Patents

Literature

61results about How to "Solve the problem of oil seepage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

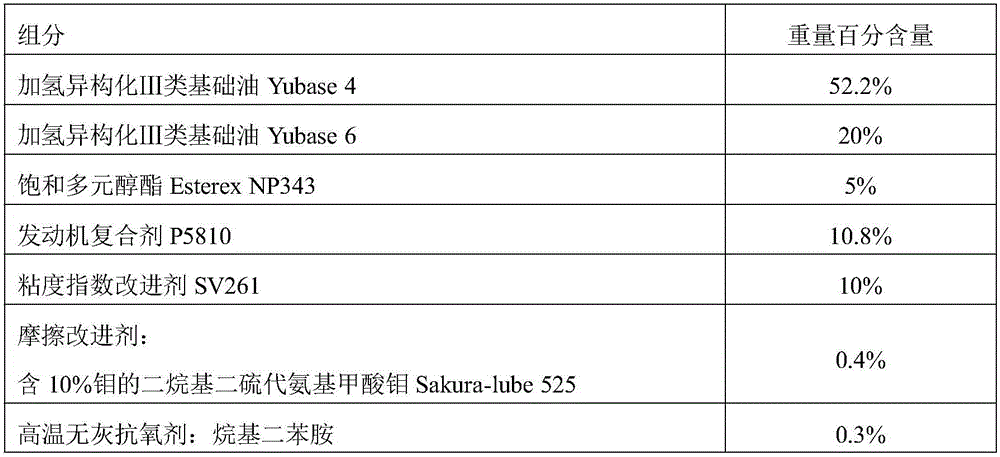

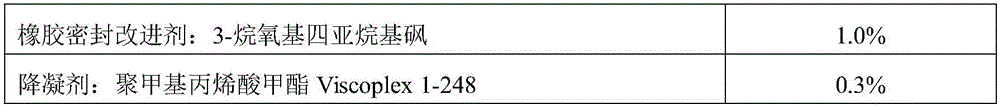

Lubricating oil composition for turbocharging direct injection engine

ActiveCN106190505AImprove high temperature detergency and dispersibilityGood for wear protectionLubricant compositionEngineeringViscosity index

The invention discloses a lubricating oil composition for a turbocharging direct injection engine. The composition is prepared from, by weight, 75-85% of base oil, 7-12% of engine oil complexing agent, 4-12% of viscosity index improver, 0.3-1.0% of friction improver, 0.3-1.0% of high-temperature ashless antioxidant, 0.3-2% of rubber seal improver and 0.1-0.5% of pour point reducer. According to the lubricating oil composition, the content of calcium, phosphorus and molybdenum in finished lubricating oil is reasonably controlled, so that the obtained product has excellent high-temperature oxidation resistance and piston cleanliness, high grease controllability and remarkable anti-wear protective property; the occurrence rate of low-speed preignition of the turbocharging direct injection engine can be effectively reduced, the fuel economy of vehicles can be improved, and the service life of the engine can be prolonged.

Owner:JIANGSU LOPALTECH

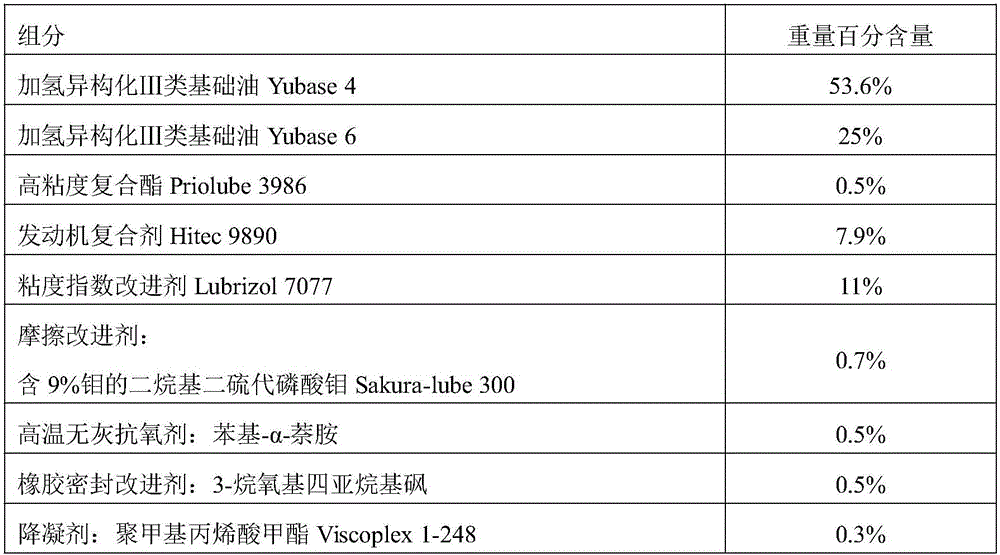

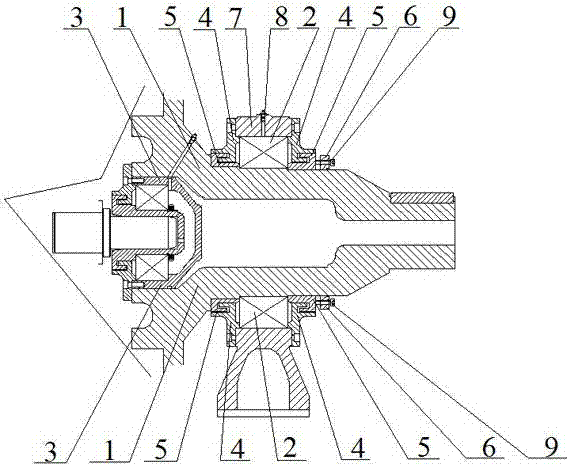

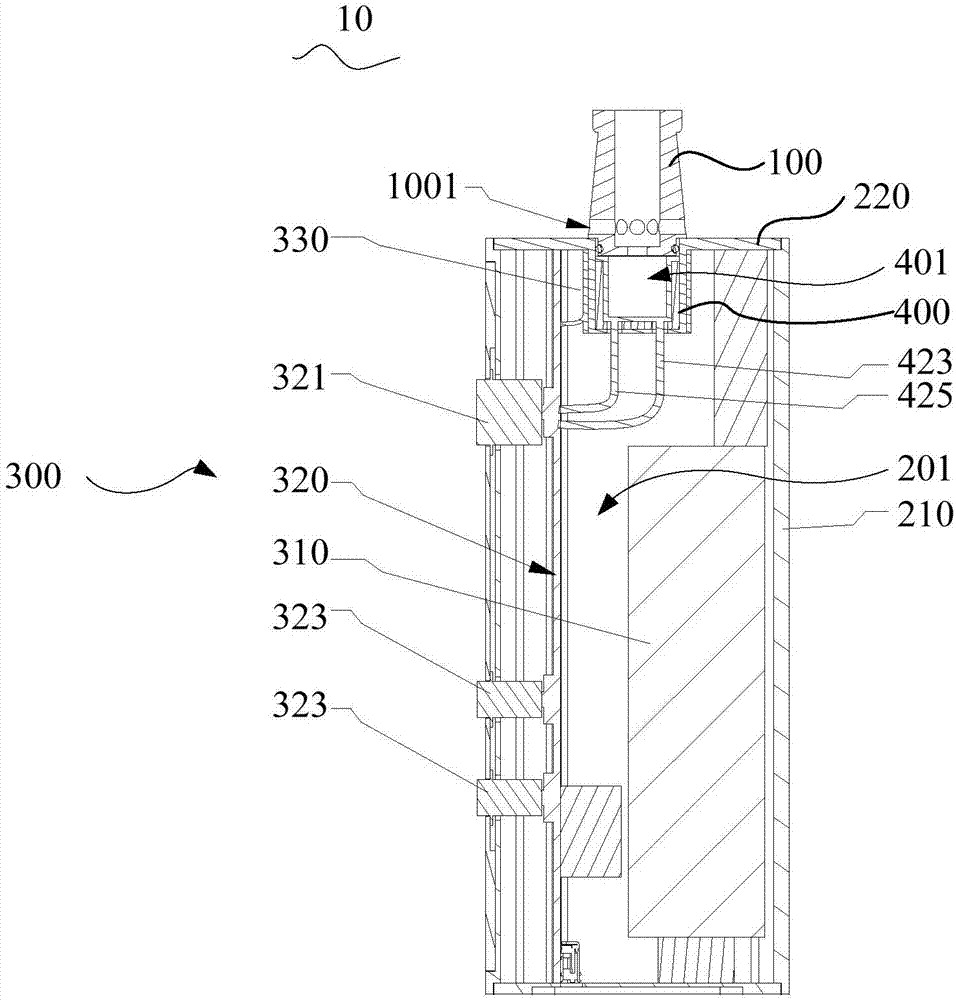

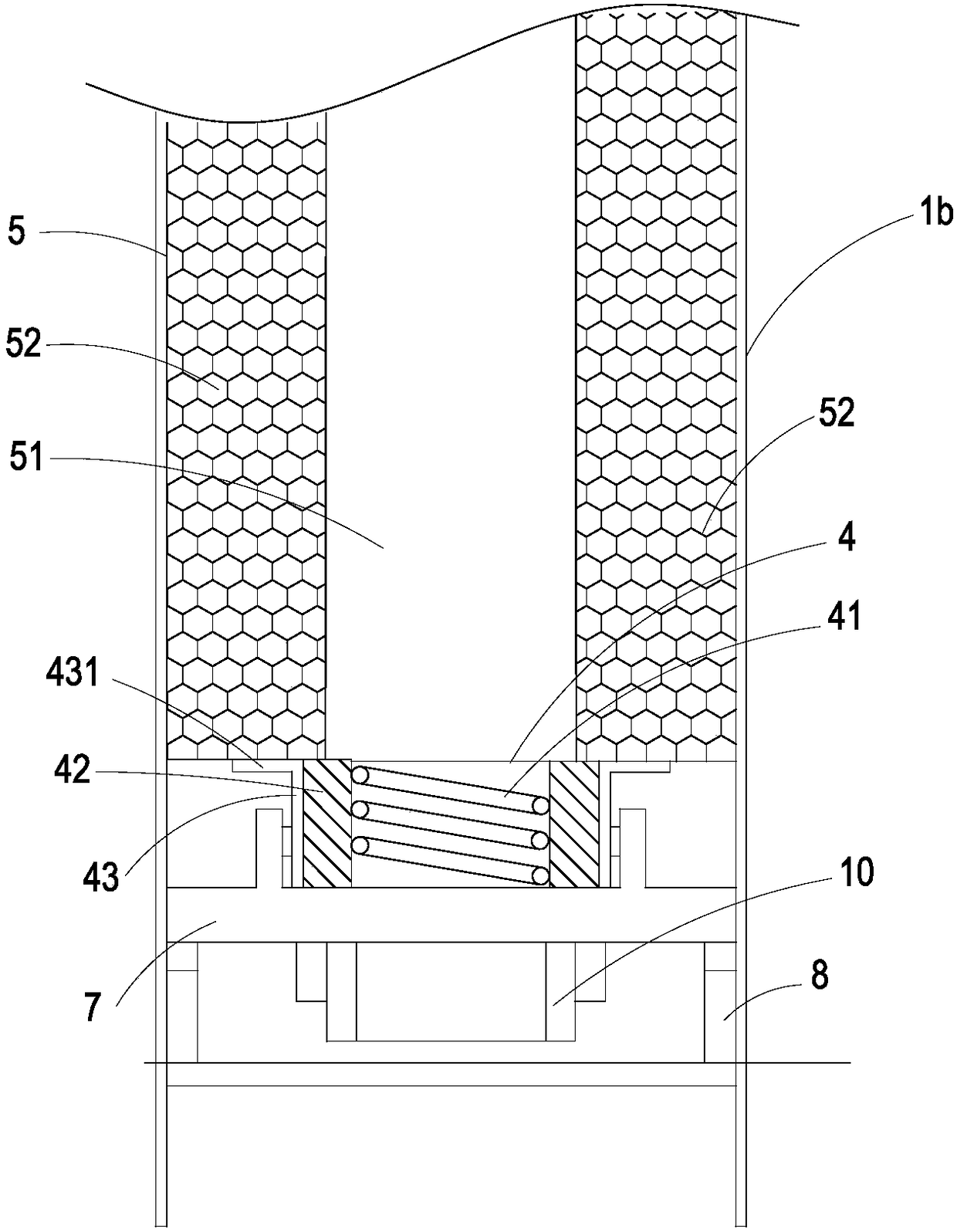

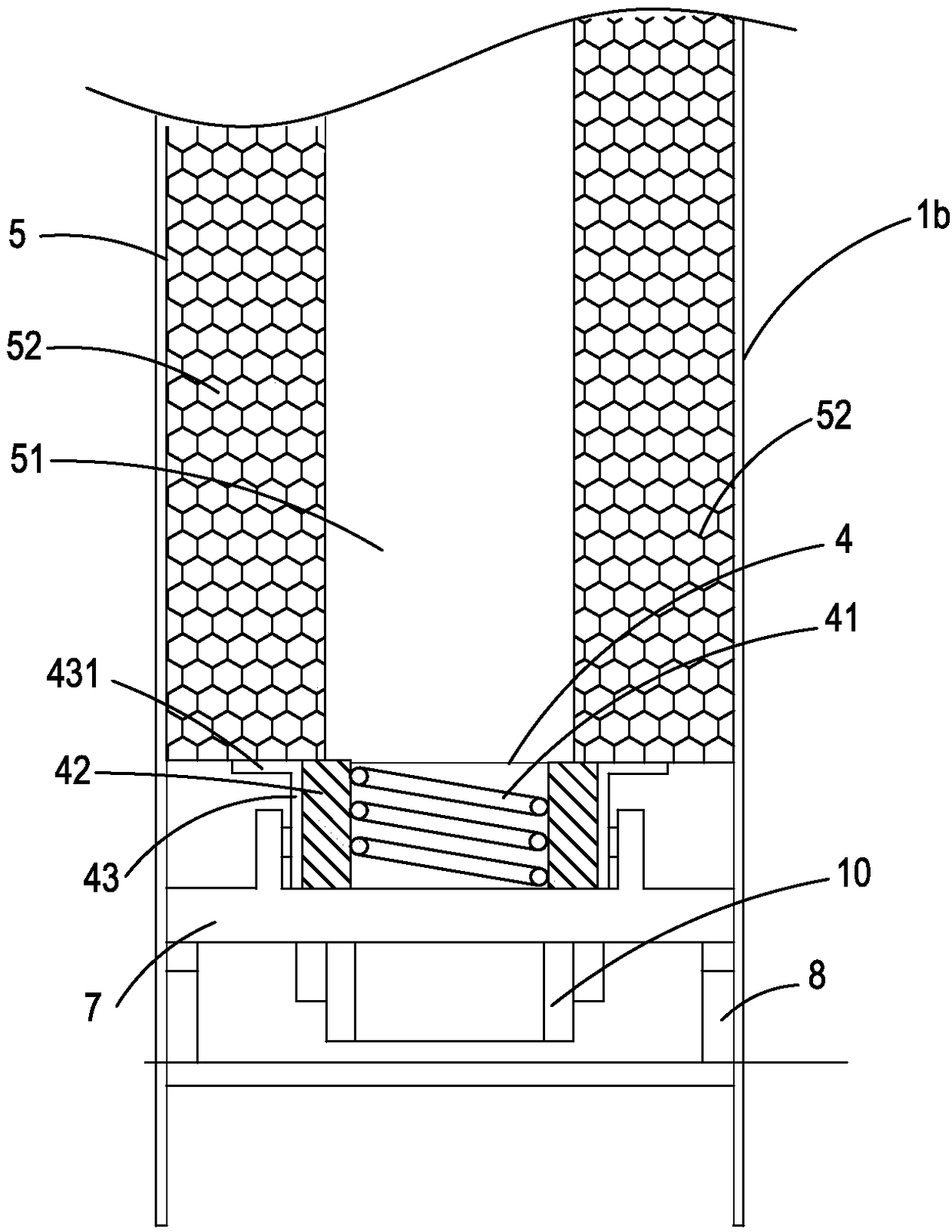

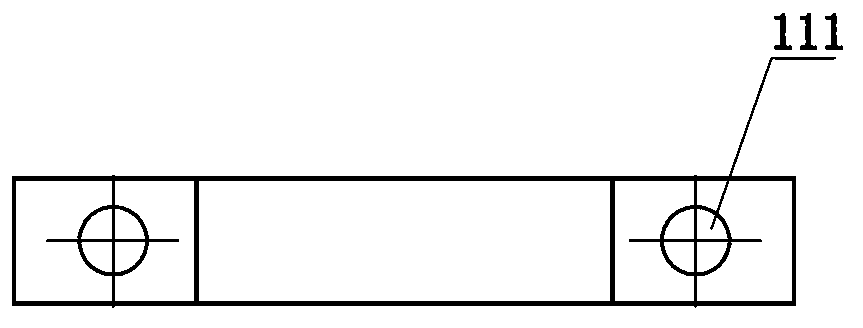

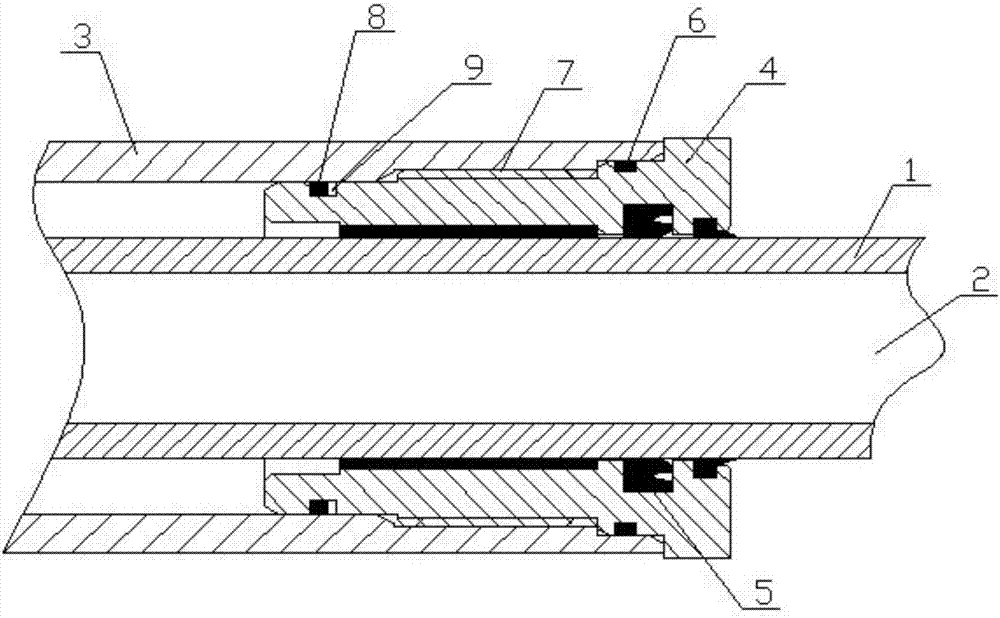

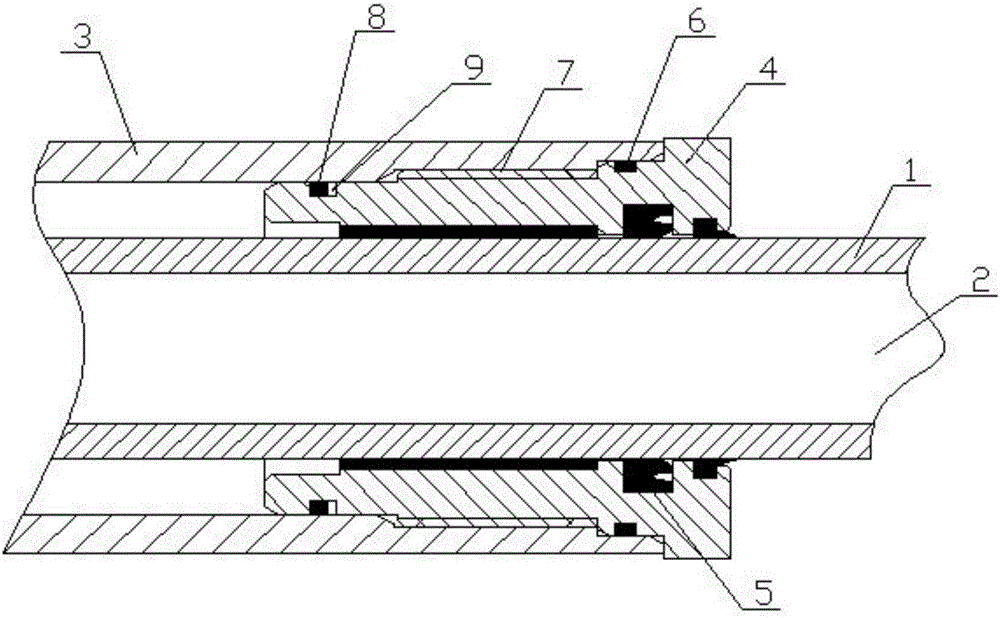

Locking device for vacuum turning roll

InactiveCN102734468AUnable to oozePlay a relieving effectEngine sealsPaper-making machinesEngineeringMechanical engineering

The invention provides a locking device for a vacuum turning roll, which effectively solves the problem of oil leakage due to oil pressure during oiling, saves the cost and largely improves the production efficiency. The locking device comprises a roll neck and a bearing, wherein the roll neck is arranged on a bearing shell, a bearing block is used for fixing the bearing, an oiling opening is arranged on the bearing block, the bearing is fixed at the end part of the roll neck, and bearingcaps are fixedly arranged on the two sides of the bearing. The locker further comprises maze-shaped rings and a retainer ring, wherein the bearing caps and the maze-shaped rings are clamped through corresponding intervals, and the retainer ring fastens the maze-shaped ring on one side through a screw.

Owner:WUXI HONGCHENG PAPER MAKING MACHINERY

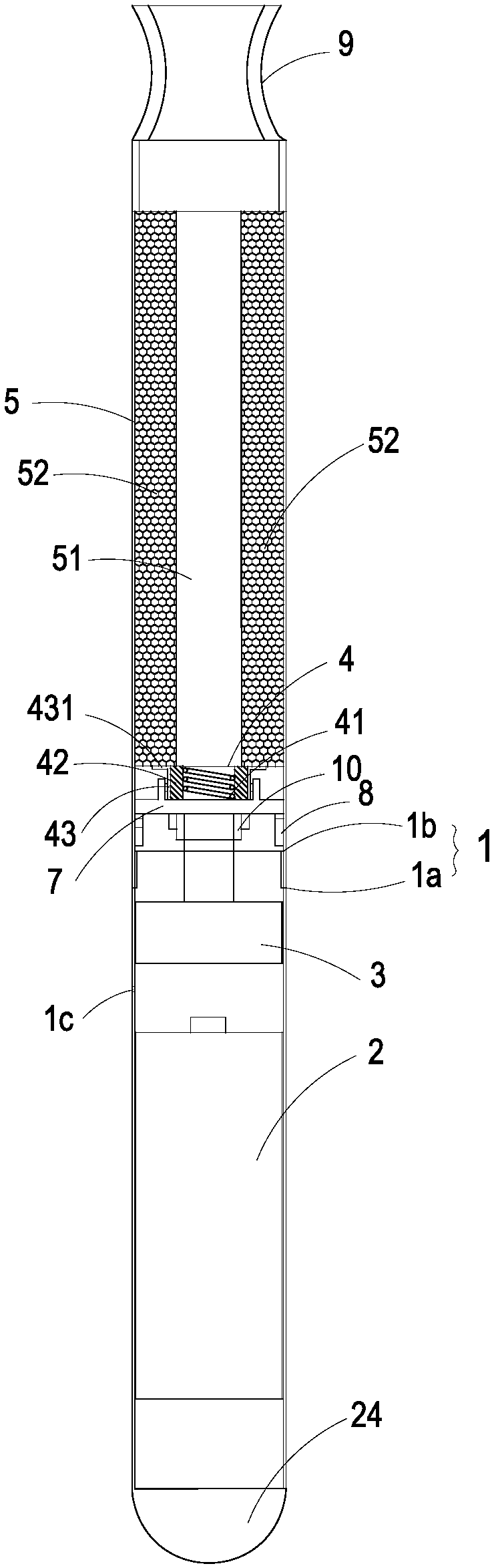

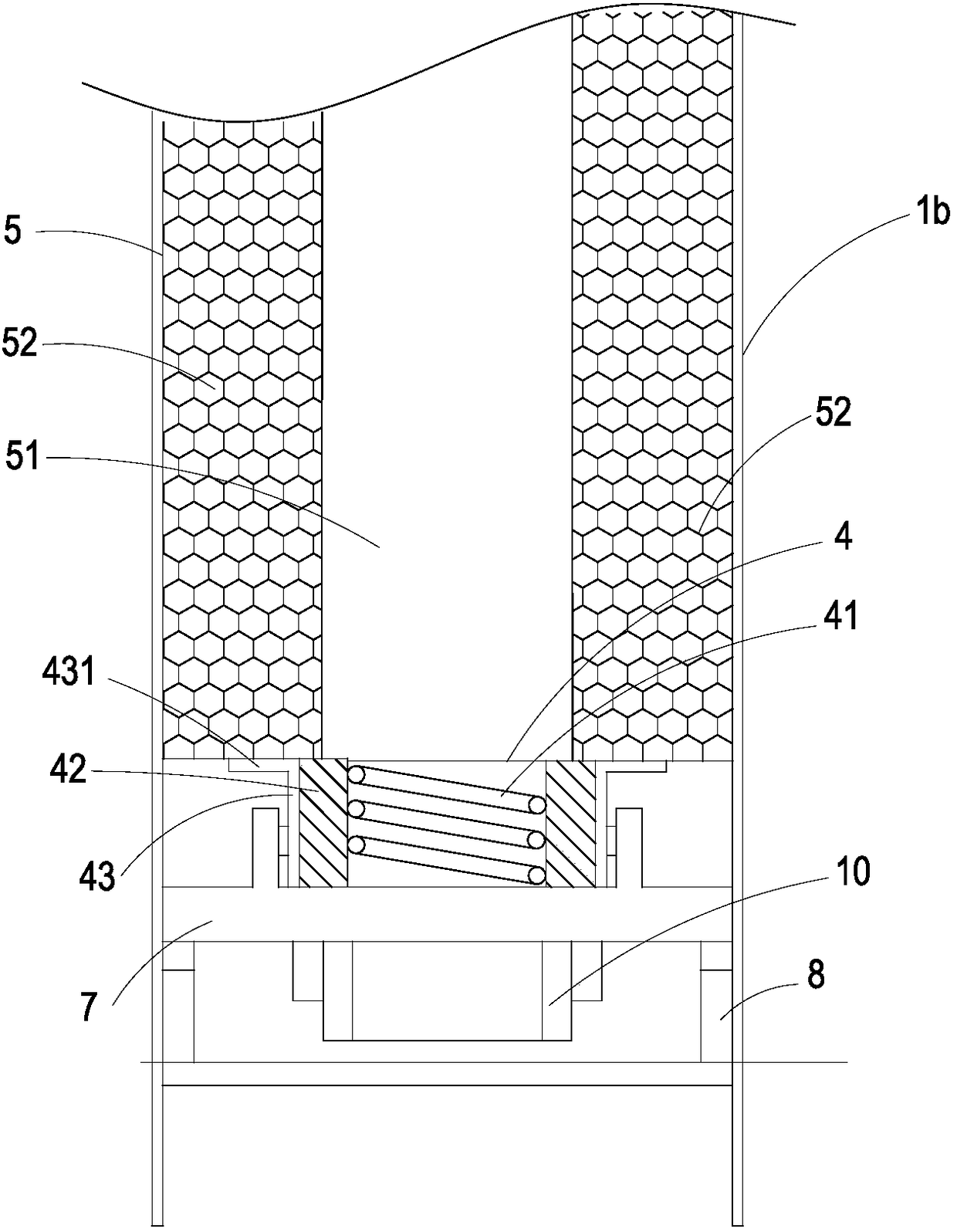

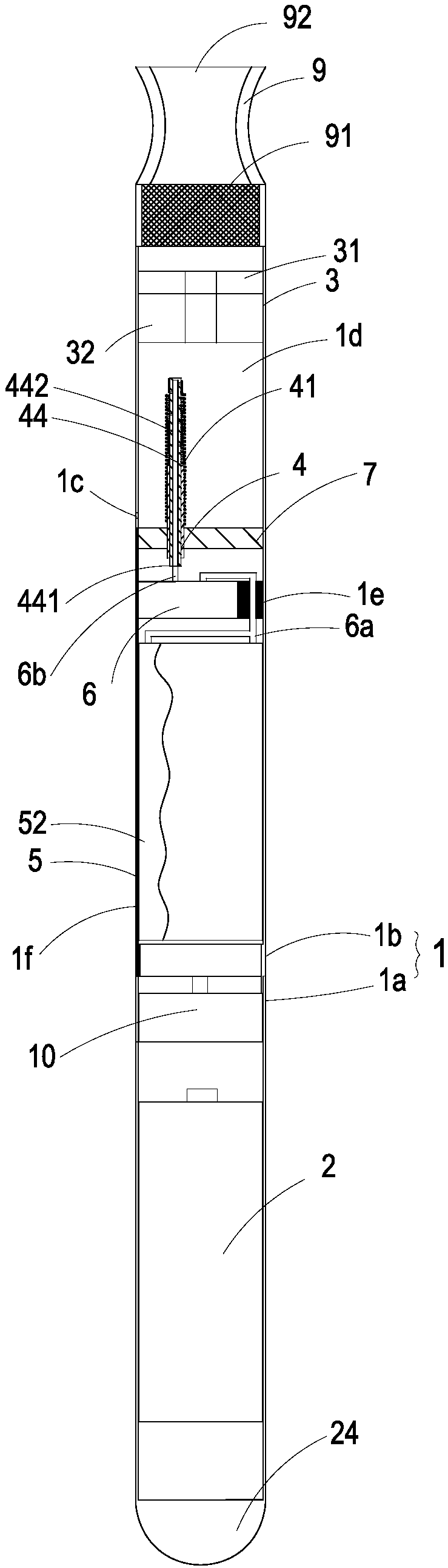

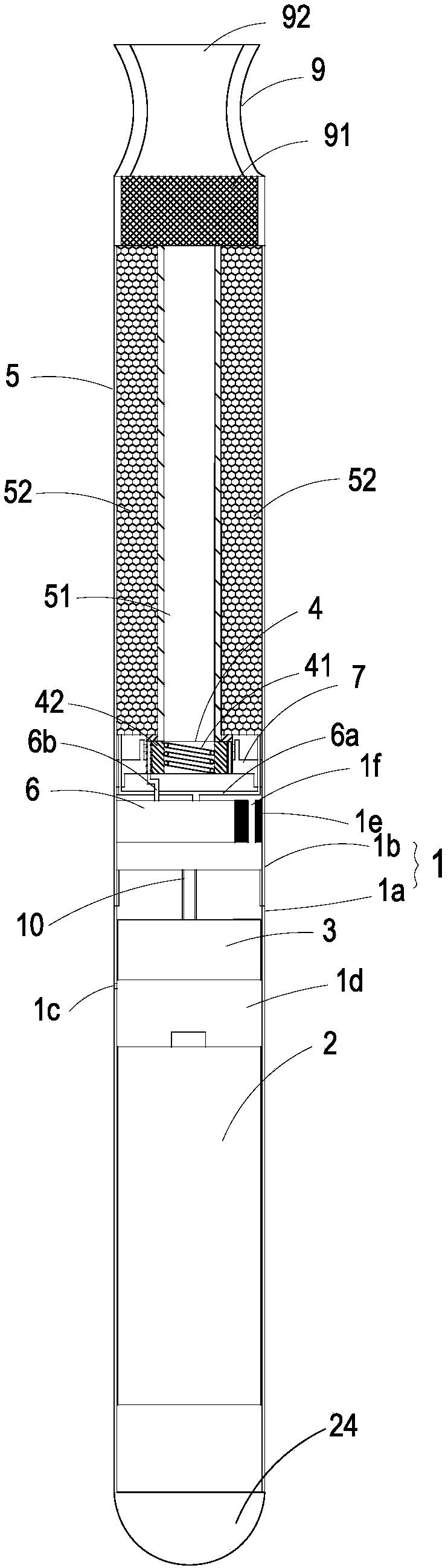

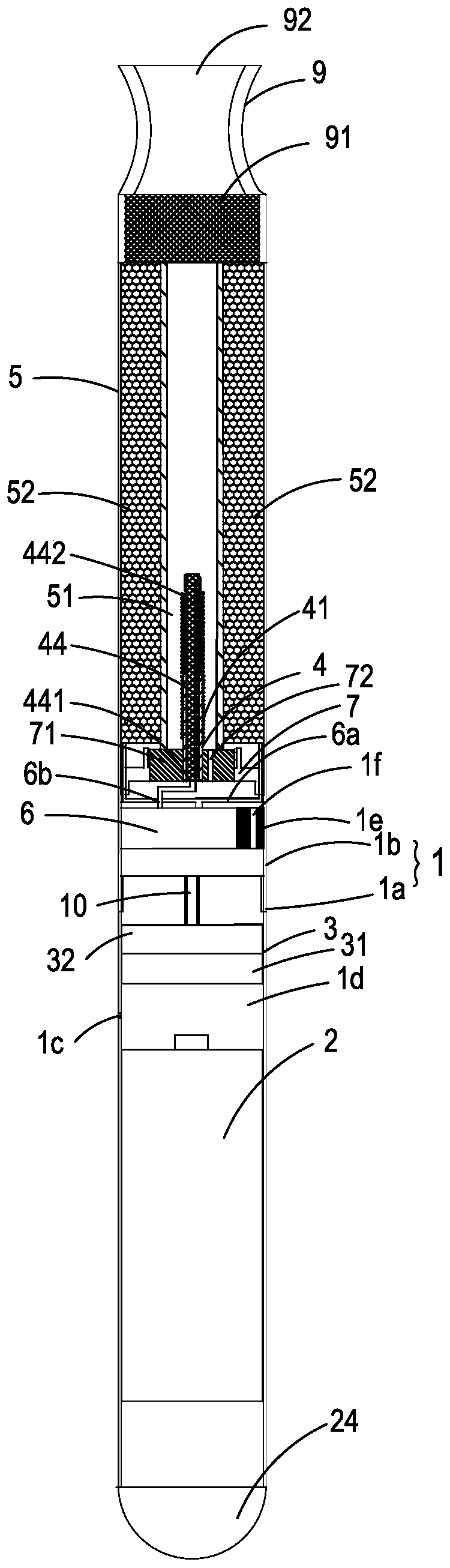

Inner core heating low-temperature cigarette based on unordered atomized sheet cigarette tobacco

InactiveCN107951069AIncrease contact areaImprove cooling effectCigar manufactureTobacco devicesCompound aEngineering

The invention provides an inner core heating low-temperature cigarette based on unordered atomized sheet cigarette tobacco. The cigarette comprises a tobacco section and a filter tip which are connected in sequence, wherein the tobacco section is the unordered sheet cigarette tobacco and is prepared in a traditional cigarette mode, cigarette paper is aluminum foil paper with the thickness of 0.03-0.08 mm, the diameter of the cigarette is 5.5-7.7 mm, and the filter tip is formed by sequentially compounding a first hollow rod, a thin film tip rod and a second hollow rod. The tobacco section is the unordered sheet cigarette tobacco, a preparation method is simple, the aluminum foil cigarette paper can reduce the oil leakage phenomenon of an atomizing agent in the cigarette paper, the filter tip adopts a three-element combination of the hollow rods at the two ends of the thin film tip rod, the heat dissipation effect and the cooling efficiency of the material are improved by utilizing large space and smoking pause time, and smoke can be effectively cooled.

Owner:HUBEI CHINA TOBACCO IND

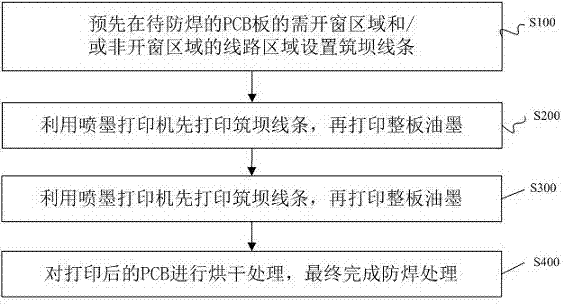

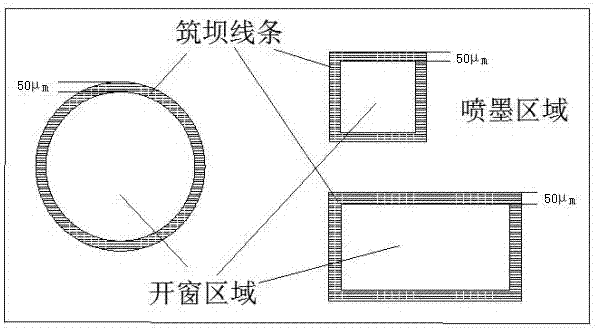

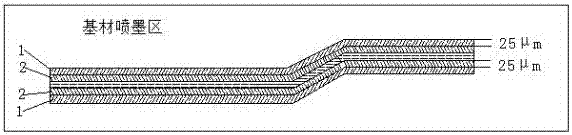

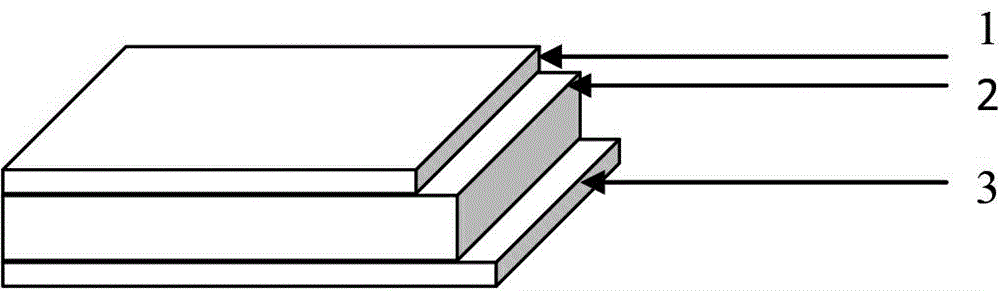

Solder-resistant processing method of PCB and PCB

ActiveCN107509317ASolve the thin ink on the edge of the lineImprove adhesionNon-metallic protective coating applicationDigital inkInkjet printing

The invention discloses a solder-resistant processing method of a PCB and a PCB. The method comprises: damming lines are arranged in line areas of an area needing windowing and a non-windowing area at a PCB on which solder-resistant processing is going to be carried in advance; and the damming lines are printed by using an ink-jet printer and then ink of the whole board is printed. According to the invention, the damming lines are arranged in the area needing windowing, the damming lines are printed by using the ink-jet printer, and the ink is printed on the board, so that a problem of the thin ink at the edge of the solder-resistant digital ink-jet printer line is solved. Meanwhile, super-roughening processing is carried out before printing, so that a problem of ink leakage during the jet printing process of the solder-resistant digital ink-jet printer technology as well as a problem of weak ink adhesive force after solder-resistant digital ink-jet printing is solved.

Owner:SHENZHEN KINWONG ELECTRONICS

Ultrahigh-loose thickness noodle bowl paper and production process thereof

InactiveCN104562828AReduce usageReduce manufacturing costChemical/chemomechanical pulpChemical and mechanical pulp mixtureMaterials sciencePulp (paper)

The invention discloses ultrahigh-loose thickness noodle bowl paper. The ultrahigh-loose thickness noodle bowl paper comprises a surface layer, a core layer and a bottom layer, wherein both the surface layer and the bottom layer comprise bleached needlebush sulfate pulp, and the content of the bleached needlebush sulfate pulp in the surface layer and the bottom layer is 35 to 50 percent by weight. The invention also provides a production process of the ultrahigh-loose thickness noodle bowl paper. On the premise of improving the loose thickness of the noodle bowl paper, the difficulties of curling cracking, side seepage and oil seepage can be solved.

Owner:ZHUHAI HUAFENG PAPER

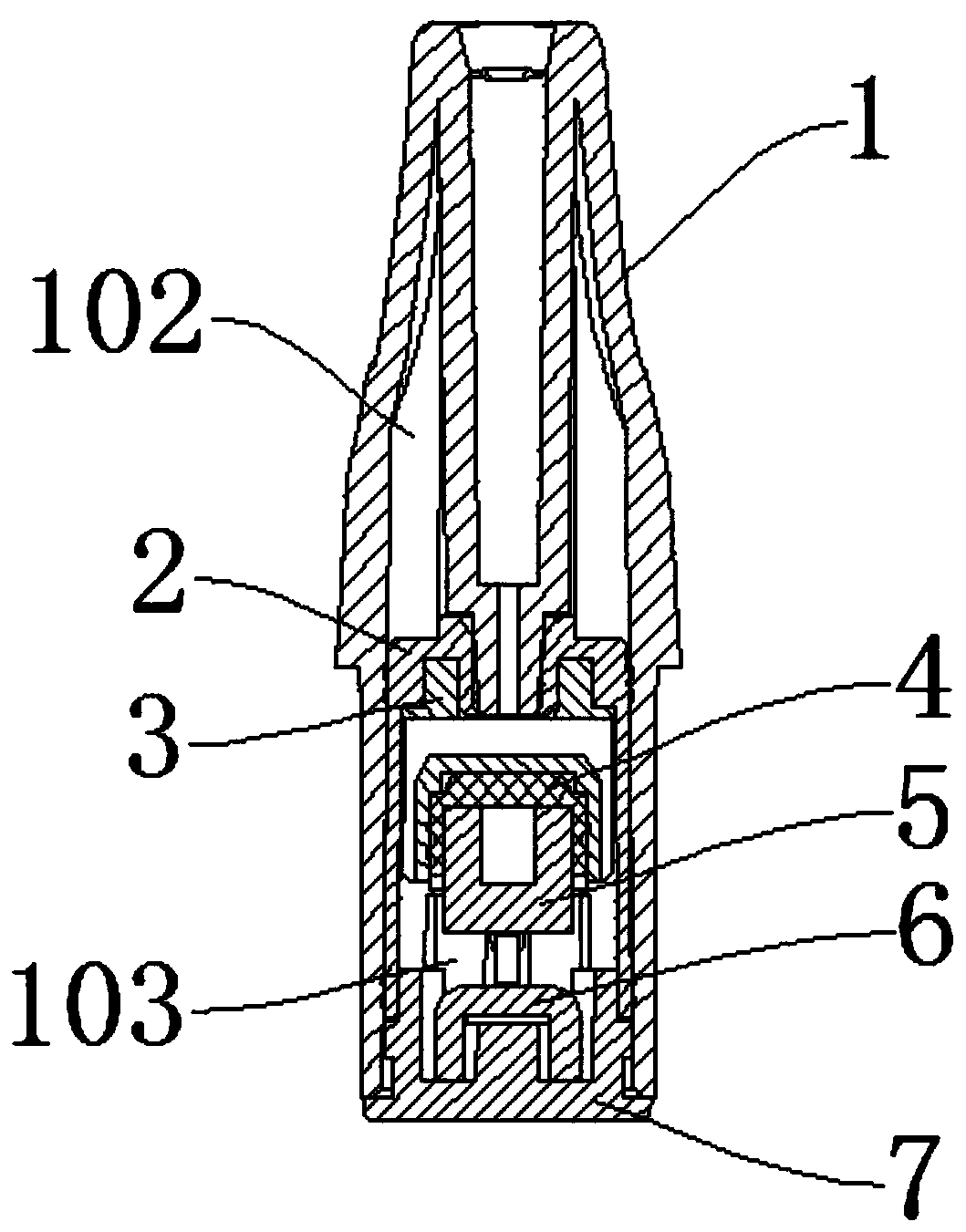

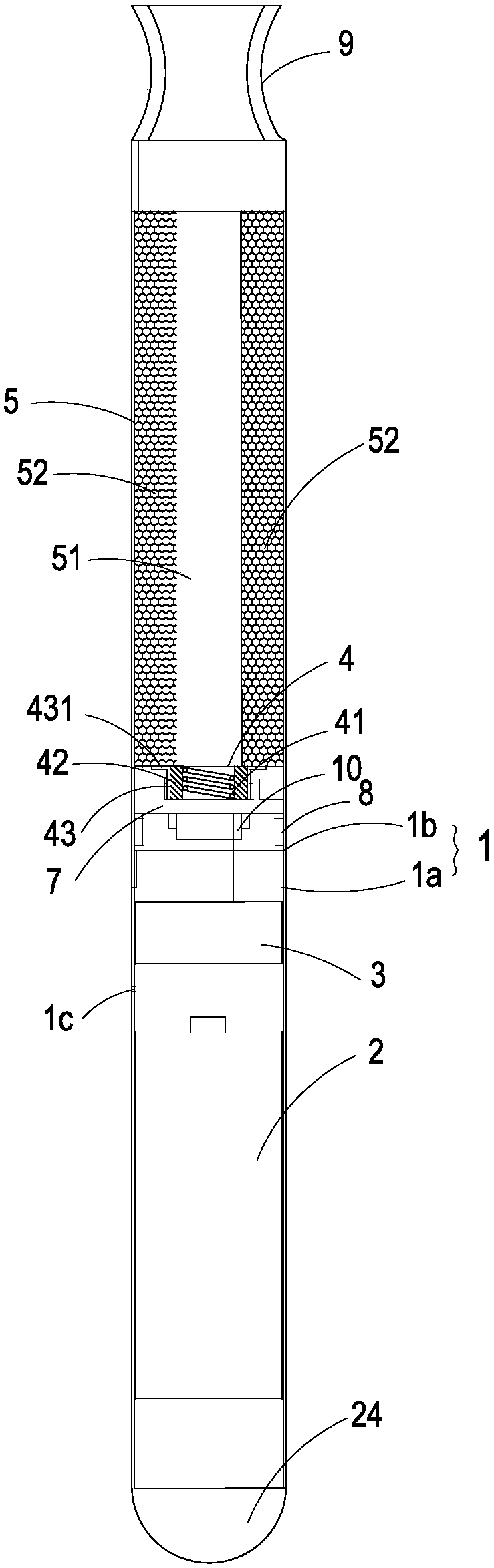

Electronic atomization device

ActiveCN106983178ATo achieve the feeling of "smoking"Reaching the Smoking" FeelingTobacco devicesCooking & bakingControl system

The invention relates to an electronic atomization device. The electronic atomization device comprises an outer cover shell, a suction nozzle, a power source component and an atomizer, the atomizer comprises a baking cup and a heating piece, the heating piece comprises a heating core, a first pin and a second pin, the heating core covers the inside of the side wall of the baking cup, and the first pin and the second pin are exposed outside the side wall separately and are connected with a circuit control system. When the electronic atomization device is in use, tobacco or solid tobacco tar can be contained in a baking cavity, and is heated through the heating core covering the inside of the side wall of the baking cup, so that 'smoke' generated by directly baking the tobacco or the tobacco tar enters the suction nozzle. According to the electronic atomization device, a traditional atomization mode is replaced that liquid shaped electronic tobacco tar is adopted, and the problem of oil leakage or oil seep is effectively solved.

Owner:HANGSEN GRAND TECH(DONGGUAN) CO LTD

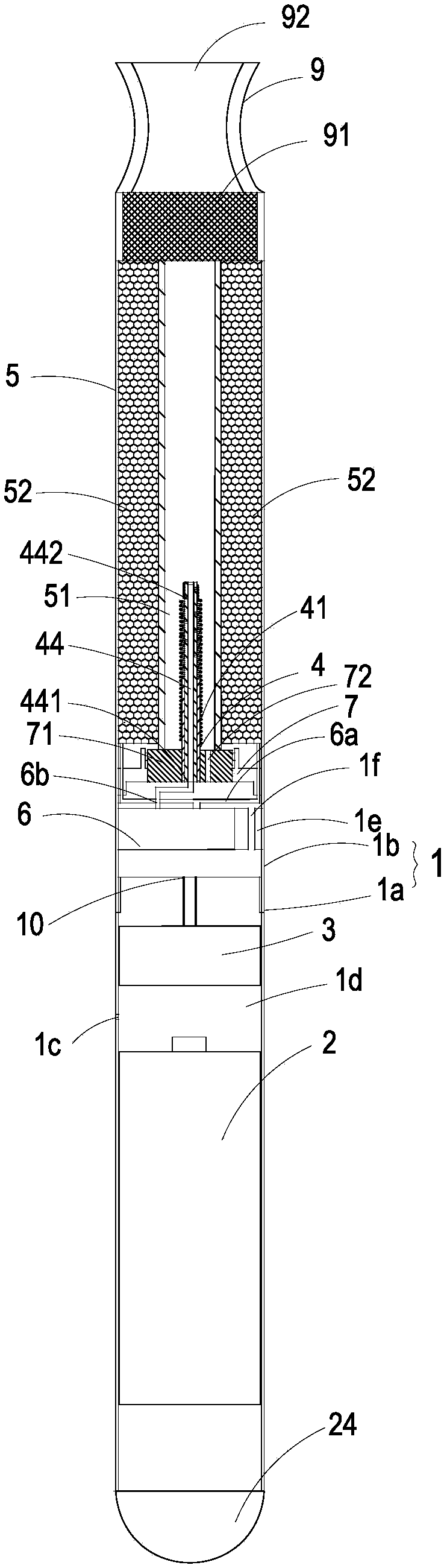

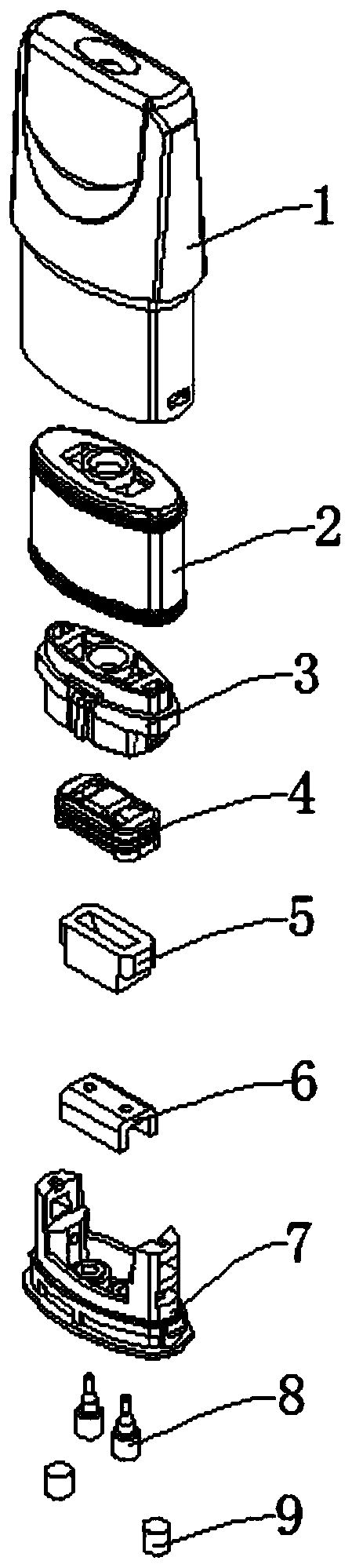

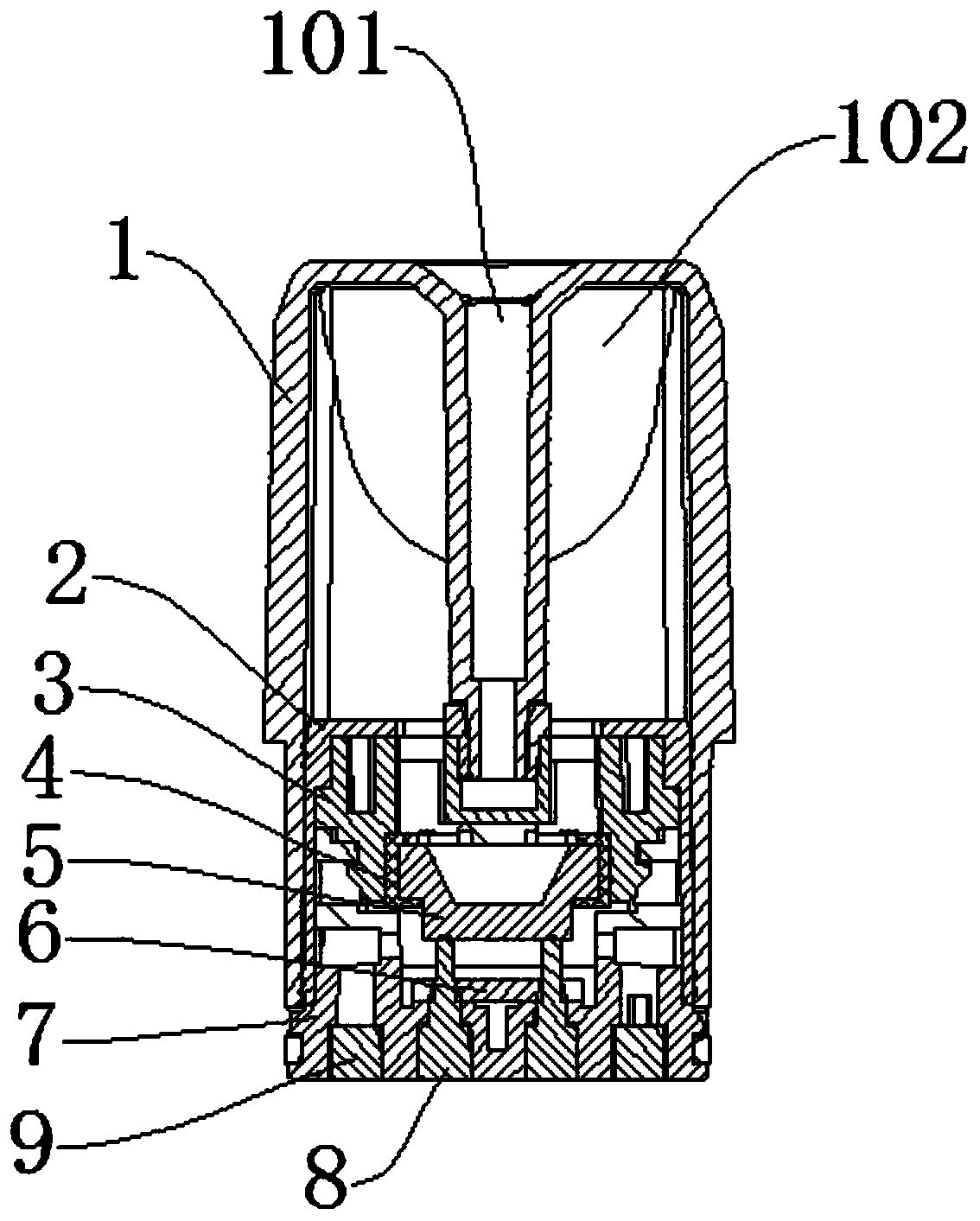

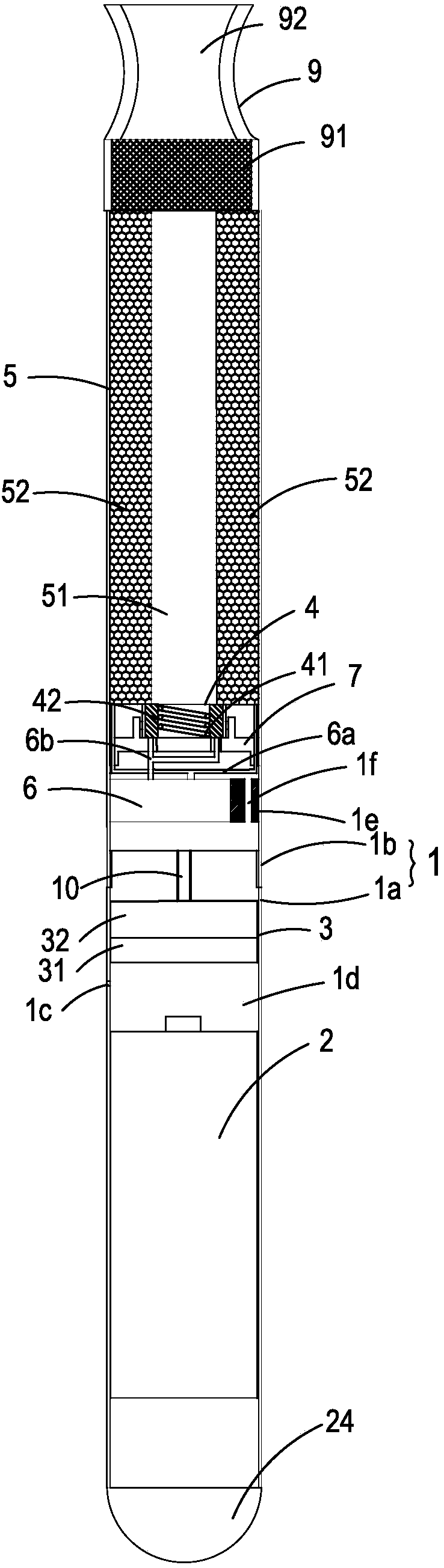

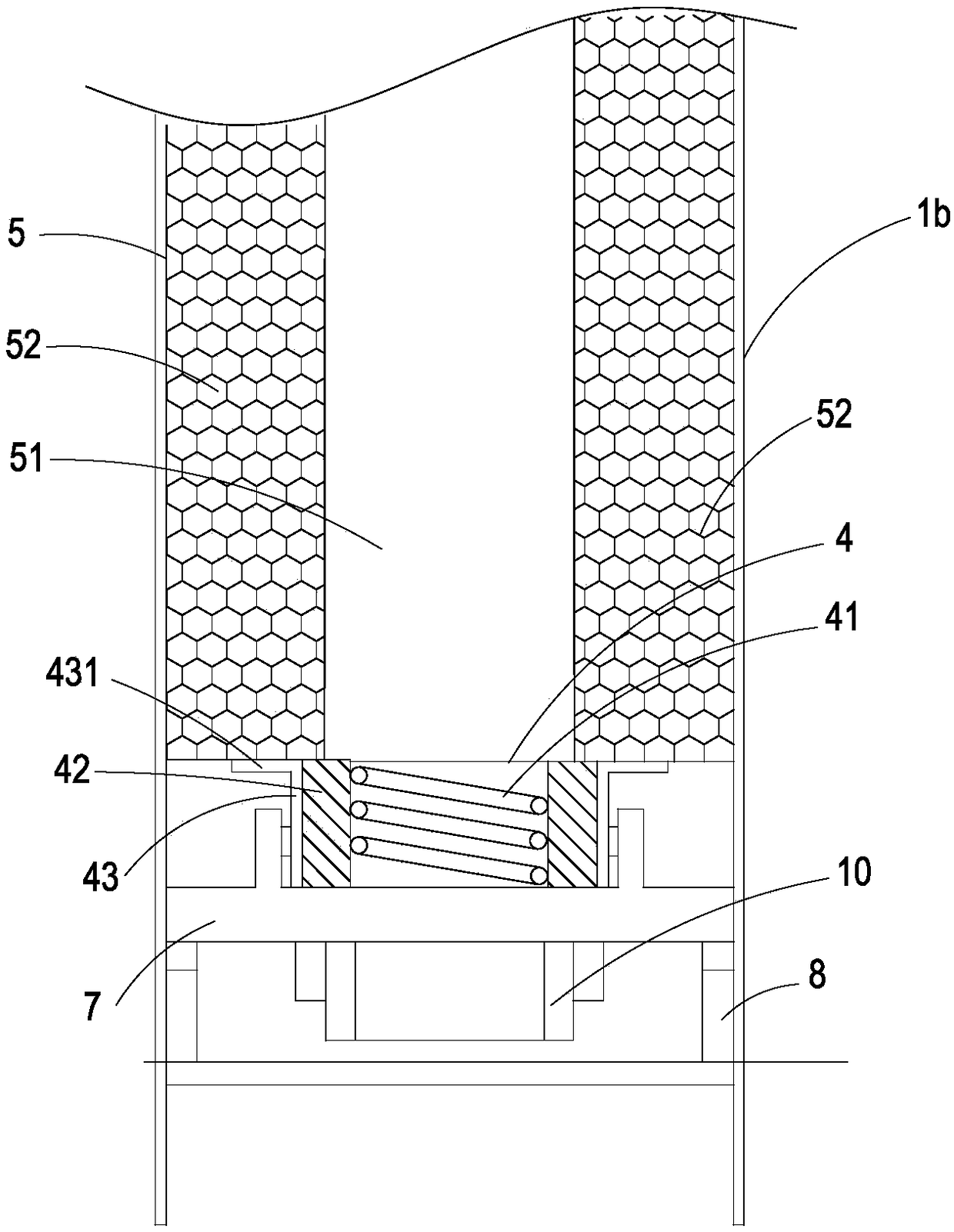

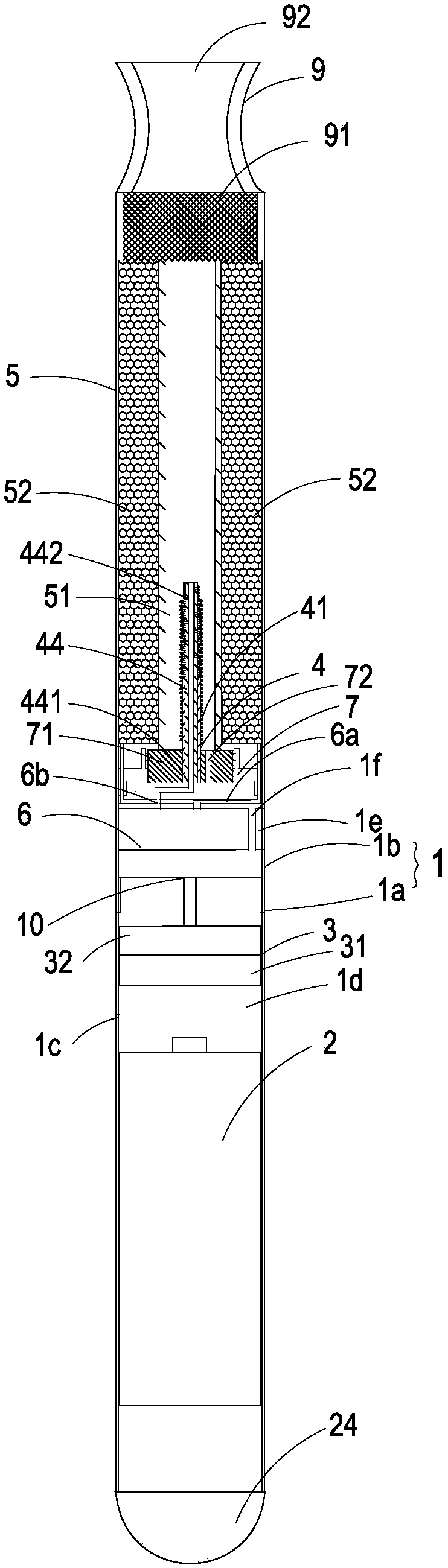

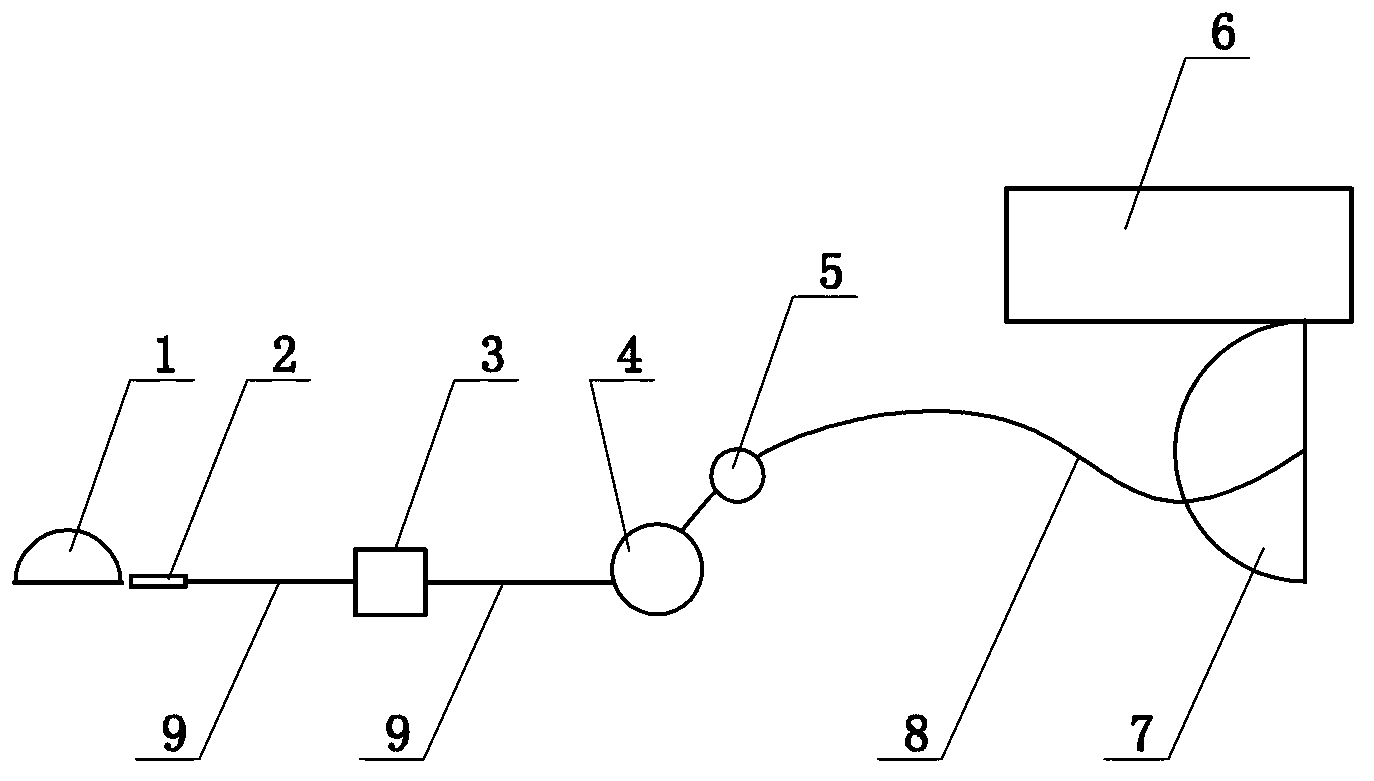

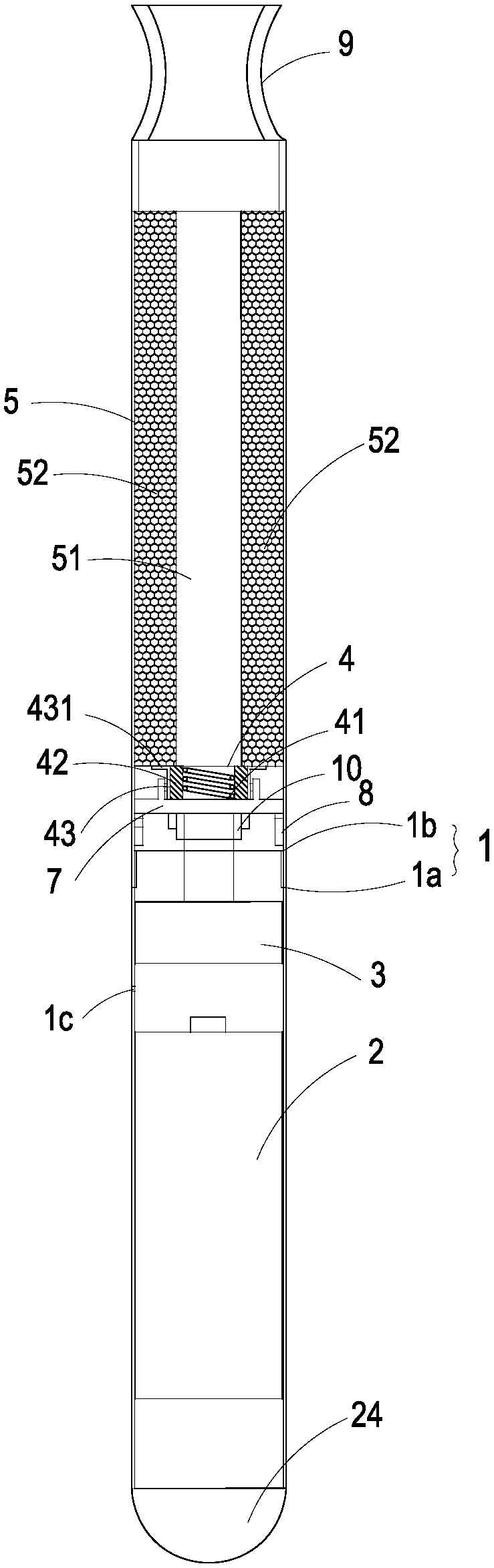

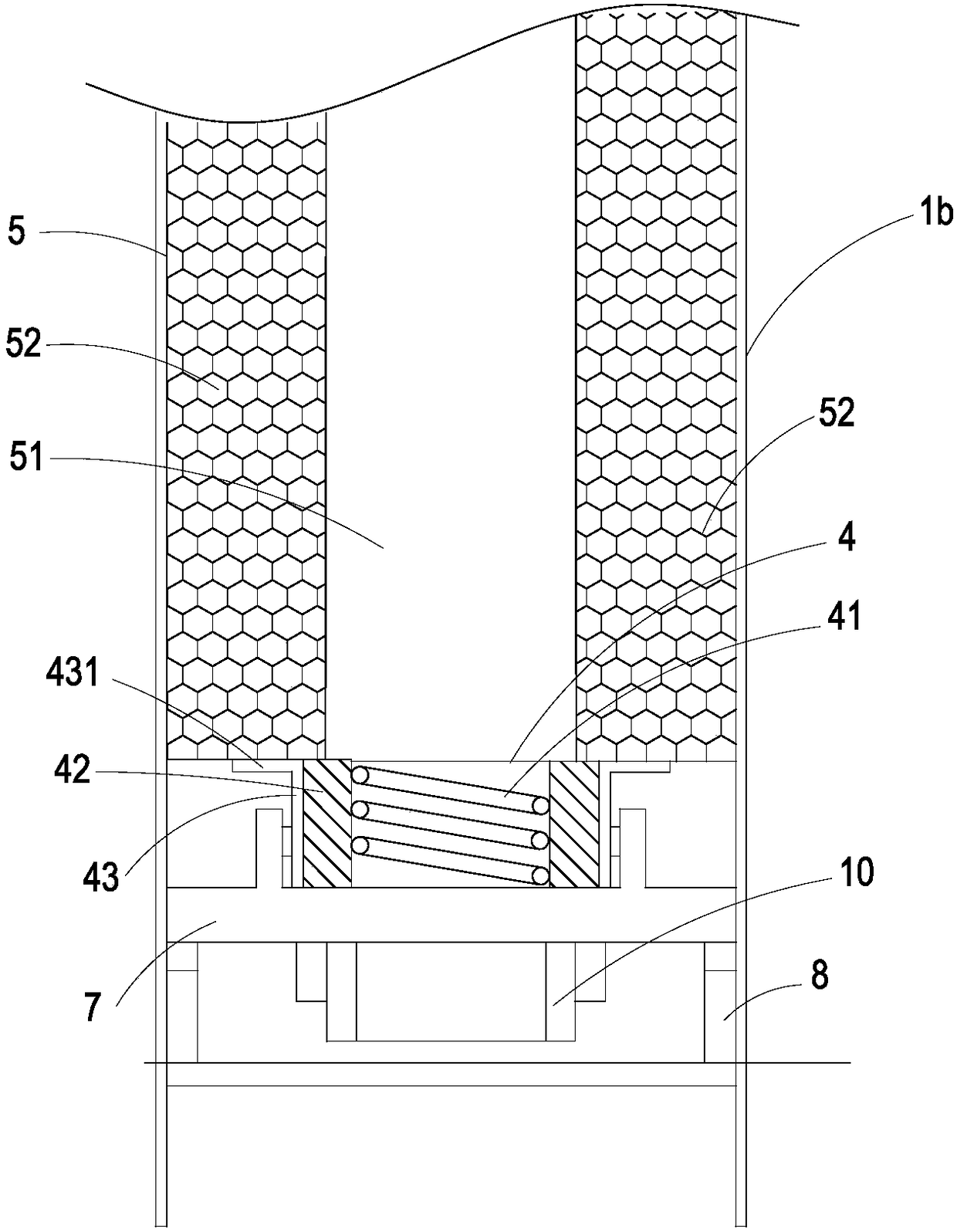

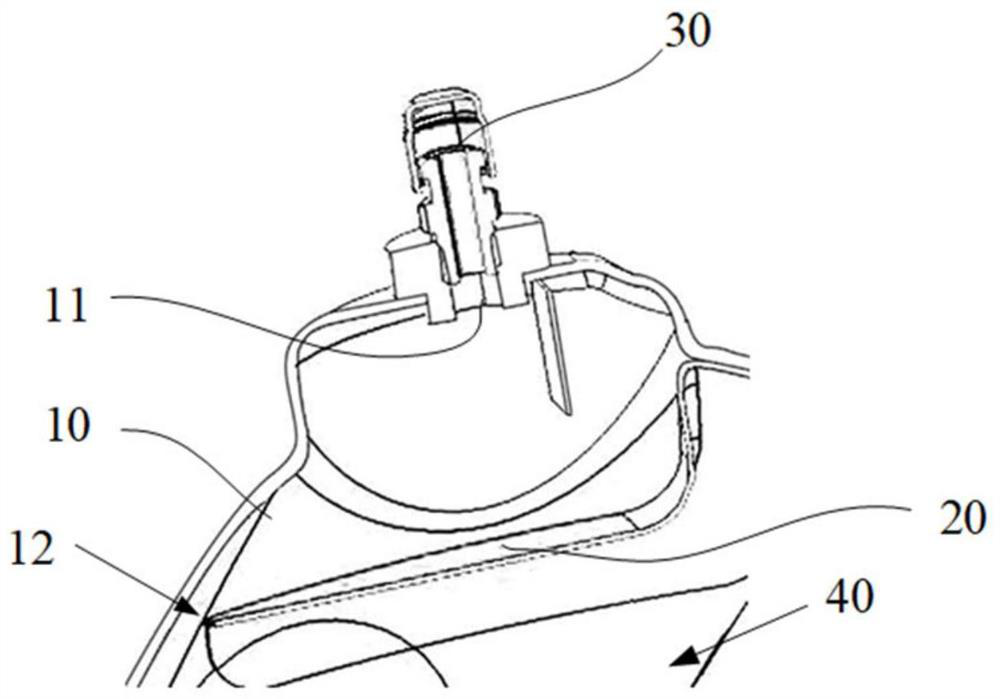

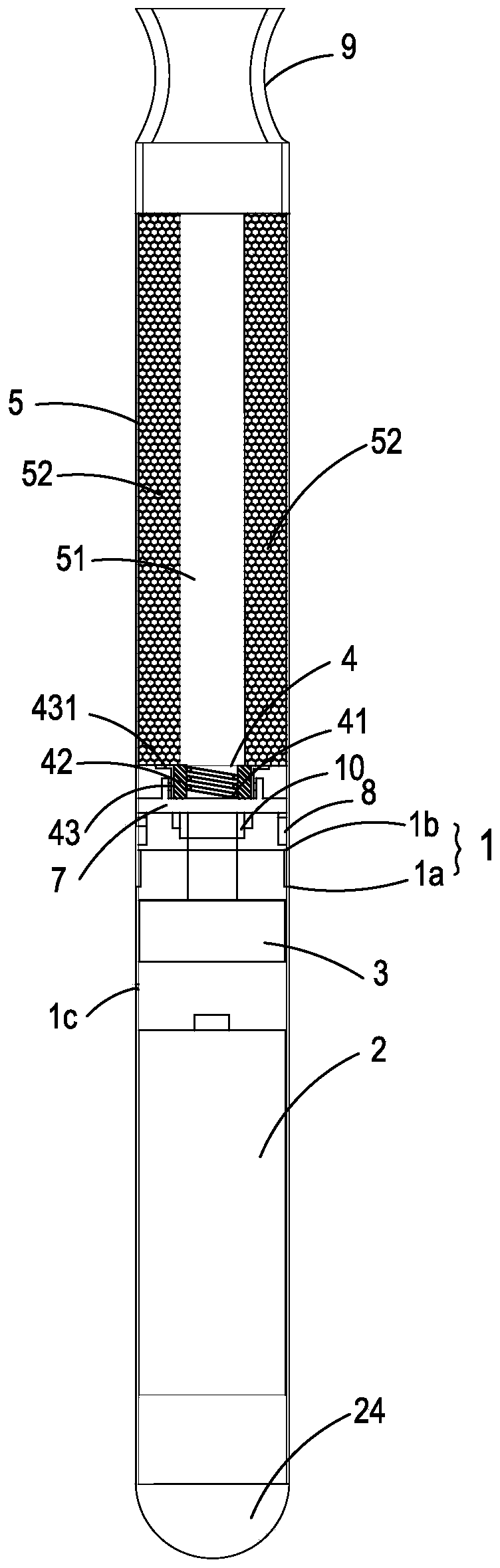

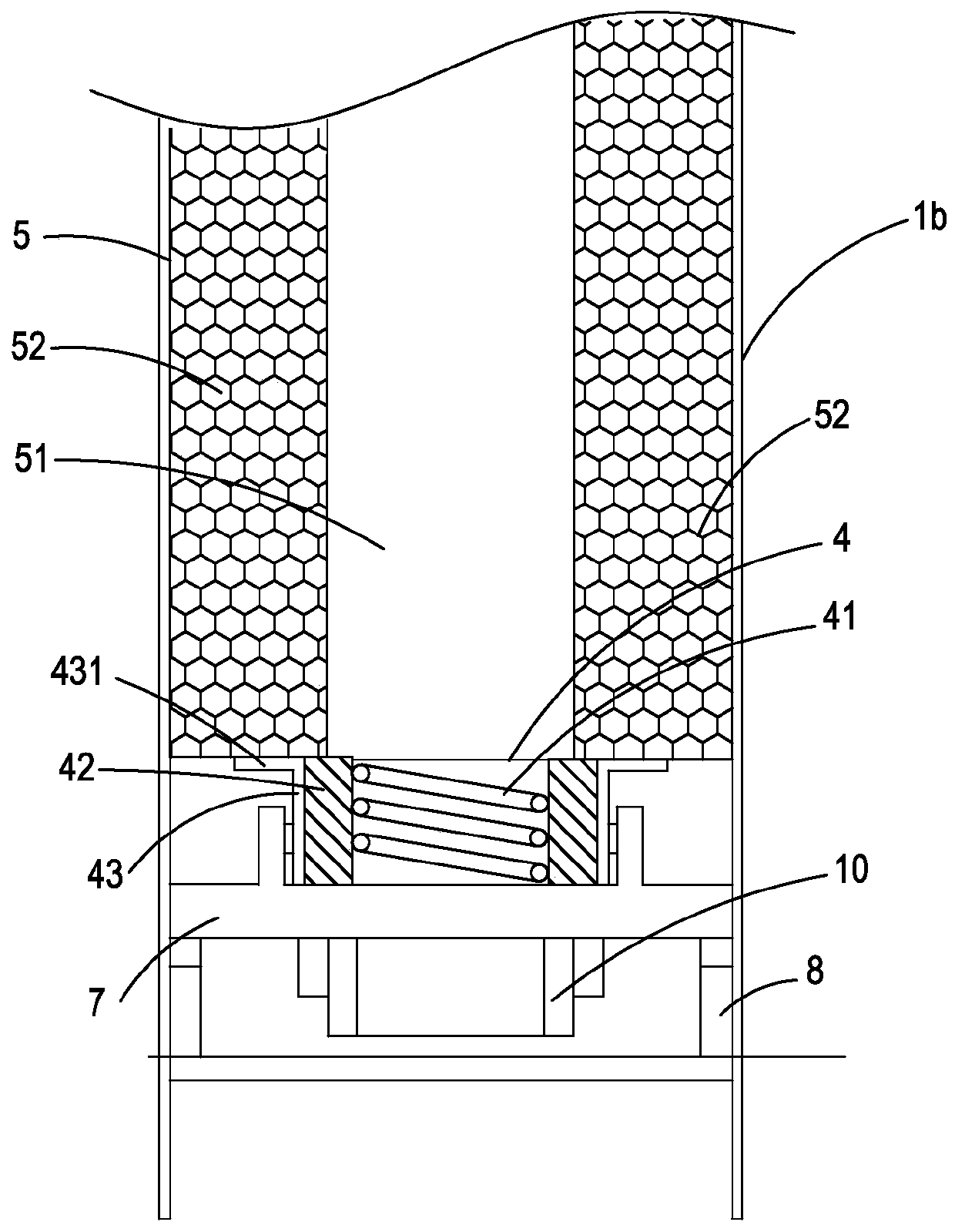

Electronic cigarette

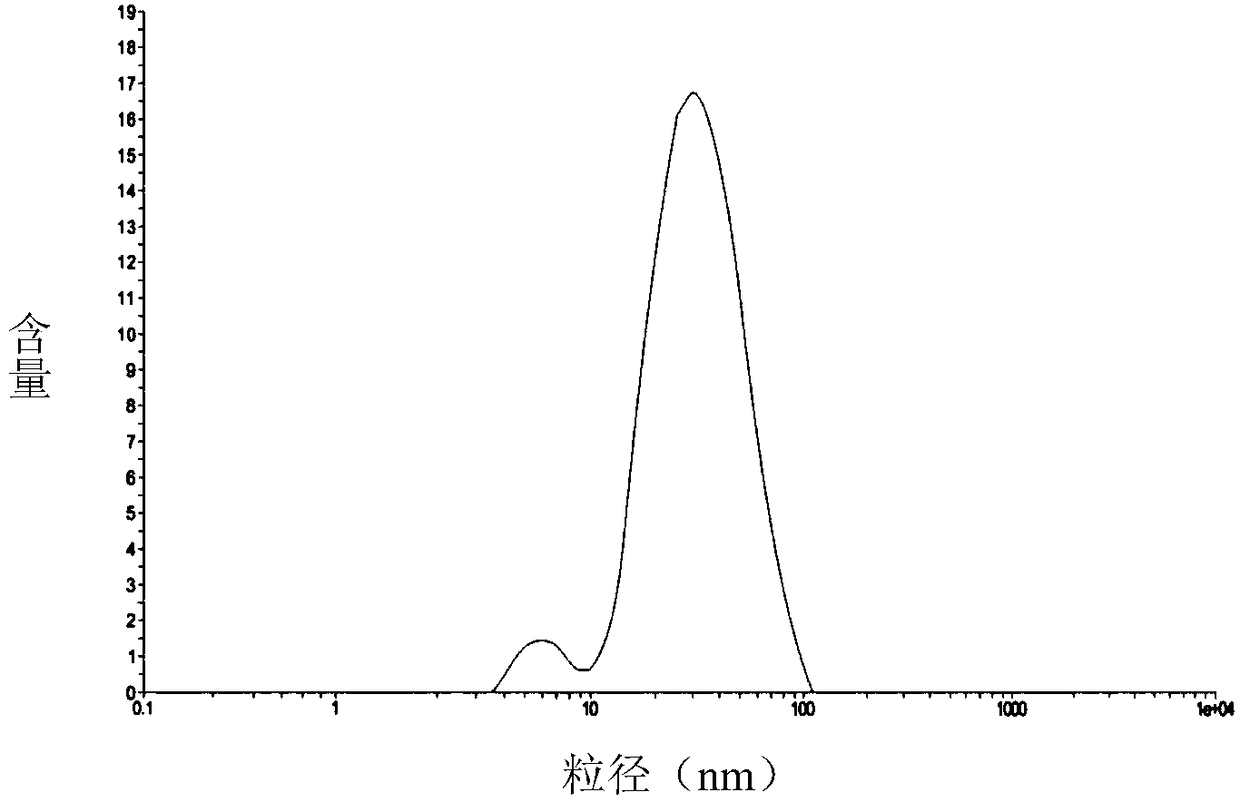

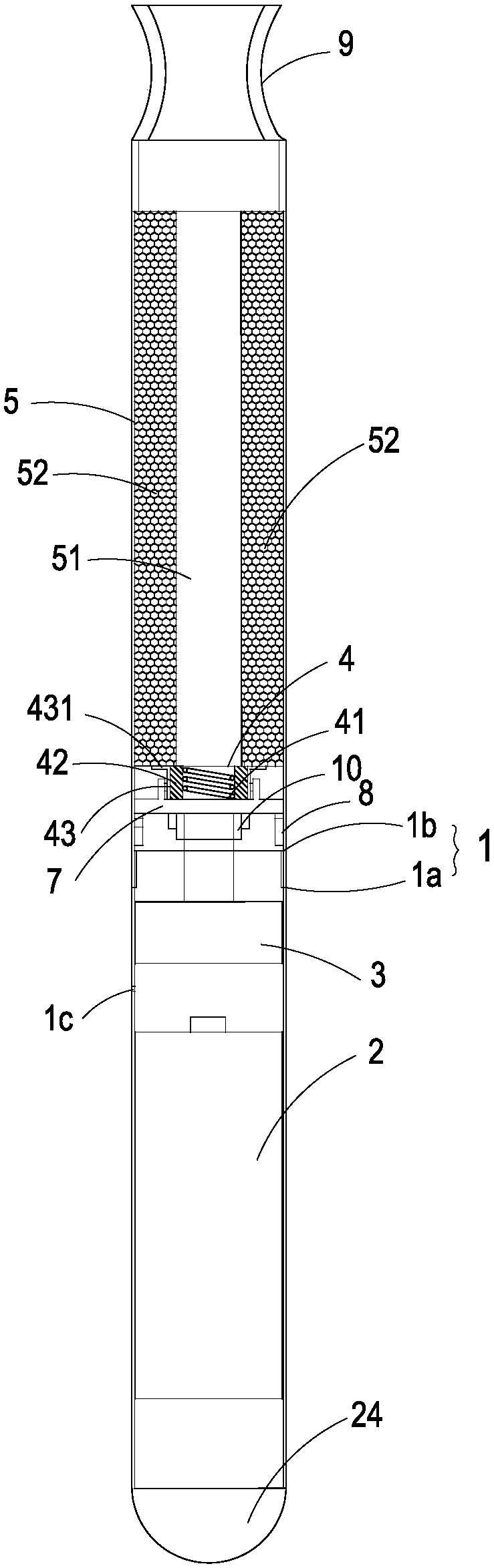

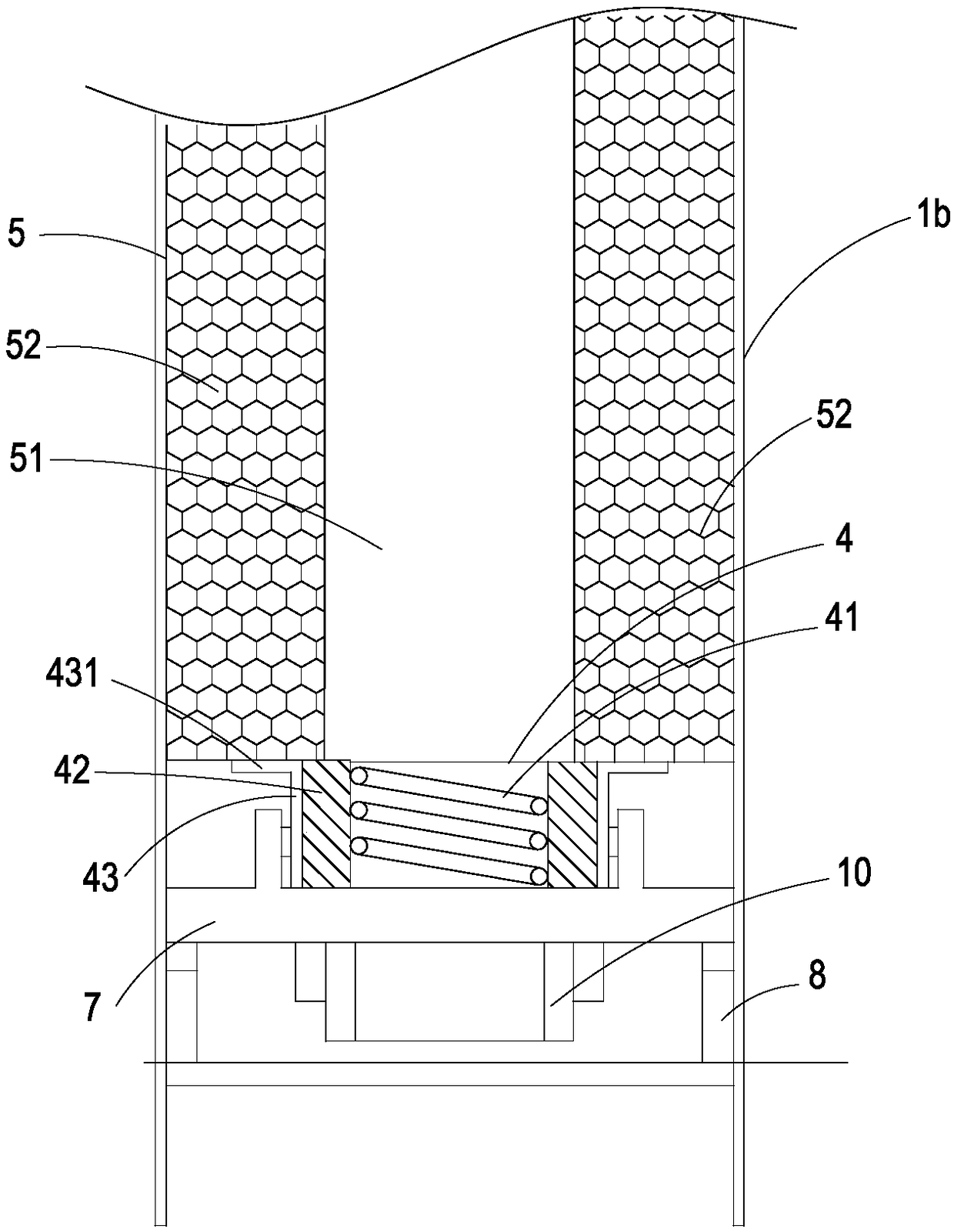

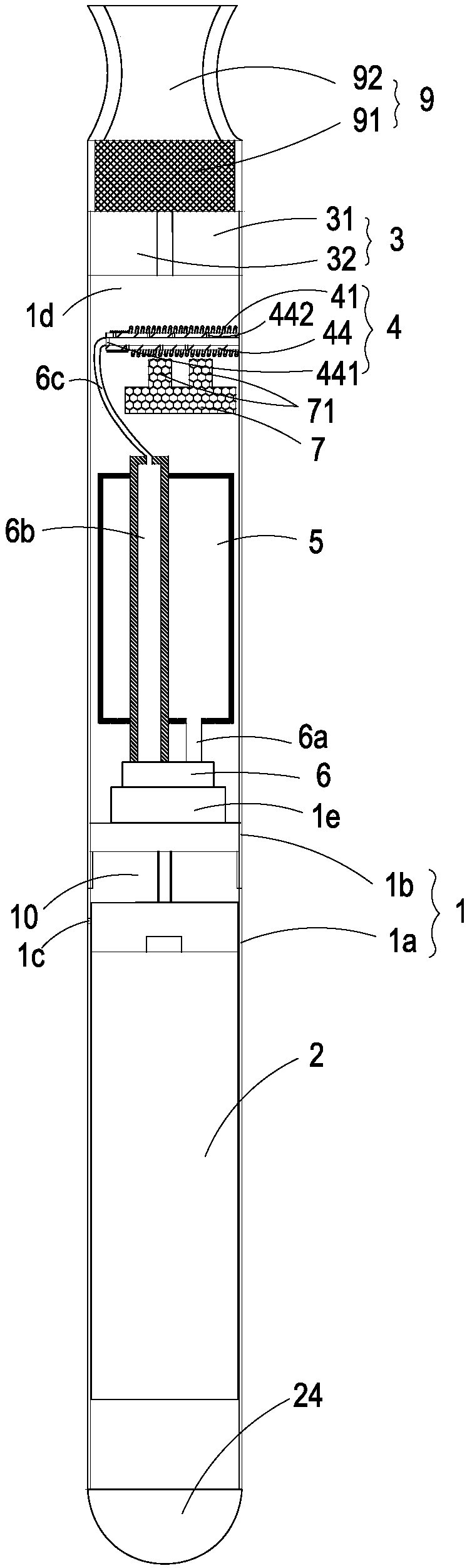

InactiveCN108685179ASolve for uniformitySolve the problem of oil seepageTobacco devicesEngineeringElectronic cigarette

The invention discloses an electronic cigarette. The electronic cigarette comprises a power supply device, an atomizing component, a liquid storage component, a fluid conveying device, a sensor, a shell body and a suction nozzle, wherein the atomizing component comprises an electric heater and a liquid guiding pipe; cigarette liquid is stored in the liquid storage component; the fluid conveying device is provided with inputting and outputting passages, the inputting passage is communicated with a liquid storage container, and the outputting passage is communicated with the liquid guiding pipeto control the cigarette liquid quantitatively conveyed to the electric heater of the atomizing component so as to generate atomizing smoke; the sensor comprises an air flow sensor and an air pressuresensor, the air flow sensor switches on or off the whole circuit of the power supply device according to the passed air flow, and the air pressure sensor adjusts outputting signals according to the pressure of the passed air flow; an air inlet is formed in the outer surface to make air communicated with the sensor through an air flow cavity chamber from the air inlet so as to form an air flow loop; the suction nozzle seals one end of the shell body, is communicated with the air flow loop, and is provided with an open hole to suck the atomizing smoke in the air flow loop.

Owner:MICROJET TECH

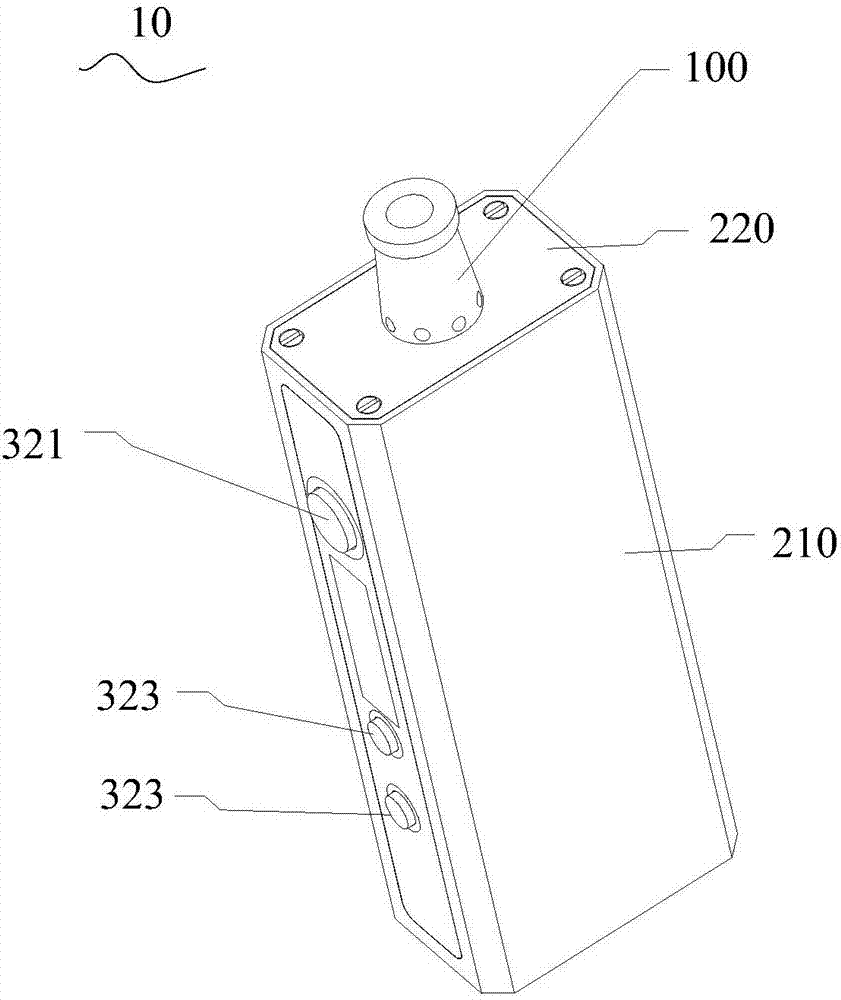

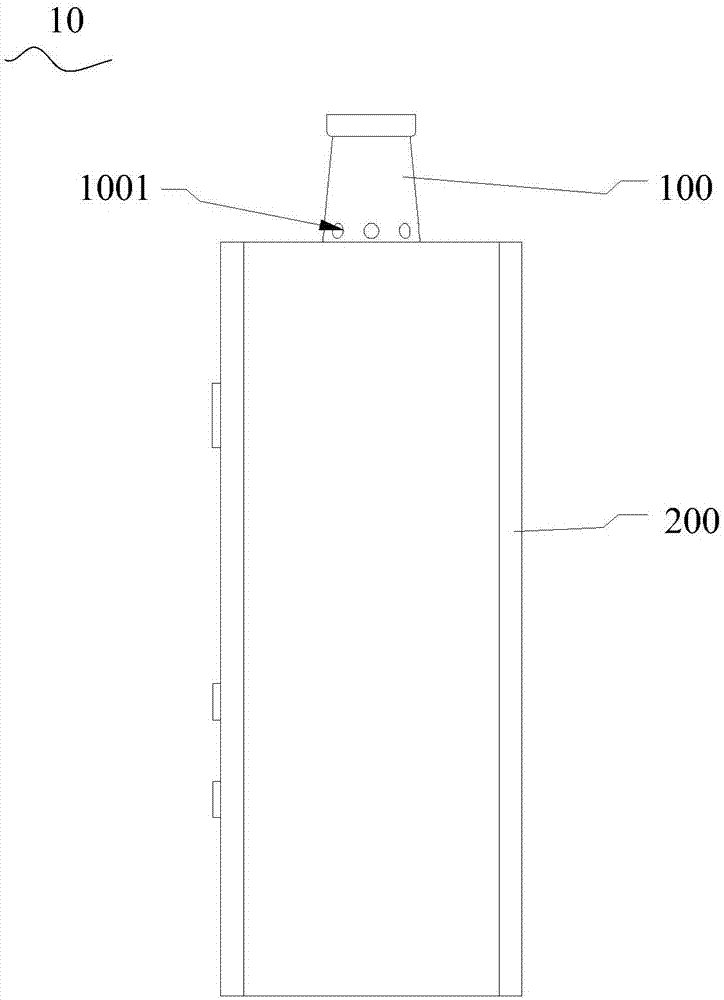

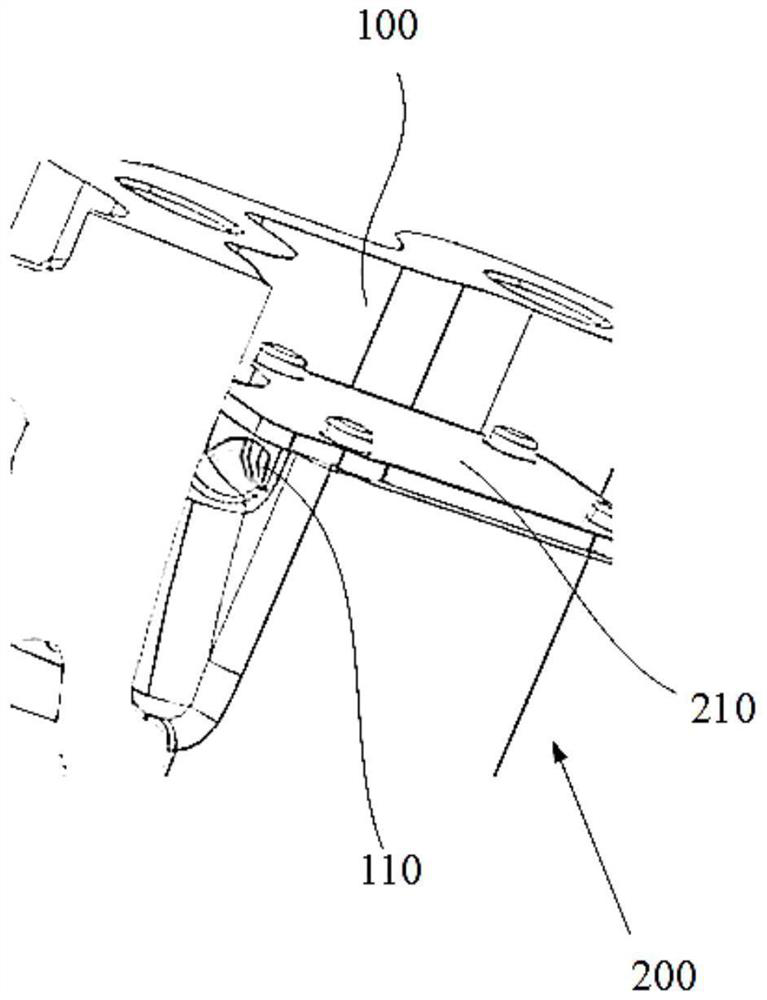

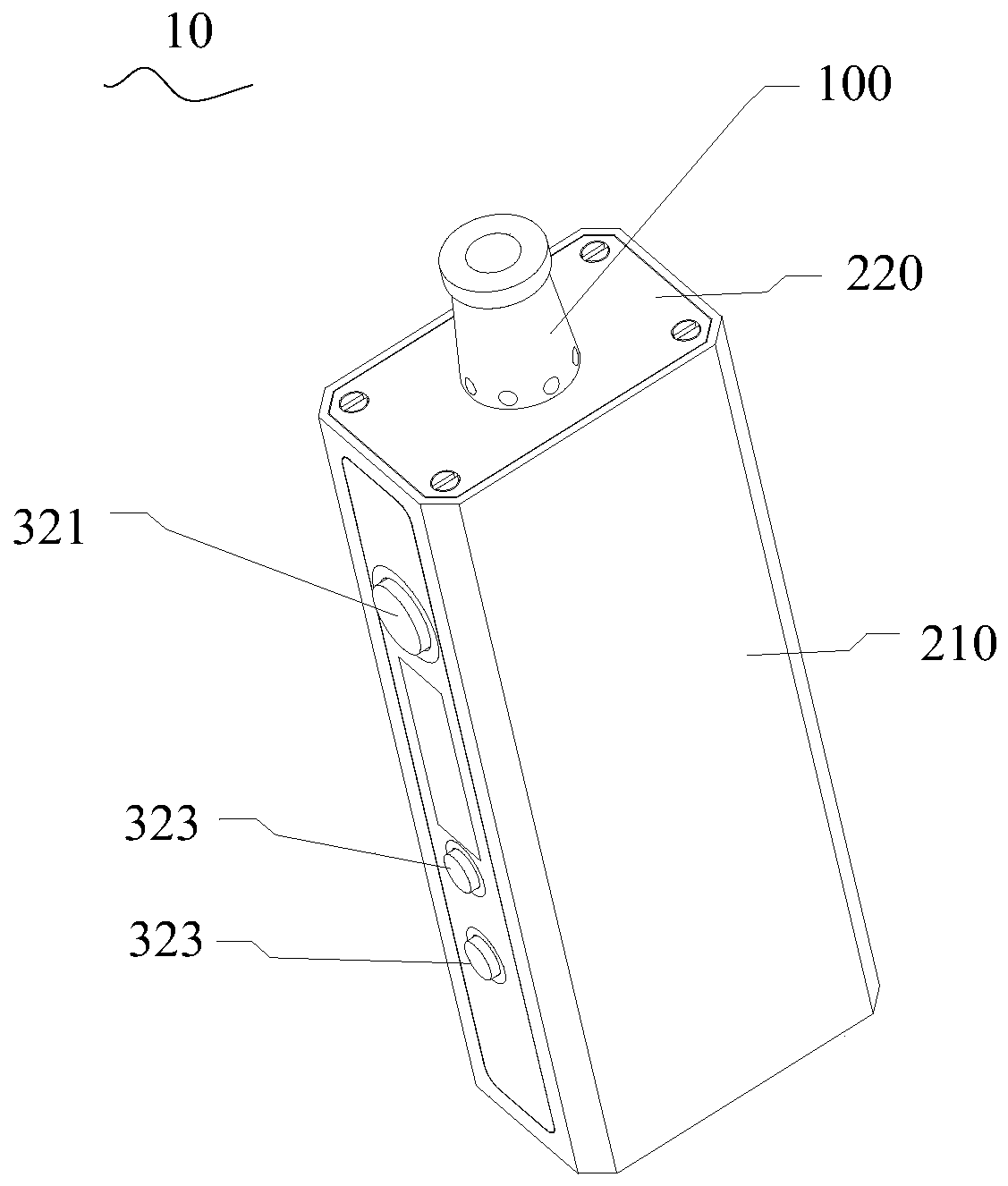

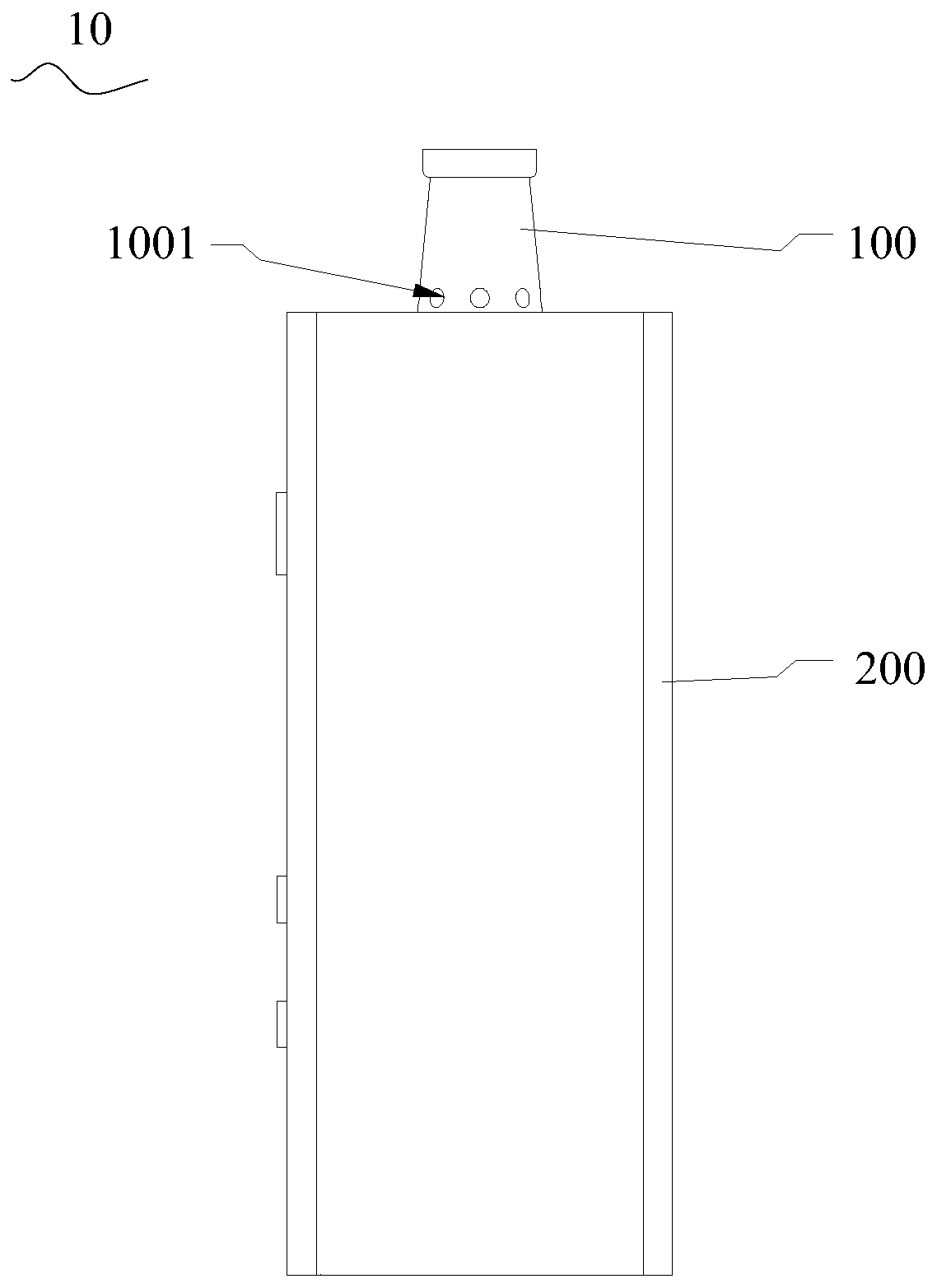

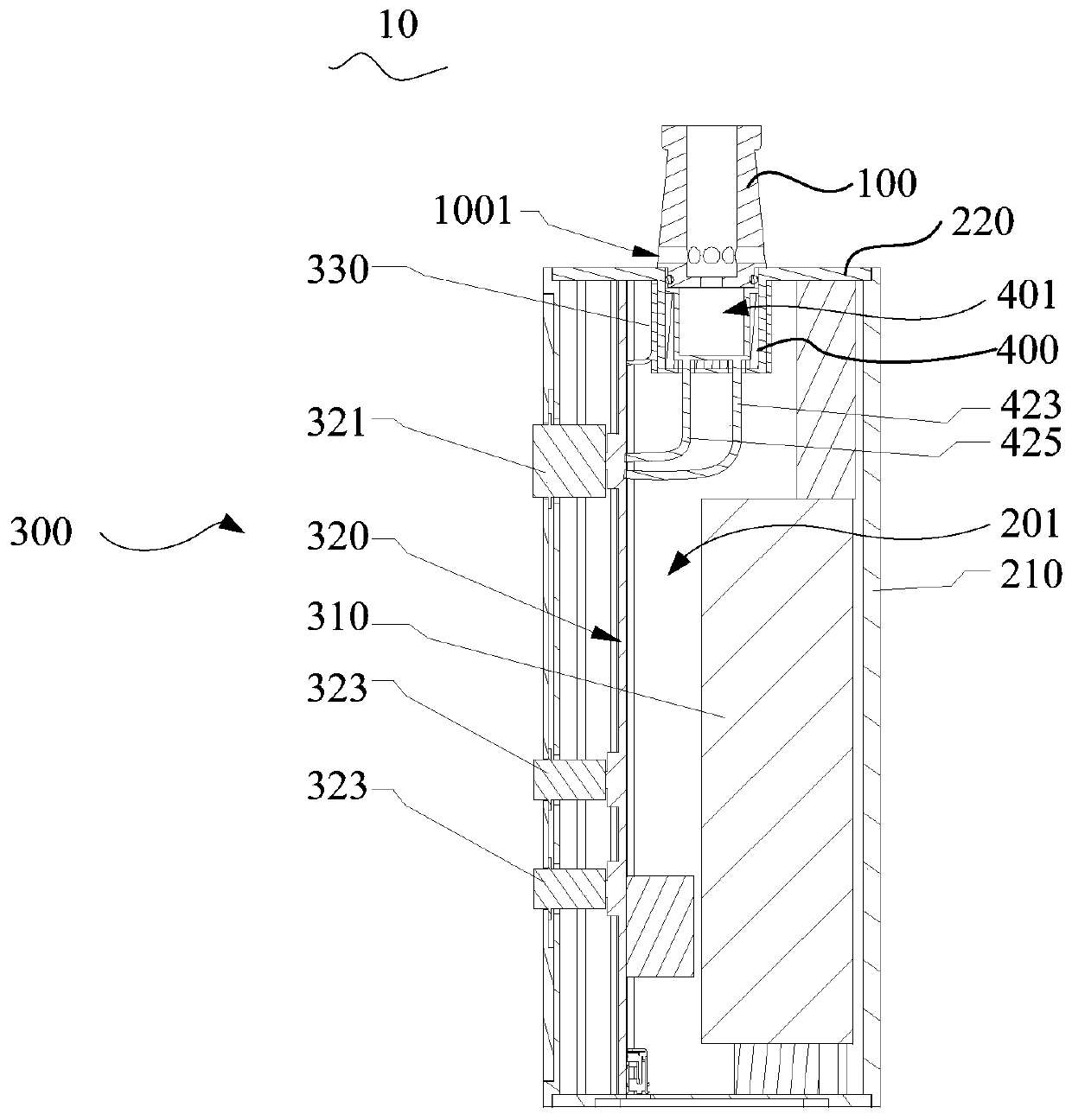

Driving module of electronic cigarette

ActiveCN109123792APrecise control of penetrationSolve for uniformityTobacco devicesVoltageElectronic cigarette

The invention discloses a drive module of an electronic cigarette, suitable for electronic cigarettes containing cigarette liquids. The electronic cigarette comprises a housing, a suction nozzle, an atomizing unit, a liquid storage unit, and a fluid transfer device. The drive module comprises a battery, a connection interface, a power board and a control board. The driving module is used for receiving the control signal and transmitting the driving signal, a voltage controller is controlled to calculate a specific voltage value according to a control signal, and then the voltage of the voltageconversion driving power supply is adjusted to a specific voltage value. A specific voltage value of the re-transmitting driving signal is supplied to the atomizing member to supply a driving power of the specific voltage value to the fluid transfer device and the atomizing unit, respectively, so that the fluid transfer device transfers cigarette liquid into the atomizing unit, and the atomizingunit atomizes the cigarette liquid to generate atomized smoke.

Owner:MICROJET TECH

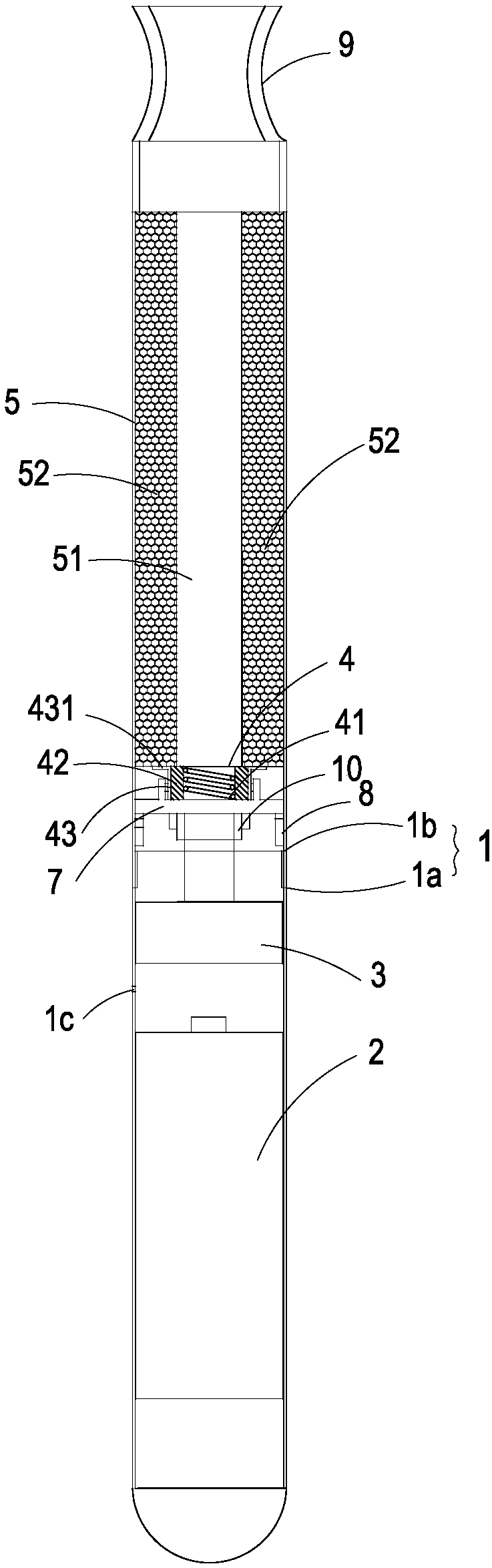

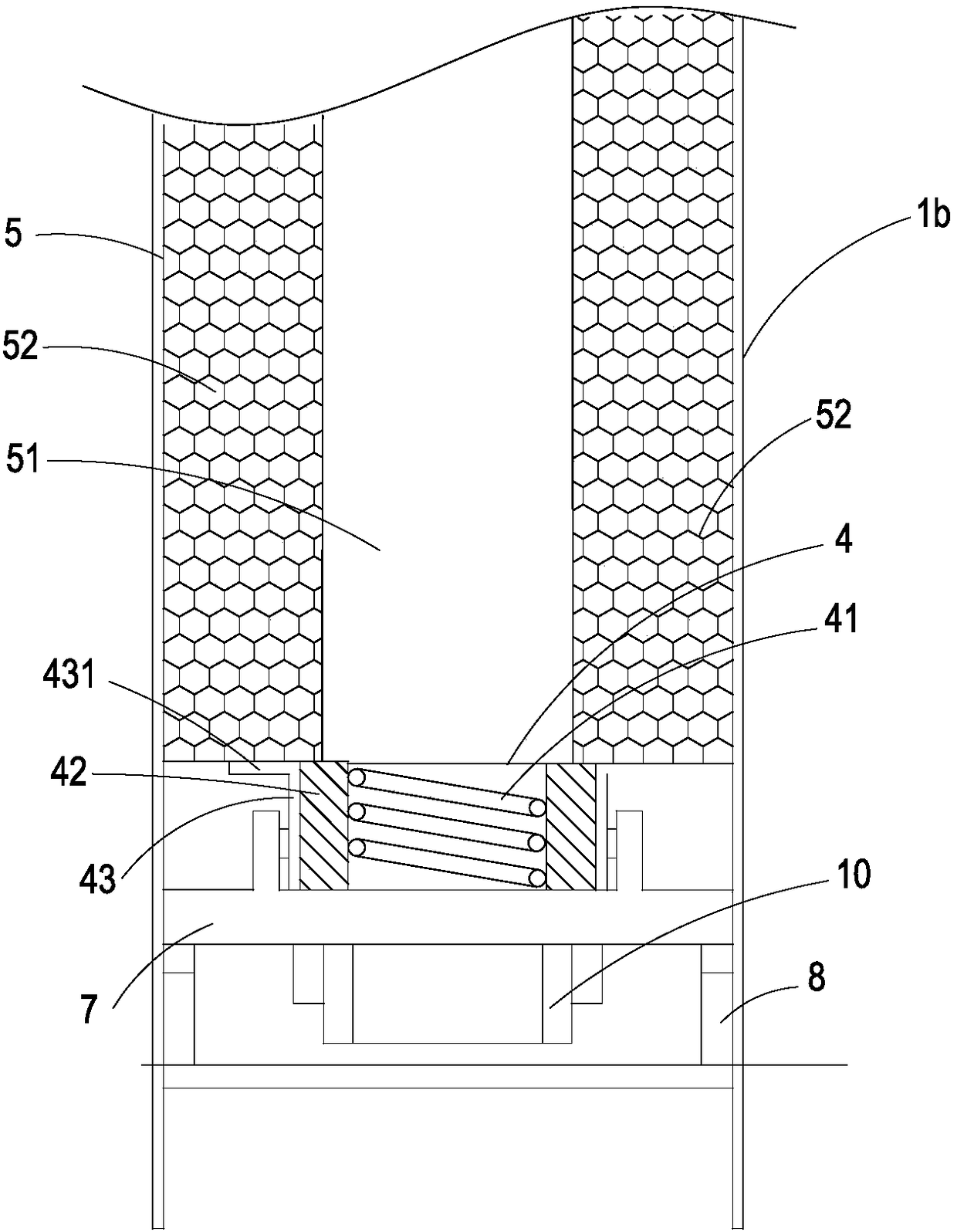

Electronic cigarette

ActiveCN108685183ASolve for uniformitySolve the problem of oil seepageTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette. The electronic cigarette comprises a power supply device, an atomizing component, a liquid storage component, a fluid conveying device, a shell body and a suction nozzle, wherein the atomizing component comprises an electric heater and a liquid guiding pipe; cigarette liquid is stored in the liquid storage component; the fluid conveying device is provided with inputting and outputting passages, the inputting passage is communicated with a liquid storage container, and the outputting passage is communicated with the liquid guiding pipe to make the cigarette liquid in the liquid storage container conveyed to the outside of the liquid guiding pipe, so that the cigarette liquid is controlled to be quantitatively conveyed to the electric heater of the atomizing component to generate atomizing smoke; the power supply device, the fluid conveying device, the atomizing component and the liquid storage component are installed in the shell body, and an air inlet is formed in the outer surface and is communicated with the front end of the atomizing component to make outside air communicated with an air flow cavity chamber through the air inlet,so that an air flow loop is formed; the suction nozzle seals one end of the shell body, is communicated with the air flow loop, and is provided with an open hole to suck the atomizing smoke in the airflow loop.

Owner:MICROJET TECH

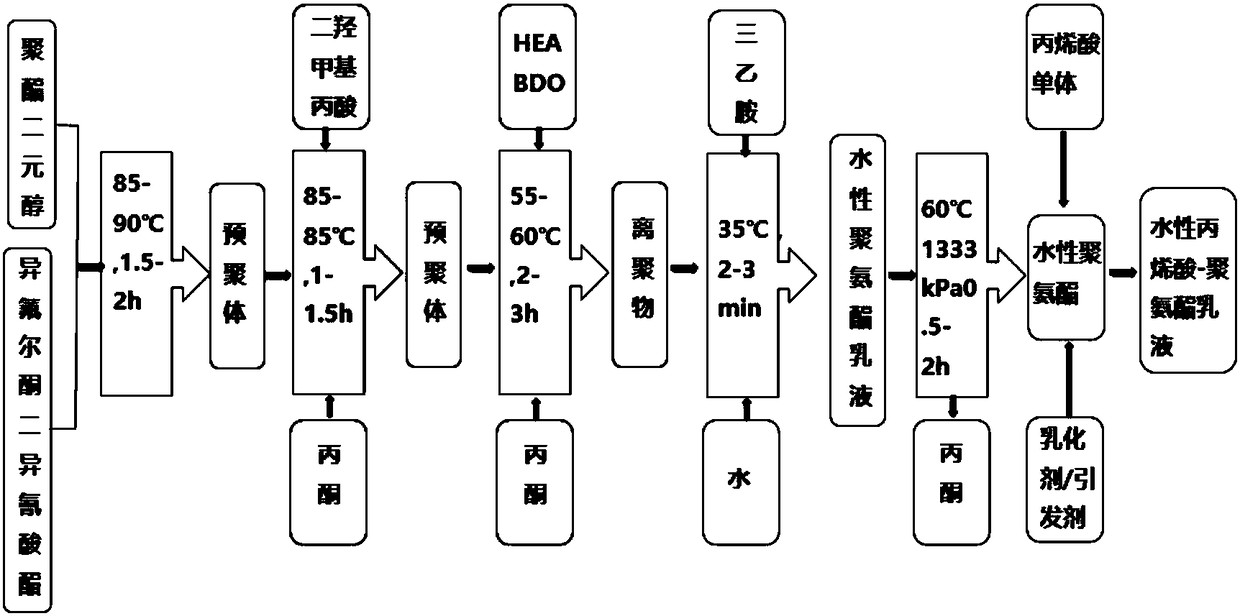

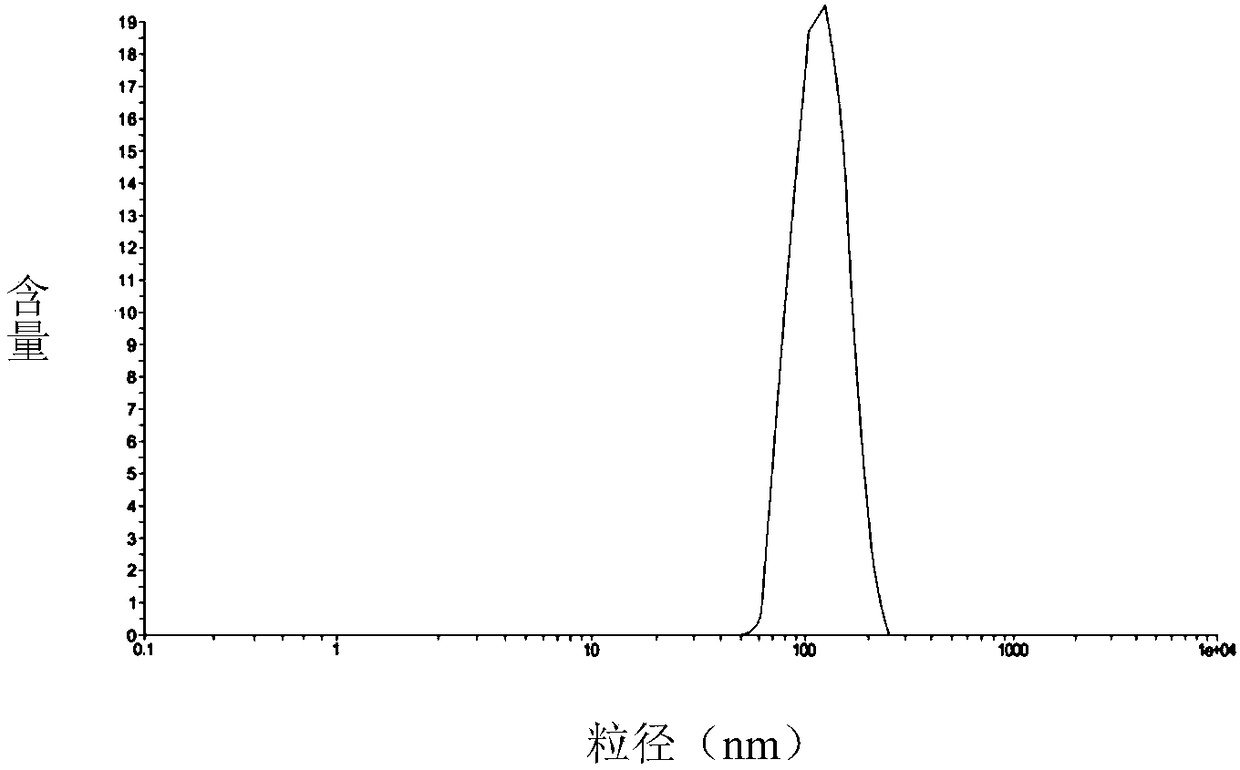

Single-component air-drying water-based sealing agent for woodware and preparation method thereof

InactiveCN108485510ASolve muscle tensionSolve bleedingPolyurea/polyurethane coatingsWater basedAcrylic monomers

The invention discloses a single-component air-drying water-based sealing agent for woodware. Polyhydric alcohols and an isocyanate monomer are mixed for a reaction for a period of time, a certain amount of acetone and dimethylolpropionic acid are added for a continuous reaction for a period of time; BDO and HEA are added for a reaction for a period of time, and then cooling is performed; triethylamine is added for neutralization, water is added for dispersion, acetone is removed, and a waterborne polyurethane dispersion is obtained; the waterborne polyurethane dispersion and an acrylic monomer are copolymerized to obtain acrylic acid-polyurethane mixed emulsion. The acrylic acid-polyurethane mixed emulsion prepared through the method has the dense film formation effect, the surface of wood can be well wrapped, and the phenomenon that the surface of a paint film is damaged due to the fact that much water in water paint is absorbed and serious base material rib expansion is caused is avoided. Meanwhile, on the basis of reasonable auxiliaries, finally, when paint is used on the surface of wood, the problems that wood rib expansion damage is caused and oil leakage and color changing are caused can be effectively avoided.

Owner:广东海顺新材料科技有限公司

Electronic cigarette

ActiveCN108968151APrecise control of penetrationSolve for uniformityTobacco devicesControl signalElectronic cigarette

Disclosed is an electronic cigarette. The electronic cigarette includes a power supply device, a sensor, an atomizing component, a fluid conveying device, a liquid storage component, a shell, a bracket, and a suction nozzle. When the sensor senses an air flow, the sensor sends a control signal to the power supply device to make the power supply device control the fluid conveying device to start operation according to the control signal, and so cigarette liquid in the liquid storage component is led out from an input channel to the atomizing component to generate atomized smoke which is suckedby a user through an opening of the suction nozzle.

Owner:MICROJET TECH

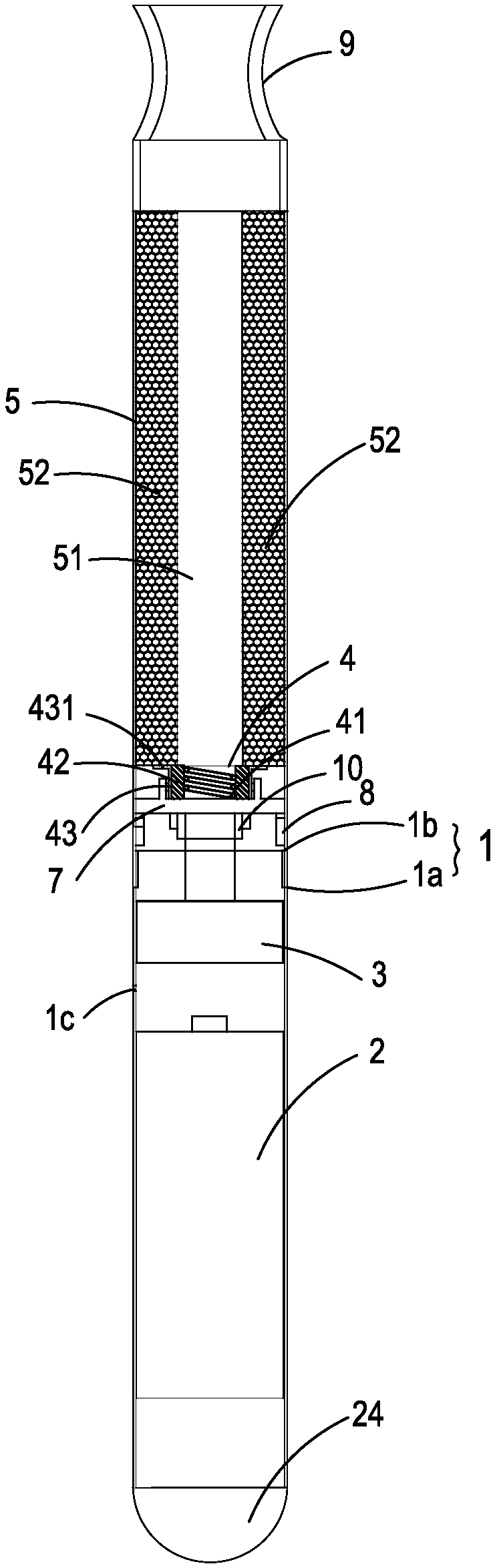

Electronic cigarette atomizer and electronic cigarette

The invention relates to an electronic cigarette atomizer, which comprises an oil cup and an atomization assembly, the atomization assembly is installed on the inner side of the oil cup, and an oil smoke cavity and an atomization cavity in the lower portion of the oil smoke cavity are formed after the atomization assembly and the oil cup are assembled; the atomization assembly comprises a base, aheating oil guide body, a heating oil guide body sealing ring and a support; the heating oil guide body is arranged on the inner side of the base; the heating oil guide body sealing ring is arranged on the heating oil guide body; the support is arranged above the heating oil guide body sealing ring, the support is buckled with the base, an integrated sealing ring is arranged above the support, a Pin needle is arranged in the middle of the lower side of the base, and a magnet is arranged on the base and located on the outer side of the Pin needle. According to the atomizer, the problems of tarseepage and tar leakage of condensate and tobacco tar are effectively solved, an atomizer finished product is obtained through a structure with few parts and low cost, the product quality is improved,and the user experience is improved.

Owner:CHOEBE DONGGUAN PRECISION TECH CO LTD

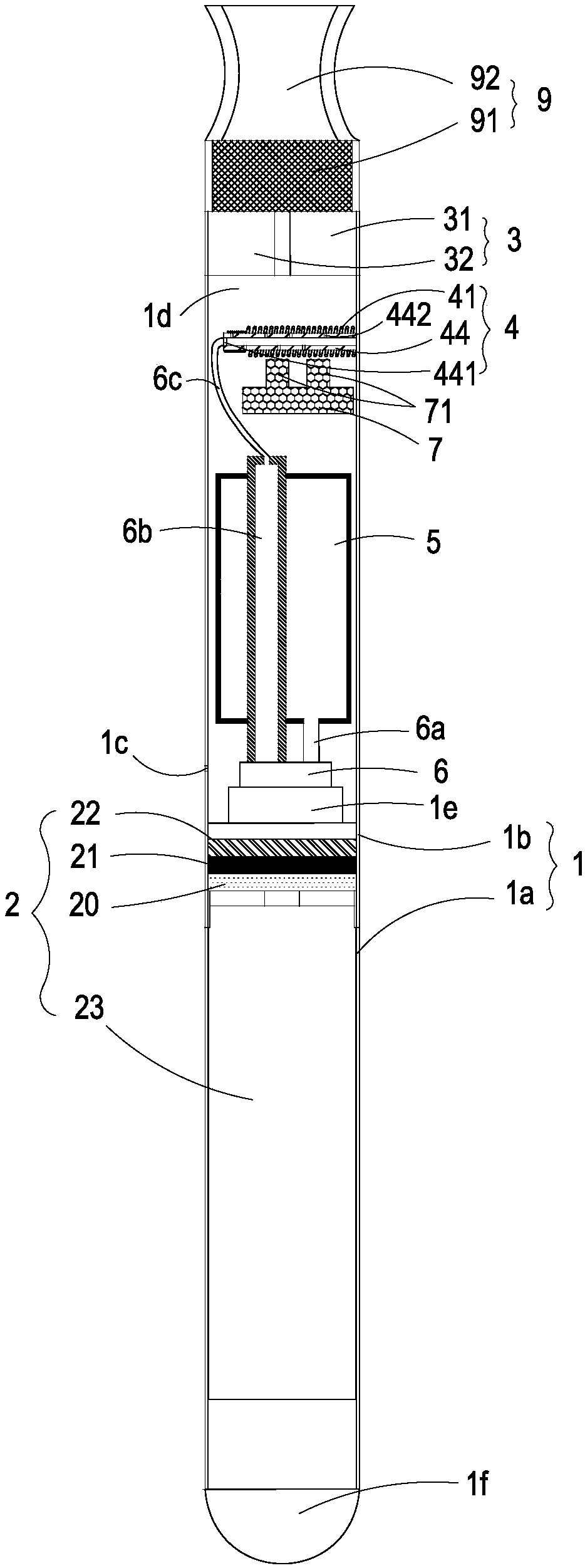

Electronic cigarette

ActiveCN108685181ASolve for uniformitySolve the problem of oil seepageTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette. The electronic cigarette comprises a power supply device, an atomizing component, a liquid storage component, a fluid conveying device, a sensor, a shell body and a suction nozzle, wherein cigarette liquid is stored inside the liquid storage component, and the fluid conveying device controls the amount of the conveyed cigarette liquid which drips onthe atomizing component from the liquid storage component; the sensor comprises an air flow sensor and an air pressure sensor to change the cigarette liquid atomizing speed of the atomizing componentand the liquid supplying speed of the fluid conveying device; the power supply device, the sensor, the fluid conveying device, the atomizing component and the liquid storage component are installed in the shell body, and an air inlet is formed in the outer surface of the shell body; the suction nozzle seals one end of the shell body.

Owner:MICROJET TECH

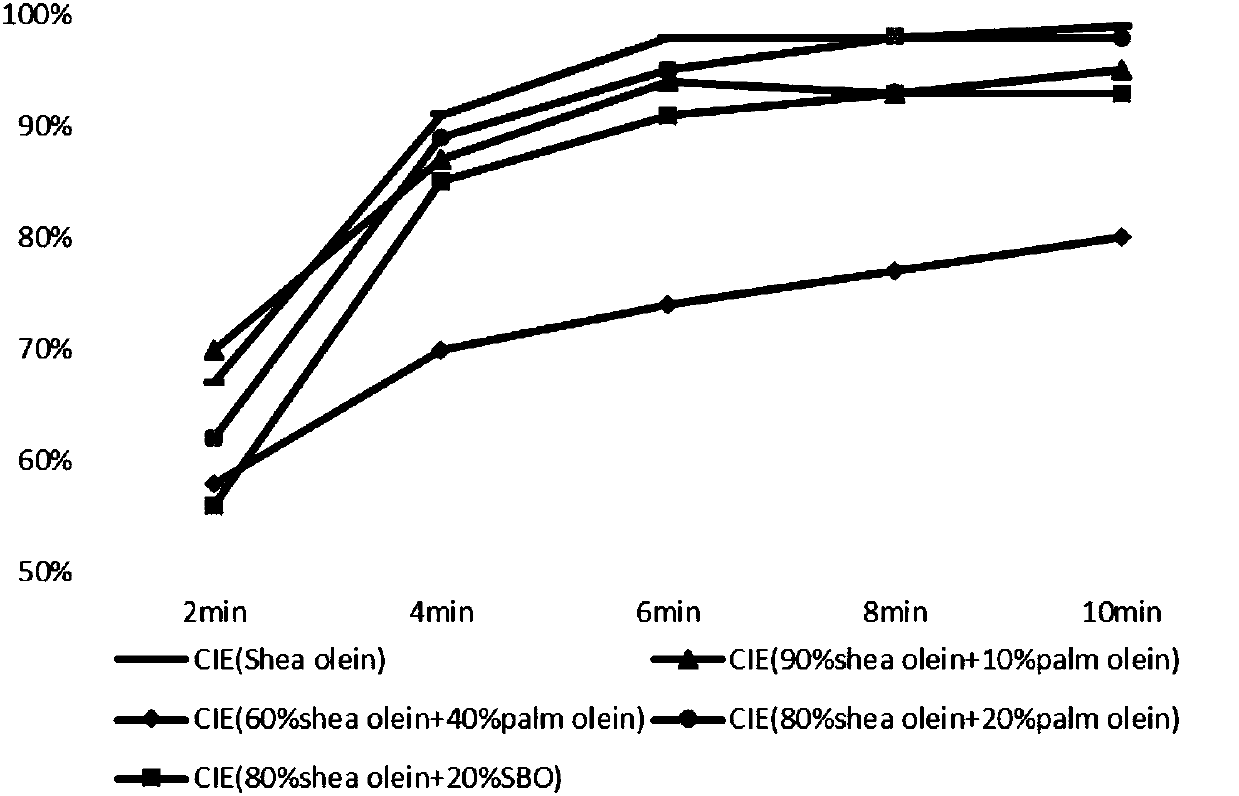

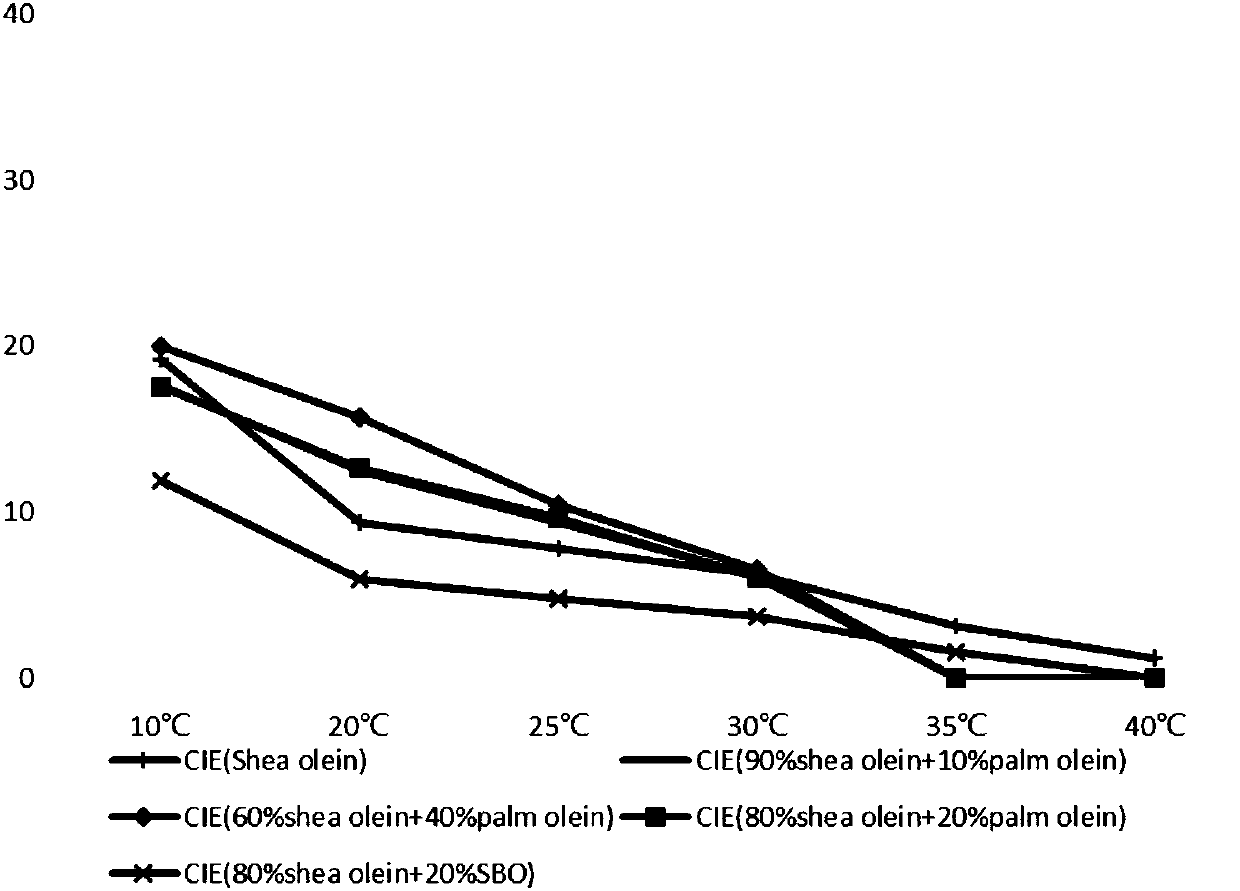

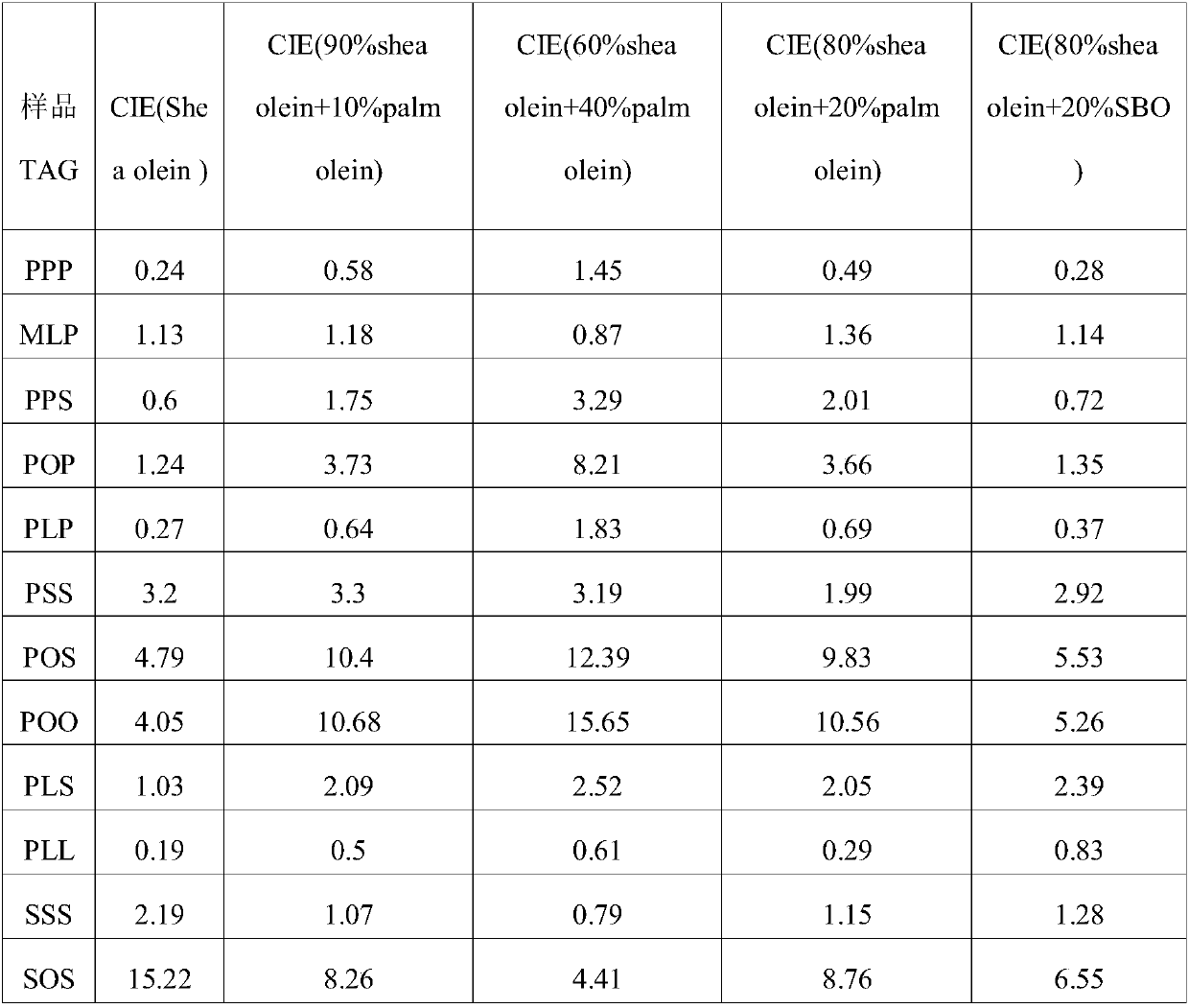

Fat composition high in crystallization rate but gentle in SFC curve

InactiveCN109953128AGreat tasteFast crystallization rateEdible oils/fats with aqeous phaseTransesterificationFractionation

The invention provides a fat composition high in crystallization rate but gentle in SFC curve. The fat composition is a random transesterification fat composition of shea butter liquid fractionation components and palm oil fractionation components. For the fat product prepared from the fat composition, the problems of oil seeping and after hardening are greatly solved.

Owner:嘉里特种油脂(上海)有限公司

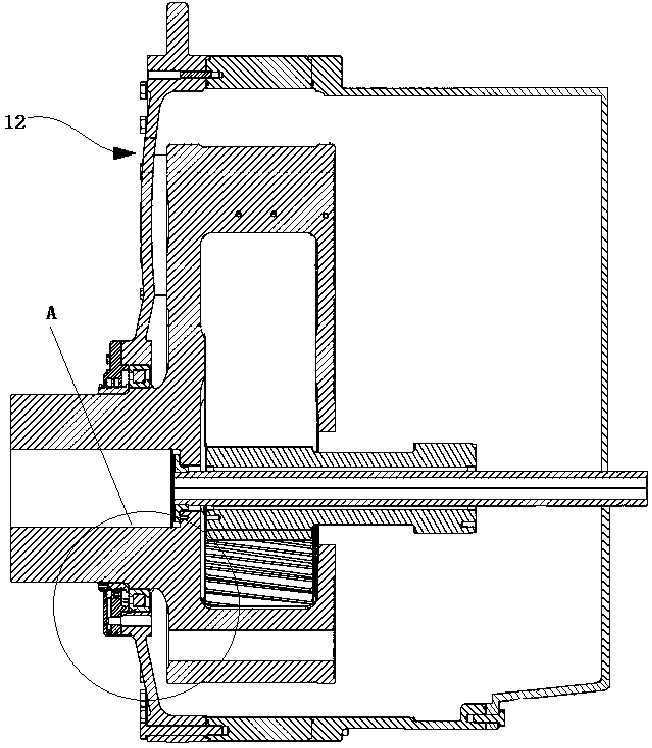

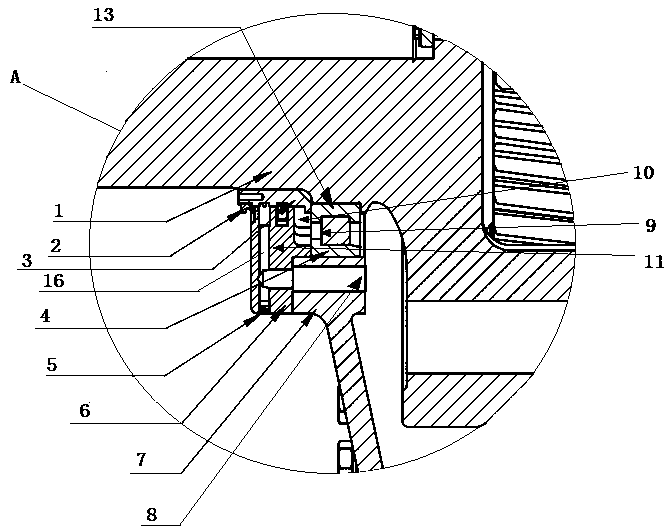

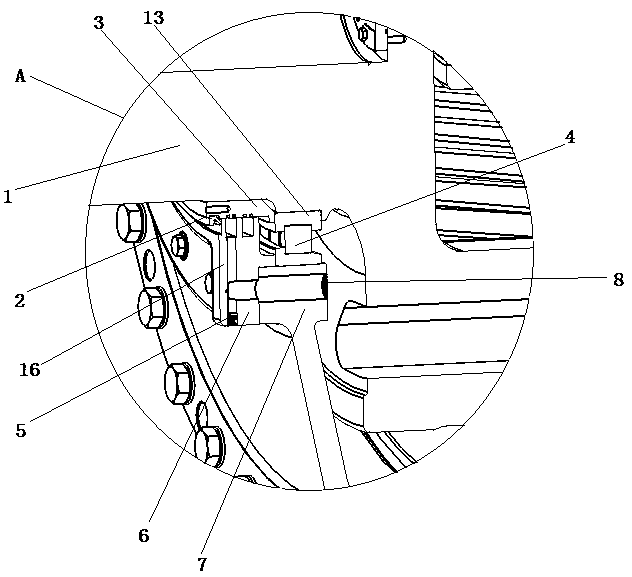

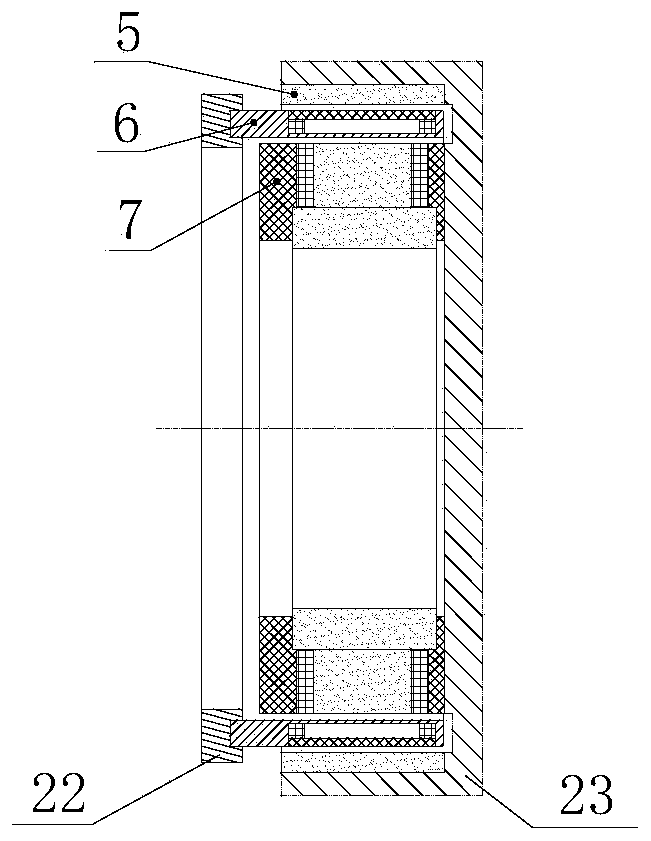

Gear case with bubble removal labyrinth seal structure

InactiveCN108953567ASolve the problem of oil seepageLow costGear lubrication/coolingMechanical engineeringLabyrinth seal

The invention relates to the field of gear case structures, in particular to a gear case with a bubble removal labyrinth seal structure. A planet carrier, a case body and a bearing are arranged in thegear case. Through the gear case, lubricating oil is directly sprayed to the bearing through a lubricating oil way. A labyrinth seal inner ring is closely attached to and sleeves the exterior of theplanet carrier. A labyrinth seal outer ring sleeves the labyrinth seal inner ring. The labyrinth seal outer ring is provided with a third groove, the third groove is in penetrating connection with thecase body, and accordingly a third oil return way is formed. The case body is connected with a bubble removal component on the end face of a third oil return way port. During usage, when the bubblesmake contact with the bubble removal component, the bubbles can disappear, and therefore the situation that the bubbles enter a third oil way and seeps into the outer surface of the gear case througha V-shaped sealing ring, and oil leakage happens is avoided; the problem that due to excessive bubbles, oil seepage happens to the gear case is effectively solved; and cost is low, and assembling is convenient.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

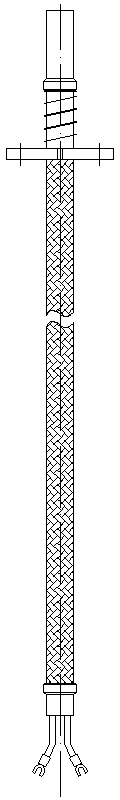

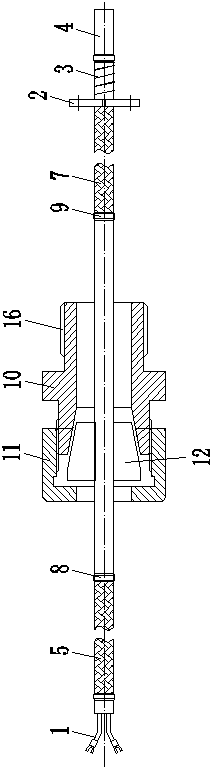

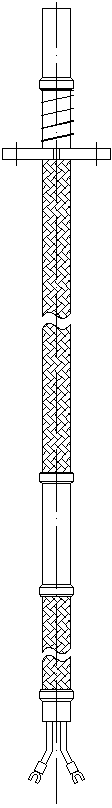

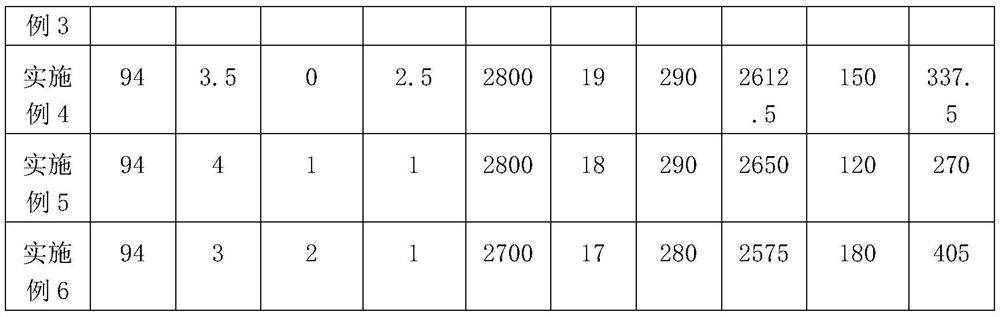

Device for measuring bearing shoe temperature of power plant steam turbine with purpose of solving lead oil leakage problem

InactiveCN103528707AImprove reliabilityEliminate damageThermometers using electric/magnetic elementsUsing electrical meansPower stationEngineering

The invention relates to a device for measuring the bearing shoe temperature of a power plant steam turbine with the purpose of solving a lead oil leakage problem. An element lead is sequentially connected by a first flexible wire, a lead armor rod and a second flexible wire. A wiring end is connected to one end of the first flexible wire, and a spring pressing sheet, a spring and a temperature measuring element are connected to one end of the second flexible wire. A seal device is sleeved on the lead armor rod, the seal device consists of a base, a pressing cap and a seal plug, the seal plug is sleeved and fixed on the lead armor rod, the base is sleeved outside the seal plug and the lead armor rod, the pressing cap is sleeved outside the lead armor rod, the pressing cap is connected with the base, the pressing cap is in tight contact with the seal plug, and the base is in tight contact with the seal plug. Not only is the oil leakage problem of the bearing shoe temperature measuring element lead of the power plant steam turbine solved by the device, but also the device is reliable in performance and convenient in installation. Meanwhile, the damage of a traditional leakage treatment method to the element lead is eliminated, and the bearing shoe temperature protection reliability of the steam turbine is improved, so that a generator set can safely and stably run.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Electronic cigarette

ActiveCN108685180ASolve for uniformitySolve the problem of oil seepageTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette. The electronic cigarette comprises a power supply device, a sensor, an atomizing component, a fluid conveying device, a liquid storage component, a shell body and a suction nozzle. The atomizing component comprises an electric heater and a liquid guiding pipe, and an inputting opening and a plurality of through holes are formed in the front and backends of the liquid guiding pipe respectively; the liquid storage component is provided with a passage and a liquid storage container, the electric heater is arranged in the passage, and cigarette liquid is stored in the liquid storage container; the fluid conveying device is provided with an inputting passage and an outputting passage, the inputting passage is communicated with the liquid storagecontainer, the outputting passage is communicate with the inputting opening to make the cigarette liquid conveyed into the liquid guiding pipe and permeate to the outside of the liquid guiding pipe through the through holes, and the cigarette liquid is controlled to drip on the electric heater so as to generate smoke; an air inlet is formed in the outer surface of the shell body; the suction nozzle seals one end of the shell body.

Owner:MICROJET TECH

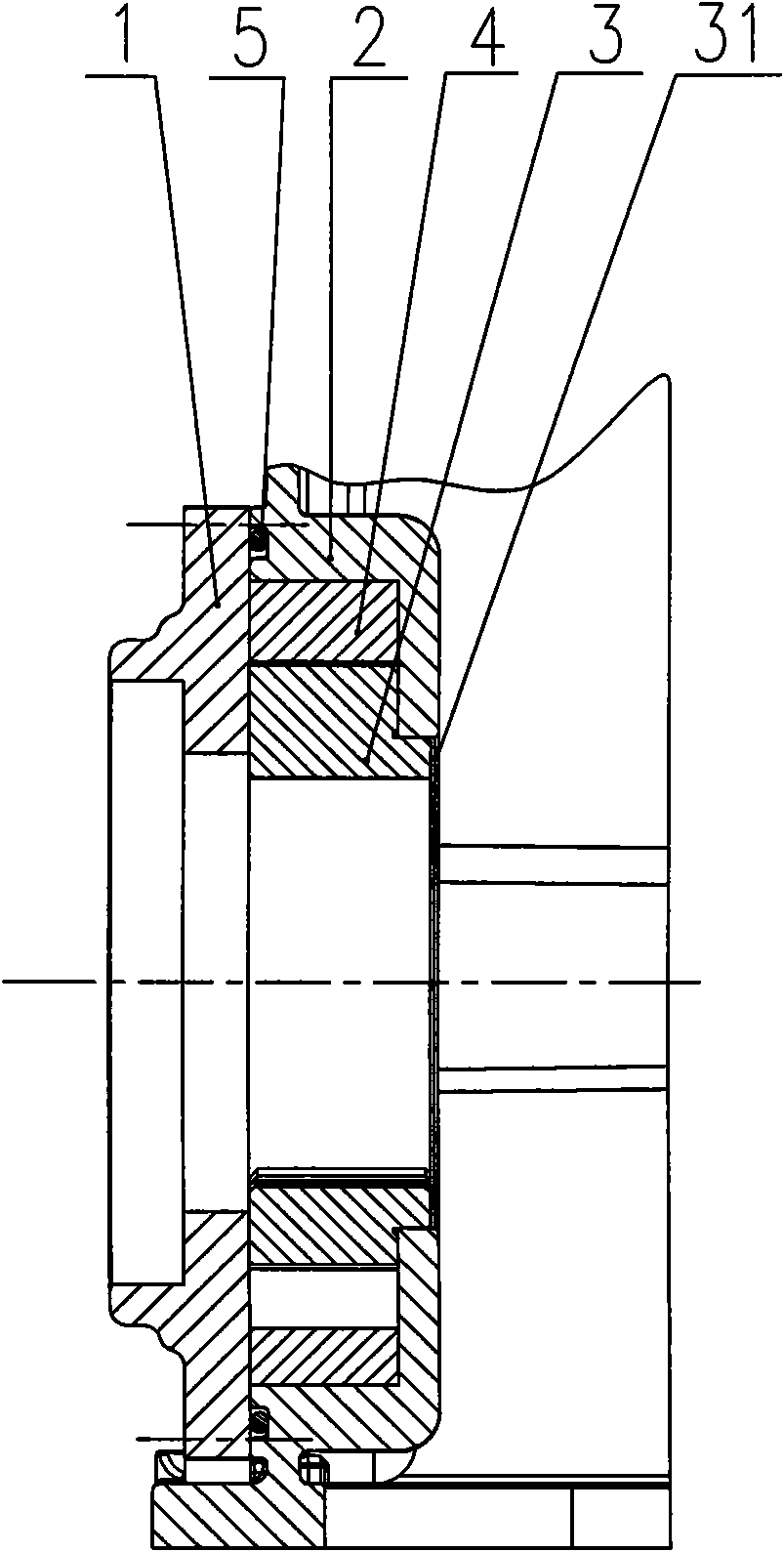

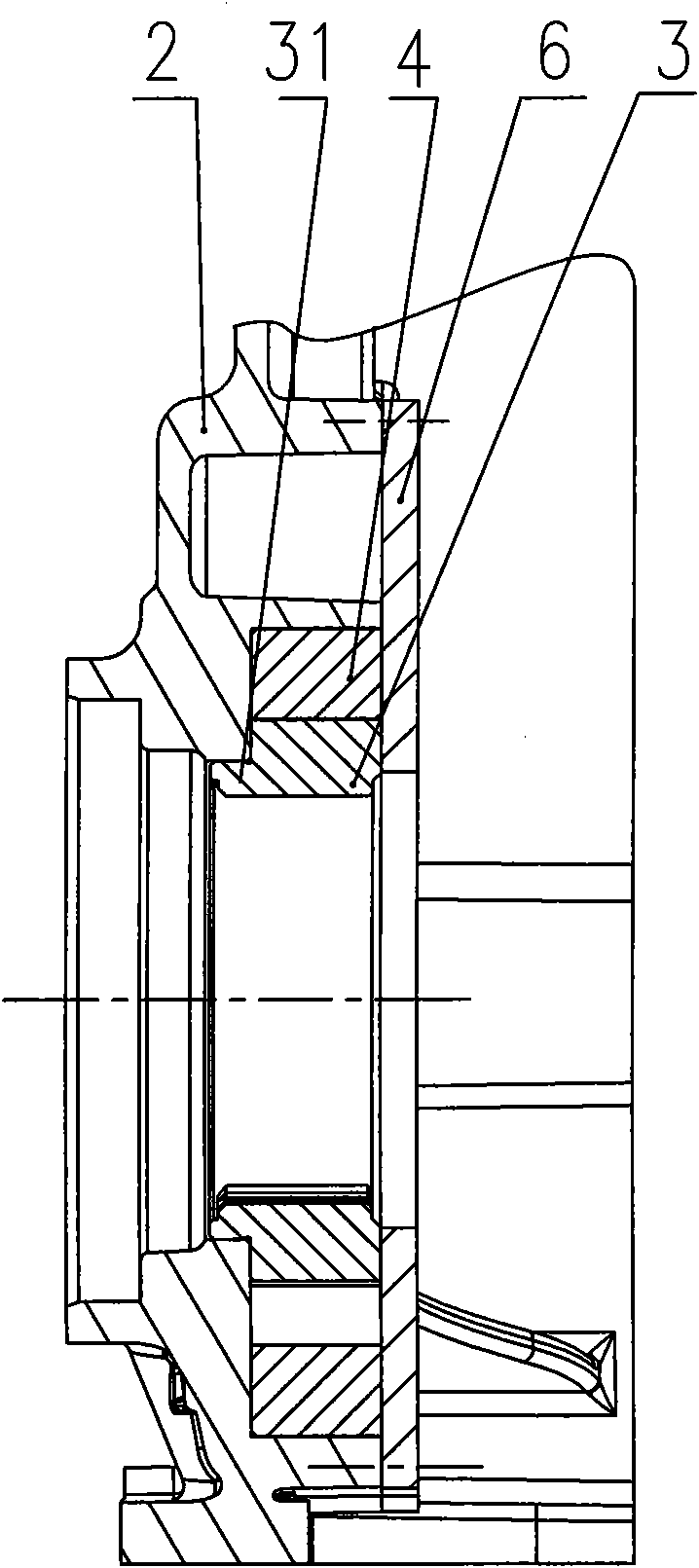

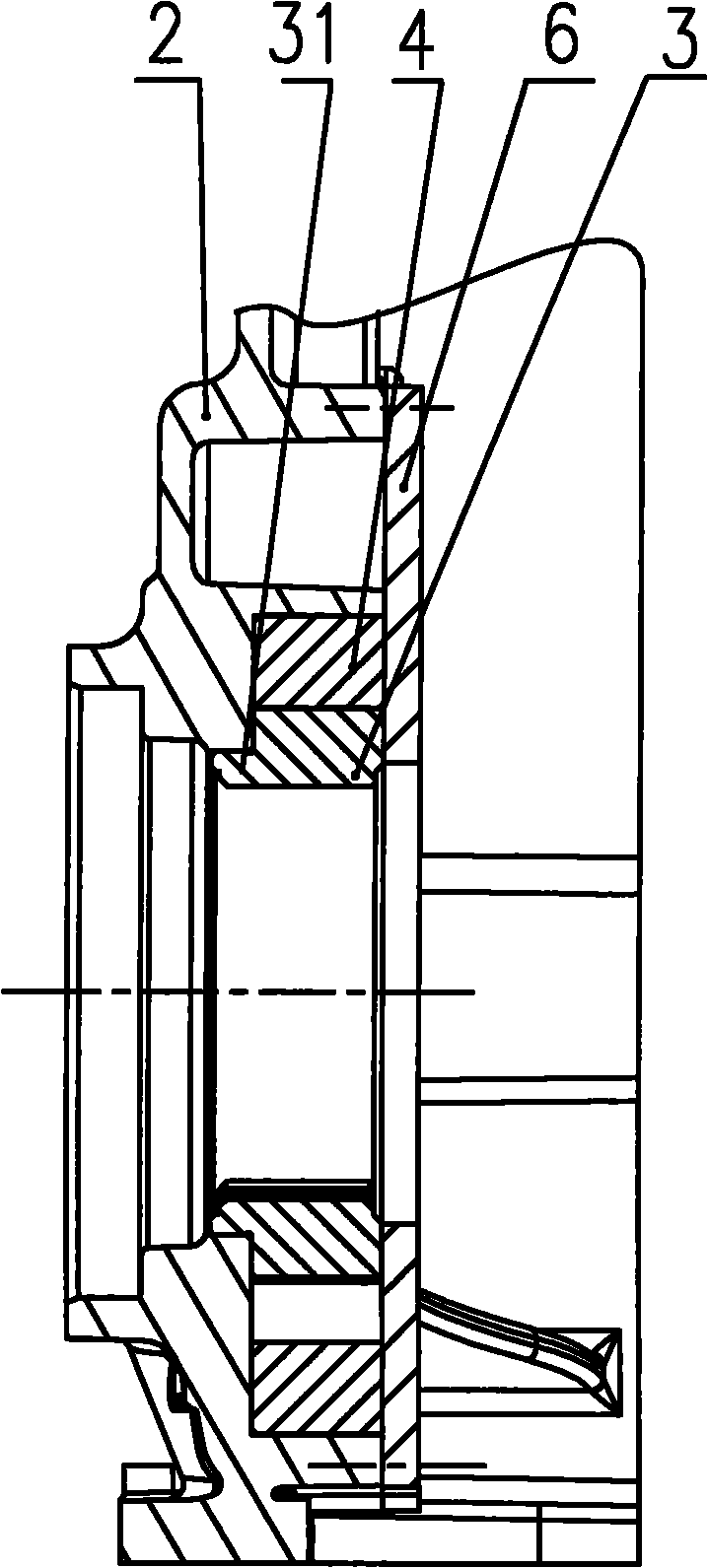

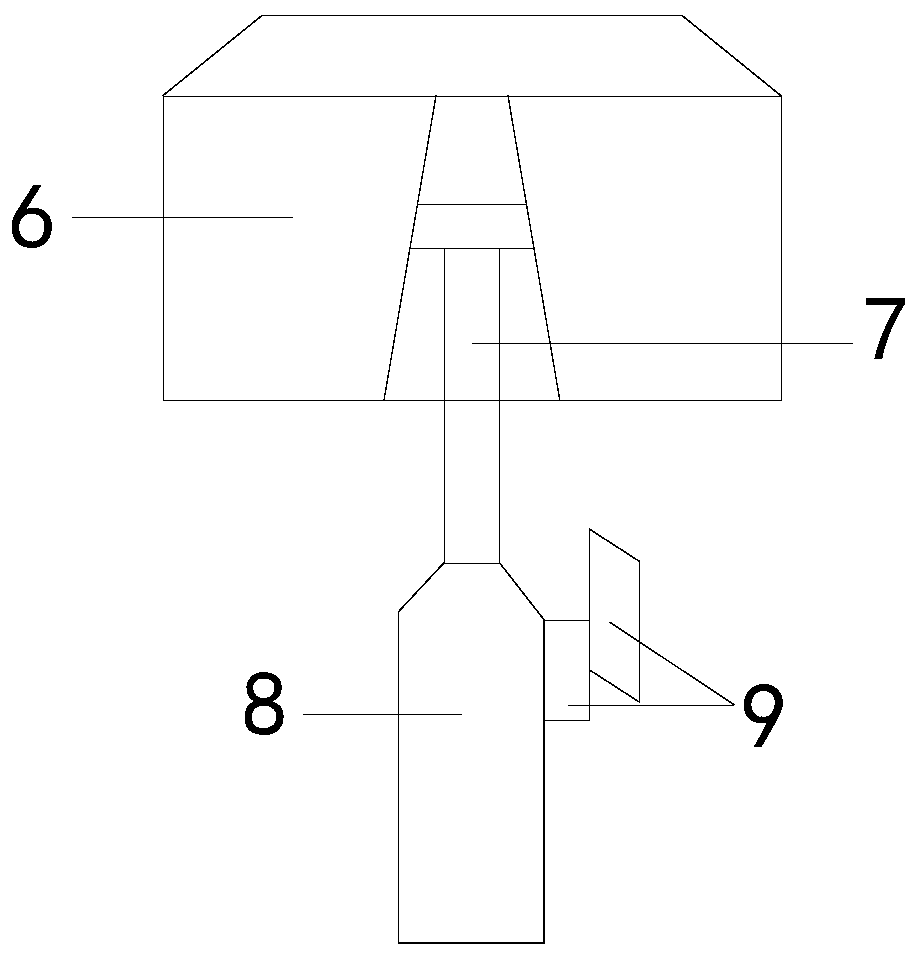

Inner pump cover rotor oil pump installed on backside of pump cover

InactiveCN102003385AImprove craftsmanshipLow costMachines/enginesRotary/oscillating piston pump componentsEngineeringMechanical engineering

The invention discloses an inner pump cover rotor oil pump installed on the backside of a pump cover. The pump comprises a pump cover 6, a pump body 2, an inner rotor 3 and an outer rotor 4, wherein the outer rotor 4 is installed in the rotor hole of the pump body 2, the inner rotor 3 is sleeved in the hole of the outer rotor 4, the inner rotor 3 is provided with a stepped locating ring 31, the stepped locating ring 31 is located on the left side of the inner rotor 3, and the pump cover 6 is installed at the backsides of the inner rotor 3, the outer rotor 4 and the pump body 2. Because an oil pump front pump cover installed on the frontage of an engine is replaced by an inner pump cover installed on the backside of the engine, the invention has the advantages that the problem of surface oil leakage is solved, and the material cost is lowered; since the pump cover is installed in the inner part of the oil pump, the faying face of the pump cover and the pump body does not require a sealing gasket, a working procedure for manufacturing a sealing groove is omitted, the manufacturability of machine work is improved, and the production cost is reduced; and especially, after the front pump cover is replaced by the inner pump cover, the sealing ring hole of the front pump cover is in an integral structure, thus the installation sealing degree of the crank shaft oil sealing hole and crank shaft of the front pump cover is improved, and the sealing efficacy is improved.

Owner:HUNAN OIL PUMP

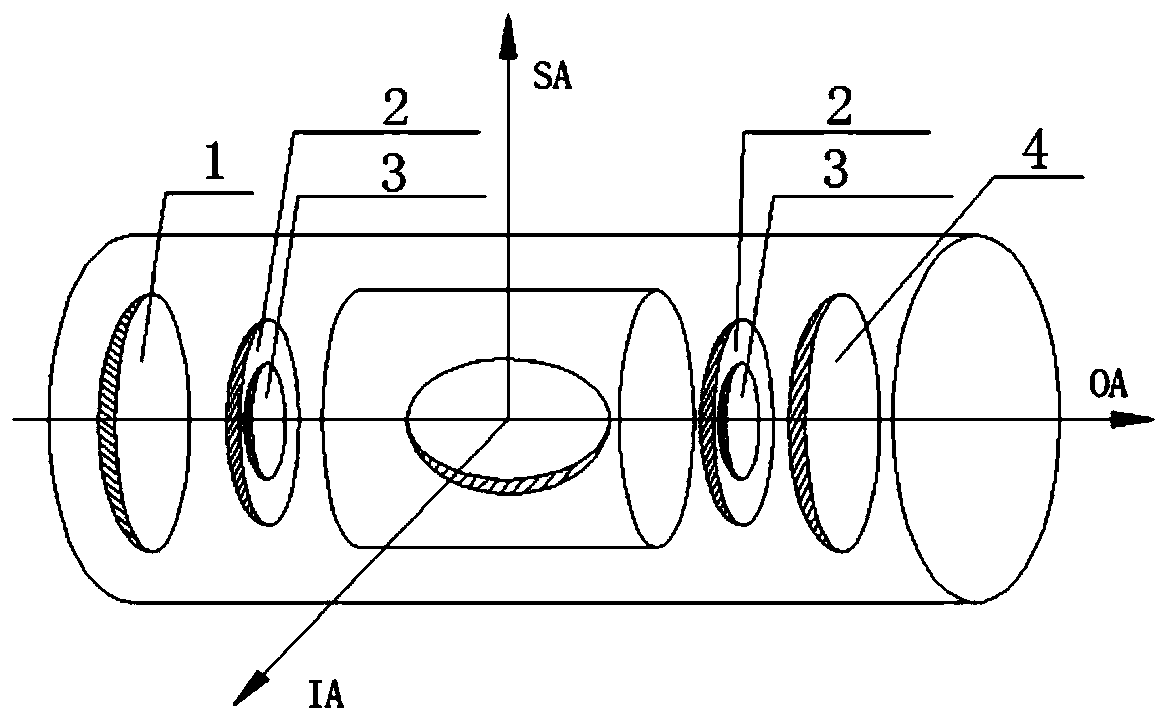

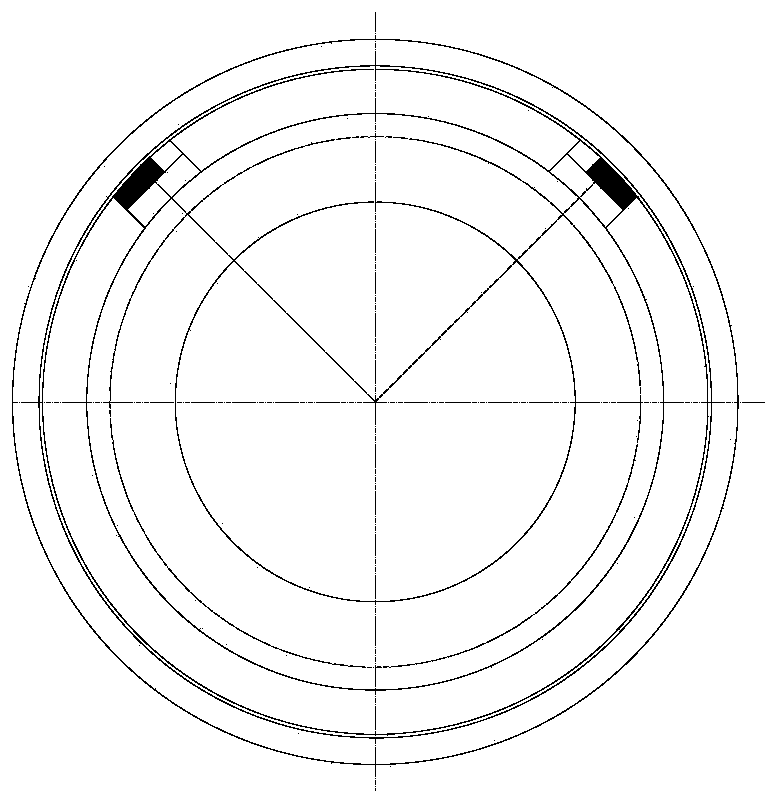

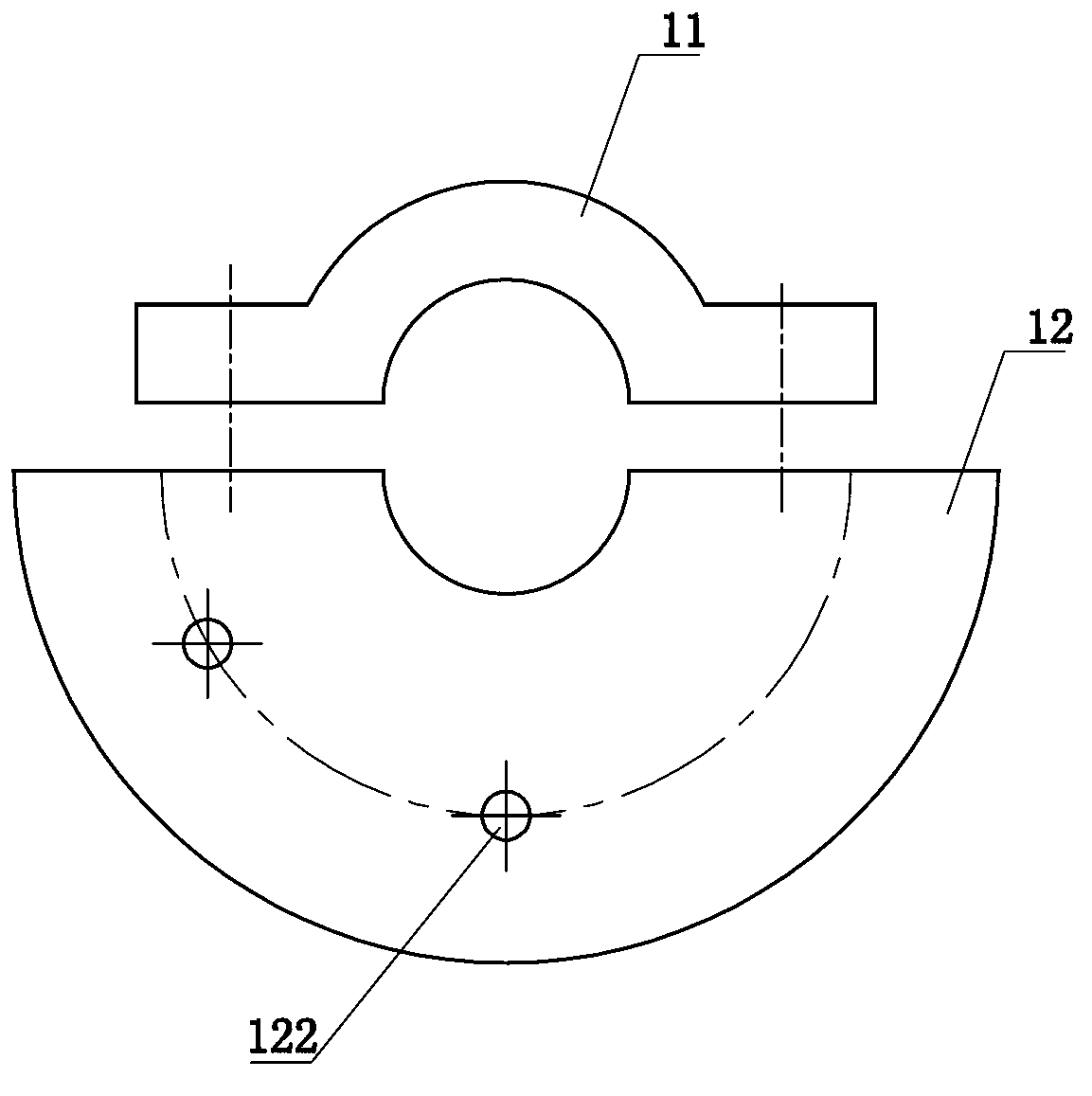

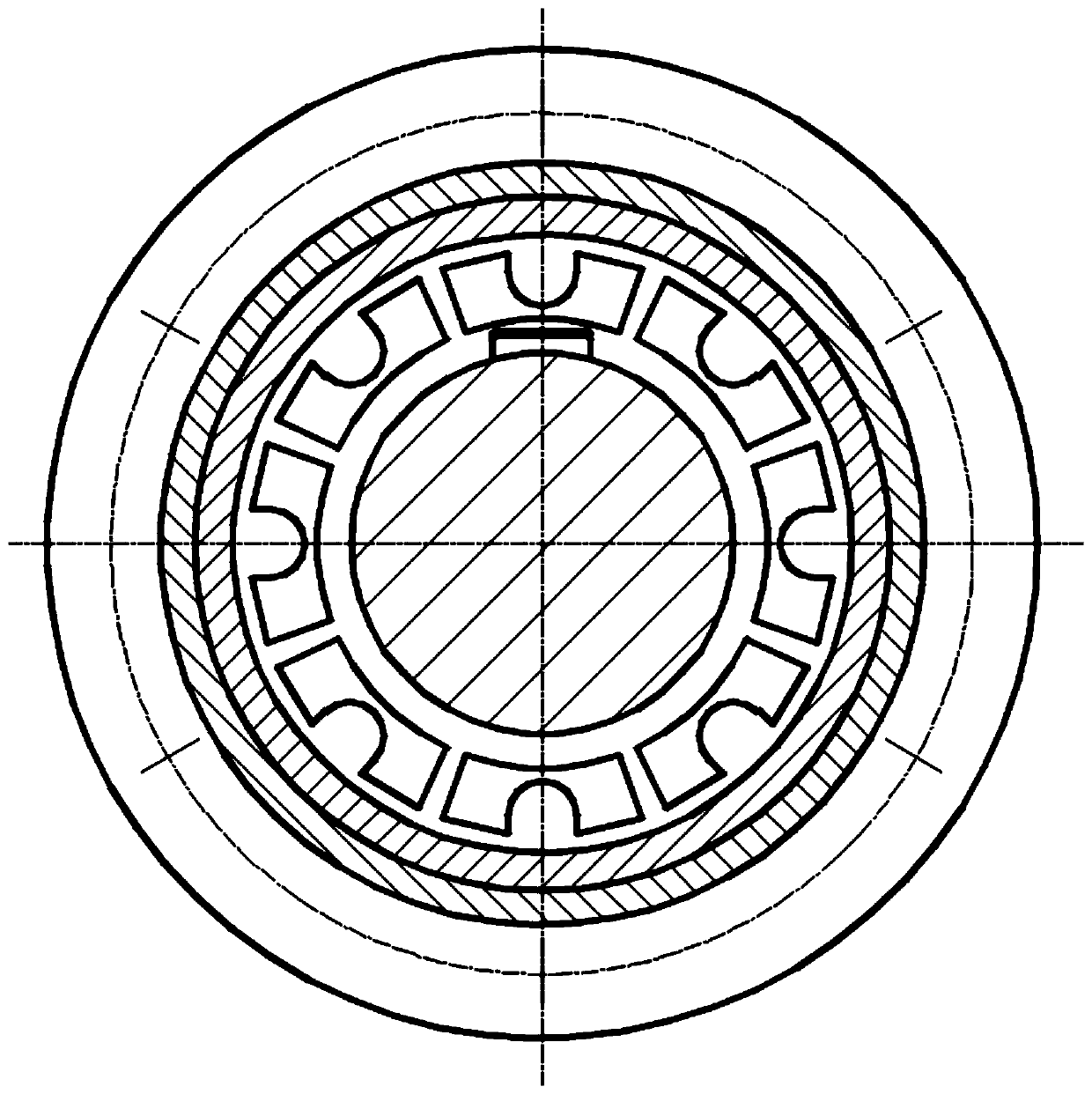

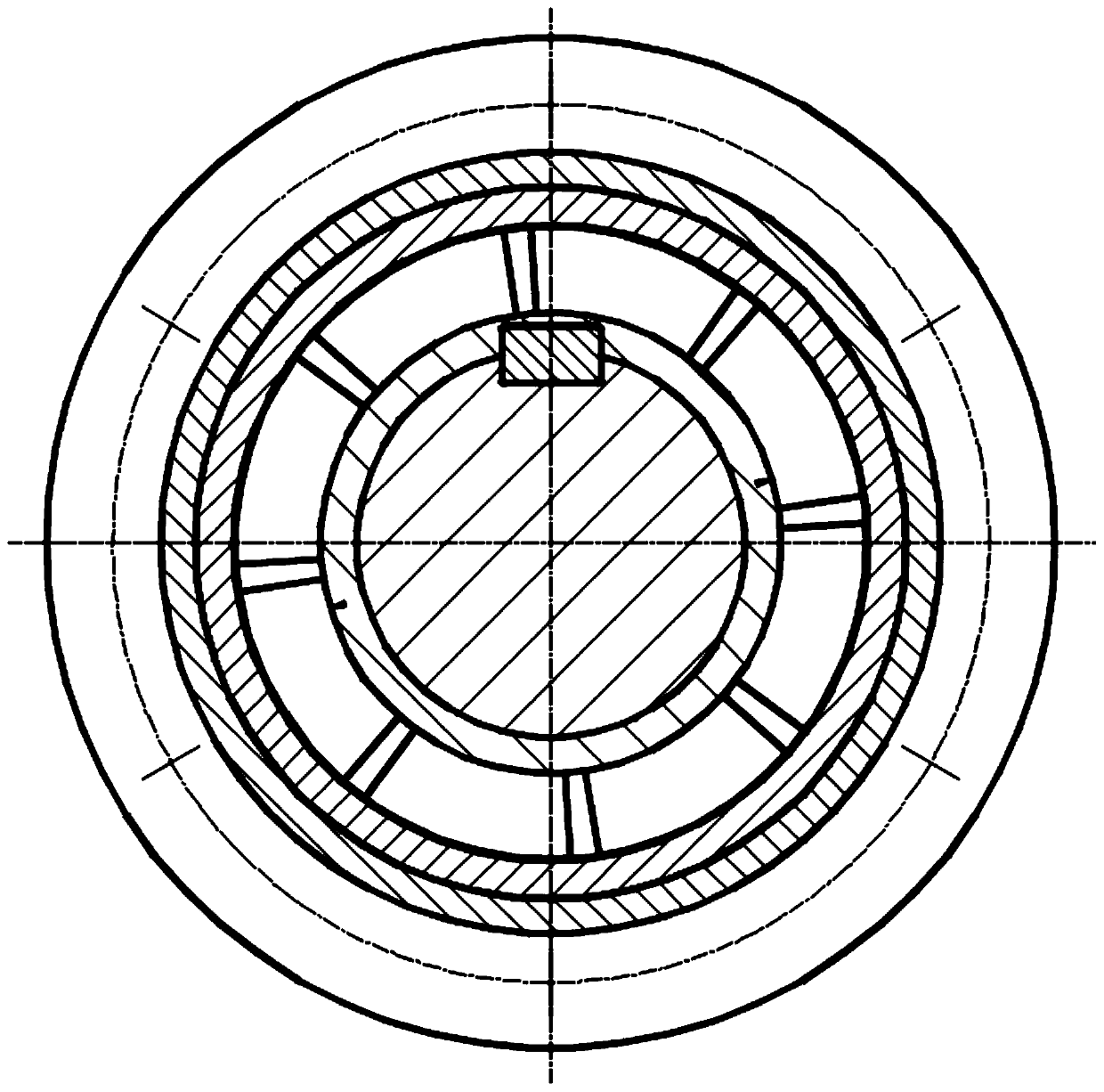

Sensor for three-floated gyroscope and stator preparation process thereof

PendingCN110926443AGyro precision and reliability guaranteeSolve the problem of zero dead zoneRotary gyroscopesStatorElectrical and Electronics engineering

The invention relates to a sensor, in particular to a sensor for a three-floated gyroscope and a stator preparation process thereof, and solves the problems of oil leakage of a sensor rotor and asymmetry of a sensor magnetic circuit of an existing moving-coil sensor device. The sensor rotor comprises a rotor bracket, a rotor coil and a rotor pouring sealant layer. The rotor support is an annular support, an annular groove is formed in the circumferential direction of the outer circumferential face of the annular support, and one side wall of the groove is a step face. The rotor coil is wound in the small end of the groove. The pouring sealant is poured in the large end of the groove along the outer peripheral surface of the rotor coil to form a rotor pouring sealant layer. The first end surface of the pouring sealant layer clings to the large end surface of the groove, and the second end surface of the pouring sealant layer is flush with the end surface of the rotor bracket. The sensorstator comprises an inner magnetic conductive ring and a plurality of magnetic poles, and the plurality of magnetic poles and the inner magnetic conductive ring are integrally arranged. By optimizingthe structure of the sensor, the center of mass of the gyroscope does not obliquely float in a certain slope trend any more, and the precision and reliability of the gyroscope are guaranteed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Method for repairing micro-arc oxide film oil leakage at seal groove of cylinder body of actuator cylinder of airplane

ActiveCN105857639ASolve the problem of oil seepageAvoid scrappingGrinding machinesGround installationsSurface roughnessActuator

The invention discloses a method for repairing micro-arc oxide film oil leakage at a seal groove of a cylinder body of an actuator cylinder of an airplane. The method comprises the followings steps: disassembling the cylinder body of the actuator cylinder assembly of the airplane; measuring the surface roughness of the micro-arc oxide film at the seal groove of the cylinder body, if the surface roughness reaches Ra 1.6 or above, detecting whether a loose layer is generated on the micro-arc oxide film at the seal groove of the cylinder body or not, and if the loose layer is generated, conducting reparation: (1) wrapping the cylinder body with a layer of soft cloth, and clamping the cylinder body on a three jaw chuck of an electric polishing machine; (2) adsorbing a gauge head and a gauge stand of a dial indicator on the other side of the electric polishing machine, rotating the cylinder body, and keeping the jerk value of the seal groove of the cylinder body to be not more than 0.05; (3) enabling a felt wheel to extend into the seal groove of the cylinder body, adjusting the rotating speed of the felt wheel, and polishing the micro-arc oxide film at the seal groove; (4) measuring the size and the roughness of the polished seal groove of the cylinder body; (5) assembling the polished qualified cylinder body on the actuator cylinder assembly, and conducting seal test detection according to the product design requirements.

Owner:SHENYANG LIMING AERO PARTS MFG

Welding device for sealing supercapacitors

InactiveCN110883450ASolve the problem of oil seepageSolve scrapWelding/cutting auxillary devicesOther manufacturing equipments/toolsSlag (welding)Right triangle

Owner:张自明

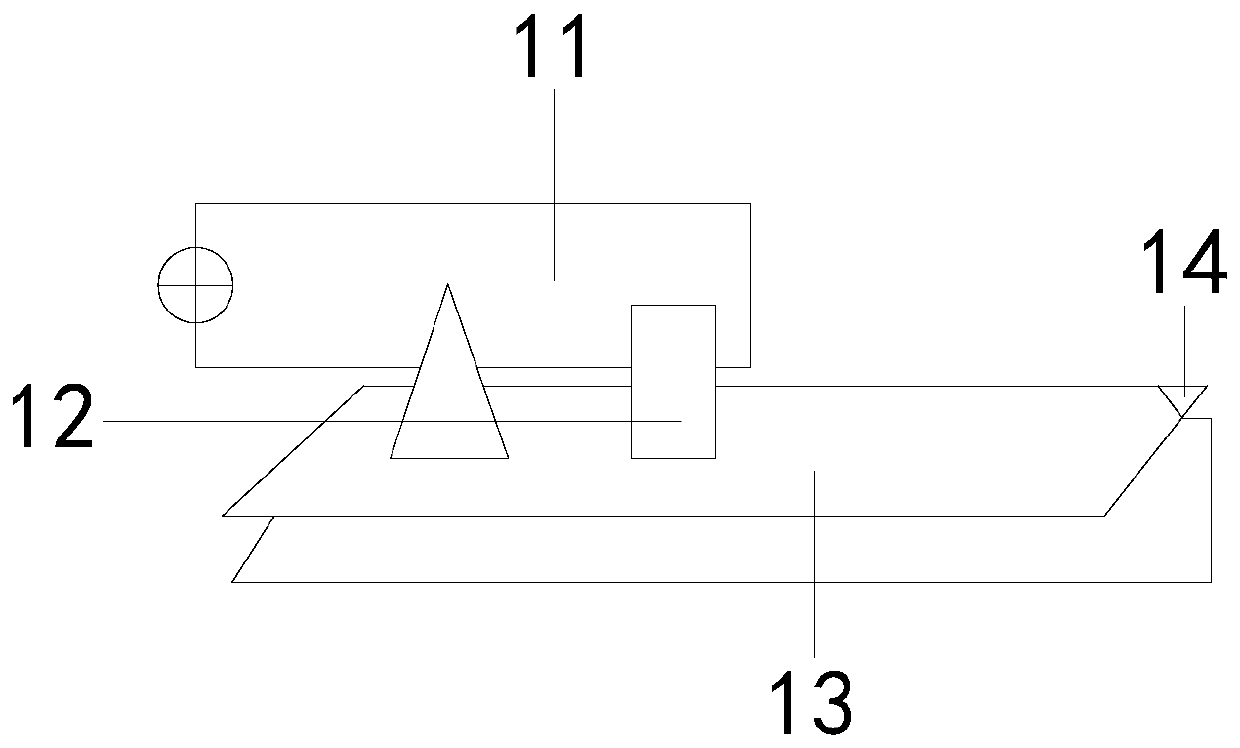

Barrel paper suction control device of cigarette packer

InactiveCN102837847AAvoid the problem of oil leakage in the gas pathThe air passage is smoothWrapping material feeding apparatusPackaging automatic controlPistonScrap

The invention discloses a barrel paper suction control device of a cigarette packer. The barrel paper suction control device comprises a disk cam arranged on a barrel paper conveying transmission shaft, a sensor corresponding to the position of the disk cam, a relay electrically connected with the sensor, an electromagnetic valve electrically connected with the relay and a suction wheel connected with the electromagnetic valve through a gas circuit, wherein the disk cam, the sensor, the relay, the electromagnetic valve and the suction wheel are arranged outside a transmission box; a filter device is arranged on the gas circuit; and the disk cam is of a combined structure and provided with an angle regulation device. According to the barrel paper suction control device, the problems of oil leakage and paper scrap suction of the gas circuit of the prior art, and the running condition in the gas circuit is more smooth; the suction and the conveying of the barrel paper by the suction wheel is more stable, and the performance of the effective operating rate of a single YB65 machine is guaranteed; a cam, a piston and a gas circuit in the transmission box are dismounted, so that the running load of the machine is reduced, and the labor intensity of maintenance personnel is reduced; and the problems of difficult clearing, long box opening time and the like are solved.

Owner:CHINA TOBACCO SHANDONG IND

A hollow piston rod assembly preventing contamination of hydraulic oil

InactiveCN106195261BSmooth inner surfaceLow fluid resistanceEngine sealsFluid-pressure actuatorsHydraulic cylinderEngineering

The invention belongs to the technical field of piston rod assemblies, discloses a hollow piston rod assembly capable of preventing pollution of hydraulic oil, and is used for solving problems of high flow resistance of the hydraulic oil and pollution of the hydraulic oil due to the fact that sizes of inner holes cannot meet requirements and the roughness of the inner holes is poor when hollow piston rods are produced from seamless steel tubes at present. The assembly comprises a piston rod body with a through hole, wherein the through hole of the piston rod body is directly machined through deep hole drilling. The through hole of the piston rod body is directly machined through deep hole drilling, compared with the hollow piston rods produced from the seamless steel tubes in the prior art, the assembly has the advantage that the required inner hole size can be machined according to the requirement of a hydraulic cylinder and the assembly has the characteristic of the smooth surface of the inner hole, the flow resistance of the hydraulic oil in the delivery process can be reduced, and meanwhile, delaminating conditions can be avoided, so that pollution of the hydraulic oil due to stains can be avoided.

Owner:SICHUAN YUEAN HEAVY IND MACHINERY EQUIP CO LTD

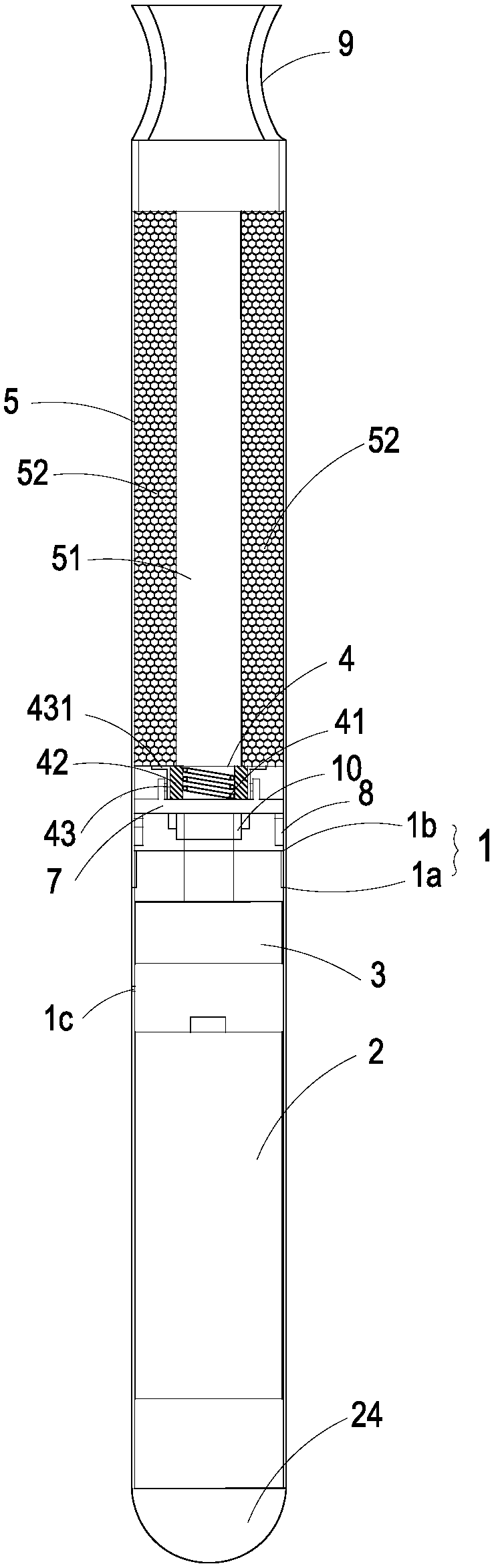

Electronic cigarette

ActiveCN108685178ASolve for uniformitySolve the problem of oil seepageTobacco devicesEngineeringSmoke

The invention discloses an electronic cigarette. The electronic cigarette comprises a power supply device, a sensor, an atomizing component, a liquid storage component, a fluid storage component and ashell body, wherein the atomizing component comprises an electric heater, a liquid permeation component and a liquid guiding ring seat, the liquid permeation component is assembled on the electric heater, the electric heater and the liquid permeation component are wholly assembled on the center hollow portion of the liquid guiding ring seat, the liquid guiding ring seat is provided with an innerliquid guiding ring part, through holes are formed in an inner layer of the inner liquid guiding part and are used for being in contact and guiding connection with the liquid permeation component, andthe liquid guiding ring seat is provided with an inputting opening and is communicated with the inner liquid guiding ring part; the liquid storage component is provided with a passage used for air flow to pass and a liquid storage container, and cigarette liquid is stored in the liquid storage container; the fluid conveying device is provided with an inputting passage and an outputting passage, the inputting passage is communicated with the liquid storage container, and the outputting passage is communicated with the atomizing component to control the cigarette liquid to be quantitatively conveyed into the atomizing component so as to generate atomizing smoke.

Owner:MICROJET TECH

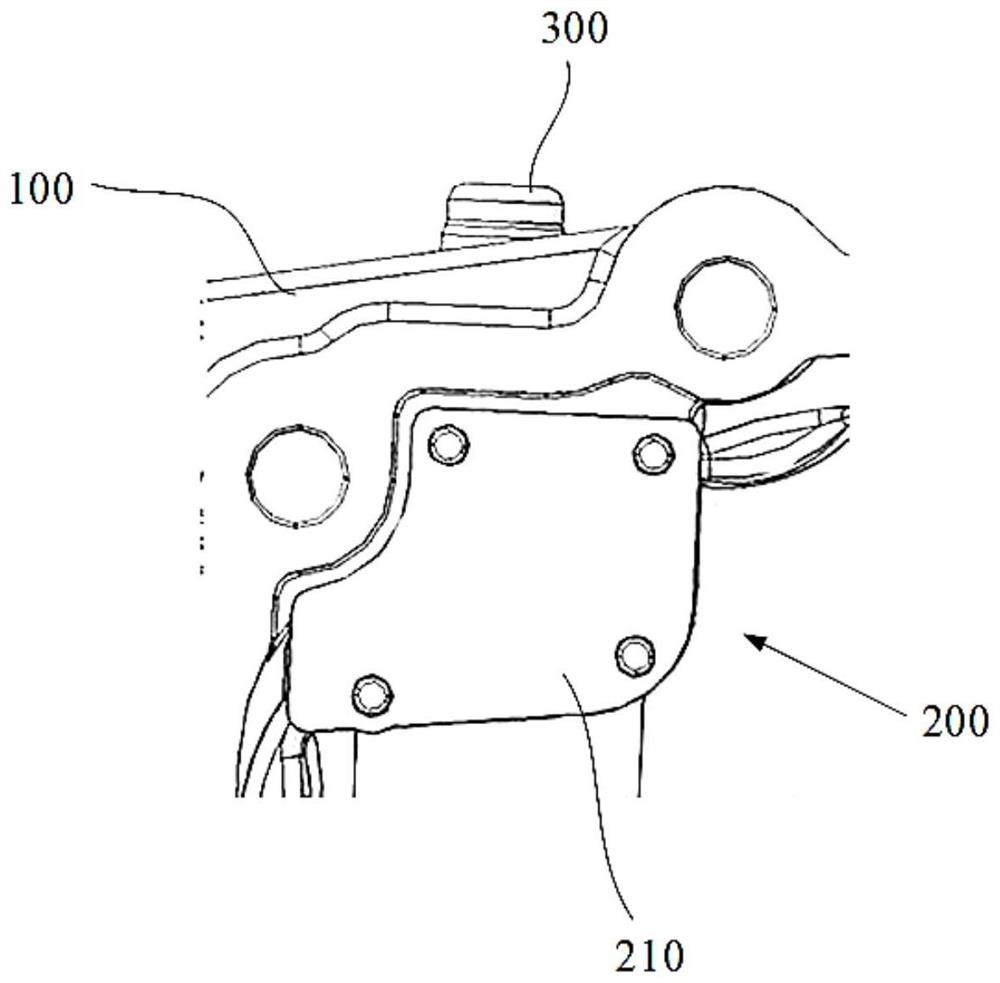

Shell body, main reducer provided with same and vehicle

PendingCN111623109AImprove blocking effectReduce the possibilityGearing detailsStructural engineeringReduction drive

The invention provides a shell body, a main reducer provided with the same and a vehicle. The shell body comprises an outer shell and a blocking structure; a main cavity, a decompression passage and adecompression hole are formed in the outer shell; the decompression passage and the decompression hole communicate with the main cavity respectively and the decompression passage communicates with the decompression hole; the blocking structure comprises an enclosure bulkhead and at least one oil blocking plate; the enclosure bulkhead is attached to the inside of the outer shell; the enclosure bulkhead and the outer shell jointly limit to form a blocking cavity; the blocking cavity is positioned between an outlet of the decompression passage and the decompression hole; and the oil blocking plate is positioned in the blocking cavity and is attached to the outer shell, so the blocking cavity is divided into at least two blocking subcavities which communicate with each other. The blocking mechanism improves the effect of blocking oil liquid and prevents the oil liquid from passing through and reaching the position of a one-way valve positioned in the decompression hole, so the problems ofoil impregnation and oil leakage at the position of the one-way valve are finally solved.

Owner:BAIC GRP ORV CO LTD

Hollow piston rod assembly capable of preventing pollution of hydraulic oil

InactiveCN106195261ALow fluid resistanceLow costEngine sealsFluid-pressure actuatorsSteel tubeSmooth surface

The invention belongs to the technical field of piston rod assemblies, discloses a hollow piston rod assembly capable of preventing pollution of hydraulic oil, and is used for solving problems of high flow resistance of the hydraulic oil and pollution of the hydraulic oil due to the fact that sizes of inner holes cannot meet requirements and the roughness of the inner holes is poor when hollow piston rods are produced from seamless steel tubes at present. The assembly comprises a piston rod body with a through hole, wherein the through hole of the piston rod body is directly machined through deep hole drilling. The through hole of the piston rod body is directly machined through deep hole drilling, compared with the hollow piston rods produced from the seamless steel tubes in the prior art, the assembly has the advantage that the required inner hole size can be machined according to the requirement of a hydraulic cylinder and the assembly has the characteristic of the smooth surface of the inner hole, the flow resistance of the hydraulic oil in the delivery process can be reduced, and meanwhile, delaminating conditions can be avoided, so that pollution of the hydraulic oil due to stains can be avoided.

Owner:SICHUAN YUEAN HEAVY IND MACHINERY EQUIP CO LTD

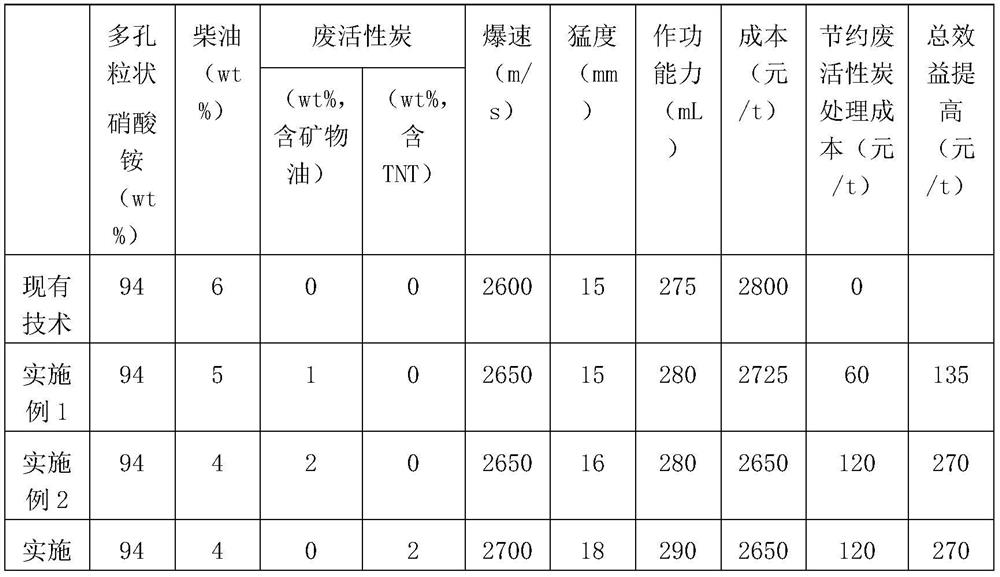

Porous granular ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN114230426AReduce usagePlay the effect of saving energy and reducing consumptionExplosive ingredient compoundingActivated carbonExplosive Agents

The invention discloses a porous granular ammonium nitrate fuel oil explosive, and also discloses a preparation method of the porous granular ammonium nitrate fuel oil explosive. The method has the advantages that 1, by adding the waste activated carbon adsorbed with mineral oil steam and TNT, the activated carbon and substances adsorbed by the activated carbon can be used as a reducing agent in the porous granular ammonium nitrate fuel oil explosive and can replace a part of diesel oil, the use amount of the diesel oil is reduced, and the effect of saving energy is achieved; 2, the waste activated carbon is used as a preparation raw material of the porous granular ammonium nitrate fuel oil explosive, so that the treatment problem of the waste activated carbon can be solved, the treatment cost of the waste activated carbon is reduced, and harm generated in the treatment process of the waste activated carbon is avoided; according to the invention, waste can be turned into wealth, and the production concept of long-term sustainable development is met; 3, the waste activated carbon is granular, so that the free-running property of the porous granular ammonium nitrate fuel oil explosive is not influenced after the waste activated carbon is added as a raw material, and on-site mixed loading is facilitated; and 4, the detonation velocity, brisance, work capability and other properties of the porous granular ammonium nitrate fuel oil explosive can be effectively improved.

Owner:内蒙古生力民爆股份有限公司

Novel shaft end sealing device

InactiveCN110159737ASimple structureReduce volumeEngine sealsGearing detailsInternal pressureImpeller

The invention discloses a novel shaft end sealing device. A bearing is mounted on a transmission shaft; a bearing inner ring is fixedly arranged close to a sleeve; a bearing outer ring is fixedly arranged close to a bearing end cover; an impeller I, an impeller II and an impeller III are sequentially mounted on the transmission shaft, fixing in the axial direction is achieved through an elastic retainer ring, and connection in the peripheral direction is achieved through a flat key, so that the three impellers synchronously rotate along with the transmission shaft; a pressure area with high pressure in middle and low pressure at the two sides is formed inside the bearing end cover, so that the problem that lubricating oil leakage is caused as internal pressure intensity of a speed reduceris greater than external pressure intensity of the speed reducer as a result of action of piston wind while the multiple unit train in high-speed operation passes through a tunnel is solved; eight tapered impeller baffle blocks are uniformly distributed and welded inside impeller rings, so that narrow seams with large and small ends are formed, and the narrow seams with large ends are mounted at abearing end; the impeller III and the impeller I are the same in structure, and are mounted in the same direction; and eight narrow seams are uniformly formed in the impeller II. The structure dimension value range of the impellers is given. The novel shaft end sealing device solves the speed reducer oil leakage problem while the multiple unit train passes through the tunnel, and has the advantages of being simple in structure, small in size, high in reliability, and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

electronic cigarette

ActiveCN108685182BSolve for uniformitySolve the problem of oil seepageTobacco devicesTobaccoElectronic cigaretteElectrical and Electronics engineering

An electronic cigarette comprises a power supply device, a sensor, an atomizing part, a liquid storage part, a liquid delivery device, a housing and a suction nozzle, wherein the atomizing part comprises an electric heater and a liquid permeation part, and the electric heater is assembled on the periphery of the liquid permeation part; a channel allowing air to flow and a liquid storage containerare arranged at the liquid storage part, the electric heater is arranged in the channel, and a cigarette liquid is stored in the liquid storage container; an input and output channel is arranged in the liquid delivery device and communicated with the liquid storage container and the liquid permeation part, the cigarette liquid of the liquid storage container is delivered and penetrates into the liquid permeation part, the cigarette liquid is controlled to be quantitatively delivered to the electric heater to produce atomized smoke; the power supply device, the sensor, the liquid delivery device, the atomizing part and the liquid storage part are mounted in the housing, and an air inlet is formed in the surface of the housing; one end of the housing is sealed by the suction nozzle.

Owner:MICROJET TECH

electronic atomization device

ActiveCN106983178BTo achieve the feeling of "smoking"Reaching the Smoking" FeelingTobacco devicesTobaccoControl systemEngineering

The invention relates to an electronic atomization device. The electronic atomization device comprises an outer cover shell, a suction nozzle, a power source component and an atomizer, the atomizer comprises a baking cup and a heating piece, the heating piece comprises a heating core, a first pin and a second pin, the heating core covers the inside of the side wall of the baking cup, and the first pin and the second pin are exposed outside the side wall separately and are connected with a circuit control system. When the electronic atomization device is in use, tobacco or solid tobacco tar can be contained in a baking cavity, and is heated through the heating core covering the inside of the side wall of the baking cup, so that 'smoke' generated by directly baking the tobacco or the tobacco tar enters the suction nozzle. According to the electronic atomization device, a traditional atomization mode is replaced that liquid shaped electronic tobacco tar is adopted, and the problem of oil leakage or oil seep is effectively solved.

Owner:HANGSEN GRAND TECH(DONGGUAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com