes of the middle bar, which is fixed with the upper nest; or the umbrella unfolding line is led out of the middle bar and is directly fixed on the lower nest; a turntable is arranged in the umbrella head; a middle bar line is connected with and coiled on the turntable; and the middle bar line upwards penetrates out and then is connected to the upper nest or the joint pipes of the middle bar. The invention can control the unfolding and the folding of an umbrella surface through the umbrella unfolding line and control the folding of the middle bar through the middle bar line, therefore, during the folding of the middle bar, the middle bar can not be flicked even unintentionally loosened the pressing of the middle bar and is always in the safety state.

Owner:张书闵

A manufacturing process of automobile insert damping block

The invention relates to a manufacturing technique for car insert damping blocks. The manufacturing technique comprises the following steps that produced-in-advance stainless steel framework pieces for the damping blocks and with the material model being 301 are taken for later use; grease dirt of the surfaces of the stainless steel framework pieces for the damping blocks are removed; the stainless steel framework pieces for the damping blocks are subjected to activating treatment; the activated stainless steel framework pieces for the damping blocks are placed into a drying oven to be dried; the stainless steel framework pieces for the damping blocks are heated in a vacuum furnace under the oxygen environment; the stainless steel framework pieces for the damping blocks are subjected to closing treatment; the stainless steel framework pieces for the damping blocks are dried; sulfuration is conducted; and cutting is conducted. Through the manufacturing technique, the surfaces of obtained good-color-and-lustre stainless steel framework unit plates are each provided with a golden oxidation film, corrosion resistance is excellent, the tensile strength is large, and the Vickers hardness is high; damping rubber blocks are high in hardness, large in tensile strength and high in elongation; after high-temperature ageing is conducted at the temperature of 90 DEG C for 94 h, change of the hardness is small, and the elongation is large; heat resistance is high; and stainless steel damping block units meet the requirement that the damping rubber blocks are not bounced off from the stainless steel framework unit plates under the effect of 20 N.

Owner:无锡绿缘汽车零部件有限公司

Horizontal intelligent alarm device for road well safety protection

The invention discloses a horizontal intelligent alarm device for road well safety protection. The horizontal intelligent alarm device comprises a fixing ring, wherein a fixing plate is arranged on the fixing ring, connecting members are arranged on the fixing plate, and the fixing plate is movably connected with the fixing ring; a groove is arranged at the upper end of the fixing plate, a controller is arranged in the groove, a warning post is arranged on the controller, and the warning post is movably connected with the controller; a controller switch is arranged on the fixing plate, a timeris arranged at the lower end of the control switch, and the timer is electrically connected with the controller; and a fixing box is arranged on one side of the timer, a fixing piece is arranged at the lower end of the fixing box, and an alarm is arranged on one side of the fixing box. The device of the invention is simple in structure and light in weight, a plurality of through holes arranged onthe fixing plate can ensure the water permeability and also reduce the weight of the device, the installation is facilitated, the three connecting members and the fixing ring are arranged to be movable, so that the installation is simpler; and a positioner and a signal sensor arranged on the alarm that is arranged on the device ensure that the device is in a safe state and can carry out monitoring and positioning in time.

Owner:贵阳三嘉五科技创新研发有限公司

A Generator Base with Protective Function

ActiveCN107959373BWon't bounceImprove protectionSupports/enclosures/casingsElectrical and Electronics engineering

The invention discloses a power generator base with a protection function. The power generator base comprises a bottom plate. Two sides of the top of the bottom plate are fixedly connected to first support rods. One side of each of the first support rods is fixedly connected to a second support rod at the top of the bottom plate. The bottoms of second damper blocks are fixedly connected to secondary buffer boards. The invention relates to the technical field of a power generator protection base. According to the power generator base with a protection function, two sides of the top of the bottom plate are fixedly connected to the first support rods, a condition that a power generator does not pop up when the power generator falls to the ground is ensured, the protection of the power generator is stronger, thus the power generator is not damaged after falling to the ground, the damage in falling is reduced, the safety of the power generator is greatly protected, thus the service life ofthe power generator is longer, and the problem that an existing power generator base with a protection function can not maintain the stability of the power generator when the power generator falls tothe ground and can not prevent the popup of the power generator is solved.

Owner:江西省一互电气有限公司

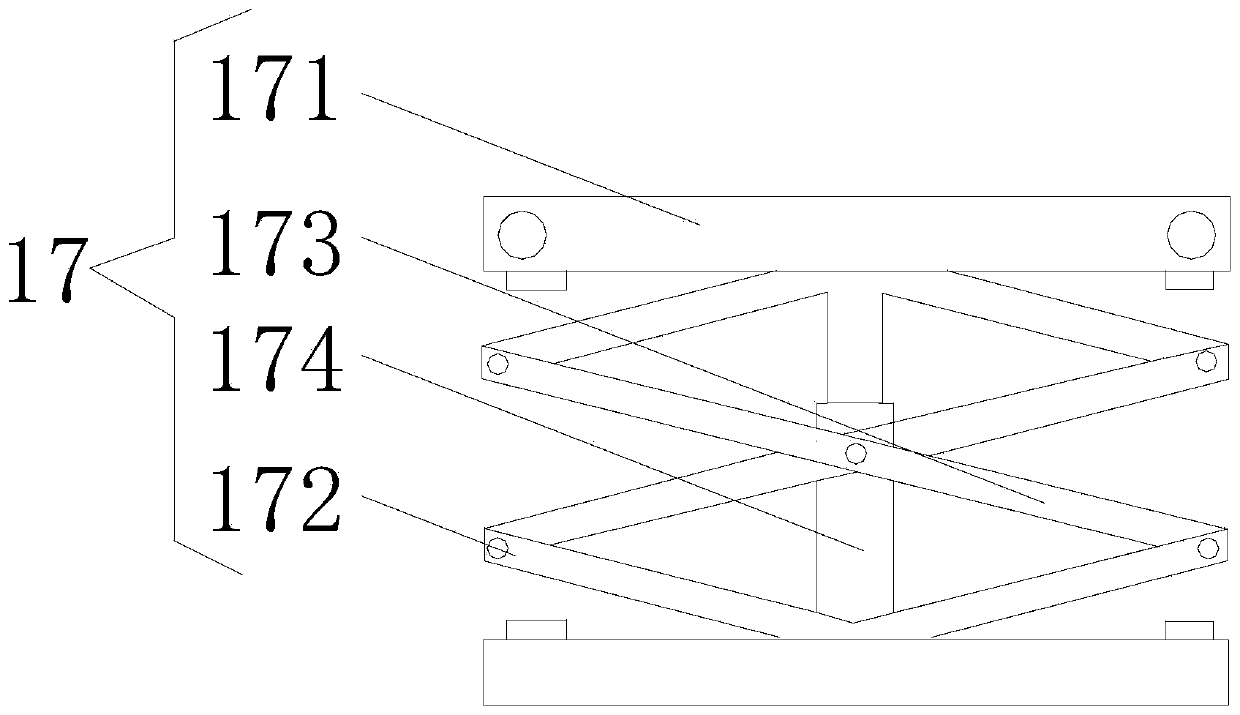

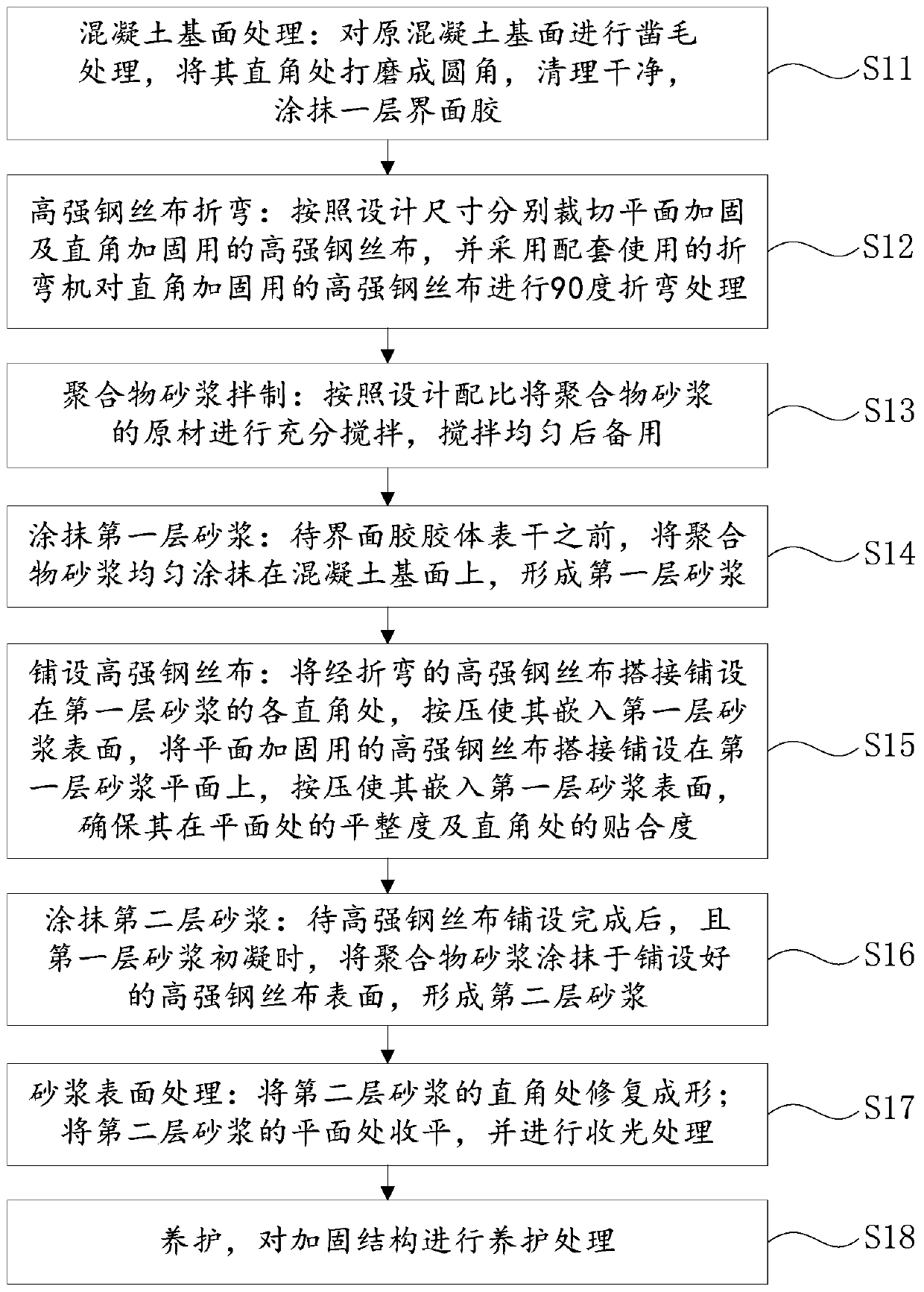

Right angle reinforcing mode for high strength wire cloth

InactiveCN110685455AWon't bounceFacilitate reinforcement construction workBuilding repairsMechanical engineeringChemistry

The invention discloses a right angle reinforcing mode for high strength wire cloth. The mode comprises the following steps: treating a concrete basal plane; bending the high strength wire cloth; mixing polymer mortar; smearing a first layer of mortar; paving the high strength wire cloth; smearing a second layer of mortar; treating the surface of the mortar; and curing the mortar. The right anglereinforcing mode for high strength wire cloth avoids phenomena of upwraps and bumps of the high strength wire cloth of the reinforced right angle of a building, so that the reinforcing quality is improved.

Owner:CARBON TECH CO LTD

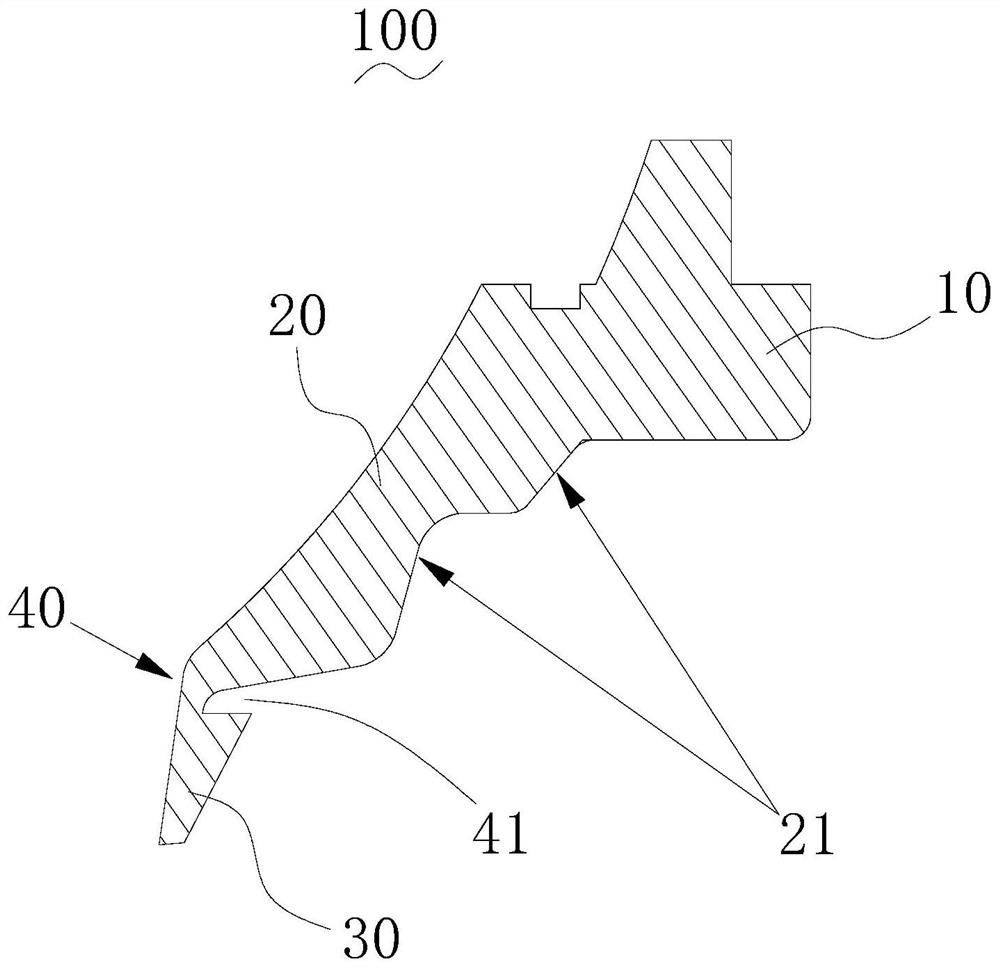

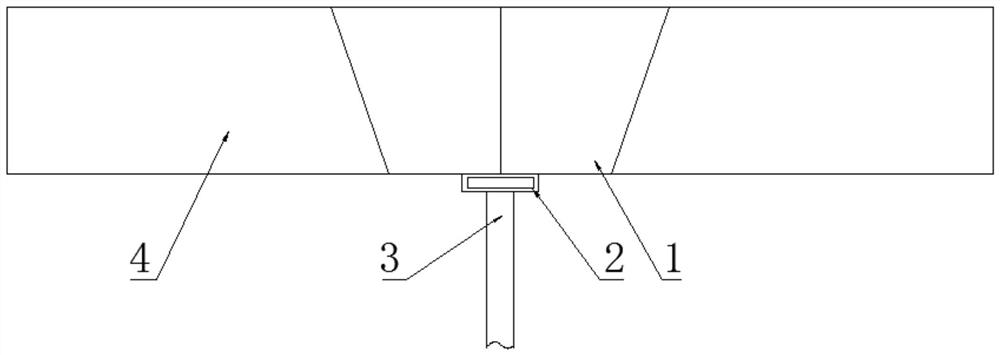

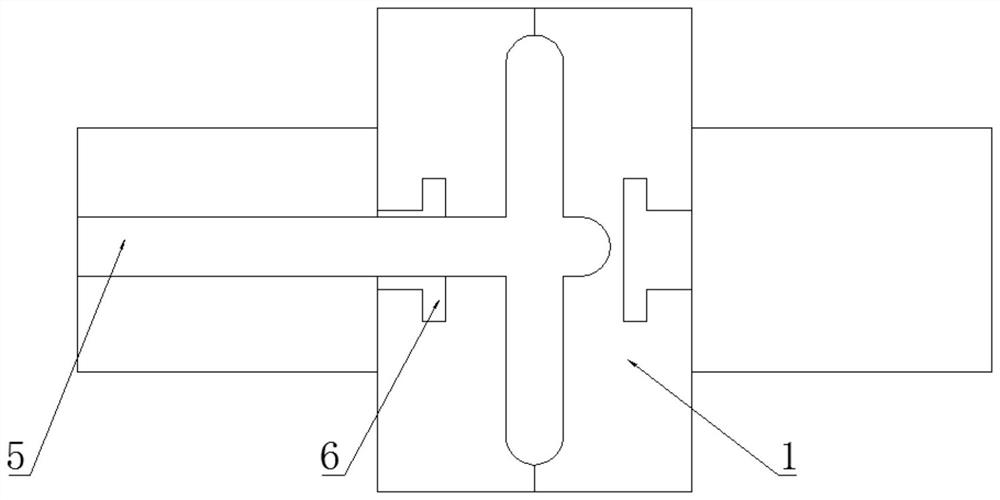

Glue inlet device with latent side sprue

The invention discloses a glue inlet device with a latent side sprue, and belongs to the technical field of injection moulding equipment. The glue inlet device comprises a convex mould and a concave mould, wherein a moulding cavity is formed between the concave mould and the convex mould; a mounting hole is formed in the convex mould; a runner and an ejector rod are sequentially arranged in the mounting hole from top to bottom; the top of the ejector rod abuts against the bottom end of the runner; the runner communicates with the side sprue; the side sprue communicates with the moulding cavity; the inner side wall of the mounting hole tilts downwards towards the ejector rod; the inner side walls of the mounting hole are correspondingly in sliding connection to sprue plates separately in atilting direction; and the top of the runner abuts against the bottoms of the sprue plates at the two sides. While the ejector rod ejects the runner and the side sprue, the side sprue can separate thesprue plates at the two sides, and can pass through from the sprue plates at the two sides; and the ejector rod ejects the runner, the side sprue and an injection moulded product to the outside of the convex mould, so that a poured material head is not bounced off while ejected out, and the side surface of the product is not damaged by pulling.

Owner:遵义群建塑胶制品有限公司

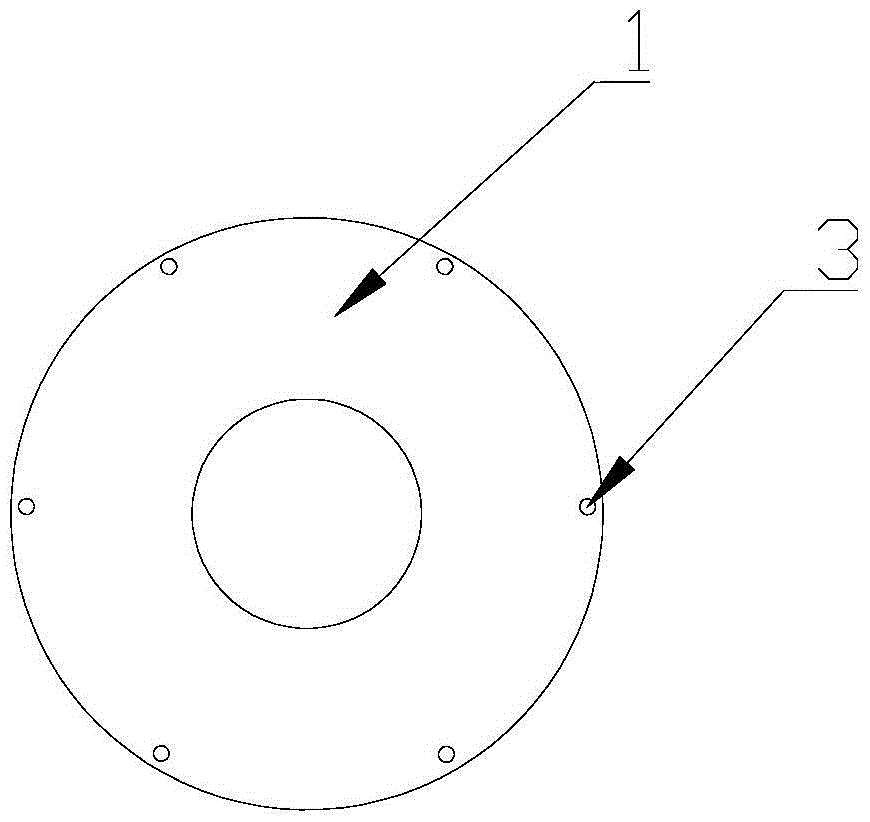

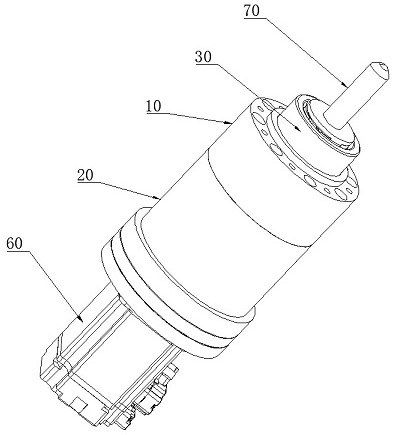

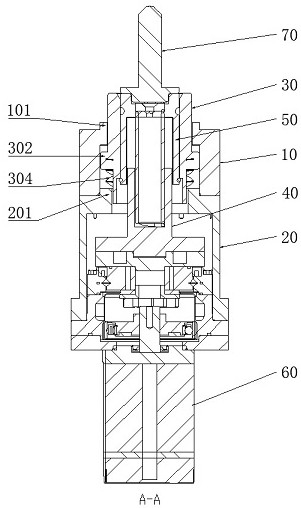

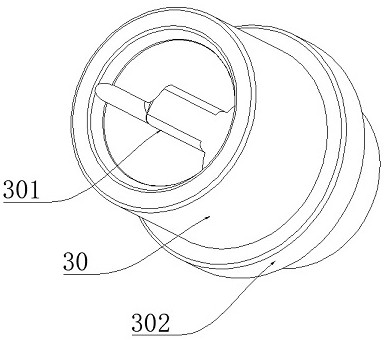

A New Type of Adjusting Dot Stability Device for Prober Inker

Owner:JIANGSU UNION SEMICON

A wire harness cutting device for instrument production

Owner:常州中端电器有限公司

Packaging structure and manufacturing method thereof

ActiveCN111354695AImprove cooling effectImprove securitySemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention provides a packaging structure and a manufacturing method thereof, the packaging structure comprises a heat conduction bottom sheet, a chip, pins and a plastic packaging material layer;the chip is fixed on the heat conduction bottom sheet, the chip is electrically connected with the pins, the packaging structure also comprises a heat conduction net, the heat conduction net wraps thechip, and the heat conduction net is embedded in the plastic packaging material layer. According to the packaging structure provided by the invention, the heat conduction net is embedded in the plastic packaging material layer, so that the heat dissipation performance of the packaging structure is improved, and the problem that heat around a chip cannot be dissipated in time due to poor heat dissipation of a plastic packaging material in an existing packaging structure is effectively solved; uniform heating of an injection molding material is facilitated, and the expansion coefficient of theinjection molding material is reduced, so that the problem that leads are easy to break away due to non-uniform injection molding heating in an existing packaging structure is effectively solved; besides, when accidental explosion occurs, the chip is wrapped by the heat conduction net so that the chip is enabled not to bounce off the shell, and thus safety of the packaging structure can be enhanced.

Owner:GREE ELECTRIC APPLIANCES INC +1

Simple anchor cable machining platform device

The invention discloses a simple anchor cable machining platform device. The simple anchor cable machining platform device comprises a U-steel support and two steel plates which are arranged on the U-steel support and used for clamping and releasing steel strands; the two steel plates are connected through a plurality of screw rods and clamp the steel strands; and the steel plates are provided with steel plate center holes. According to the simple anchor cable machining platform, the two steel plates are arranged to limit and restrain the wire outlet manner of the steel strands, and the phenomenon that the steel strands hurt people due to ejecting out is avoided. During use, the bundled steel strands are placed on the U-steel manufacturing support, the two steel plates are arranged on the two side faces of the steel strands, the steel strands are connected and clamped through the multiple screw rods, and when an anchor cable is machined, the steel strands are pulled out from the steel plate center holes formed in the steel plates, and according to the length of the anchor cable, the steel strands are manually pulled out; after being cut, the steel strands cannot eject out so as to hurt people, and therefore the steel strands be more safely manufactured; and efficiency of anchor cable manufacturing is improved. The simple anchor cable machining platform device is suitable for the anchor cable machining field.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Vehicle locking and unlocking mechanism with bolt protection function

PendingCN113211379AWon't bounceRealize power swap and lockMetal-working hand toolsElectrical batteryElectric machinery

Owner:KUNSHAN SIWOPU INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com