Novel shaft end sealing device

A new type of shaft end sealing technology, applied in the direction of engine sealing, transmission parts, engine components, etc., can solve the problems of high internal pressure of the reducer, leakage of lubricating oil, etc., to achieve simple structure, improved sealing performance, small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

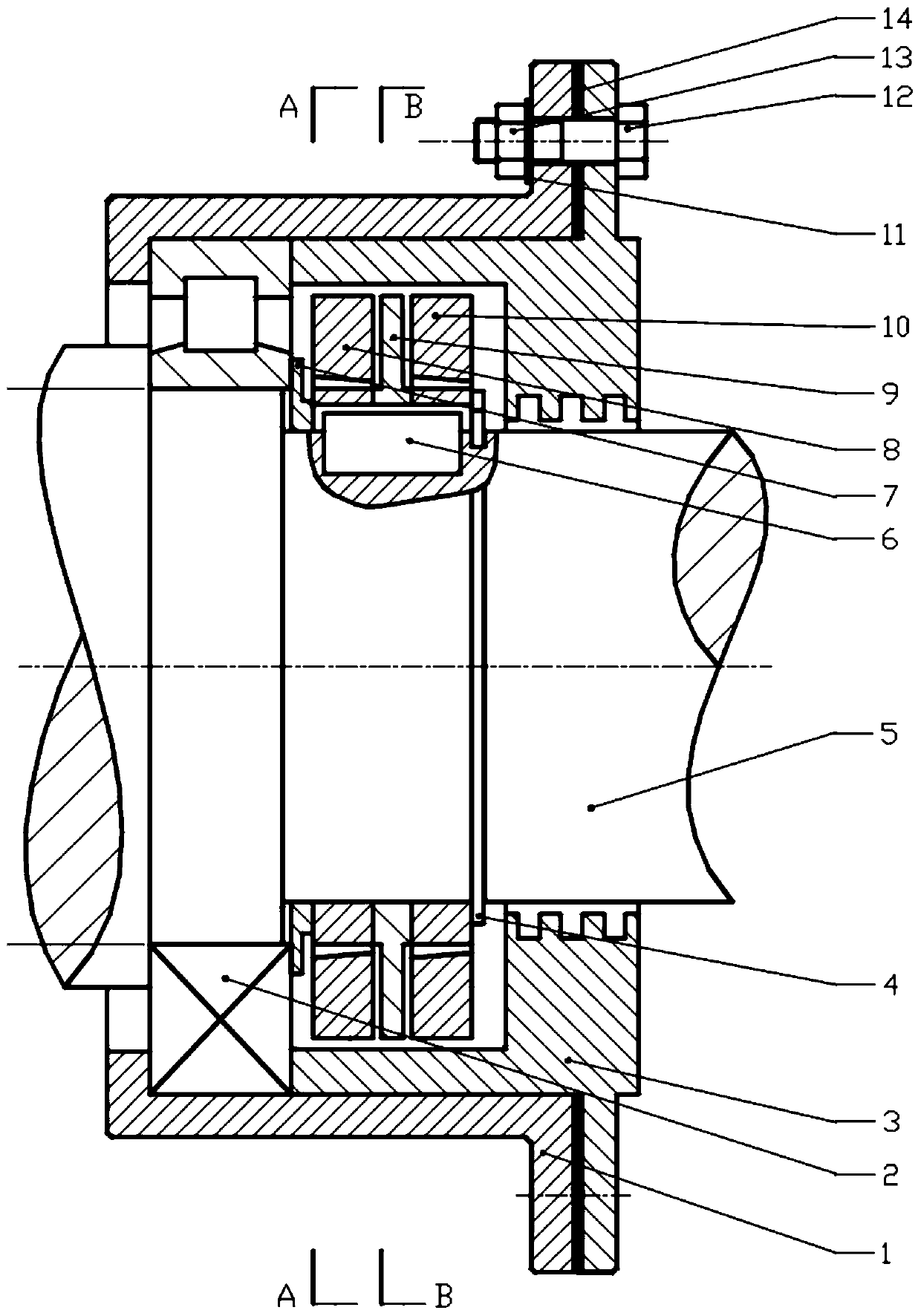

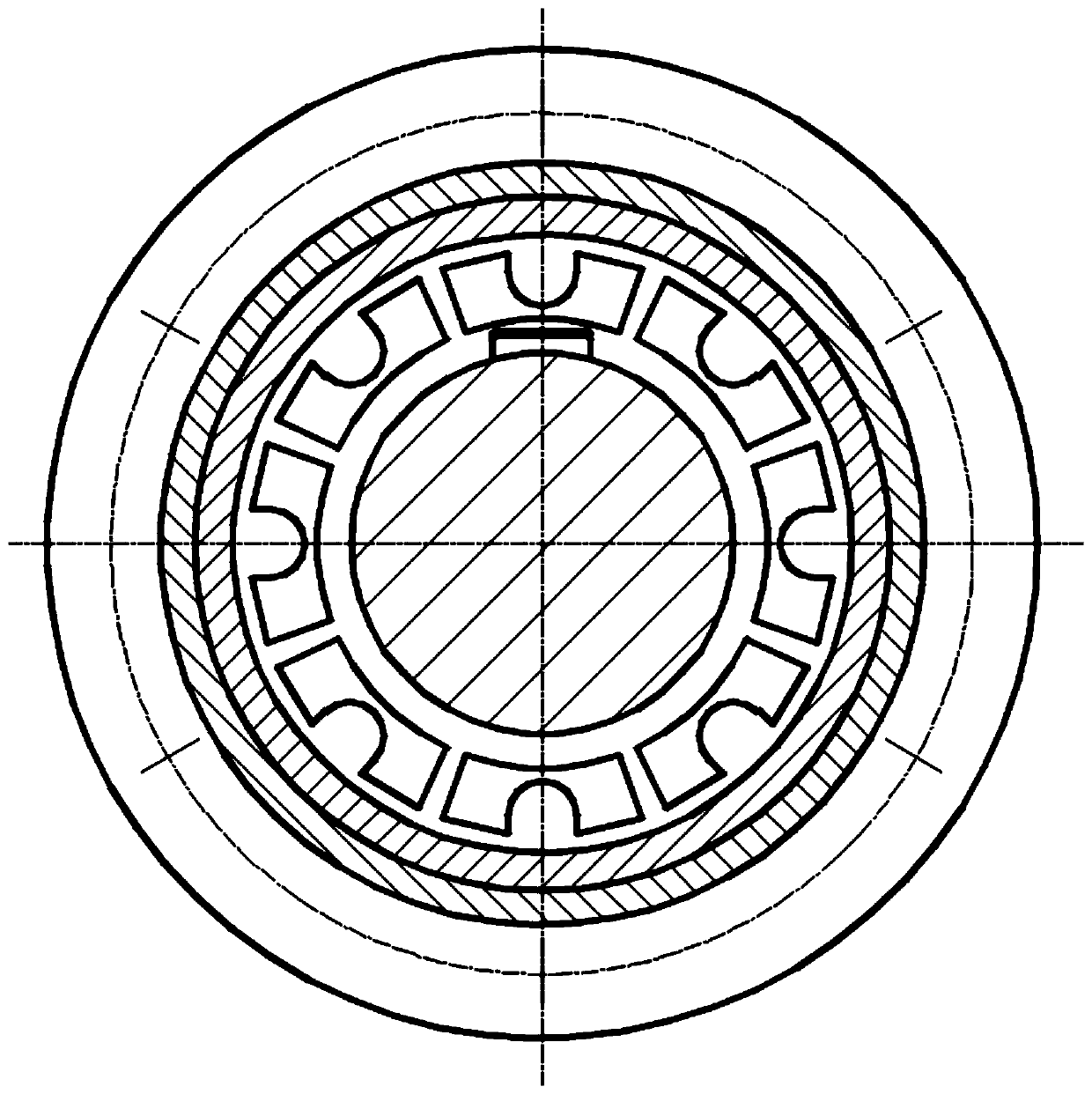

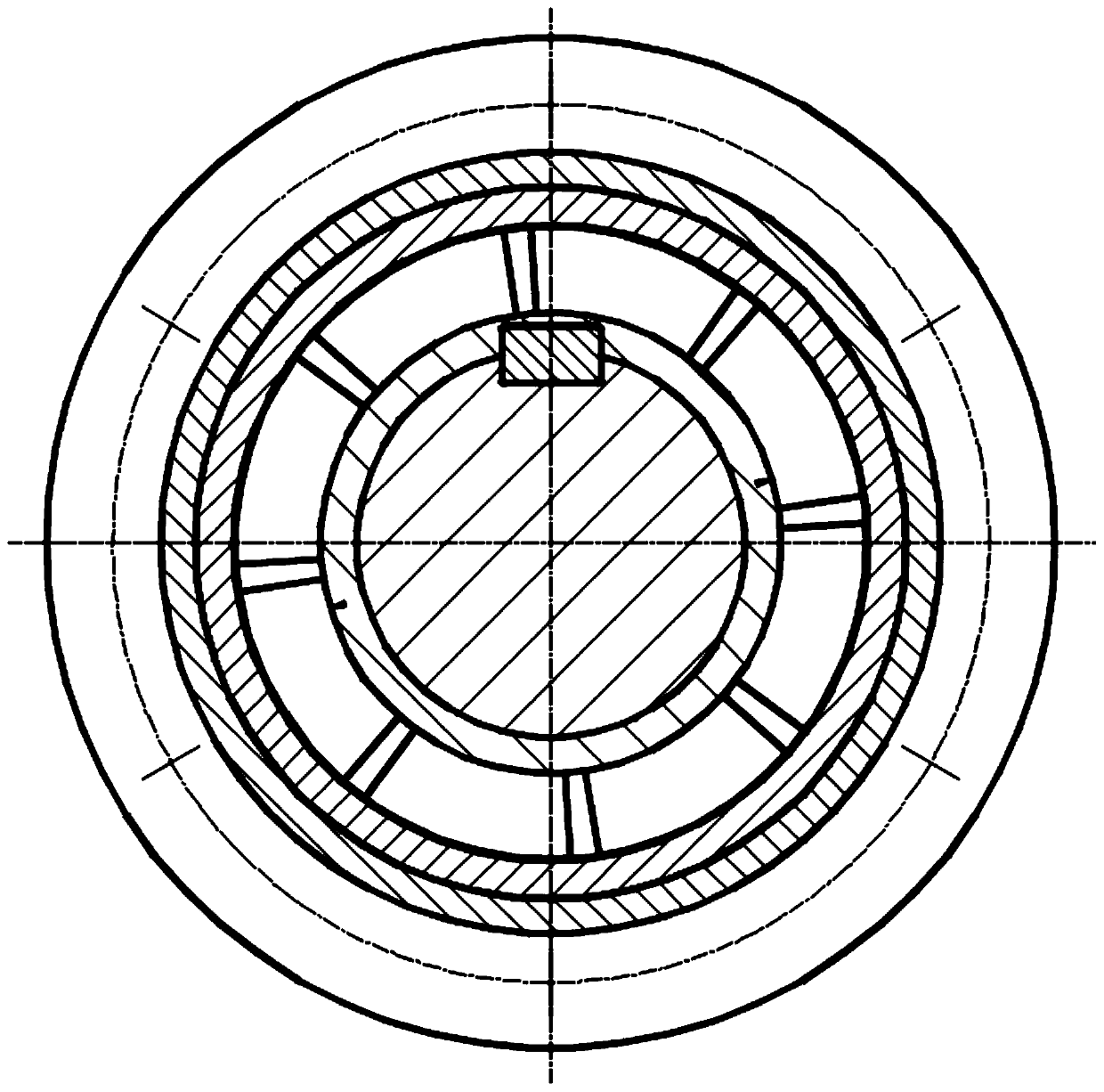

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 A new type of shaft end sealing device is shown, including box body 1, bearing 2, bearing end cover 3, shaft circlip 4, transmission shaft 5, flat key 6, sleeve 7, impeller I 8, impeller II 9, Impeller III 10, elastic gasket 11, hexagonal bolt 12, hexagonal nut 13, asbestos pad 14, characterized in that the transmission shaft 5 is equipped with a bearing 2, the inner ring of the bearing 2 is axially fixed by the sleeve 7, and the inner ring of the bearing 2 is fixed by the elastic Gasket 11, hexagonal bolt 12, hexagonal nut 13 are fixed on the shaft end cover 3 on the box body 1 to axially fix the outer ring of the bearing 2; The impeller Ⅰ8, impeller Ⅱ9 and impeller Ⅲ10 are also installed in sequence, the axial axis is fixed by the elastic retaining ring 4, and the circumferential direction is connected by the flat key 6, so that the three impellers r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com