Patents

Literature

51 results about "Brisance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brisance /brɪˈzɑːns/ is the shattering capability of a high explosive, determined mainly by its detonation pressure. The term can be traced from the French verb "briser" (to break or shatter) ultimately derived from the Celtic word "brissim" (to break). Brisance is of practical importance for determining the effectiveness of an explosion in fragmenting shells, bomb casings, grenades, structures, and the like. The sand crush test and Trauzl lead block test are commonly used to determine the relative brisance in comparison to TNT (which is considered a standard reference for many purposes).

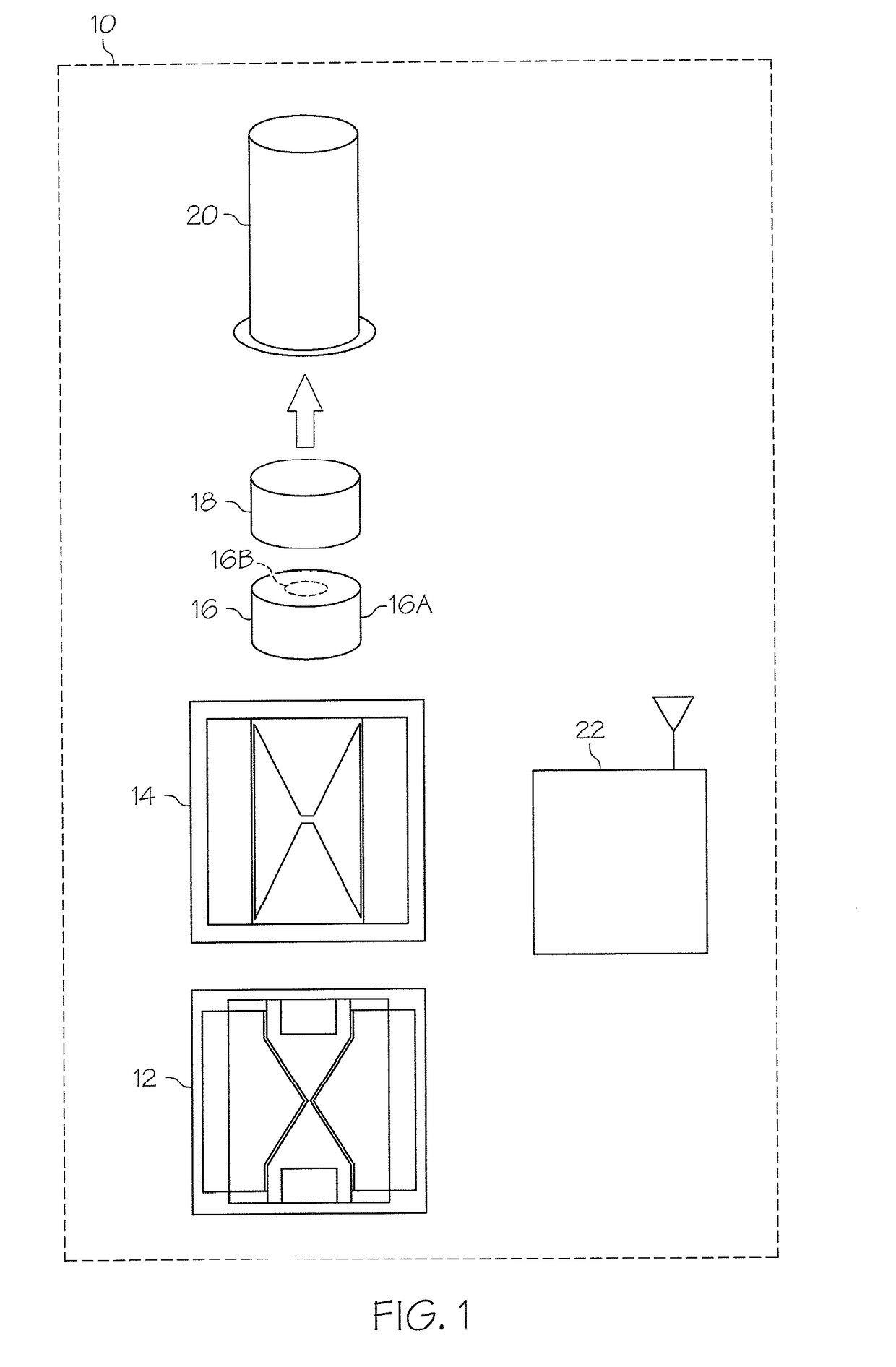

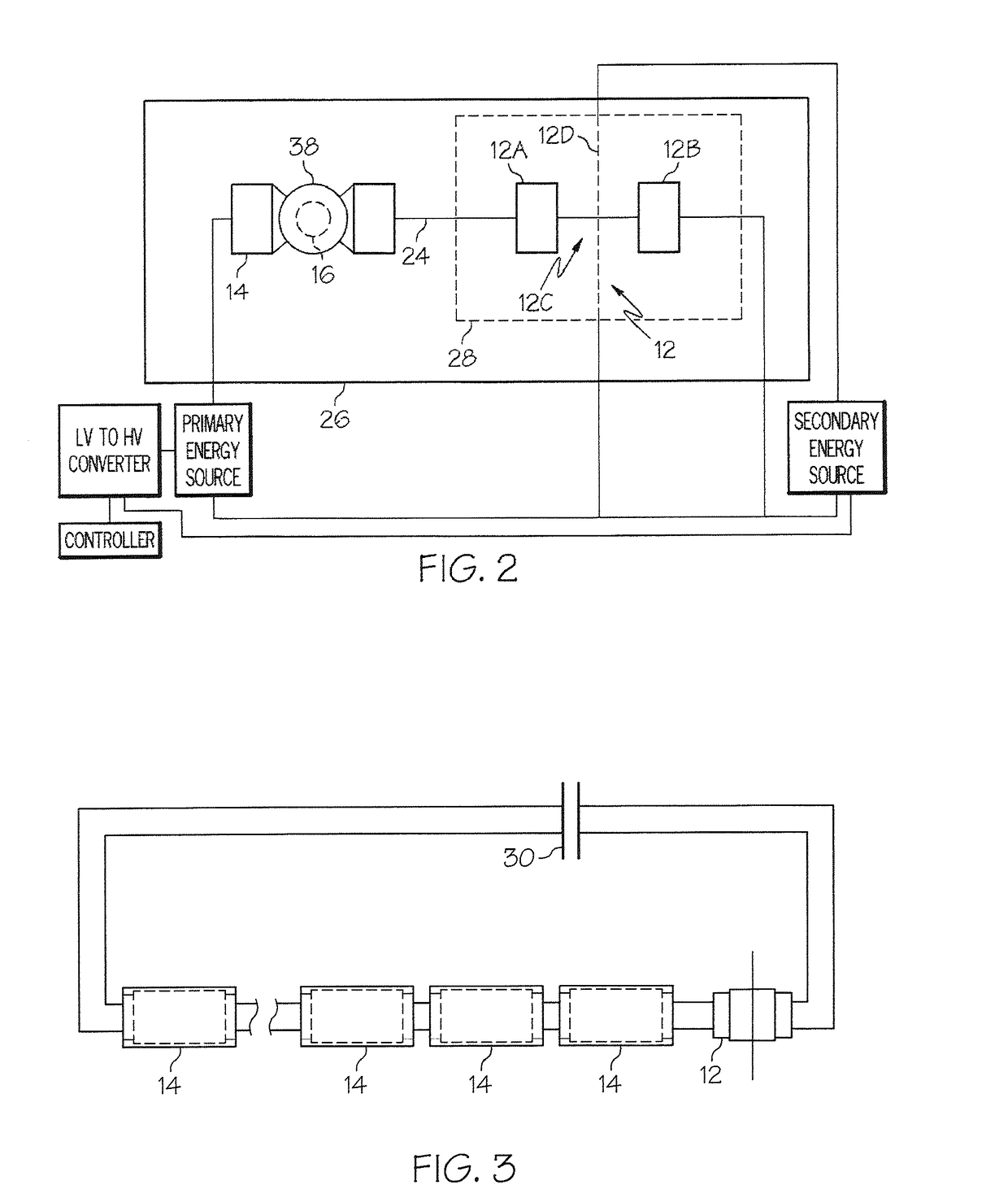

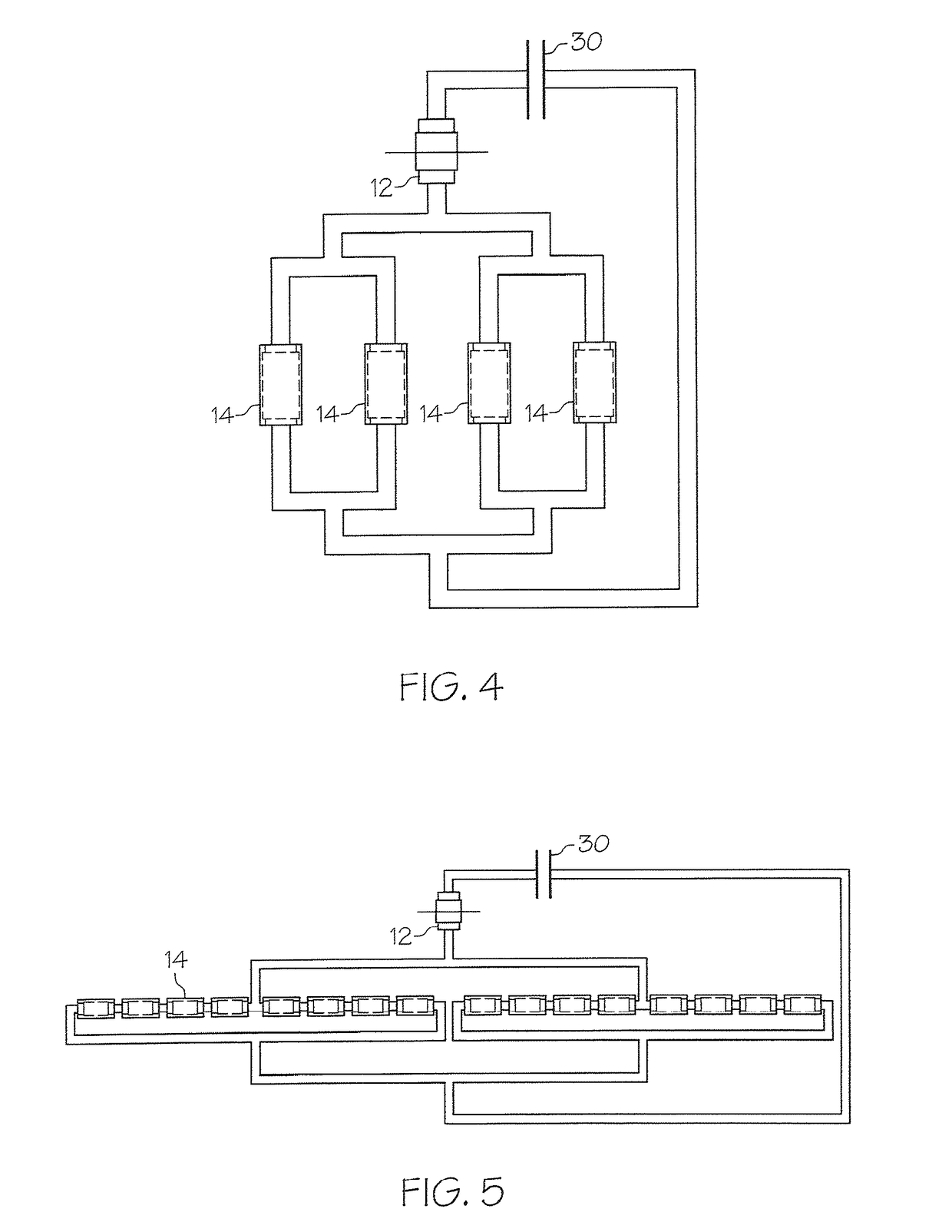

Electronic detonator system

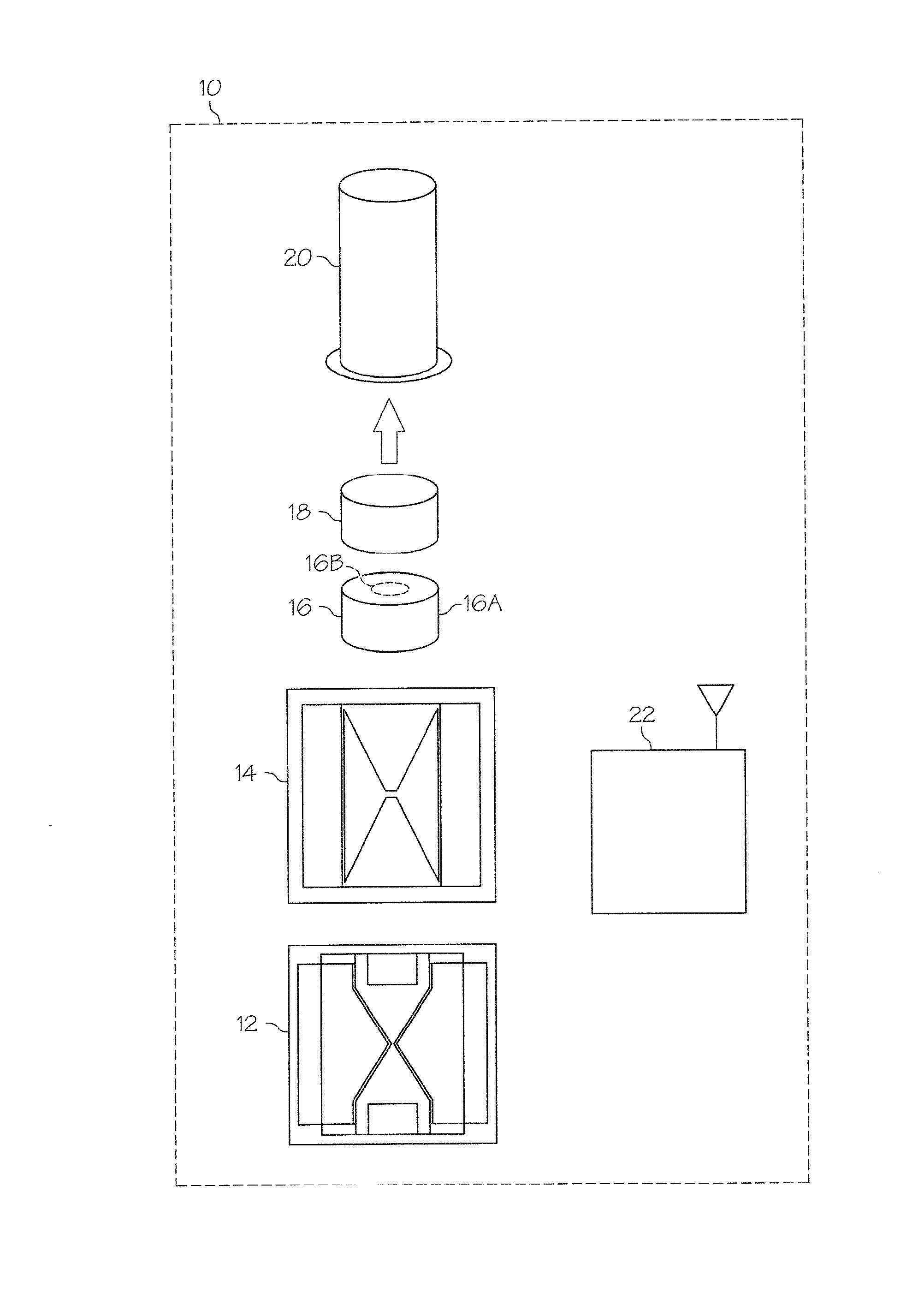

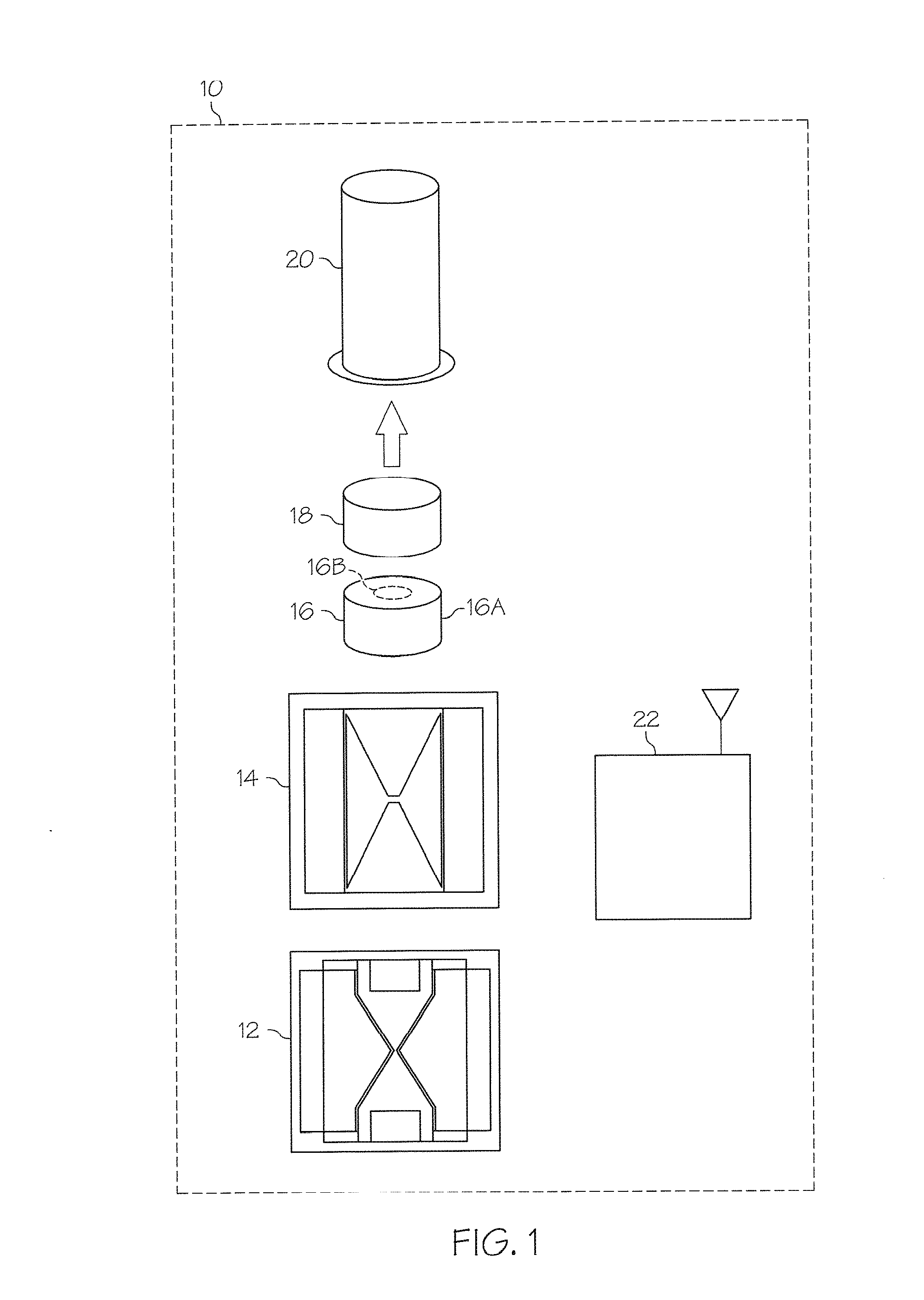

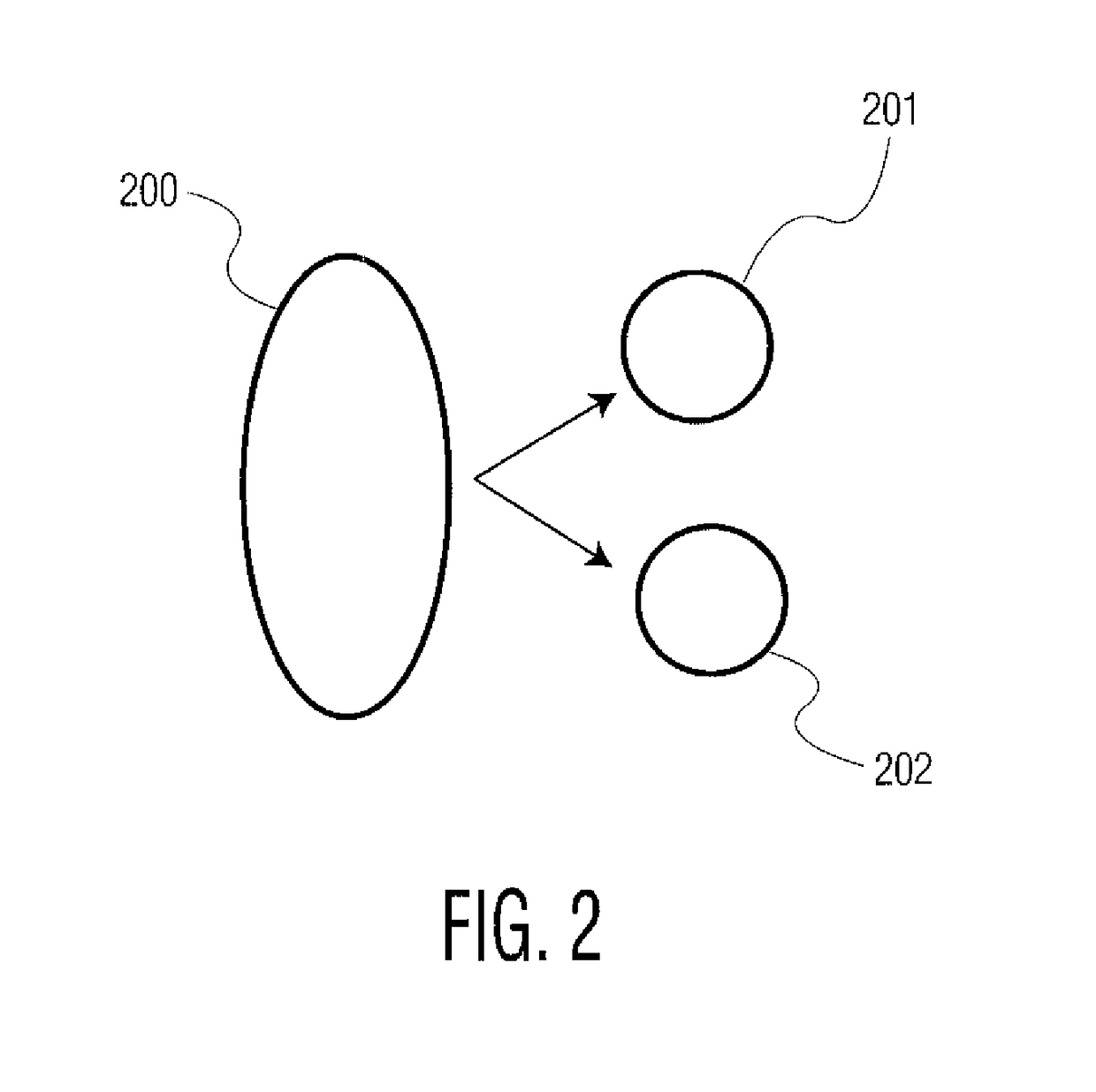

A detonator includes a high voltage switch, an initiator and an initiating pellet. The detonator also includes a low voltage to high voltage firing set coupled to the switch and initiator such that the detonator includes a high voltage power source and initiator in an integrated package. The detonator may also include inductive powering and communications, a microprocessor, tracking and / or locating technologies, such as RFID, GPS, etc., and either a single or combination explosive output pellet. The combination explosive pellet has a first explosive having a first shock energy and a high brisance secondary explosive in the output pellet having a second shock energy greater than the shock energy of the first explosive. Systems are also provided for facilitating fast and easy deployment of one or more detonators in the field.

Owner:BATTELLE MEMORIAL INST

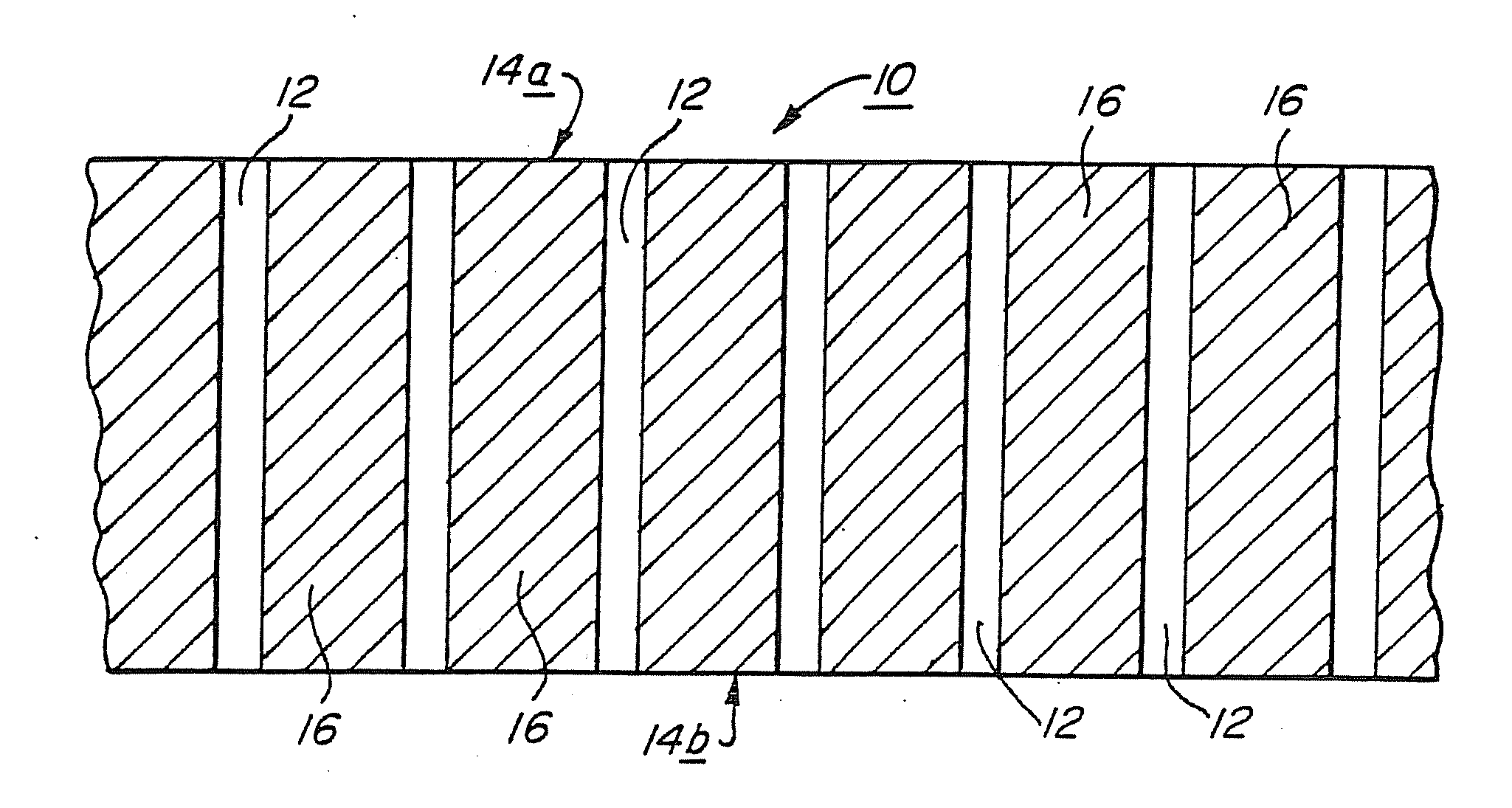

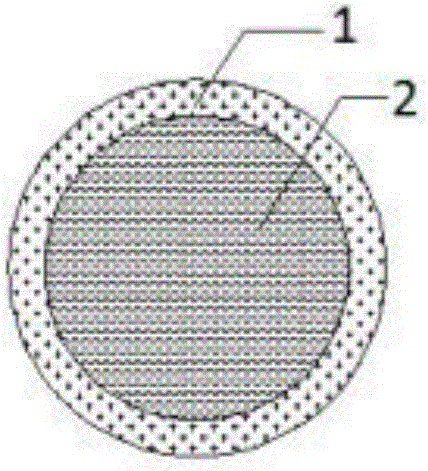

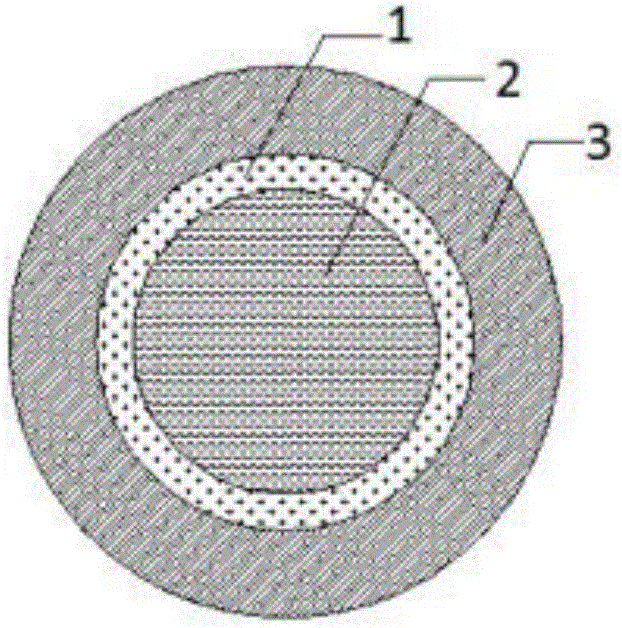

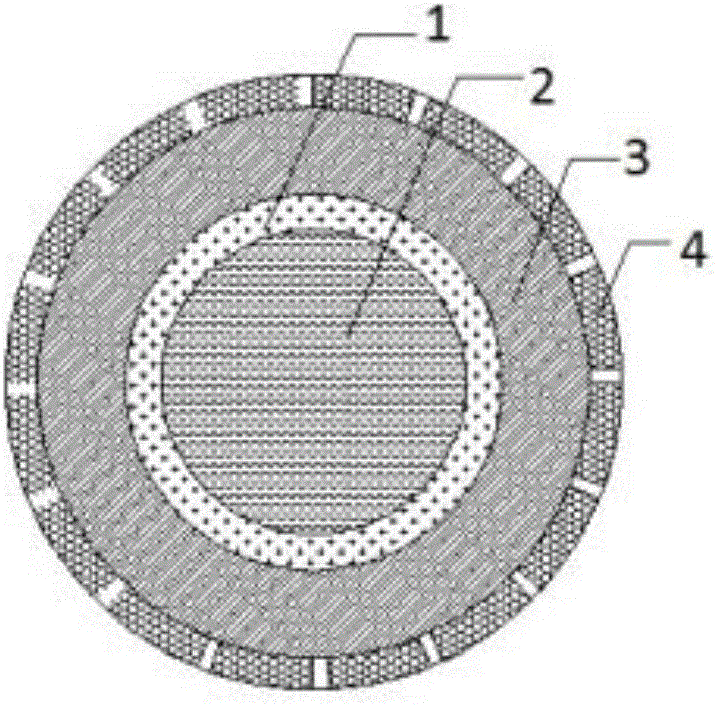

Detonating cord and methods of making and using the same

InactiveUS20070214990A1Lower velocity of detonationReduce the average velocityBlastingFuse detonationMicrosphereDiluent

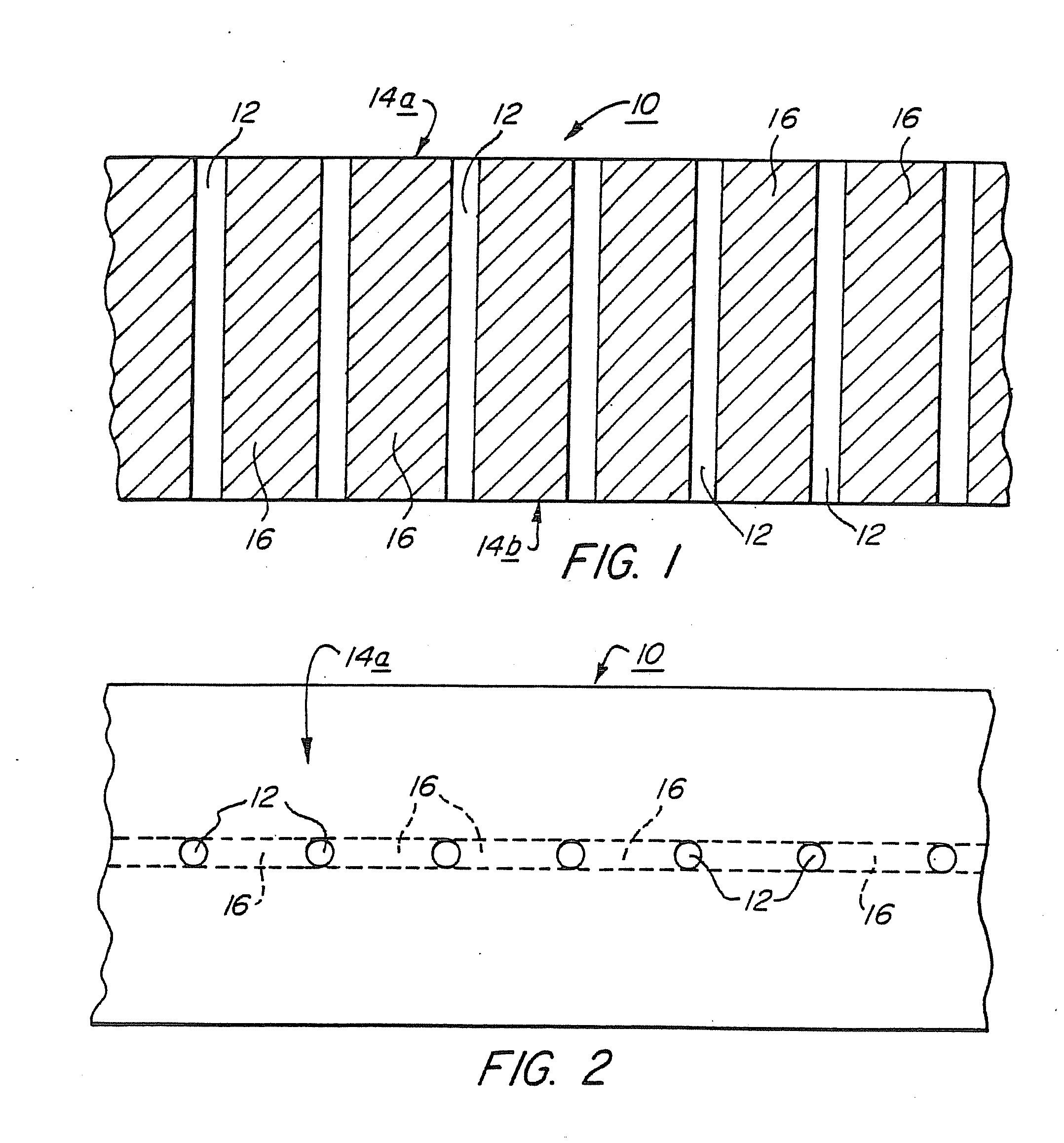

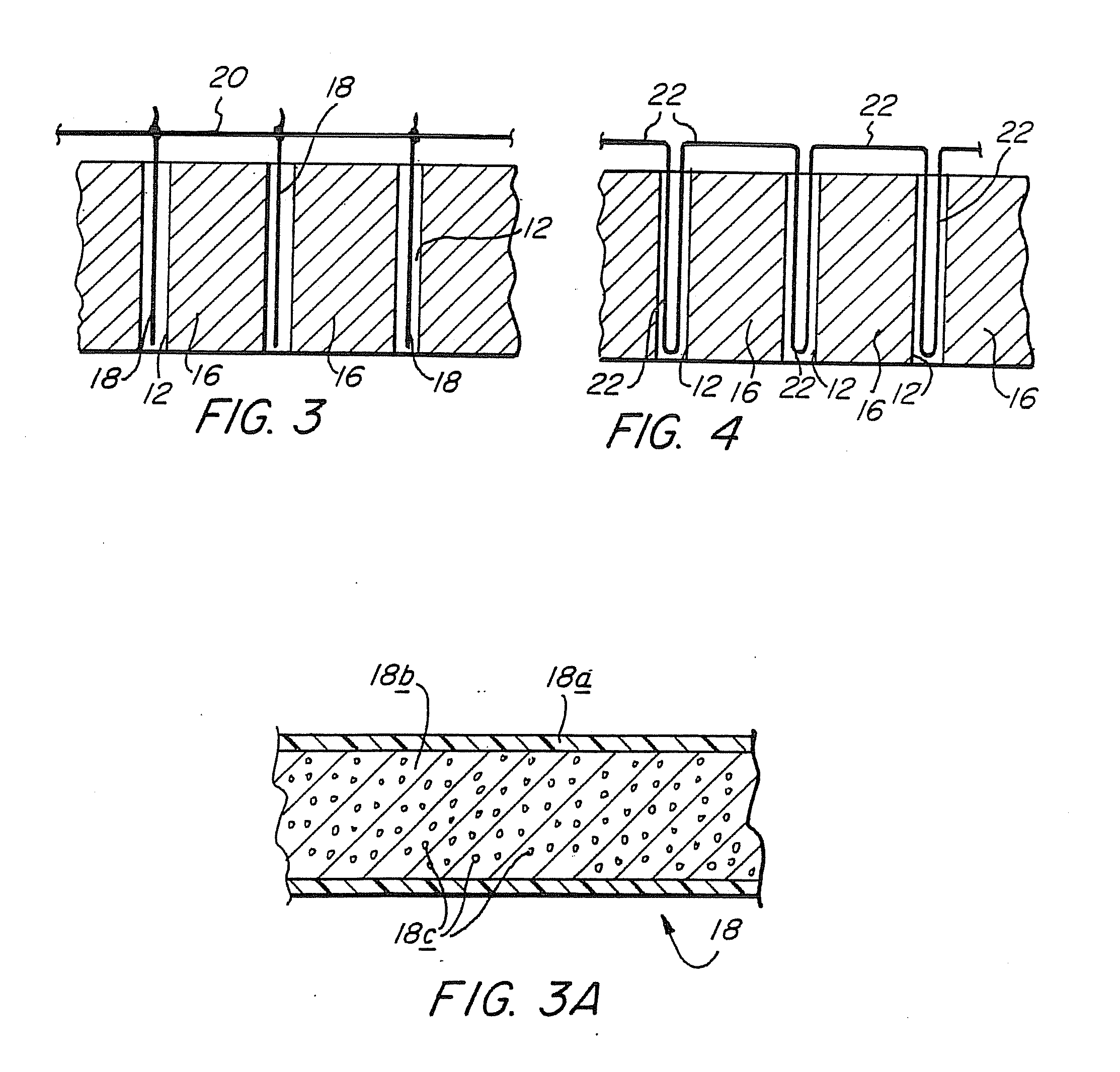

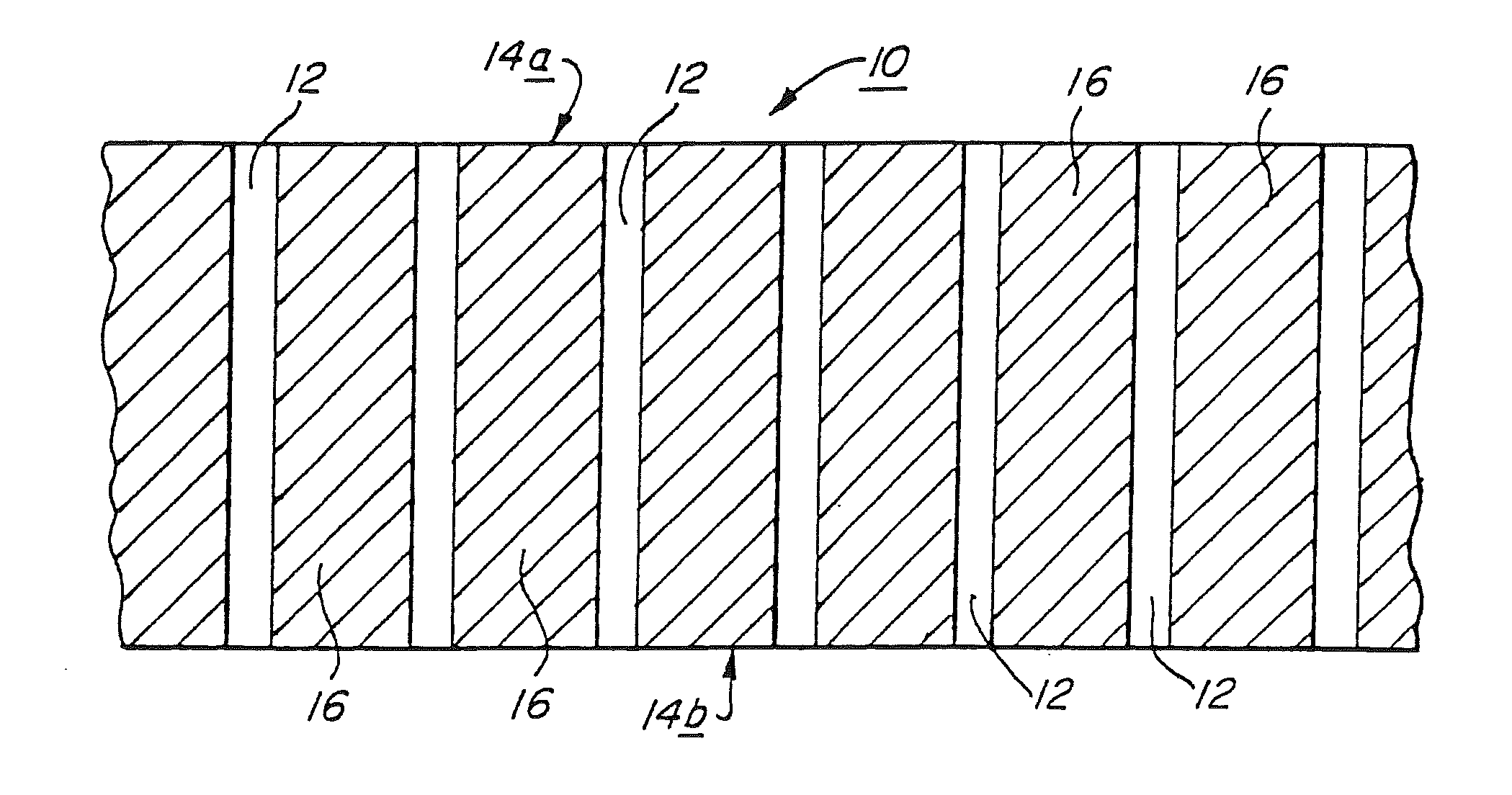

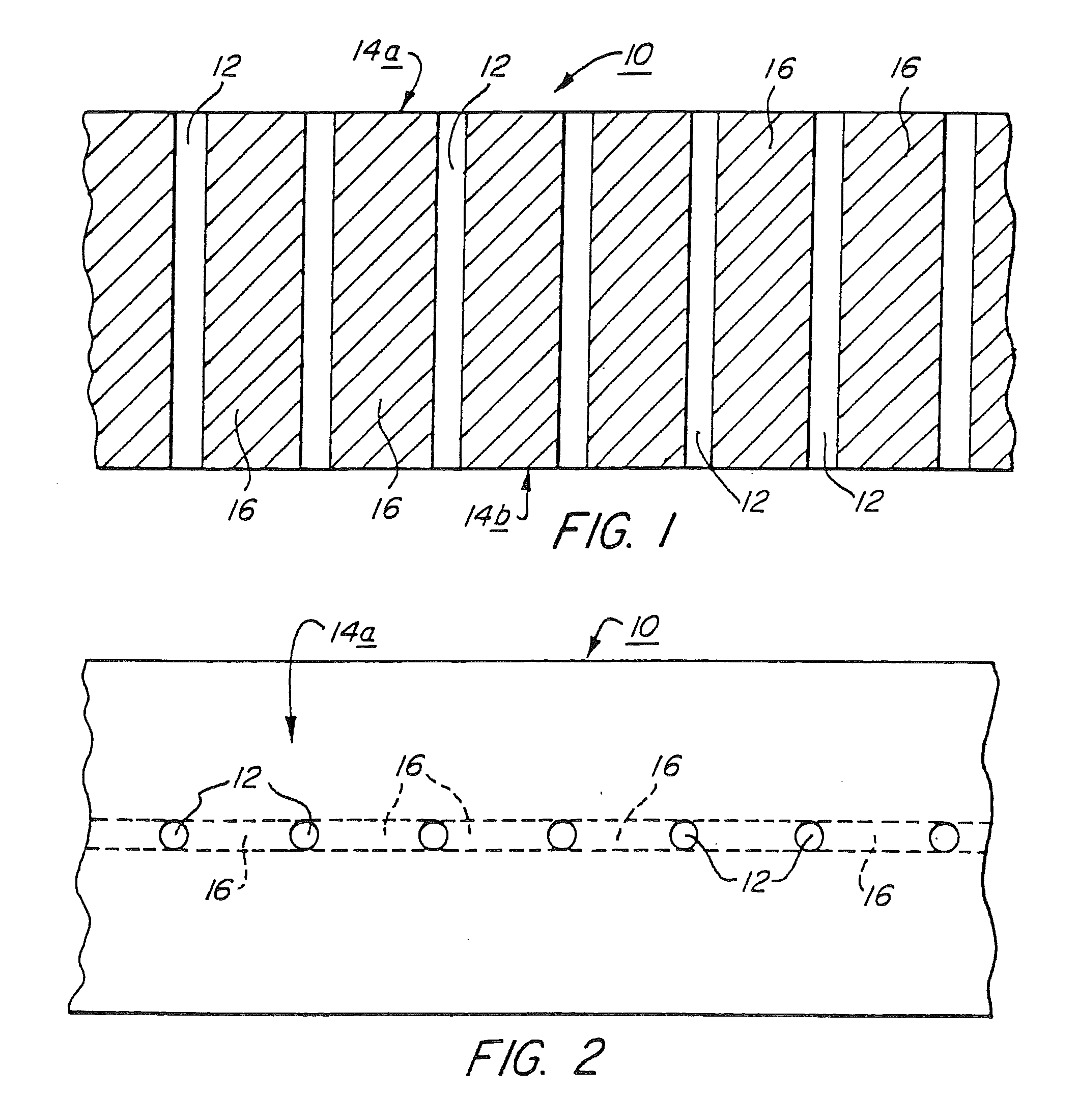

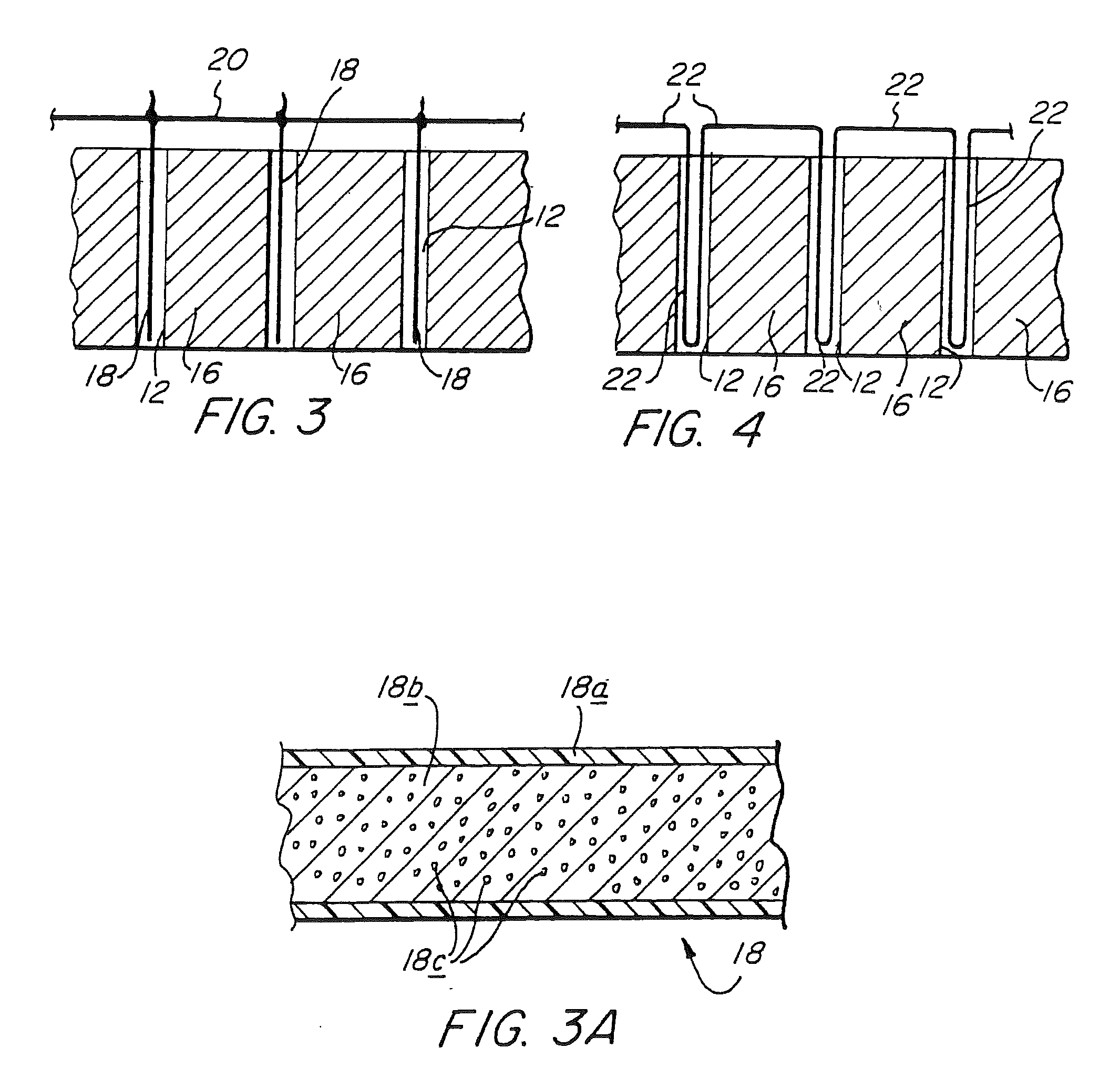

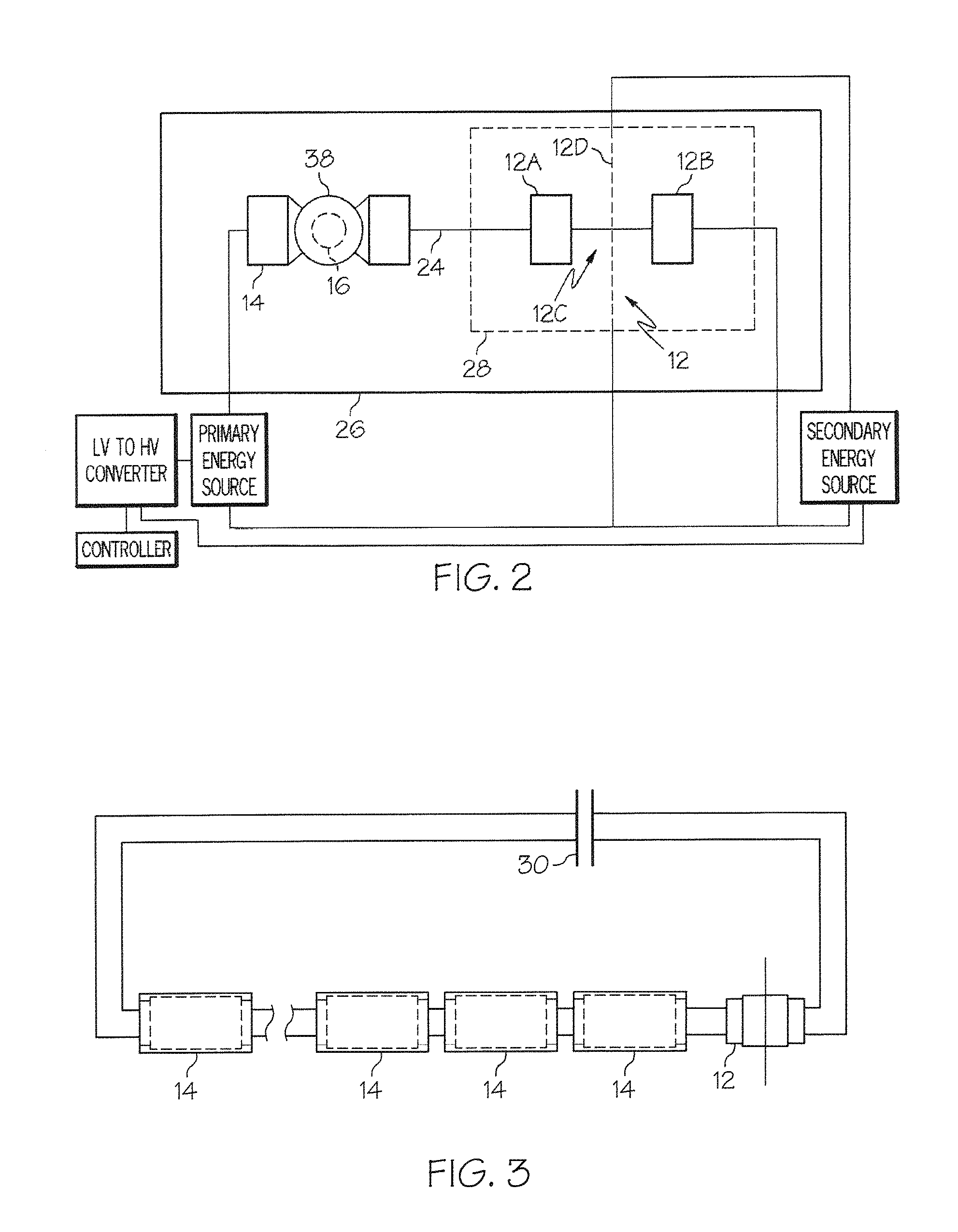

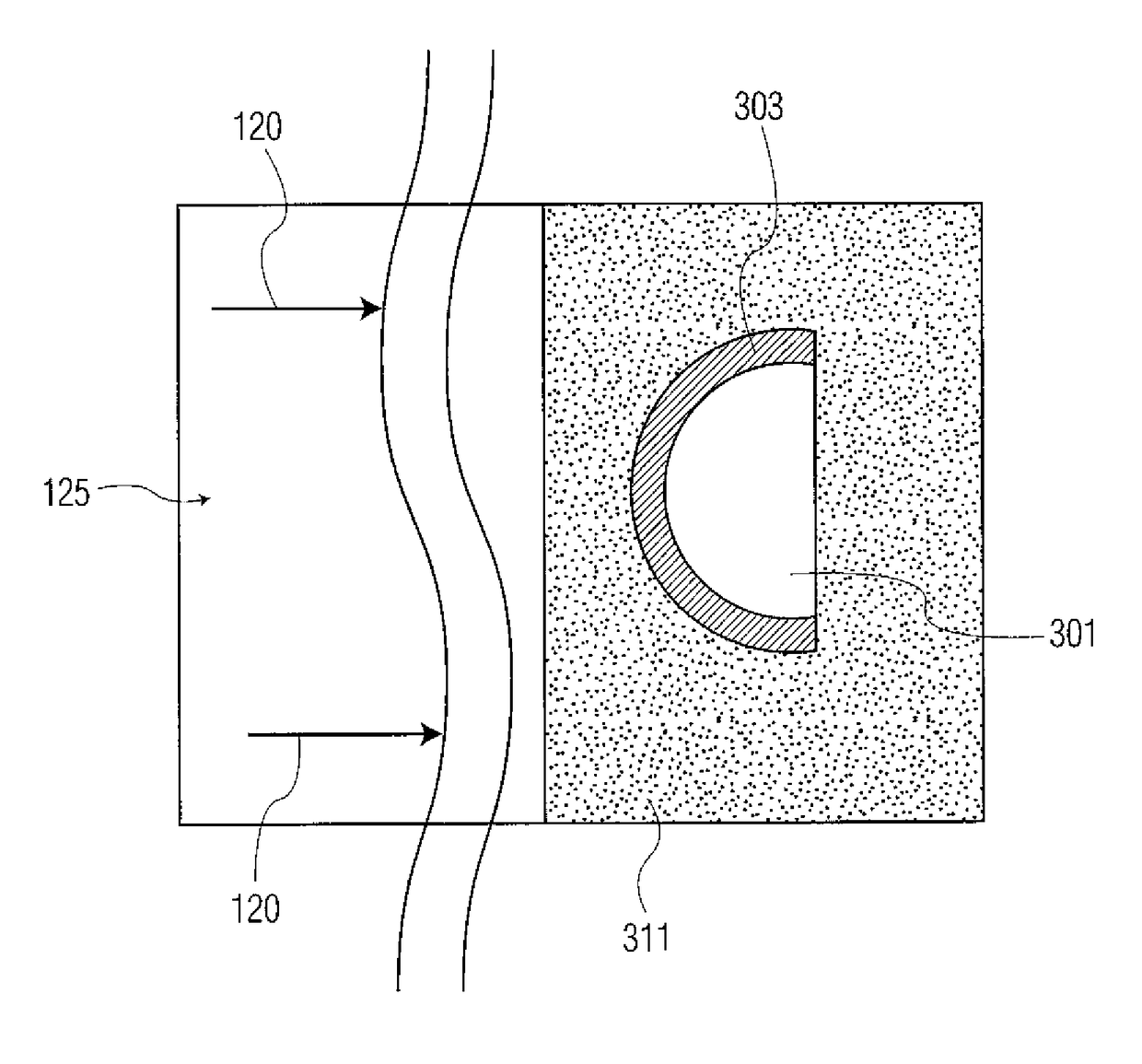

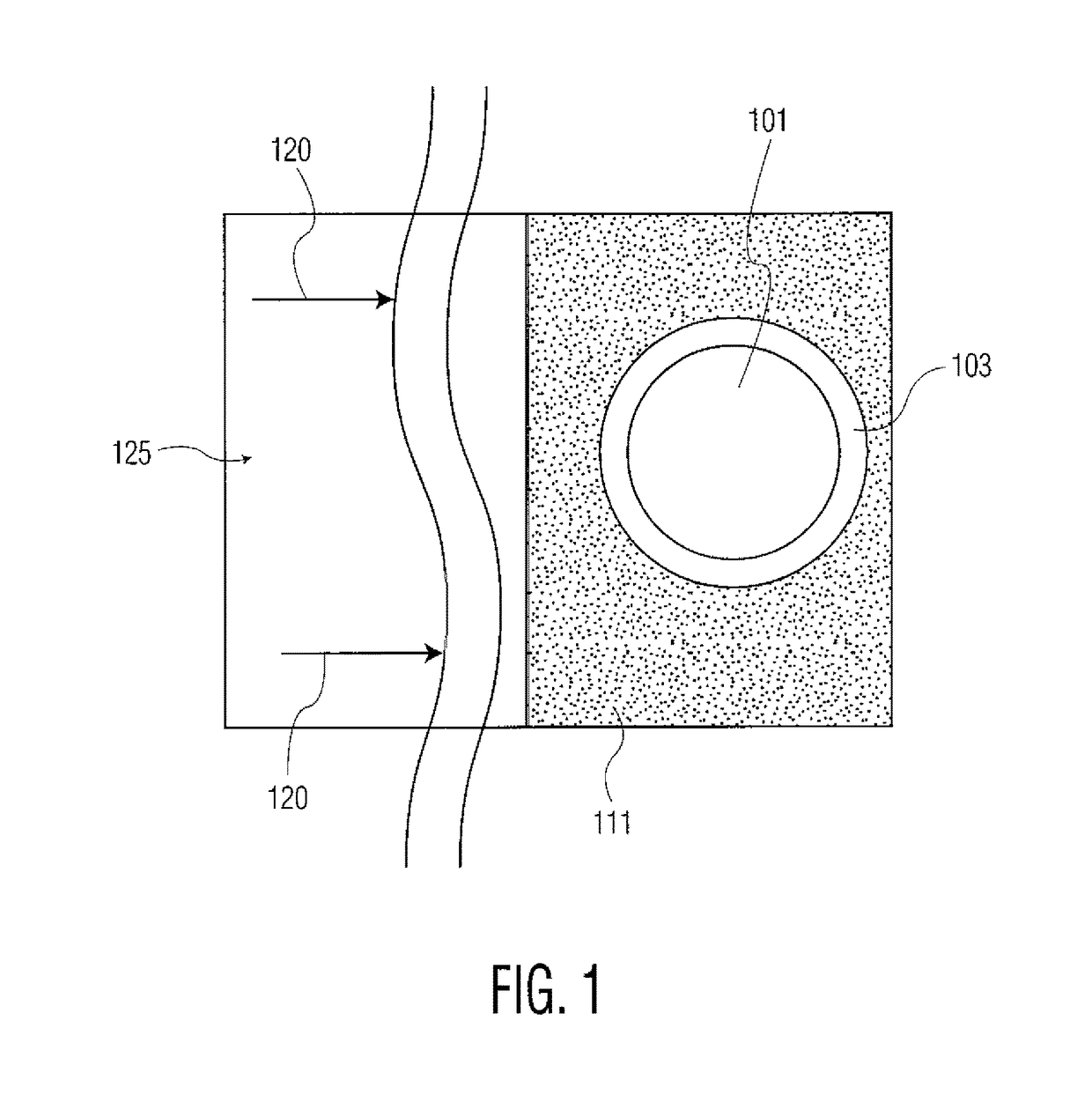

The velocity of detonation of an explosive such as detonating cord (18, 22) is controlled by the addition of a diluent to the explosive, e.g., to the core of the detonating cord (18, 22). An explosively inert diluent, or a diluent comprised of an explosive of lower brisance than the principal explosive comprising the core of the detonating cord, will serve to reduce the velocity of detonation. Such reduced velocity of detonation has beneficial effects in certain operations, including cleaving rock (10), wherein it is observed to significantly reduce radial cracks (24) and stickers (26) (long radial cracks) in the vicinity of the boreholes (12) in which the low-velocity detonating cord (18, 22) is functioned to cleave the rock (10). The low-velocity detonating cord also facilitates leaving behind a smoother face in cutting trenches and tunnels through rock. The method of manufacture of low-velocity detonating cord includes incorporating a suitable diluent, such as phenolic microballoons, into an explosive core of, e.g., PETN.

Owner:BARKLEY THOMAS L +4

Detonating cord and methods of making and using the same

InactiveUS20100037793A1Reduce the average velocityLower velocity of detonationBlastingExplosive working-up apparatusDiluentEngineering

The velocity of detonation of an explosive such as detonating cord (18, 22) is controlled by the addition of a diluent to the explosive, e.g., to the core of the detonating cord (18, 22). An explosively inert diluent, or a diluent comprised of an explosive of lower brisance than the principal explosive comprising the core of the detonating cord, will serve to reduce the velocity of detonation. Such reduced velocity of detonation has beneficial effects in certain operations, including cleaving rock (10), wherein it is observed to significantly reduce radial cracks (24) and stickers (26) (long radial cracks) in the vicinity of the boreholes (12) in which the low-velocity detonating cord (18, 22) is functioned to cleave the rock (10). The low-velocity detonating cord also facilitates leaving behind a smoother face in cutting trenches and tunnels through rock. The method of manufacture of low-velocity detonating cord includes incorporating a suitable diluent, such as phenolic microballoons, into an explosive core of, e.g., PETN.

Owner:LEE ROBERT A +4

Electronic detonator system

A detonator includes a high voltage switch, an initiator and an initiating pellet. The detonator also includes a low voltage to high voltage firing set coupled to the switch and initiator such that the detonator includes a high voltage power source and initiator in an integrated package. The detonator may also include inductive powering and communications, a microprocessor, tracking and / or locating technologies, such as RFID, GPS, etc., and either a single or combination explosive output pellet. The combination explosive pellet has a first explosive having a first shock energy and a high brisance secondary explosive in the output pellet having a second shock energy greater than the shock energy of the first explosive. Systems are also provided for facilitating fast and easy deployment of one or more detonators in the field.

Owner:BATTELLE MEMORIAL INST

Energetic compound sensitizer for emulsified explosive and preparation method of energetic compound sensitizer

ActiveCN106748589APlay a double roleHigh charge densityNon-explosive/non-thermic compositionsWhole bodyMicrosphere

The invention discloses a sensitizer, specifically an emulsified explosive energetic sensitizer, and particularly relates to a sensitizer formed by coating high-energy metal powder on porous silicon dioxide hollow microspheres and a preparation method of the sensitizer. The sensitizer mainly comprises the following components in parts by weight: 50-65 parts of a metal powder, 2-10 parts of a coating agent, and 30-45 parts of silicon dioxide. According to the preparation method provided by the invention, the high-energy metal powder for coating the porous silicon dioxide hollow microspheres is prepared through a four-step method, and is added into an emulsion matrix, and the high-energy metal powder and the emulsion matrix are mixed uniformly to prepare a high-strength emulsion explosive; shells of the porous silicon dioxide hollow microsphere of the energetic sensitizer achieve the effect of a sensitizer, and the high-energy metal powder inside the energetic sensitizer achieves the effect of an energetic additive. The sensitizer and the high-energy metal powder are combined into a whole body, the brisance of the emulsified explosive is improved under the condition that the sensitivity of the explosive is not influenced; moreover, the raw materials are wide in source, the cost is low, and the production process is simple, so that the sensitizer has a very good market prospect.

Owner:ANHUI UNIV OF SCI & TECH

Low detonation velocity powdery emulsifying explosive

ActiveCN101423448ALow detonation velocityQuality assuranceExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsion explosiveUltimate tensile strength

The invention relates to a powdery emulsion explosive with low detonation velocity. A rock powdery emulsion explosive, talcum powder and coarse bran are placed into a mixer for fullly stirring to ensure that the mixture is mixed evenly and then is packaged and sold, wherein the bulk density of the rock powdery emulsion explosive is between 0.58 and 0.62 / g.cm<-3>, the detonation velocity is between 3,500 and 3,700 / m.s<-1>, the brisance is between 15 and 17 / mm, the sympathetic detonation is between 9 and 11 / cm, the capacity for work is 360 / ml, and the storage period is 6 months; the bulk density of the talcum powder is between 0.95 and 1.0 / g.cm<-3>, and the grain diameter is 300 meshes; and the bulk density of the coarse bran is between 0.28 and 0.35 / g.cm<-3>, and the grain diameter is between 0.8 and 1mmr. In the invention, the powdery emulsion explosive with low detonation velocity is applied to double metal explosive welding first, which ensures the quality of explosive welding of double metal explosive composite welding and ensures that the double metal explosive welding fully meets the requirement. The powdery emulsion explosive is safe, also has no pollution after the explosion, and has no harm to the health of blasters. The storage period of the powdery emulsion explosive with low detonation velocity can reach more than 180 days, so the powdery emulsion explosive can be mixed by manufacturers without field mixed-making and the labor intensity of the blasters is reduced.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

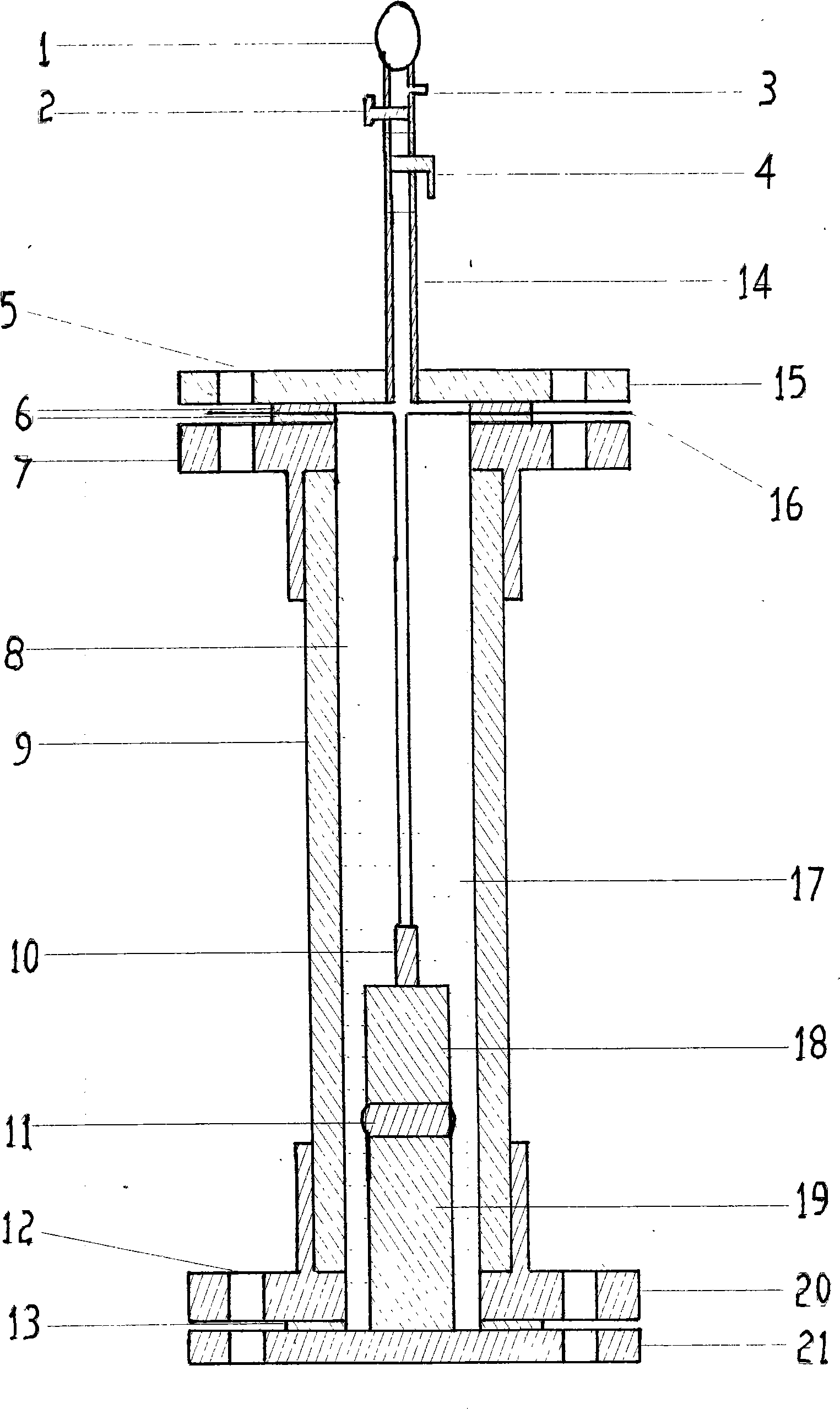

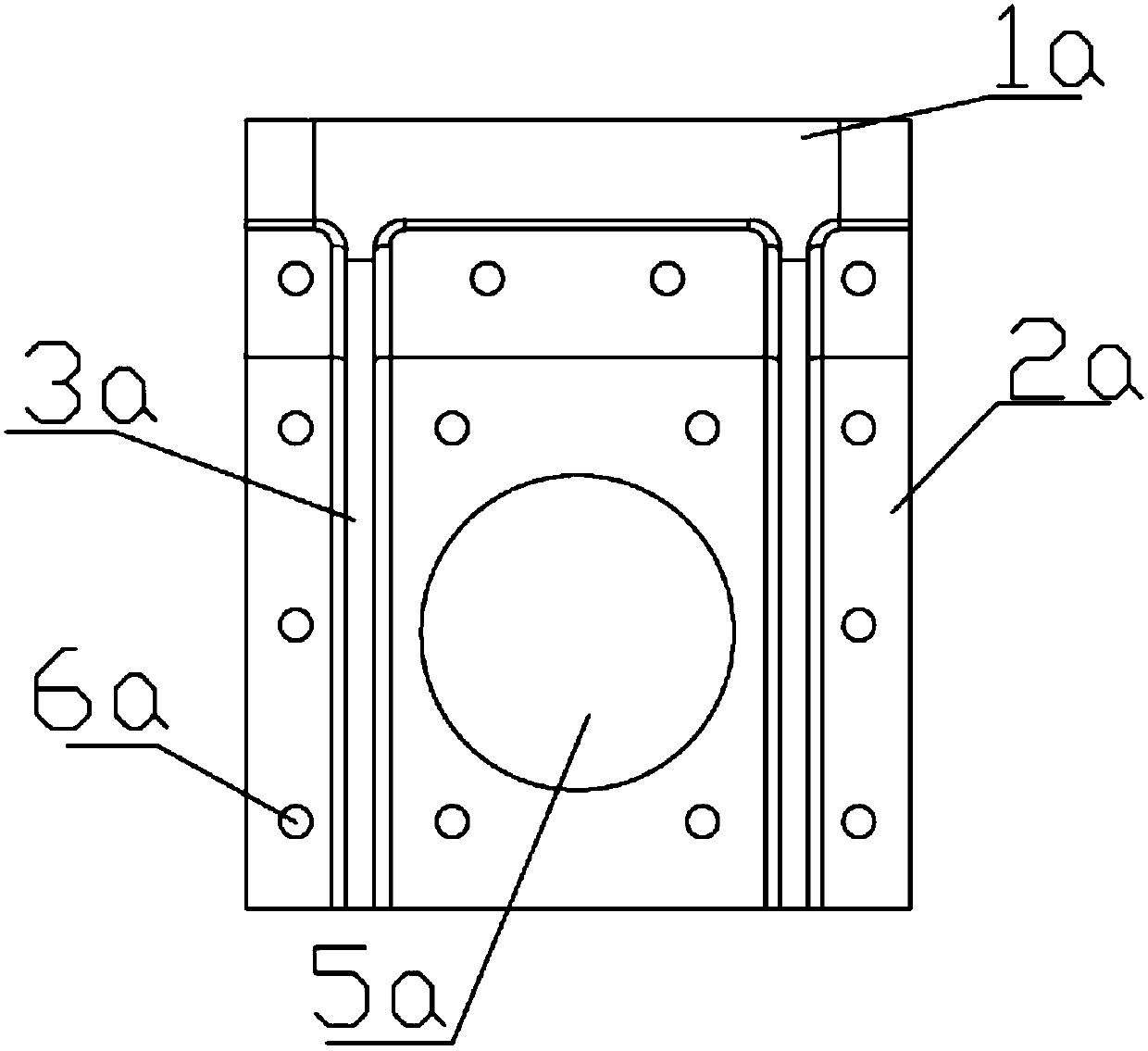

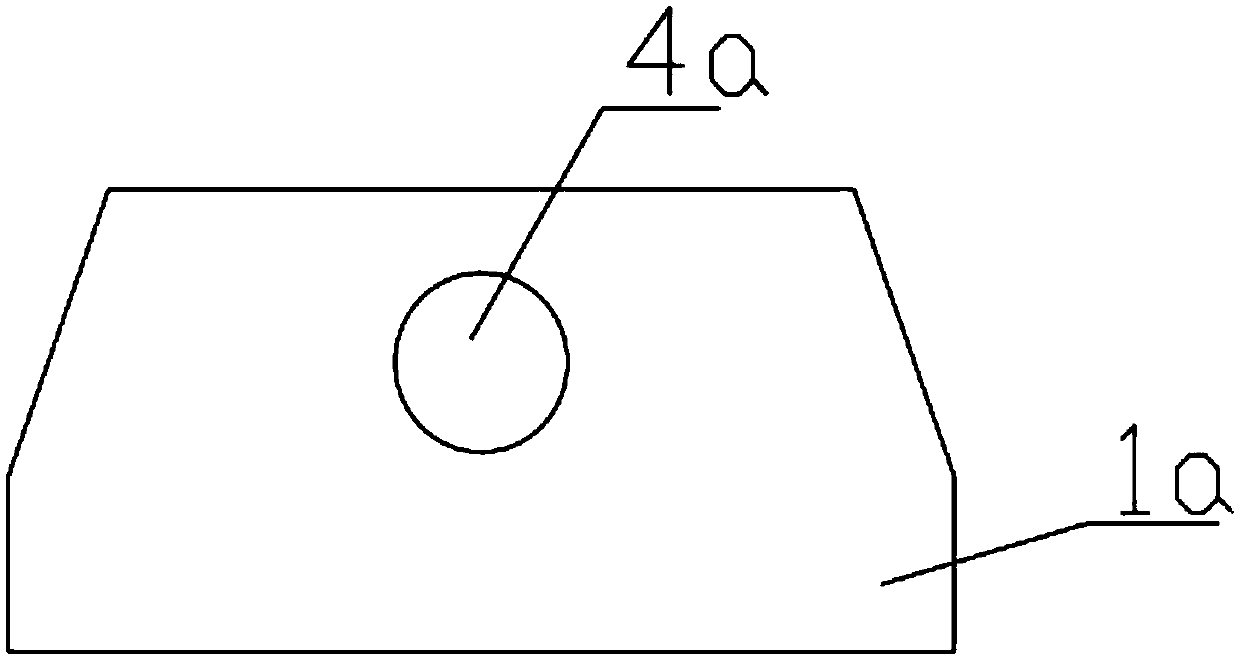

Device for testing underwater brisance of explosive

The invention provides a device for testing underwater brisance of an explosive, comprising a pressure device and an explosion chamber; wherein, the explosion chamber comprises a tube upper seal, a tube body, a tube lower seal; when brisance is tested, the inside of a tube chamber is sealed, an explosion sample, a primer, a sheet steel and a lead block are arranged inside the tube chamber; water is injected to submerge the explosive sample, gas is injected into a chamber above the water; pressure is increased to the pressure of simulative corresponding positions under the water; then the explosive is detonated, the length of the lead block before and after the explosion, in such a way, simulative brisance in case of explosion under the same condition under the water can be worked out. Since brisance is one of the important parameters for measuring explosion property of the explosive, the measurement of the brisance is conducive to further guiding development on under water blasting and the explosive therefore. The device of the invention can adopt the simulative deepwater environment to measure brisance of the explosive at different water depths, thus solving the problem that measurement of the brisance in case of underwater blasting is difficult.

Owner:KUNMING UNIV OF SCI & TECH

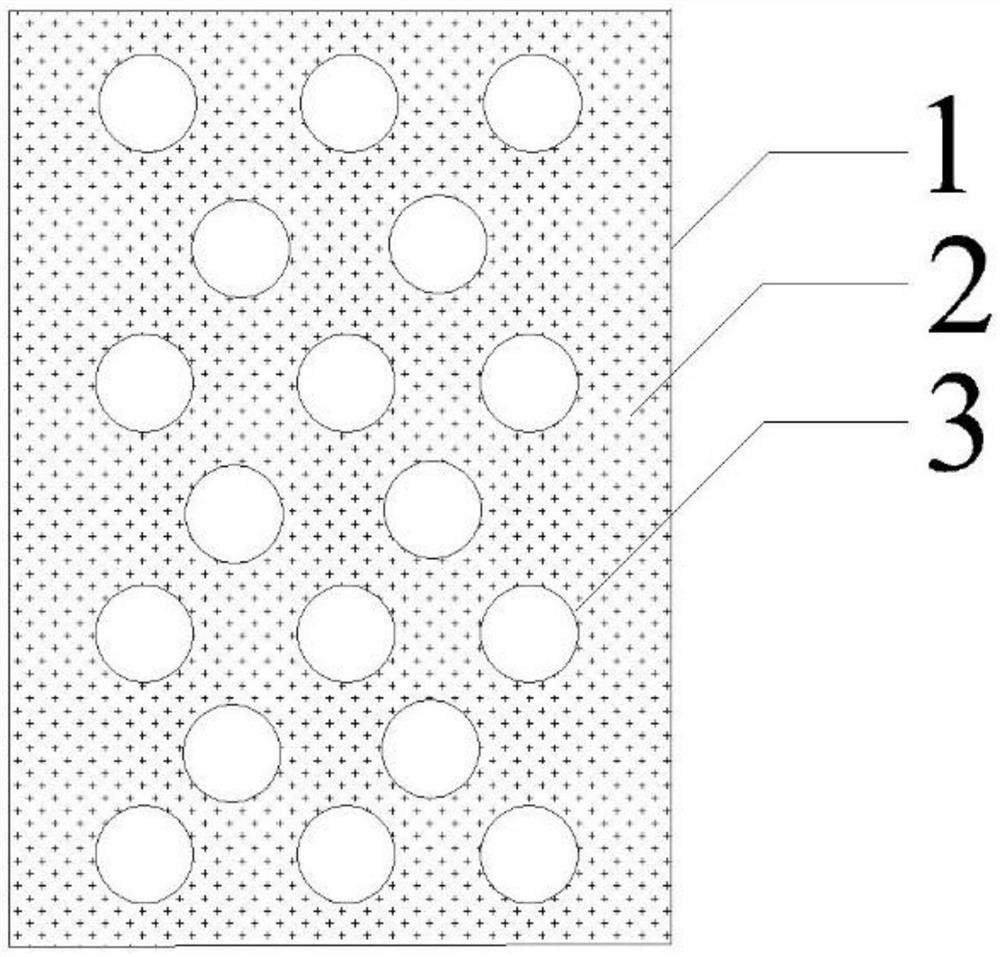

Modified ammonium nitrate-fuel oil explosive for explosive welding and preparation method of modified ammonium nitrate-fuel oil explosive

ActiveCN103058801AMeet explosive welding requirementsHigh densityExplosivesTEX-explosiveMetallic materials

The invention discloses a modified ammonium nitrate-fuel oil explosive for explosive welding and a preparation method of the modified ammonium nitrate-fuel oil explosive. According to the modified ammonium nitrate-fuel oil explosive, the density of the explosive is decreased by using expanded perlite, and the explosive performance of the explosive is reduced by using refined salt. The preparation method comprises the following steps of: weighing ammonium nitrate and a composite modifier according to proportions of raw materials, mixing, crushing, and drying at 80-95 DEG C; adding a composite oil phase into the dried materials, and mixing uniformly at 80-95 DEG C; and conveying wood powder, the refined salt and the expanded perlite into a cold mixer in turn, and mixing uniformly. The explosive performances, such as the density, the brisance and the explosion speed, are improved by adjusting the proportions of the raw materials of the modified ammonium nitrate-fuel oil explosive and adjusting the production process, so that the explosive can be ensured to meet explosive welding requirements of different metal materials.

Owner:LIAONING HONGSHAN CHEM

Fast sensitizer for emulsion explosive

ActiveCN101870626AGood explosive performanceHigh intensityNon-explosive/non-thermic compositionsThioureaEmulsion explosive

The invention relates to a fast sensitizer for emulsion explosive, which comprises components A and B in weight percent: component A: 15-42% of sodium nitrite, 15-42% of ammonium nitrate and 14-68% of water; component B: 40-60% of oxalic acid and 40-60% of thiourea; and the mixed ratio of component A to component B is 30-50:1. The fast sensitizer of the invention has fast foaming speed, simple process, convenient operation, low production cost and no aftereffect reaction; and the emulsion explosive prepared by the fast sensitizer has good explosive property, high brisance and strong work capacity.

Owner:广东华威化工股份有限公司

High brisance metal powder explosive

ActiveUS9828303B1Large capacityImprove explosive powerExplosive chargesAmmunition projectilesShaped chargeNitrogen

A very high brisance metal powder explosive is created by including a multitude of hollow aluminum / aluminum oxide micro-particle shells deposited within a high explosive composition matrix. The interior of such micro-particle shells may contain air, nitrogen, other gases, combinations thereof, or possibly even be a vacuum. The invention might be used on warheads that are fragmentation warheads, explosively formed penetrators, air blast warheads, shaped charge jets of shaped charge warheads, or other high explosive-driven devices.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Powdery emulsion explosive for on-site mixed loading and preparation method of powdery emulsion explosive

ActiveCN106008122AReduce production and transportation costsImprove intrinsic safetyExplosive working-up apparatusNon-explosive/non-thermic compositionsCelluloseExplosive Agents

The invention discloses a powdery emulsion explosive for on-site mixed loading. The powdery emulsion explosive comprises powdery latex substrate and a sensitizer. The mass ratio of the powdery latex substrate to the sensitizer is 30: (1-1.5). The powdery latex substrate comprises sodium nitrate, crystal modifiers, flame inhibitors, water, compound additives, oil-phase materials, compound emulsifiers and emulsification assistants. The sensitizer comprises expanded perlite, carboxymethyl cellulose, polyvinyl alcohol, ammonium bicarbonate, phosphoric acid, water, urea and ammonium nitrate. The invention further discloses a preparation method of the powdery emulsion explosive for on-site mixed loading. The emulsion explosive has high detonation velocity, brisance and coupling degree and few fumes; cost is low, the state of the explosive is hard, and work capacity is high; less poisonous gas is generated during preparation, safety of operators can be improved, and environment protection can be realized; the preparation process is simple and easy to operate.

Owner:宜兴市阳生化工有限公司

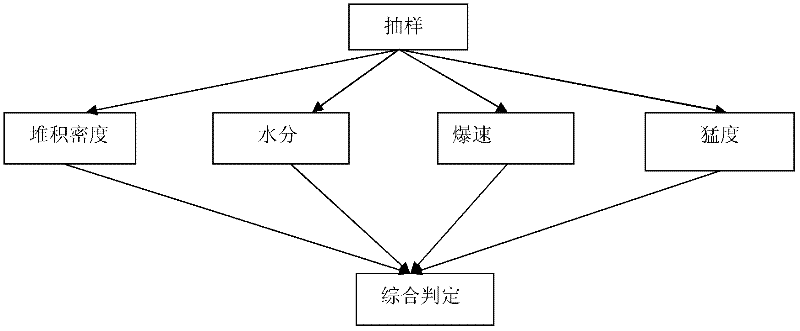

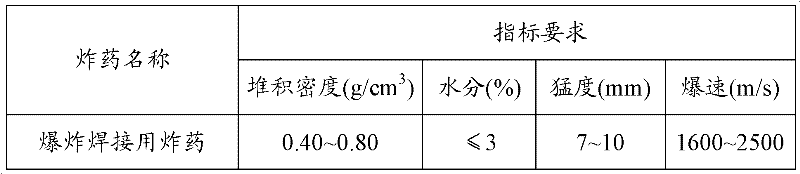

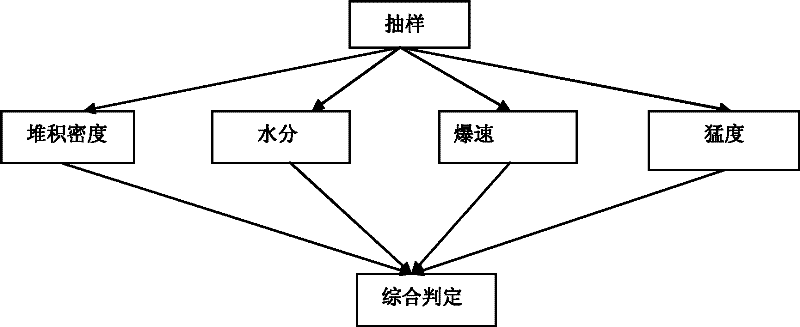

Method for inspecting explosive for explosive welding

The invention relates to a method for inspecting an explosive for explosive welding. Whether the explosive is qualified is judged by measuring the bulk density, moisture, detonation velocity and brisance of the explosive and comparing measured data of the bulk density, moisture, detonation velocity and brisance of the explosive with corresponding standard values. By the method for inspecting the explosive for the explosive welding, the explosive consumption for tests and the waste of metal plates can be reduced; and the method achieves the effects of energy conservation and environment friendliness, is easy to operate, and has a practical effect.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

Low-explosion-speed rock powder emulsion explosive

InactiveCN104262068ANot easy to agglomerateAdjust detonation velocityNon-explosive/non-thermic compositionsNon-electric welding apparatusEmulsion explosiveVolumetric Mass Density

The invention discloses low-explosion-speed rock powder emulsion explosive which is prepared by mixing the following components in parts by weight: 50-60 parts of rock powder emulsion explosive, 1.5-2 parts of a density adjusting agent and 40-50 parts of sodium chloride, wherein the density adjusting agent is prepared by mixing expanded glass beads and talcum powder. The explosion speed of the low-explosion-speed rock powder emulsion explosive disclosed by the invention can be stabilized to be 2100+ / -50m / s, the brisance of the explosive is 8-10mm, the gap distance of the explosive is 6-8cm, the natural bulk density of the explosive is 0.72-0.78g / cm<3>, the requirements of low explosion speed and low brisance in using the explosive in explosive welding are met, and the explosive is applicable to explosive welding of high-end out-phase metal plates.

Owner:SHANXI TOND CHEMICAL CO LTD

Powdery expanded ammonium nitrate explosive and preparation method for same

InactiveCN104163744ALow costClean and safe production processExplosive working-up apparatusLiquid stateOil phase

The invention discloses a powdery expanded ammonium nitrate explosive and a preparation method for the same. The explosive is prepared by mixing the following constituents in percentage by mass: 80-88% of ammonium nitrate, 5-20% of urea, 0-7% of wood flour, and 0-2% of anti-caking and anti-water agent. In the method, urea is used as a combustible agent for replacing an oil-phase material, so that the cost of the explosive is reduced, and the production process is clean and safe; and the oxidant ammonium nitrate is mixed with the combustible agent urea, and the anti-caking and anti-water agent in a liquid-state molecular state, so that the obtained explosive is excellent in explosion performance, wherein the explosion speed is 3500-4000 m / s (32 mm cartridge), the brisance is 14-18 mm, and the gap distance is 5-10 cm.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of hollow polymer microsphere sensitized emulsion explosive for explosive welding

InactiveCN113860976ALow detonation velocityReduced Explosive Welding RequirementsNon-explosive/non-thermic compositionsPolymer scienceExplosive Agents

The invention discloses a preparation method of a hollow polymer microsphere sensitized emulsion explosive for explosive welding, the emulsion explosive for explosive welding is composed of an emulsion matrix and hollow polymer microspheres, the mass fraction of the emulsion matrix is 60%-80%; the mass fraction of the hollow polymer microspheres is 20%-40%; the emulsion matrix consists of ammonium nitrate, sodium nitrate, water, an emulsifier and a compound oil phase; the hollow polymer microspheres are formed by combining one or more of polymethyl methacrylate, polystyrene, polysiloxane and polyamide microspheres. In addition, the invention provides a preparation method of the emulsion explosive for explosive welding sensitized by the hollow polymer microspheres, the hollow polymer microspheres integrate the functions of a diluent and a sensitizer, and the raw materials of the emulsion explosive are low in cost and free of pollution to the environment. Meanwhile, enterprises can adjust the proportion and content of the hollow polymer microspheres according to the requirements of different composite materials, so that emulsion explosives for explosive welding with different detonation velocities and brisance are prepared.

Owner:ANHUI UNIV OF SCI & TECH

Low-detonation-velocity explosive with adjustable detonation velocity and brisance and preparation process thereof

The invention provides a low-detonation-velocity explosive with adjustable detonation velocity and brisance and a preparation process thereof. According to the technical scheme, the low-detonation-velocity explosive is prepared by mixing the following components in percentage by mass: 52%-73% of ammonium nitrate, 2.0%-3.0% of a complex oil phase, 3%-16% of wood powder, 20%-30% of industrial salt and 0.3%-0.42% of a modifier. By the low-detonation-velocity explosive with adjustable detonation velocity and brisance, such problems of the existing explosive for explosive welding as high sensitivity, uneven explosive mixing, poor safety, poor fluidity, instable detonation velocity and the like are solved.

Owner:陕西红旗民爆集团股份有限公司

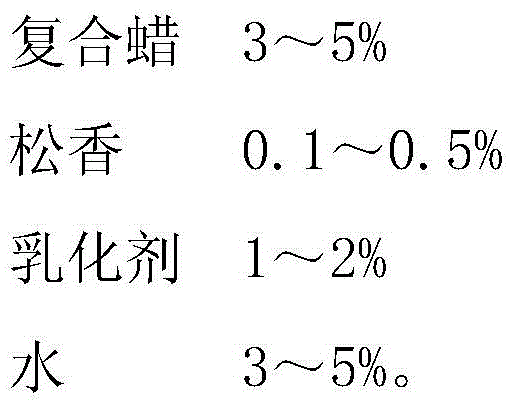

Emulsified explosive with long-term storage stability

InactiveCN109942353AHigh detonation velocityHigh intensityExplosivesMicrocrystalline waxEmulsion explosive

The invention discloses an emulsified explosive with long-term storage stability, belongs to the technical field of explosives, and relates to an emulsified explosive. The problem that an existing emulsified explosive is short in storage period is solved. The emulsified explosive with the long-term storage stability is prepared from, by weight, 72.23 parts of ammonium nitrate, 9.85 parts of sodiumnitrate, 11.71 parts of water, 1.46 parts of paraffin, 1.46 parts of microcrystalline wax, 0.31-0.96 part of base oil, 0.62-1 part of Span-80 and 0.93-2.36 parts of LZ2820. Accordingly, two emulsifiers of Span-80 and LZ2820 are mixed to prepare the emulsion explosive, and the emulsion explosive is high in detonation speed and brisance, better in storage stability and good in water resistance.

Owner:山西壶化集团金星化工有限公司

Low-detonation-velocity explosive for explosive welding and preparation method thereof

InactiveCN104761418AReduced ability to workPerformance lossExplosivesTEX-explosiveEmulsion explosive

The invention relates to a low-detonation-velocity explosive for explosive welding and a preparation technique thereof. The low-detonation-velocity explosive for explosive welding is mainly prepared from 60-83 wt% of third-grade coal mine allowable powder emulsion explosive, 10-25 wt% of talcum powder, 5-10 wt% of silicon aluminum powder and 3-5 wt% of wheat straw powder. The preparation technique comprises the following steps: respectively weighing the following raw materials in percentage by mass: third-grade coal mine allowable powder emulsion explosive, talcum powder, silicon aluminum powder and wheat straw powder; and drying the talcum powder, silicon aluminum powder and wheat straw powder at 80-95 DEG C until the water content is not higher than 0.5 wt%, uniformly mixing, adding the wheat straw powder to obtain the low-detonation-velocity explosive for explosive welding, and packaging for later use. The low-detonation-velocity explosive for explosive welding is easy to produce, and has the advantage of stable performance. The low-detonation-velocity explosive for explosive welding satisfies the requirement that the explosive welding explosive brisance is 9-11mm, the detonation velocity is 2500-2750 m / s, thereby ensuring the explosive welding effect.

Owner:HONGDA MINING IND +2

Emulsion explosive and preparation method thereof

The invention relates to an emulsion explosive and a preparation method thereof. The emulsion explosive is prepared from the following raw materials and auxiliary materials in percentage by weight: 70 to 85 percent of ammonium nitrate, 2 to 10 percent of sodium nitrate, 5 to 15 percent of water, 1 to 5 percent of composite wax, 0.5 to 5 percent of composite emulsifier, 0.5 to 3 percent of Vaseline and 0.1 to 2 percent of mechanical oil. The emulsion explosive is low in cost, proper in state and performance, accurately metered, convenient to use, simple in process, easy to operate, safe and reliable, and has high explosion performance, high brisance and strong power.

Owner:DALIAN ANTAI CHEM

Novel low-detonation velocity explosive suitable for titanium material compounding, and preparation method thereof

InactiveCN105384588AMeet the needs of the development of domestic chemical industry and other industriesDensity adjustmentNon-explosive/non-thermic compositionsEffective densityEmulsion explosive

The invention discloses a novel low-detonation velocity explosive suitable for titanium material compounding, and a preparation method thereof. The method comprises the following steps: taking 40 parts by weight of a rock powdery emulsion explosive with the bulk density of 0.58-0.62g.cm<-3>, the detonation velocity of 3500-3700m / s, the brisance of 15-17mm, the gap distance of 9-11cm and the work capacity of 360 / ml, taking 45 parts of sands with the bulk density of 1.40g.cm<-3> and the particle size of 300 meshes, putting above taken materials in a medicine mixer, stirring the materials for 3-5min, taking 7 parts of bran with the bulk density of 0.50g.cm<-3> and the particle size of 300 meshes, putting the taken bran in the medicine mixer, stirring the obtained mixture for 20min until fullness and uniformity, and detecting the density and the detonation velocity of the above obtained product. The sands are used to reduce the detonation velocity, and the bran is used as a density adjusting agent to adjust the density of the obtained mixed explosive; and the effective density of the rock powdery emulsion explosive is reduced through synergism of the sands and the bran, and the novel low-detonation velocity explosive prepared through mixing above materials in proportion can improve the production efficiency, and solves the problem of lack-of-fit of large-area titanium-steel composite plates.

Owner:安徽宝泰特种材料有限公司

Main charge for charging of emulsified seismic explosive column

InactiveCN105418341ASolve the situation where the density change is unstableStable storageExplosivesPerformance indexVolumetric Mass Density

The invention relates to an explosive, in particular to a main charge for charging of an emulsified seismic explosive column used in the field of seismic exploration. According to the technical scheme, the main charge for charging of the emulsified seismic explosive column is prepared from, by weight, 74 parts of ammonium nitrate, 9.5 parts of sodium nitrate, 9.5 parts of water, 7 parts of a composite oil phase and 2.3 parts of perlite, wherein the perlite accounts for 2.3% by weight of a matrix. The main charge adopts a pure physical sensitizing technology, and therefore the problem that the changing and unstable density of the main charge cannot be controlled due to the fact that the seismic explosive column charged through chemical sensitizing is subjected to environmental changes is solved; meanwhile, the adjustment of charge component proportion follows the zero-oxygen principle of explosive design, and the best combination of performance indexes required for exploration is also achieved, and the detonation velocity is up to 5300-5500 m / s. The main charge is simple in formula, large in brisance, stable in storage, long in storage time, harmless to human bodies and environment and low in cost.

Owner:山西江阳兴安民爆器材有限公司

High-density insensitive rock heavy ammonium nitrate fuel oil explosive

ActiveCN104276909AImprove water resistanceExcellent high densityNon-explosive/non-thermic compositionsDetonatorWax

The invention discloses a high-density insensitive rock heavy ammonium nitrate fuel oil explosive. The high-density insensitive rock heavy ammonium nitrate fuel oil explosive is prepared by adding 95-98 parts by weight of ammonium nitrate and 2-5 parts by weight of light diesel oil into per 100 parts by weight of a rock emulsion matrix for mixing, wherein the rock emulsion matrix is prepared by blending 70-75% by weight of ammonium nitrate, 8-10% by weight of sodium nitrate, 10-12% by weight of water, 2-5% by weight of an emulsifier and 3-5% by weight of special wax for emulsification. The high-density insensitive rock heavy ammonium nitrate fuel oil explosive disclosed by the invention has very excellent high density and water resistance, can be directly sunk to the bottom of water in an environment with the water or a mixture of slurry and the water, and can realize complete explosion by being immersed into the water which is 1m deep for 24h. The high-density insensitive rock heavy ammonium nitrate fuel oil explosive disclosed by the invention has good plasticity, high detonation velocity value, high brisance value, no sensitivity of a detonator and safety in production, storage, transportation and use.

Owner:SHANXI TOND CHEMICAL CO LTD

Environmental-friendly powder emulsion explosive and preparation method thereof

InactiveCN105566018ASacrifice distance increasedHigh intensityEnergy inputExplosive working-up apparatusWaxAdditive ingredient

Owner:HUBEI SHUAILI CHEM

Novel low-detonation-velocity explosive applicable to stainless steel composite and preparation method thereof

InactiveCN105541521ADensity adjustmentReduce adverse effectsNon-explosive/non-thermic compositionsEffective densityEmulsion explosive

The invention discloses a novel low-detonation-velocity explosive applicable to stainless steel composite and a preparation method thereof; the preparation method comprises the steps: taking 60 parts by weight of a rock powdery emulsion explosive with the bulk density of 0.58 g*cm<-3>-0.62 g*cm<-3>, the detonation velocity of 3500 m / s-3700 m / s, the brisance of 15 mm-17 mm, the sympathatic detonation distance of 9 cm-11cm and the capacity for work of 360 / ml, taking 36 parts by weight of sand with the bulk density of 1.40 / g*cm<-3> and the particle size of 300 mesh, putting the two raw materials into a drug mixing machine, stirring for 3-5 minutes, then taking 17 parts by weight of chaff with the bulk density of 0.50 / g*cm<-3> and the particle size of 300 mesh, putting the chaff into the drug mixing machine, stirring for 20 minutes, fully stirring evenly, and then detecting the density and the detonation velocity of the product. The sand is used for reducing the detonation velocity, and the chaff is used as a density regulator for regulating the density of the mixed explosive; the effective density of the rock powdery emulsion explosive is reduced by the combined action of the sand and the chaff; the novel low-detonation-velocity explosive obtained by mixed loading of the raw materials in proportion can increase the production efficiency and solves problems of unfit large-area stainless steel-steel composite plates.

Owner:安徽宝泰特种材料有限公司

Low-density high-detonation-velocity explosive and preparation method thereof

InactiveCN108002965ASolve the problem of non-fittingIncrease productivityNon-explosive/non-thermic compositionsEmulsion explosiveEngineering

The invention discloses low-density high-detonation-velocity explosive and a preparation method thereof. The low-density high-detonation-velocity explosive is used for explosive welding of large-scalecopper-steel composite boards. The low-density high-detonation-velocity explosive is prepared from, 50 parts of emulsion explosive, 30 parts of perlite and 45 parts of bran. The pure explosive density of the emulsion explosive is 0.73 cm<3>, the brisance is 20 mm, and the explosive velocity is 4000 m / s. The low-density high-detonation-velocity explosive is suitable for explosive welding of the large-scale copper-steel explosion composite boards, the problem is effectively solved that large-scale copper-steel explosion composite boards are not fitted, and the production efficiency is greatly improved.

Owner:安徽宝泰特种材料有限公司

Preparation method of high detonation velocity and low density explosive for copper-steel compounding

InactiveCN106518580ARealize continuous weldingReduce adverse effectsNon-explosive/non-thermic compositionsDetonatorEmulsion explosive

The invention relates to a preparation method of a high detonation velocity and low density explosive for copper-steel compounding. The preparation method comprises detecting whether the pure density, brisance and detonation velocity of an emulsion explosive satisfy factory explosion parameters, adding the emulsion explosive and perlite into a mixing machine together according to a weight ratio of 50: 45 when the emulsion explosive has the eligible explosion parameters, carrying out uniform stirring, adding bran into the mixing machine, fully stirring the mixture, wherein a weight ratio of the emulsion explosive, perlite to bran is 50: 30: 45, and detecting product density, brisance and detonation velocity in the mixing machine, wherein the product with the density of 0.78-0.81g / cm<3>, the intensity of 12-14mm and detonation velocity of 2400-2500m / s is an eligible product. The copper-steel composite plate obtained by preparation of the explosive has minimum shear strength tau b of greater than or equal to 140Mpa, and has a bonding rate of 100% in the area except a detonator shadow region.

Owner:安徽宝泰特种材料有限公司

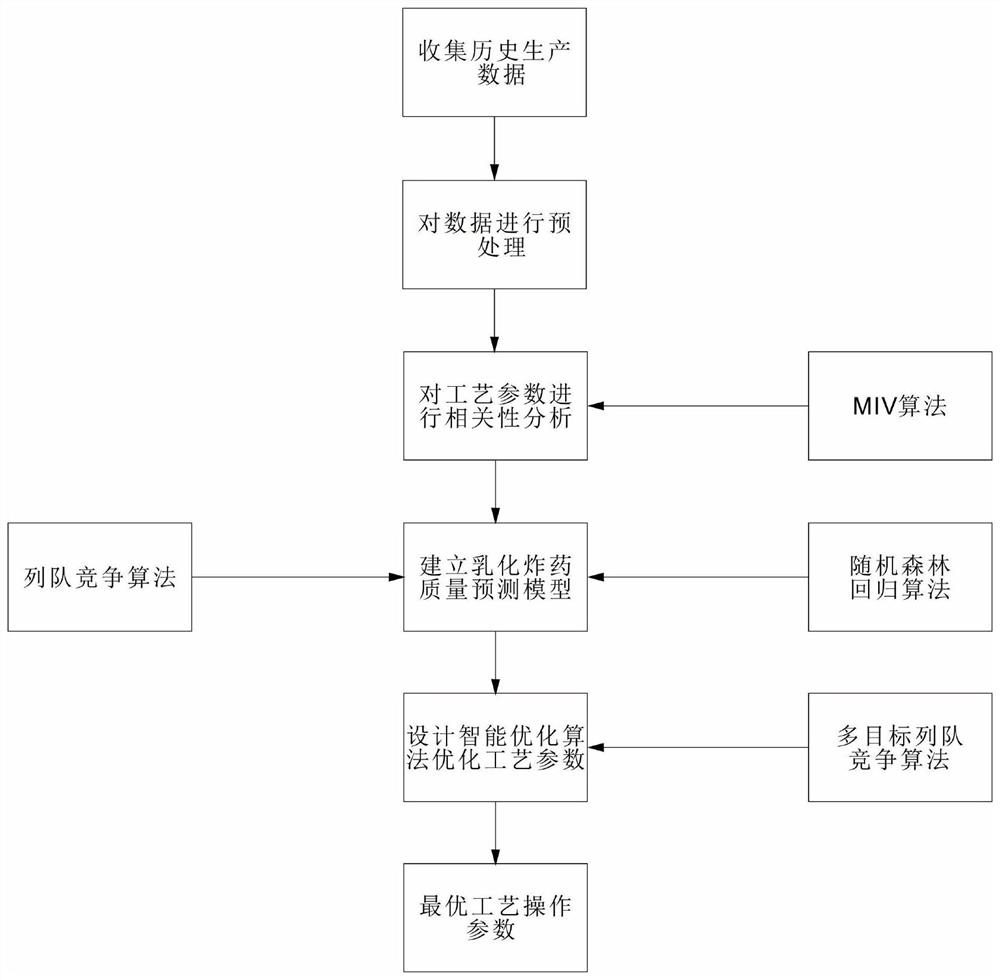

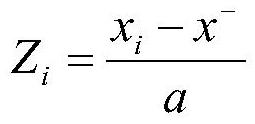

Emulsion explosive quality prediction and optimization method

PendingCN113515891AReal-time prediction qualityImprove the pass rate of product qualityForecastingCharacter and pattern recognitionExplosive AgentsEmulsion explosive

The invention relates to an emulsion explosive quality prediction and optimization method. The method comprises the following steps: acquiring historical data of an emulsion explosive, preprocessing the historical data, performing correlation analysis on process parameters of an emulsion explosive production process and the quality of the emulsion explosive, and selecting the process parameters; establishing a random forest emulsion explosive quality prediction model, and designing a queue competition algorithm to optimize random forest model parameters; on the basis of the established random forest emulsion explosive quality prediction model, taking maximizing the emulsion explosive quality index brisance and detonation velocity as optimization objectives, taking the technological parameter operation range as a constraint condition, establishing an emulsion explosive quality double-objective optimization model, designing a multi-objective queue competition algorithm for solving, and solving to obtain the optimal process operation parameters under the condition of maximizing the brisance and the detonation velocity.

Owner:ZHEJIANG YONGLIAN CIVIL EXPLOSIVE MATERIALS

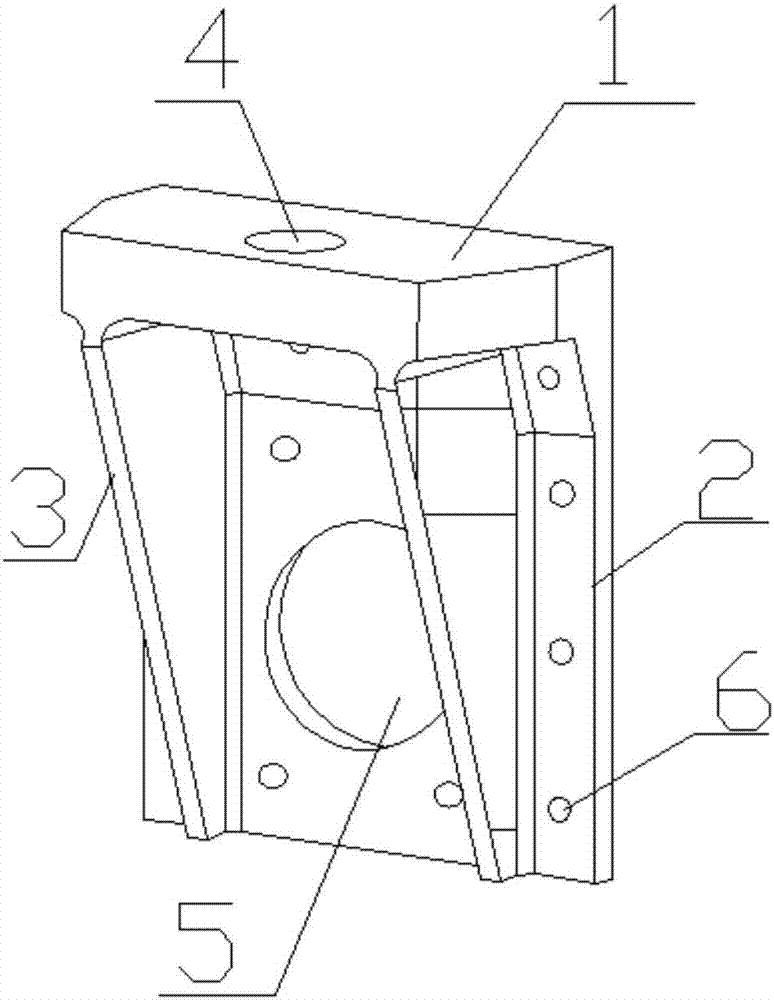

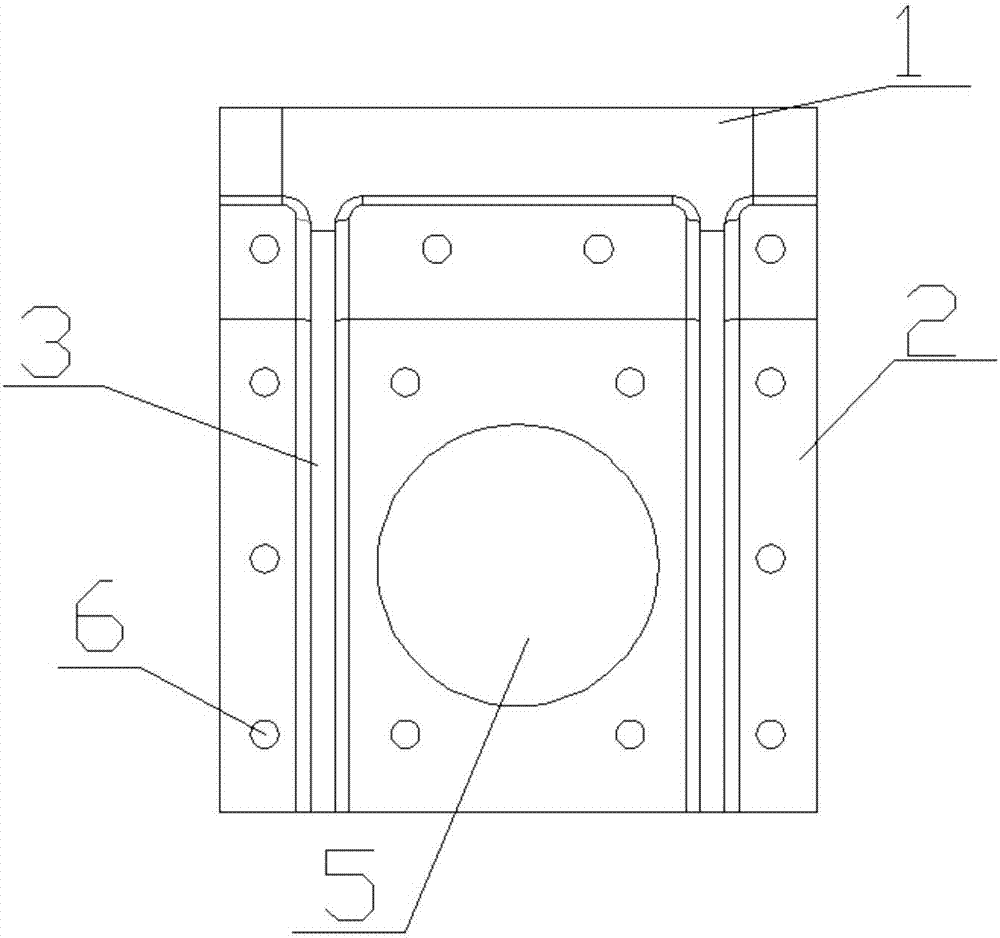

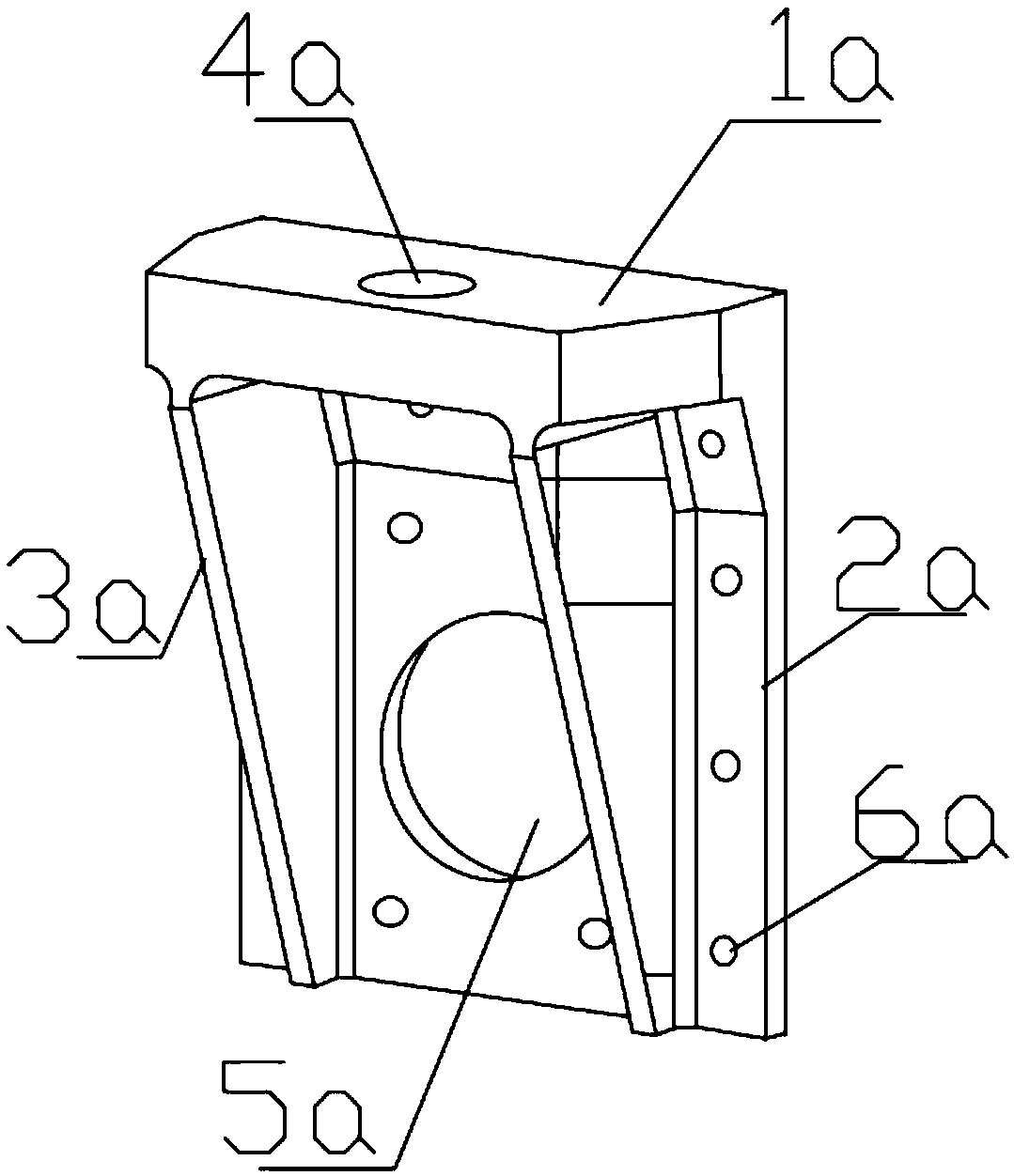

Explosive bolt box and preparation method thereof

ActiveCN107253337AImprove bearing capacitySolve the problem of uneven hands and complex preparationSelf-propelled projectilesEngineeringMachining

The invention discloses an explosive bolt box and a preparation method thereof and relates to a bolt box and a preparation method thereof. The explosive bolt box solves the problem that an existing explosive bolt is poor in load bearing capacity, not high in strength, easy to cause pollution by brisance and hard to control. Two explosive bolt box side plates are mounted on two sides of an explosive bolt box back plate; a top plate is arranged on the explosive bolt box back plate and the two explosive bolt box side plates, a weight-reducing hole is formed in the center of the back plate, and a plurality of screws or rivet through holes are formed. The preparation method comprises the following steps of: paving a prepreg on the surface of a valve; putting the valve in a positioning groove; paving residual skin; combining dies; heating; curing; cooling; demoulding; and machining. The explosive bolt box disclosed by the invention is applied to the aerospace field.

Owner:HARBIN INST OF TECH

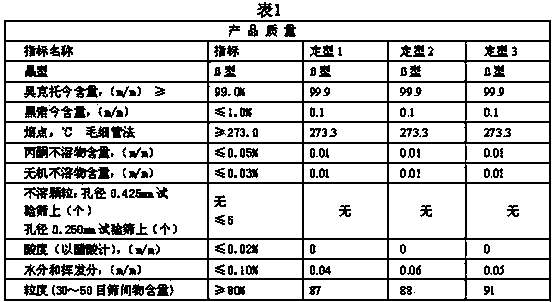

Specific HMX (cyclotetramethylene tetranitramine)

Owner:SHANXI BEIHUA GUANLYU CHEM IND

A kind of explosive bolt box and preparation method thereof

The invention discloses an explosive bolt box and a preparation method thereof and relates to a bolt box and a preparation method thereof. The explosive bolt box solves the problem that an existing explosive bolt is poor in load bearing capacity, not high in strength, easy to cause pollution by brisance and hard to control. Two explosive bolt box side plates are mounted on two sides of an explosive bolt box back plate; a top plate is arranged on the explosive bolt box back plate and the two explosive bolt box side plates, a weight-reducing hole is formed in the center of the back plate, and a plurality of screws or rivet through holes are formed. The preparation method comprises the following steps of: paving a prepreg on the surface of a valve; putting the valve in a positioning groove; paving residual skin; combining dies; heating; curing; cooling; demoulding; and machining. The explosive bolt box disclosed by the invention is applied to the aerospace field.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com