Barrel paper suction control device of cigarette packer

A machine box and packaging technology, which is applied in the direction of packaging material feeding device, packaging automatic control, packaging, etc., can solve the problems of YB65 single machine carton paper absorption and transportation, affecting the effective operation rate of equipment, air path resistance, etc., to avoid The problem of oil leakage in the air path, the stability of the suction and delivery of carton paper, and the effect of reducing the operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further illustrated in a non-limiting manner below in conjunction with the accompanying drawings and examples.

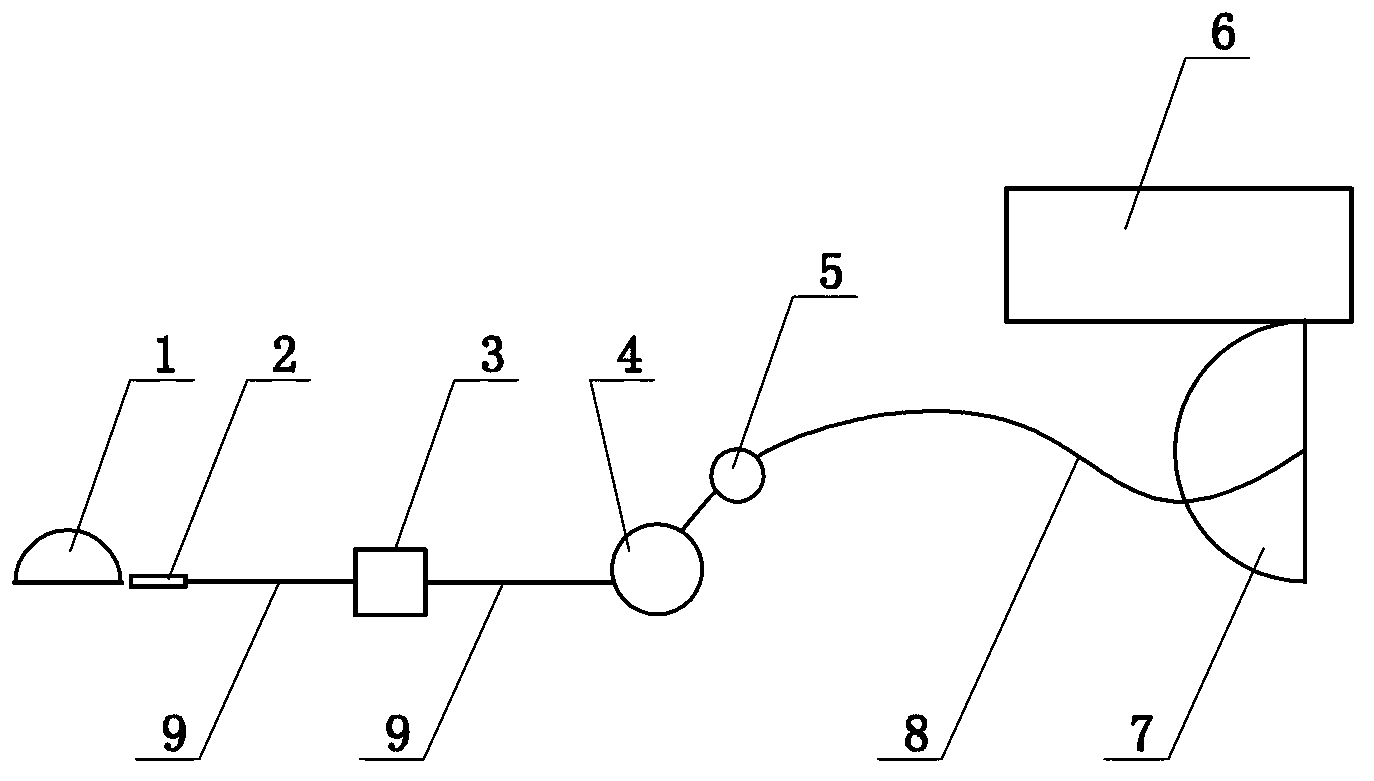

[0024] Such as figure 1 As shown, the cigarette packaging machine carton paper suction control device of the embodiment of the present invention includes the following parts arranged outside the transmission box: a disc cam 1, which is installed on the carton paper transmission shaft; 2 is a metal sensor, the sensor 2 is installed on the transmission box through a base, and corresponds to the position of the disc cam 1; the relay 3 is electrically connected to the sensor 2 through the wire 9; the solenoid valve 4 is a pneumatic two-position three-way solenoid valve , the solenoid valve 4 is electrically connected to the relay 3 via the wire 9;

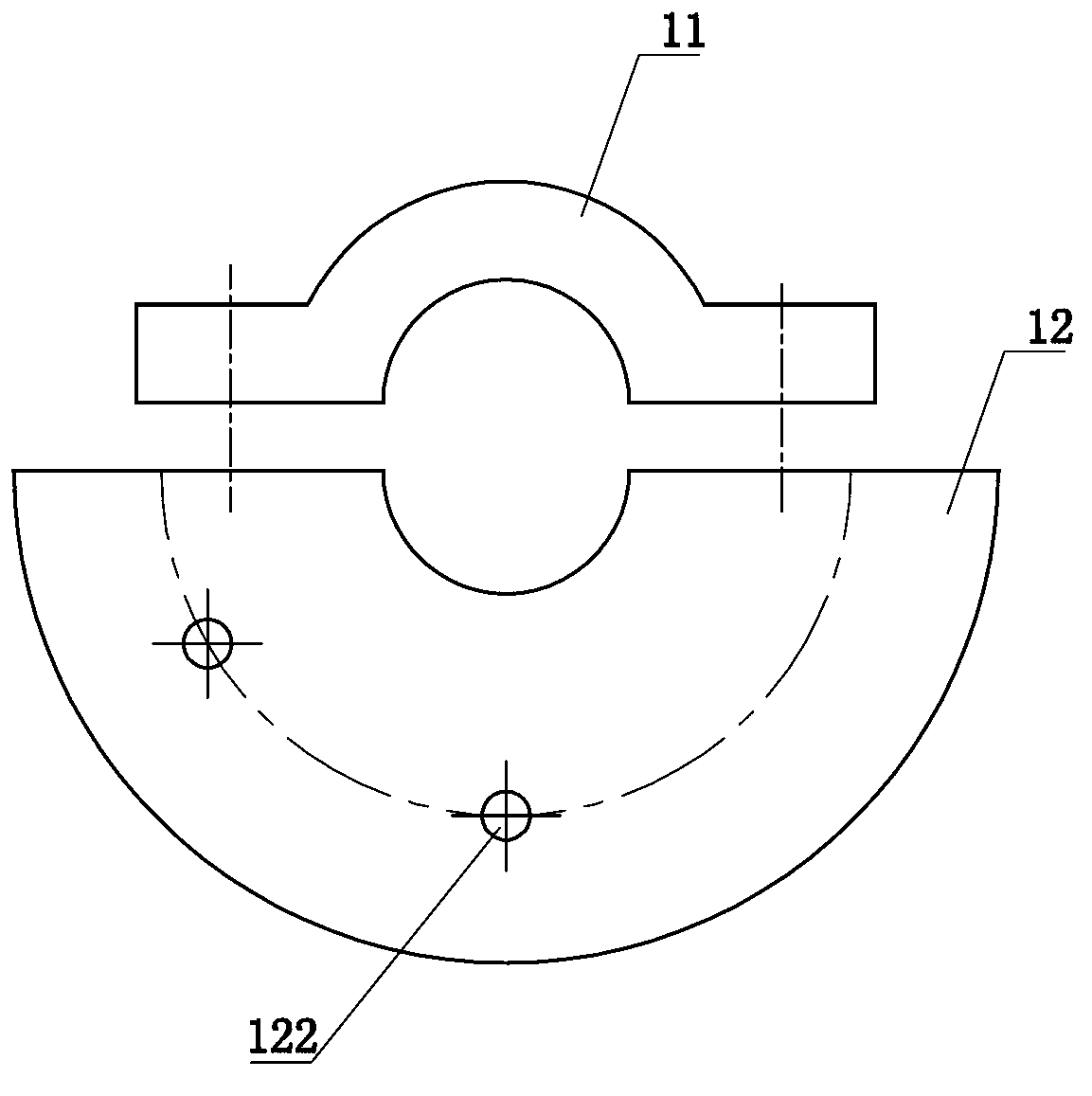

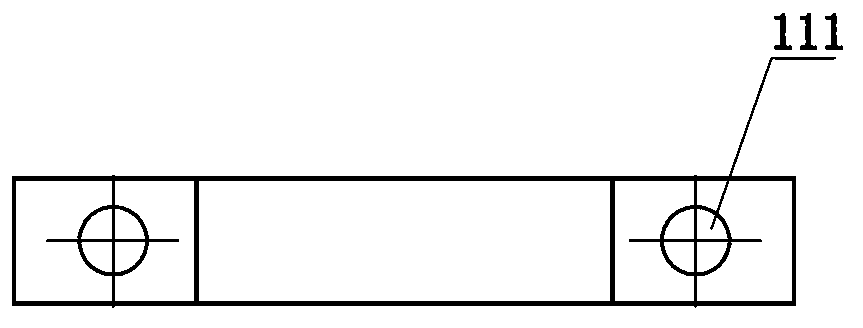

[0025] Such as figure 2 , image 3 with Figure 4 As shown, the disc cam 1 of this embodiment is a combined structure, and the disc cam 1 is assembled from a large diameter half disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com