Method for inspecting explosive for explosive welding

An inspection method, explosive welding technology, applied in the direction of material inspection products, fuel oil testing, etc., can solve problems such as inconvenient operation, waste of metal plates, unfavorable environmental protection, etc., to achieve simple and practical environmental protection operation, reduce possible waste, and reduce test doses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

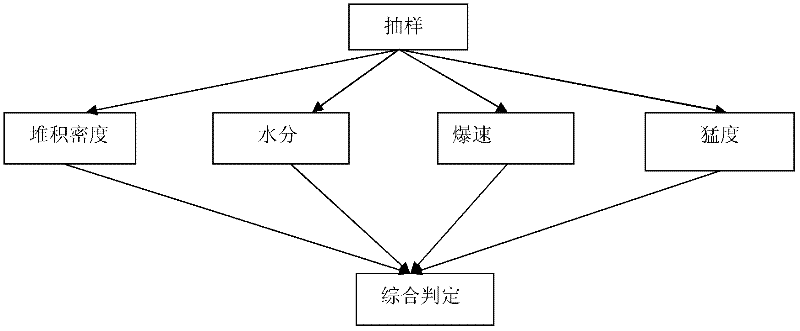

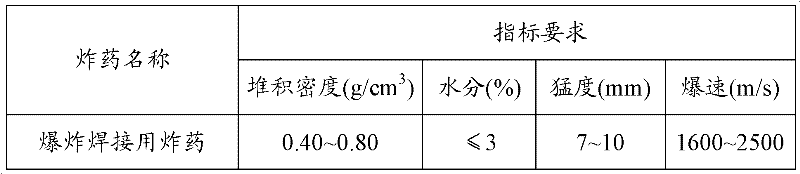

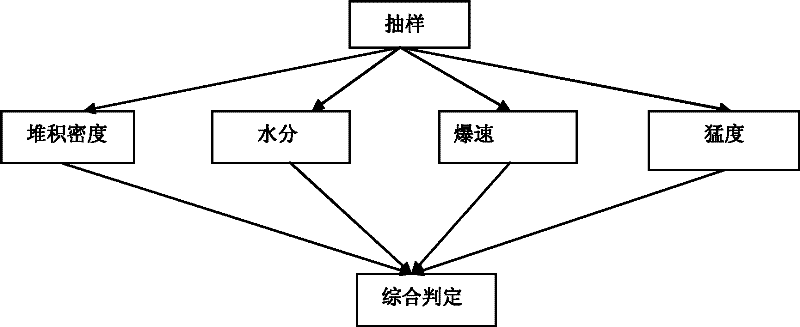

Method used

Image

Examples

Embodiment 1

[0036] Take the powdery emulsion explosive for explosive welding as an example. This powdery explosive can be used for explosive welding. The sample temperature should be controlled within normal temperature when testing its bulk density, intensity and detonation velocity:

[0037] Bulk density and moisture are detected according to the determination method of bulk density and moisture, respectively 0.52g / cm 3 , 1.8%;

[0038] Violence measurement: Take 50.0g of explosives, inject them into the paper tube slowly and evenly, gently level the surface of the explosives, put a round cardboard with holes on the explosives, insert the detonator shell into the center hole of the explosive charge, and insert the Depth 15mm. Other steps shall be carried out according to GB / T 12440-1990. The average value of the measured jerk is 9.56mm.

[0039] Detonation velocity measurement: Choose five empty paper tubes with a diameter of 32mm, no obvious deformation in specifications, similar le...

Embodiment 2

[0042] Take the modified ammonium oil explosive for explosive welding as an example. This powdery explosive can be used for explosive welding. The sample temperature should be controlled within normal temperature when testing its bulk density, intensity and detonation velocity:

[0043] Bulk density and moisture are detected according to the determination method of bulk density and moisture, respectively 0.69g / cm 3 , 0.5%;

[0044] Violence measurement: Take 50.0g of explosives, inject them into the paper tube slowly and evenly, gently level the surface of the explosives, put a round cardboard with holes on the explosives, insert the detonator shell into the center hole of the explosive charge, and insert the Depth 15mm. Other steps shall be carried out according to GB / T 12440-1990. The average value of the measured jerk is 9.86mm.

[0045] Detonation velocity measurement: Select five empty paper tubes with a diameter of 32mm, no obvious deformation in specifications, simil...

Embodiment 3

[0048] Take the expanded ammonium nitrate explosive for explosive welding as an example. This powdery explosive can be used for explosive welding. The sample temperature should be controlled within normal temperature when testing its bulk density, intensity and detonation velocity:

[0049] Bulk density and moisture are detected according to the determination method of bulk density and moisture, respectively 0.72g / cm 3 , 0.3%;

[0050] Violence measurement: Take 50.0g of explosives, inject them into the paper tube slowly and evenly, gently level the surface of the explosives, put a round cardboard with holes on the explosives, insert the detonator shell into the center hole of the explosive charge, and insert the Depth 15mm. Other steps shall be carried out according to GB / T 12440-1990. The average value of the measured jerk is 9.89mm.

[0051] Detonation velocity measurement: Select five empty paper tubes with a diameter of 32mm, no obvious deformation in specifications, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com