Patents

Literature

73results about How to "Density adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

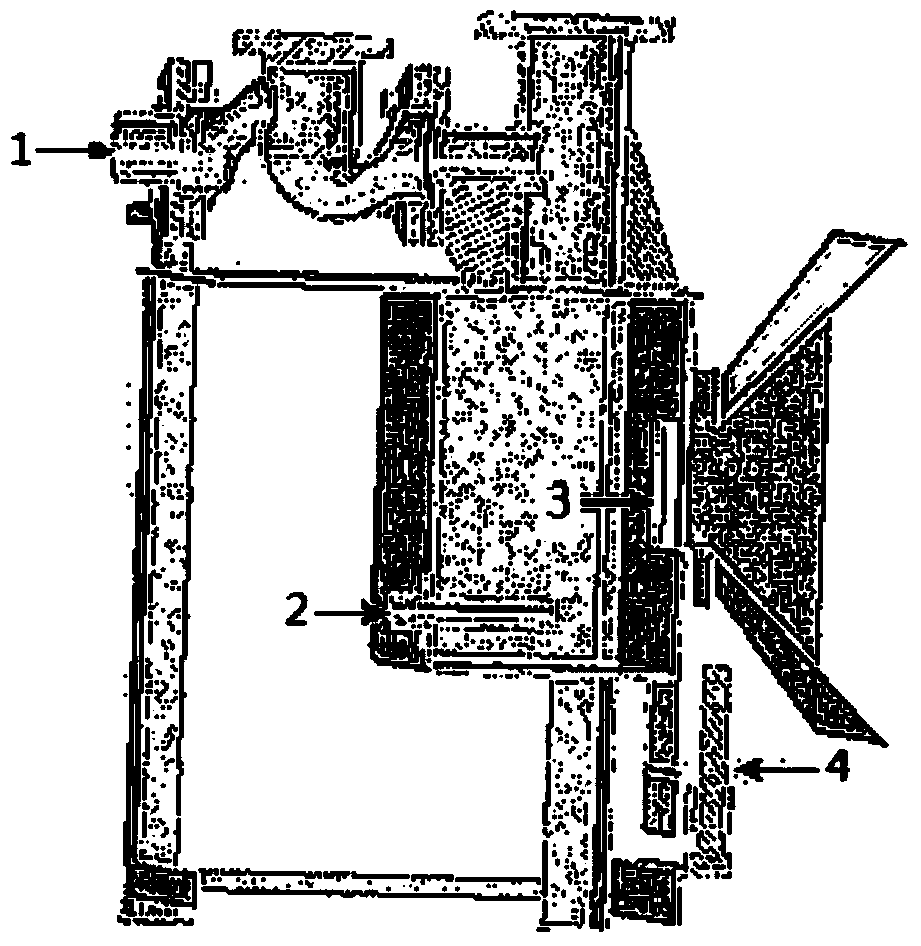

Fluid product service life testing device and testing method

PendingCN108254276AImprove work efficiencyPrevent sinkingInvestigating abrasion/wear resistanceProduct testingBiomedical engineering

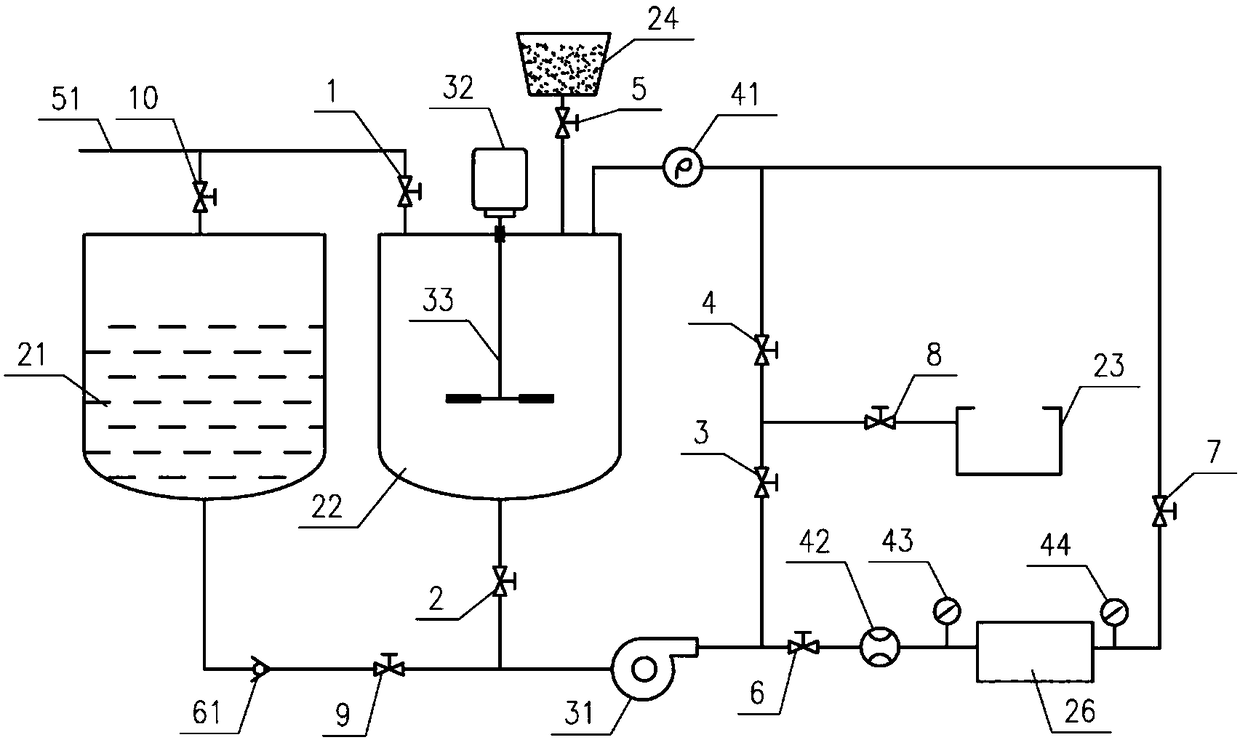

The invention provides a fluid product service life testing device. The fluid product service life testing device comprises a fluid generation device, a fluid product testing region and a washing device, wherein a fluid circulating pipeline is formed between the fluid generation device and the fluid product testing region; fluid flows into the fluid product testing region from the fluid generationdevice and then continually flows back into the fluid generation device; the washing device is communicated with the fluid circulating pipeline; the washing device is communicated with the fluid product testing region and then is communicated with the fluid generation device through the fluid circulating pipeline; the fluid generation device is connected with a sediment recycling device. The fluid product service life testing device can be used for testing the service life of a product through simulating fluid flowing of production conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

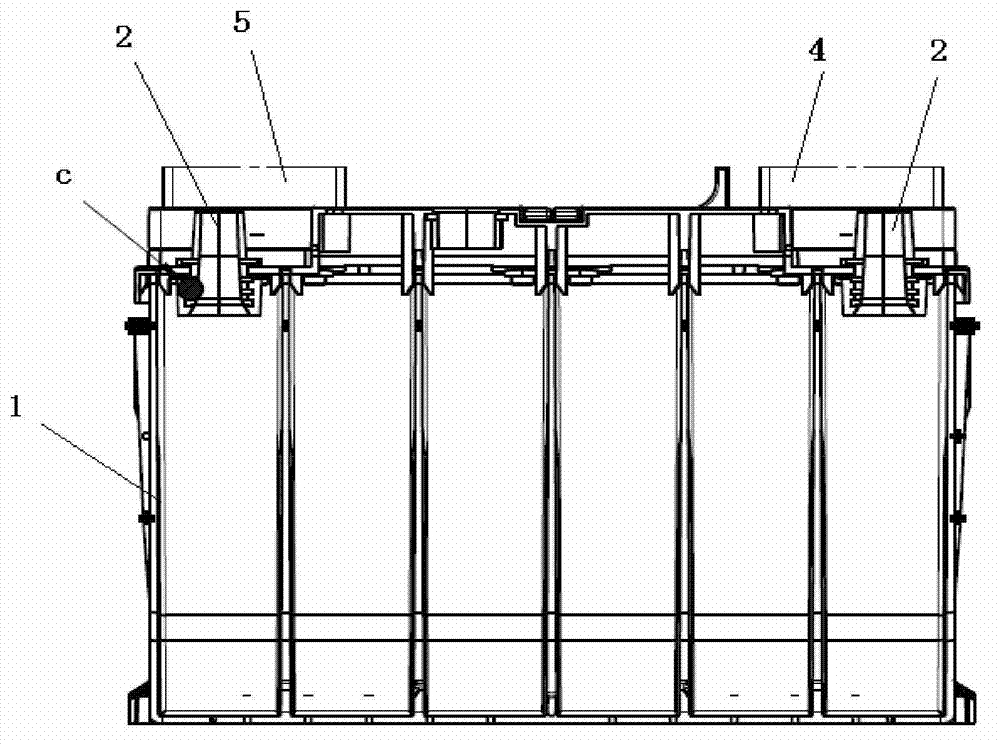

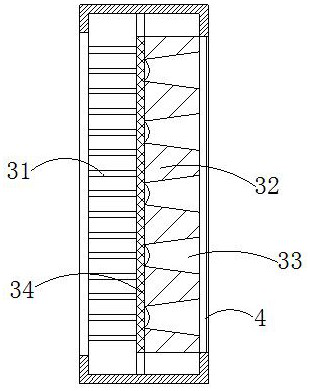

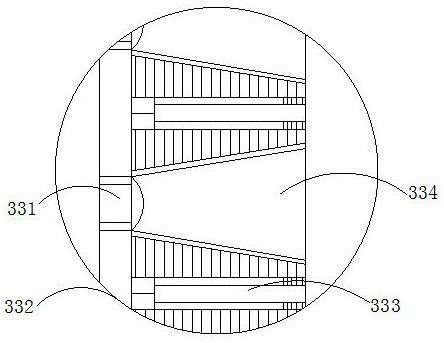

Vertical type net laying device capable of adjusting upright cotton density

ActiveCN104805597ADensity adjustmentGood for changing speedNon-woven fabricsVolumetric Mass DensityEngineering

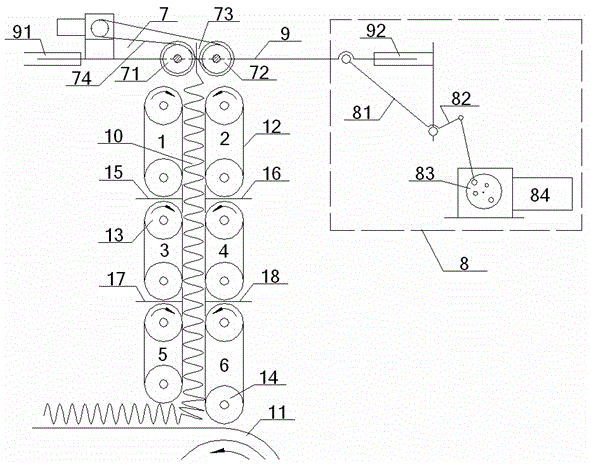

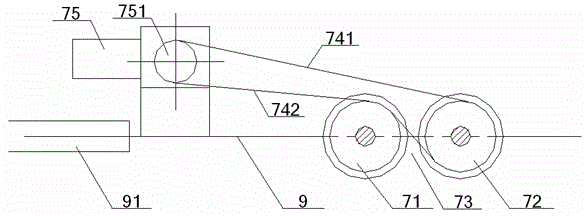

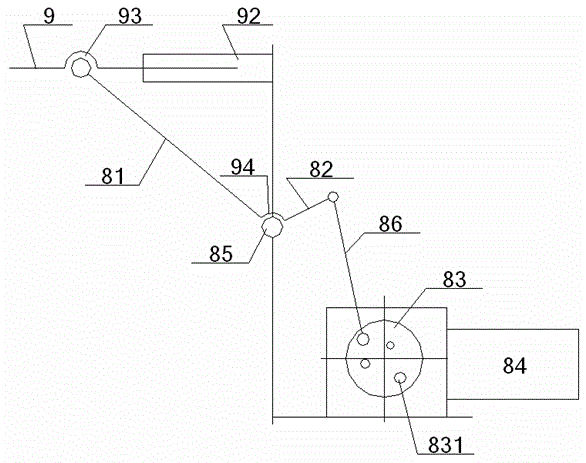

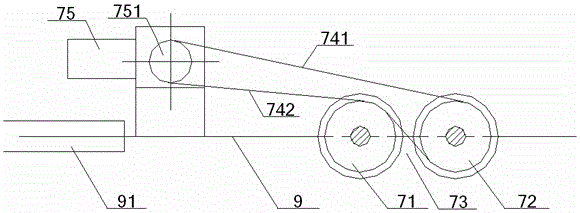

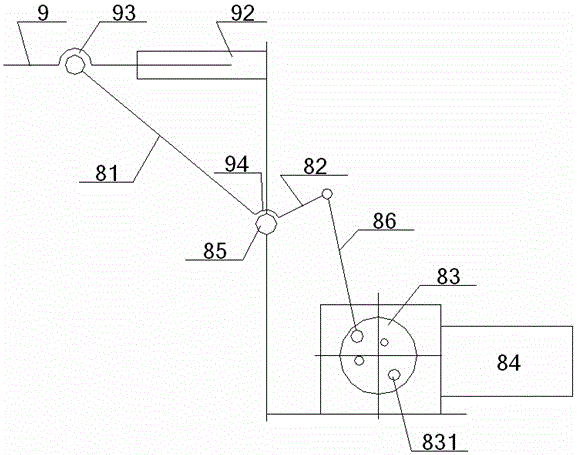

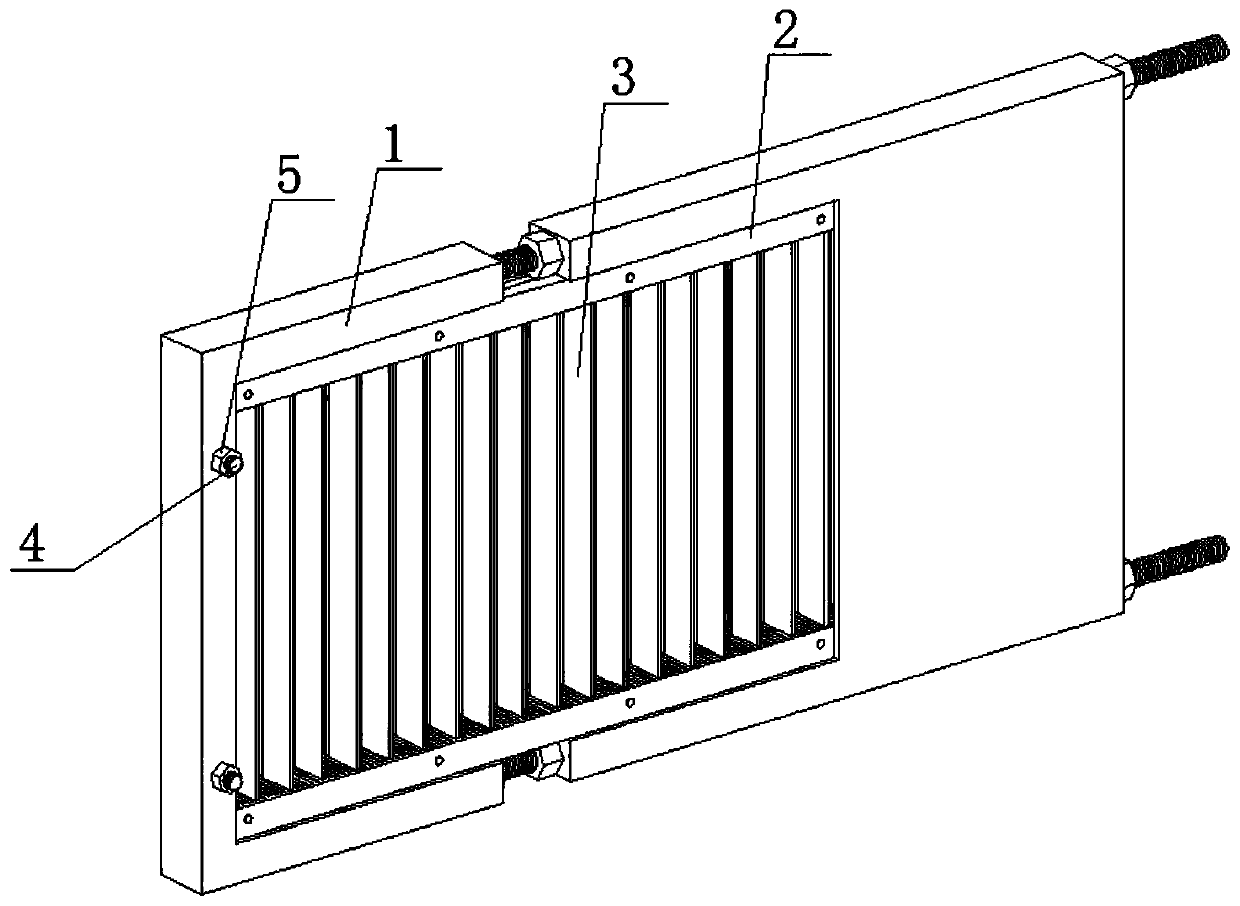

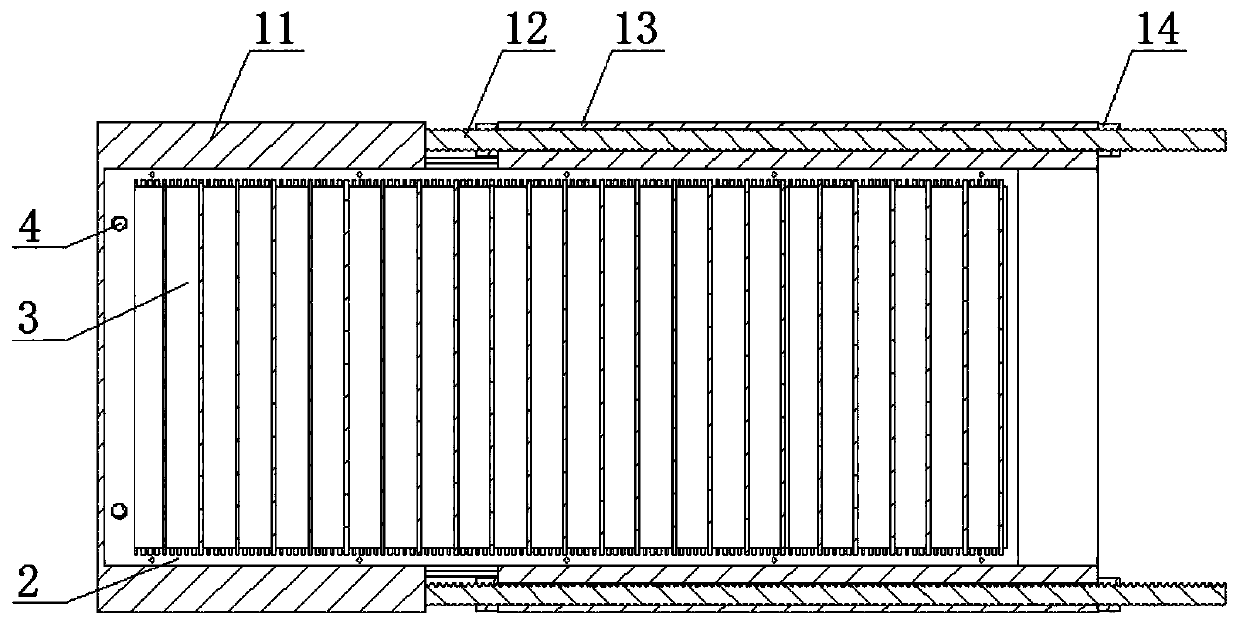

The invention discloses a vertical type net laying device capable of adjusting upright cotton density. The vertical type net laying device capable of adjusting the upright cotton density comprises a reciprocating type cotton feeding system, a vertical type cotton arrangement system and a horizontal conveying belt, the reciprocating type cotton feeding system comprises a reciprocating power part and a cotton feeding part mutually connected, a cotton feeding groove is formed in the middle of the cotton feeding part, the outlet of the cotton feeding groove is communicated with the inlet of a forming tunnel in the vertical type cotton arrangement system, the outlet of the forming tunnel is communicated with the horizontal conveying belt below the outlet, the vertical type cotton arrangement system comprises three layers, and each layer comprises a left cotton arrangement roll set and a right cotton arrangement roll set bilaterally symmetrical to the forming tunnel. When using, the density of a final product can be changed through setting different running speeds for left and right cotton arrangement roll sets in each layer. The vertical type net laying device capable of adjusting the upright cotton density is capable of adjusting the density and width of the upright cotton, and moreover, the structure is simple, and the operation is facilitated.

Owner:KUNSHAN TENGFEI UNDERWEAR TECH

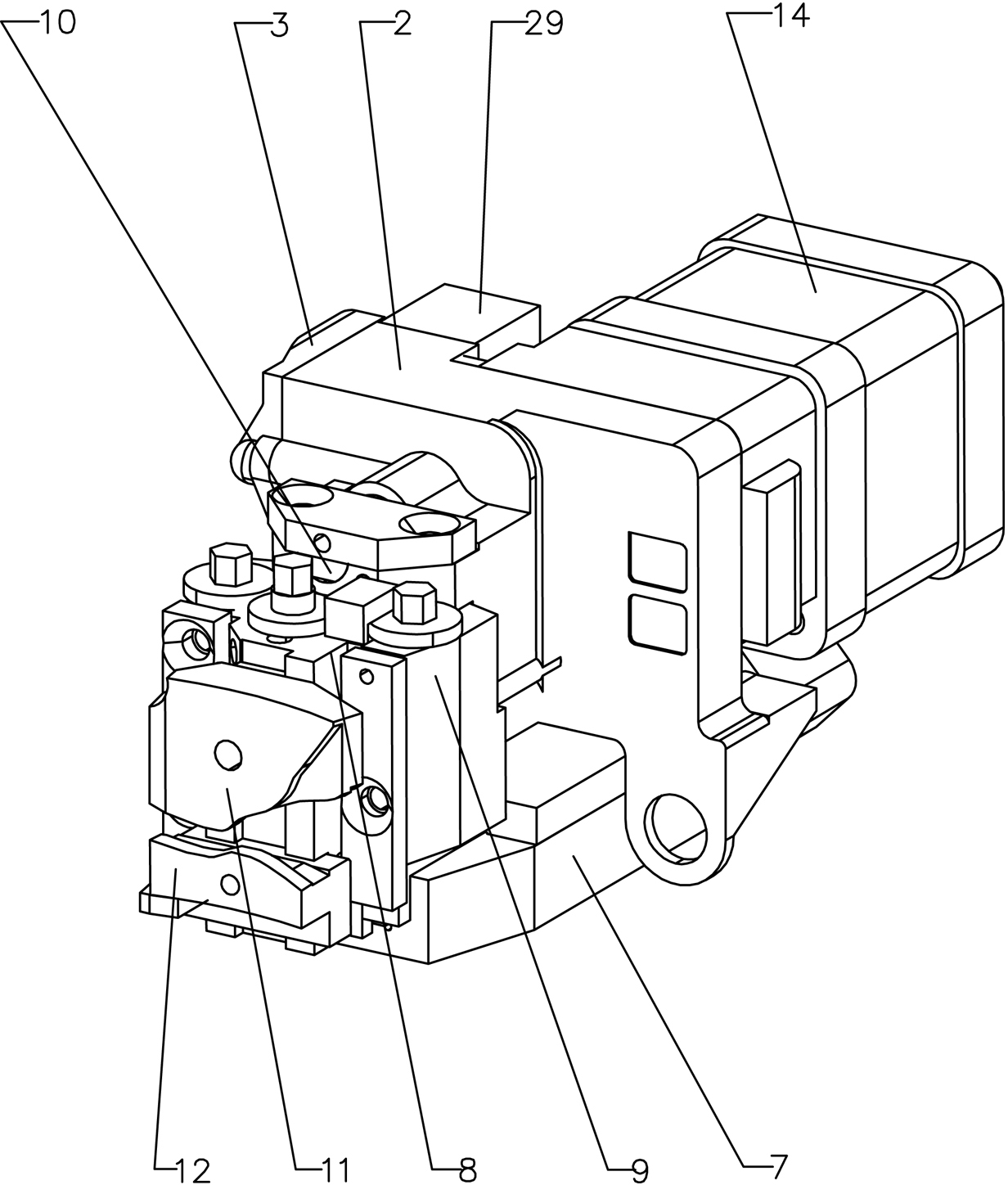

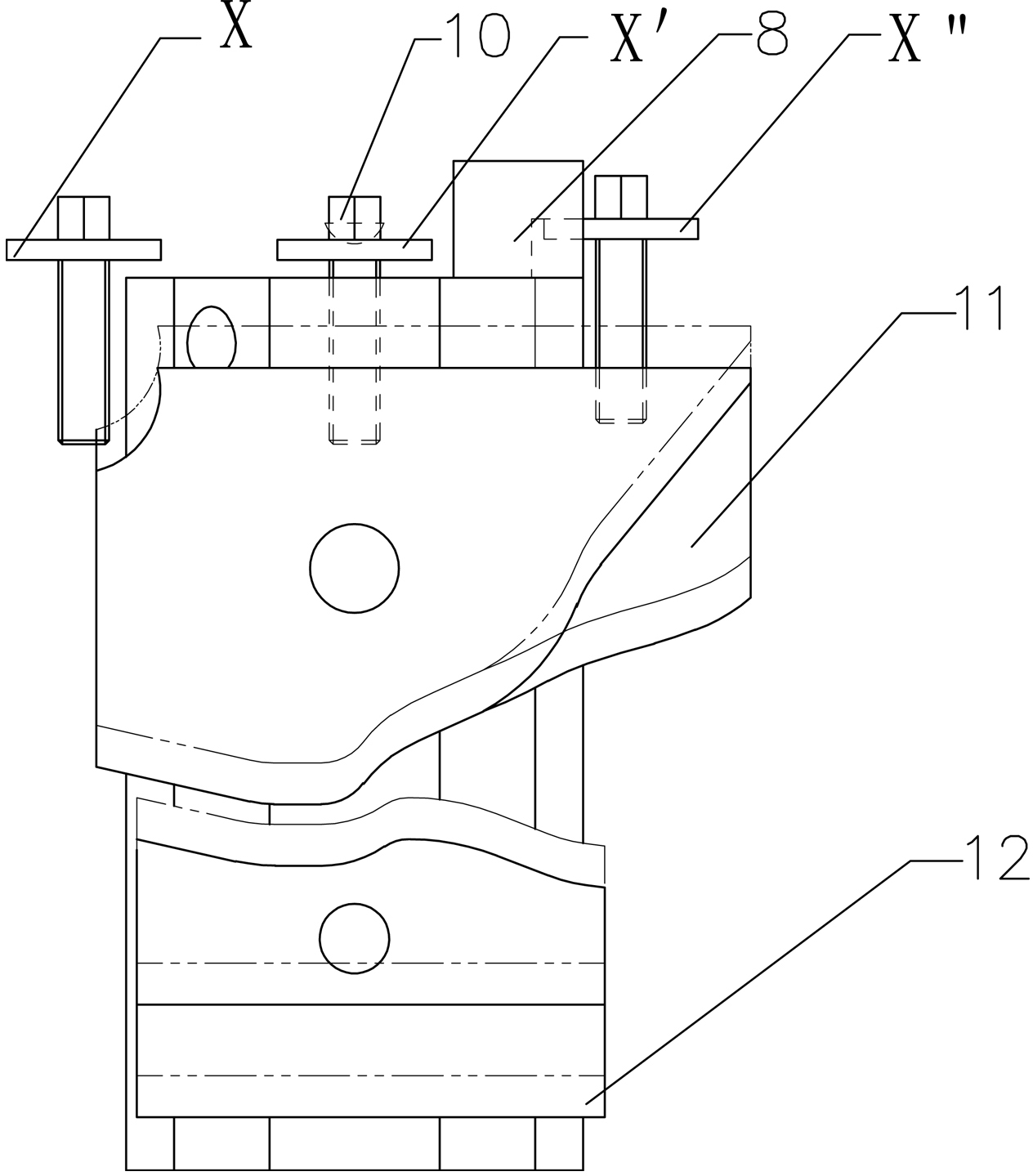

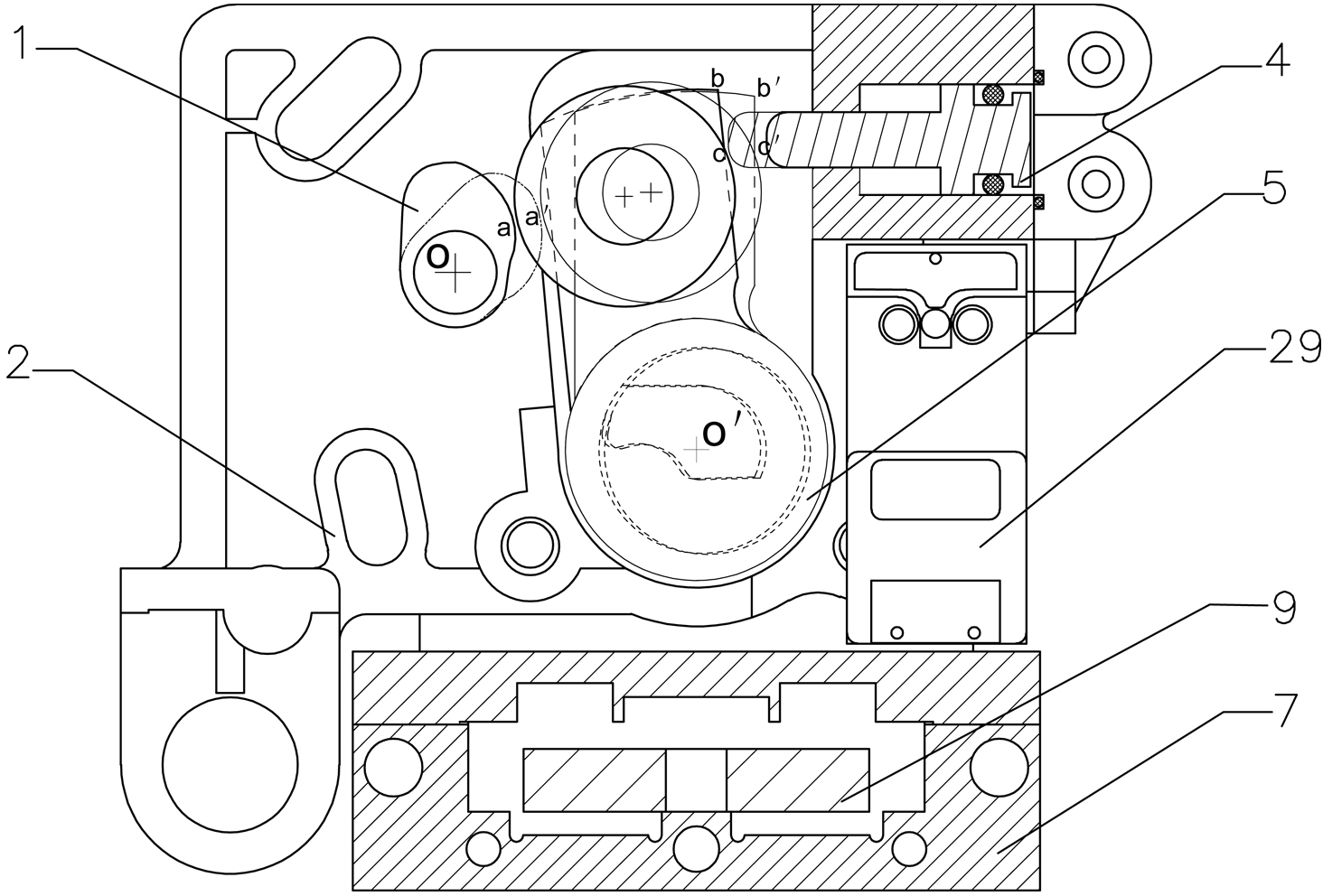

Density adjusting device of computer silk stockings machine

The invention discloses a density adjusting device of a computer silk stockings machine, which comprises a density triangular seat, a base cylinder and the front frame of the cylinder, wherein the density triangular seat is connected with a density triangular base in a sliding mode; the density triangular base is connected with a triangular sliding block in a sliding mode; the triangular sliding block is provided with a needle pressing triangle and a needle raising triangle; a full-position piston and a semi-position piston are arranged in the base cylinder and are used for respectively pushing the density triangular base to move forwards corresponding to the density triangular seat; a motor, an adjusting cam and a density cam are fixed on the density triangular base; the adjusting cam is coaxially connected with the motor and is abutted against one side of the rear end of the density cam; the front end of the density cam passes through the density triangular base and is matched with the triangular sliding block in a sliding mode; and the front frame of the cylinder is connected with the density triangular base and is provided with a motor frame piston abutted against the other side of the rear end of the density cam. The density adjusting device has the capability of realizing multichannel combined knitting, no gap density adjustment and more stable density control on the density.

Owner:NINGBO YUREN NUMERICAL CONTROL TECH

Emulsified powder-like explosive

InactiveCN101024594ALow detonation velocityLow costExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsionDiluent

The invention relates to an emulsion powder explosive that has low detonation velocity. The feature is that it has 80-95 portions emulsion powder explosive, 5-20 portions diluents agent, and 0-10 portions density regulator. It could gain emulsion powder explosive that has 2000-2800m / s low detonation velocity, and density at 0.5-1.0g / cm3. The invention could lower the cost to 10-15% and has no adverse effect to explosive.

Owner:宜兴市阳生化工有限公司

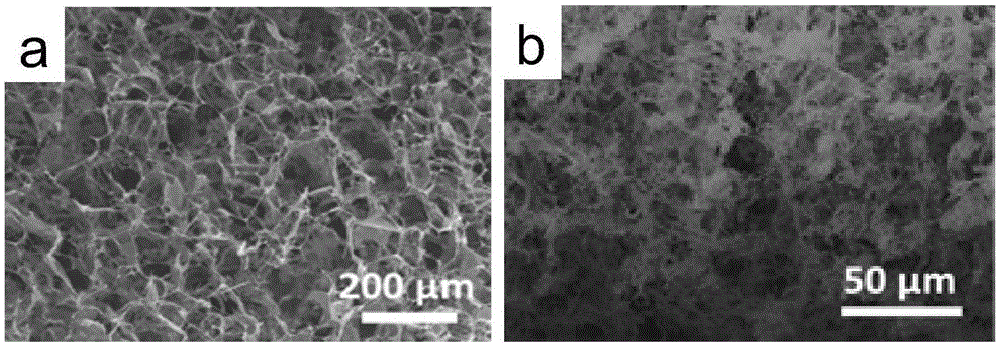

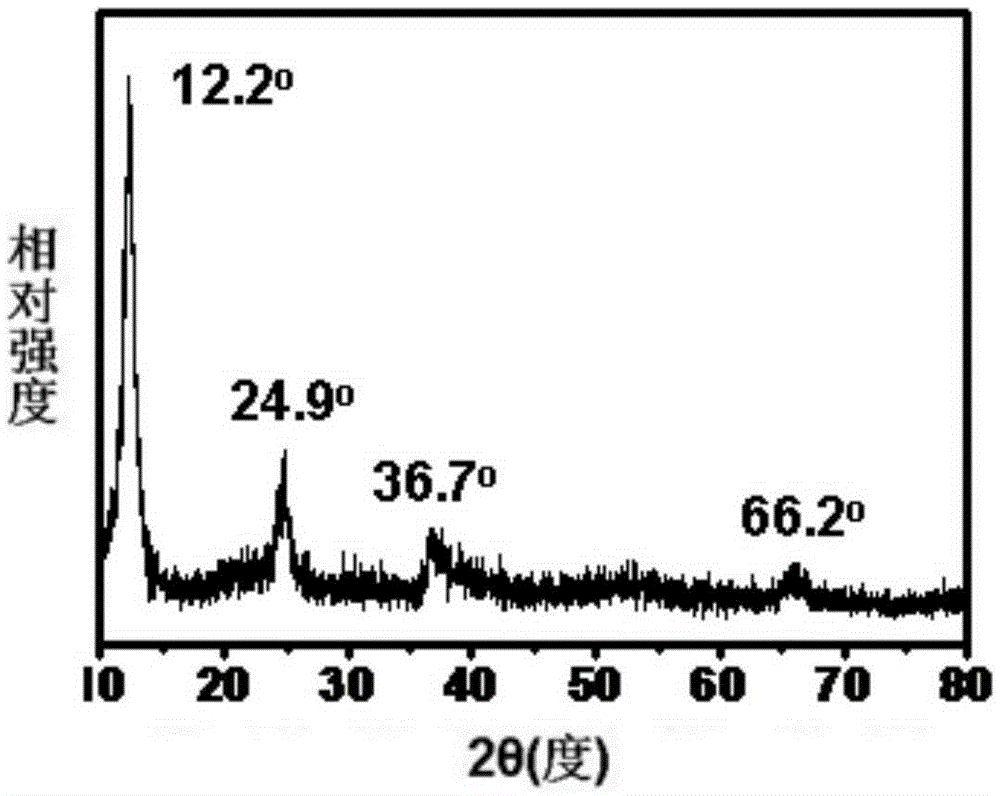

Method for preparing ultralight manganese dioxide aerogel

ActiveCN105271422AEasy to prepareDensity adjustmentManganese oxides/hydroxidesSelf-assemblyChemistry

The invention belongs to the technical field of aerogel and specifically relates to a method for preparing ultralight manganese dioxide aerogel by self-assembly of ice template-mediated ultrathin nanoflakes. Beginning with preparation of an ultrathin manganese dioxide nanoflakes colloidal solution, by the utilization of self-assembly of ice crystal template effect-mediated nanoflakes during refrigeration and through the vacuum freeze-drying process, the ultralight manganese dioxide aerogel is conveniently and quickly prepared. The aerogel shows a microscopic three-dimensional porous structure, average pore size of pores is 45-60 microns, average length of a pore wall skeleton structure is 35-60 microns, and average diameter is 2.0-3.0 microns. Density of the prepared manganese dioxide aerogel can be as low as 0.51 mg / cm<3>. The manganese dioxide aerogel is ultralight (density is less than 1 mg / cm<3>) manganese dioxide aerogel reported for the first time. In addition, the aerogel has high purity and high crystallinity and can be widely applied in fields of cell, sensing, catalysis and the like.

Owner:JILIN UNIV

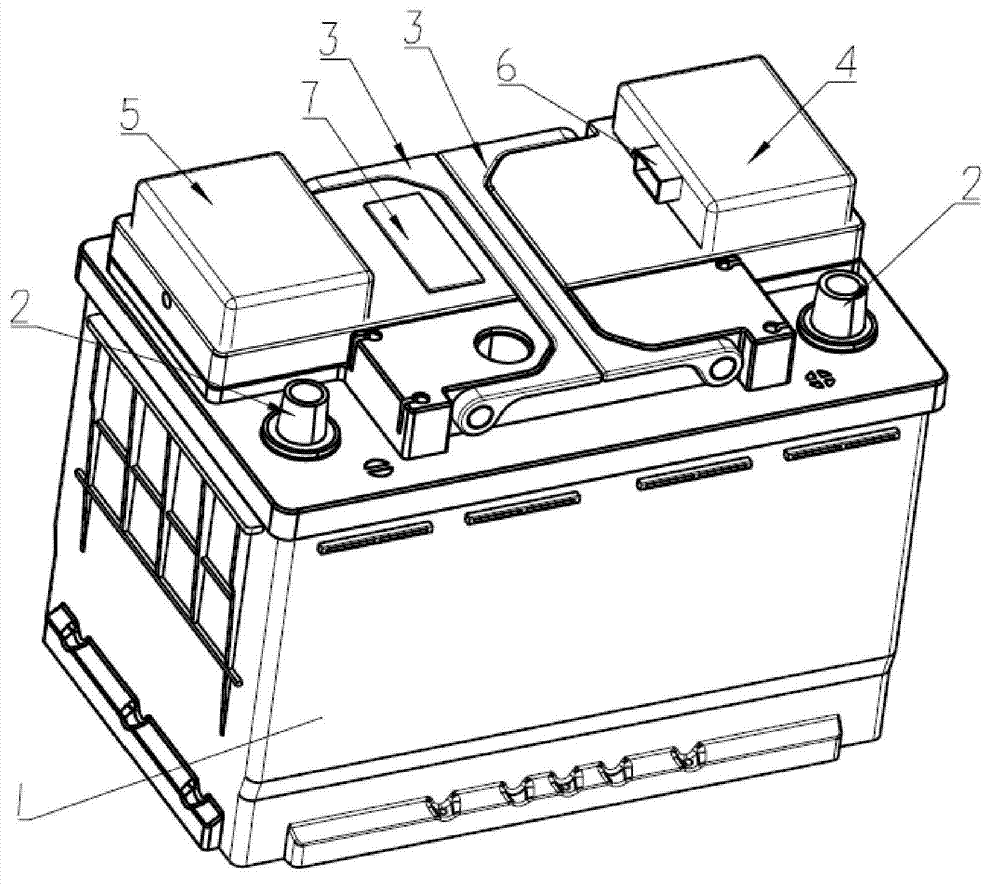

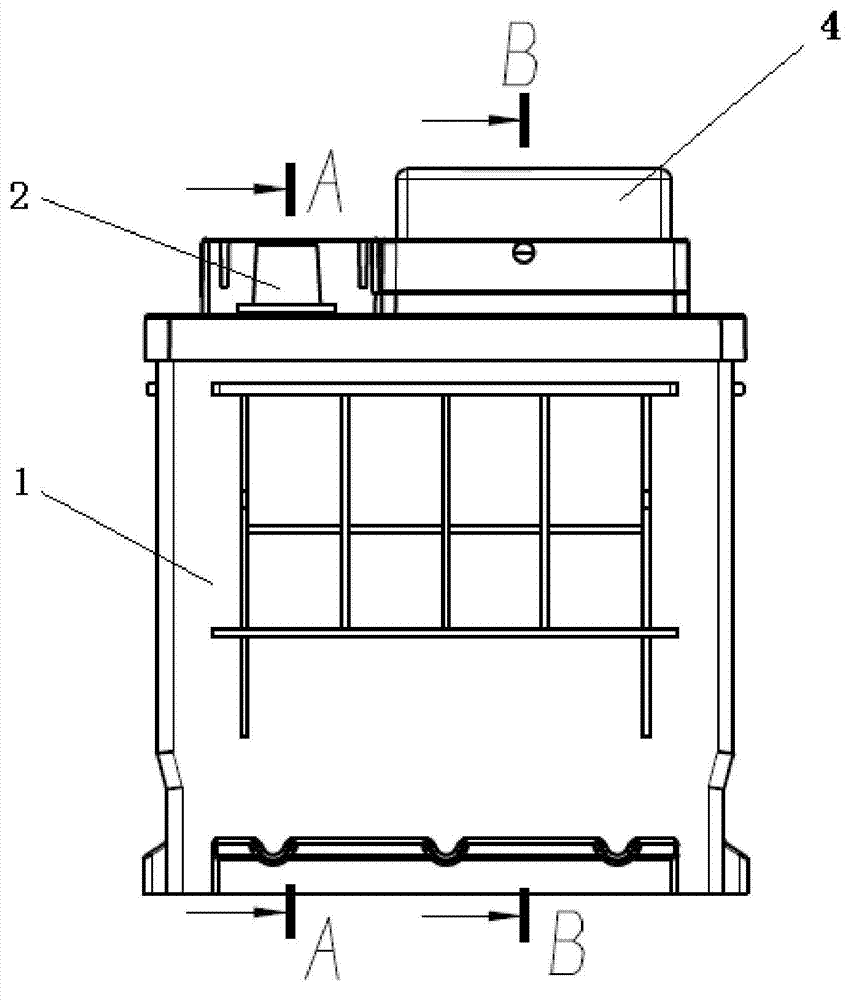

Storage battery with intelligent management function

ActiveCN103094634AIntelligent maintenanceImprove performanceSecondary cells servicing/maintenanceInformation processingIntelligent management

The invention discloses a storage battery with an intelligent management function, and relates to the field of automobile storage battery design. The storage battery comprises a storage battery body as well as a detection unit, an executor and an intelligent module unit which are arranged on the storage batter body, wherein the detection unit is used for automatically detecting a state of the storage battery; the executor is used for adjusting the state of the storage battery; and the intelligent module unit is used for processing feedback information of the detection unit of the storage battery and controlling the executor based on an information processing result so as to correct the state of the storage battery. Therefore, the storage battery is more intelligently maintained; the performance of the storage battery is improved; the service life of the storage battery is prolonged; and the negative influence on a vehicle due to a storage battery fault is effectively prevented.

Owner:VIRIDI E MOBILITY TECH NINGBO CO LTD +1

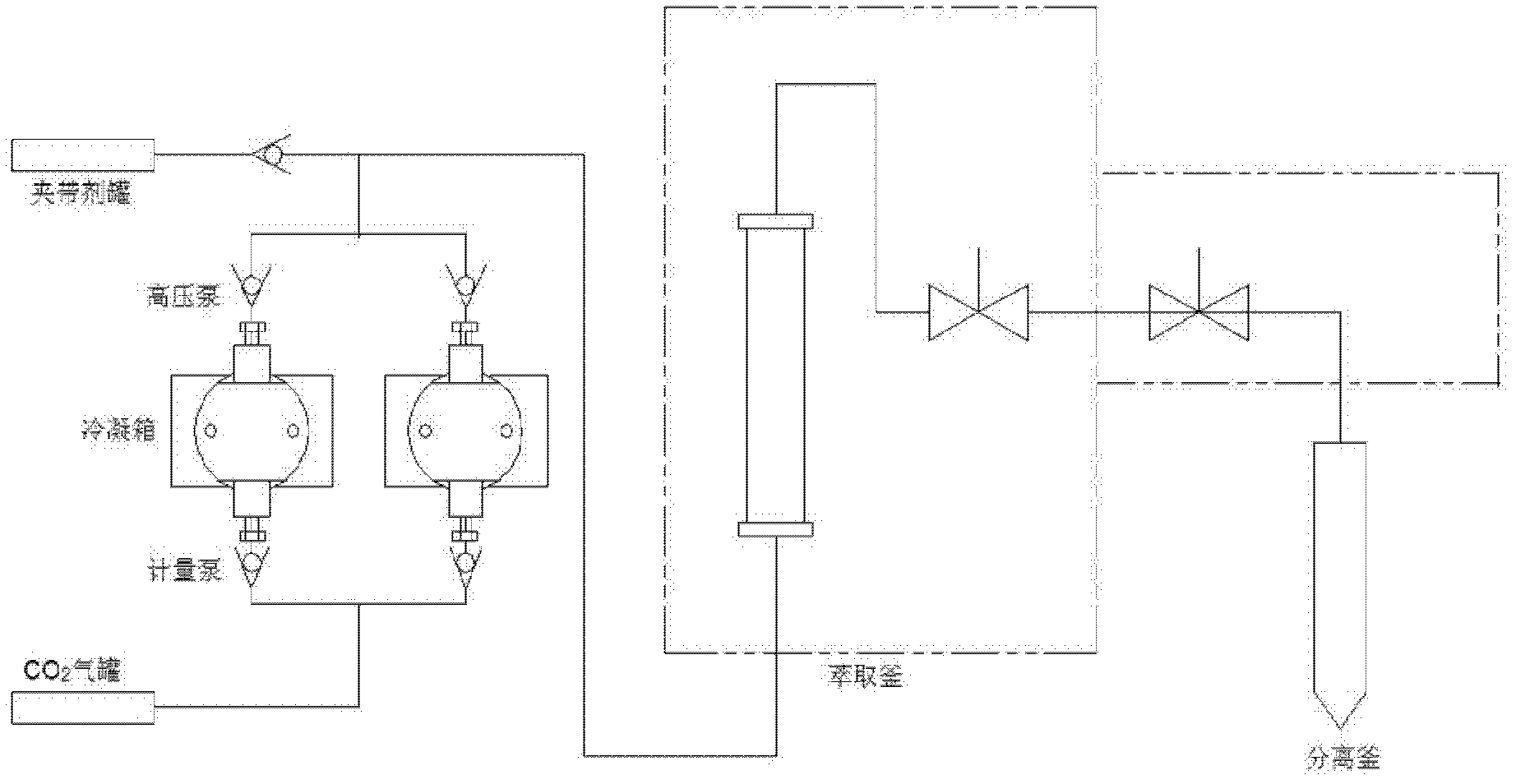

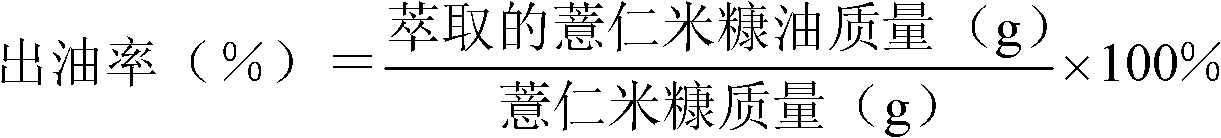

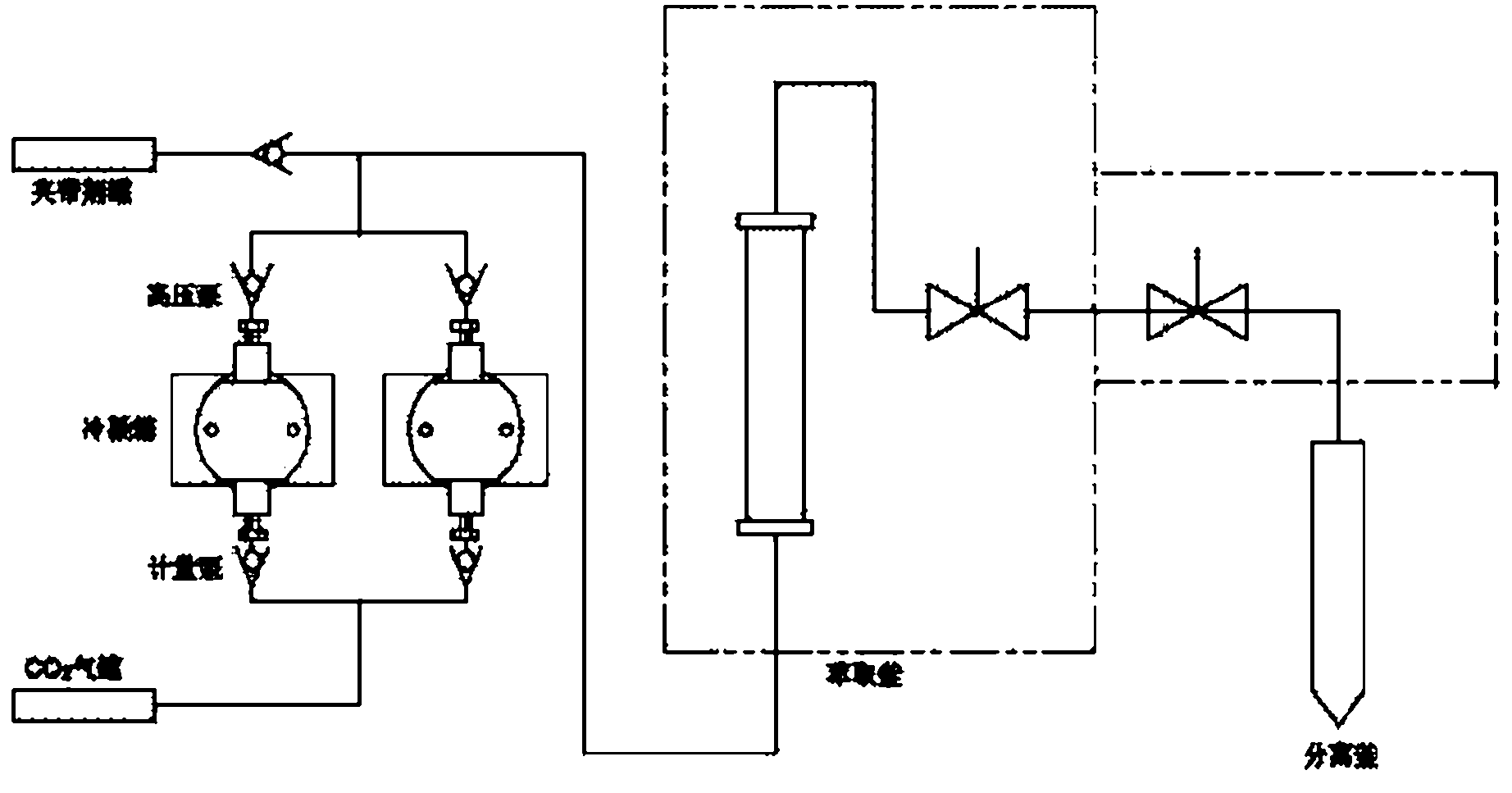

Method for extracting coix seed rice bran oil by utilizing supercritical CO2 technology

The invention discloses a method for extracting coix seed rice bran oil by utilizing a supercritical CO2 technology. According to the method, the coix seed rice bran oil is extracted by utilizing the supercritical CO2 technology. The method comprises the following steps of: pretreating coix seed rice bran, putting the pretreated coix seed rice bran into a supercritical fluid extractor, extracting at the extraction temperature of between 40 and 50 DEG C under extraction pressure of between 30 and 45 MPa under the condition that the flow of CO2 is 9 to 11 milliliters / minute, and separating at the separation temperature of between 45 and 55 DEG C to obtain the coix seed rice bran oil. The coix seed rice bran oil is high in purity, and the oil extraction rate is more than 17 percent. The method is easy to operate, and environment-friendly; and reaction conditions are mild.

Owner:SHANGHAI JIAO TONG UNIV

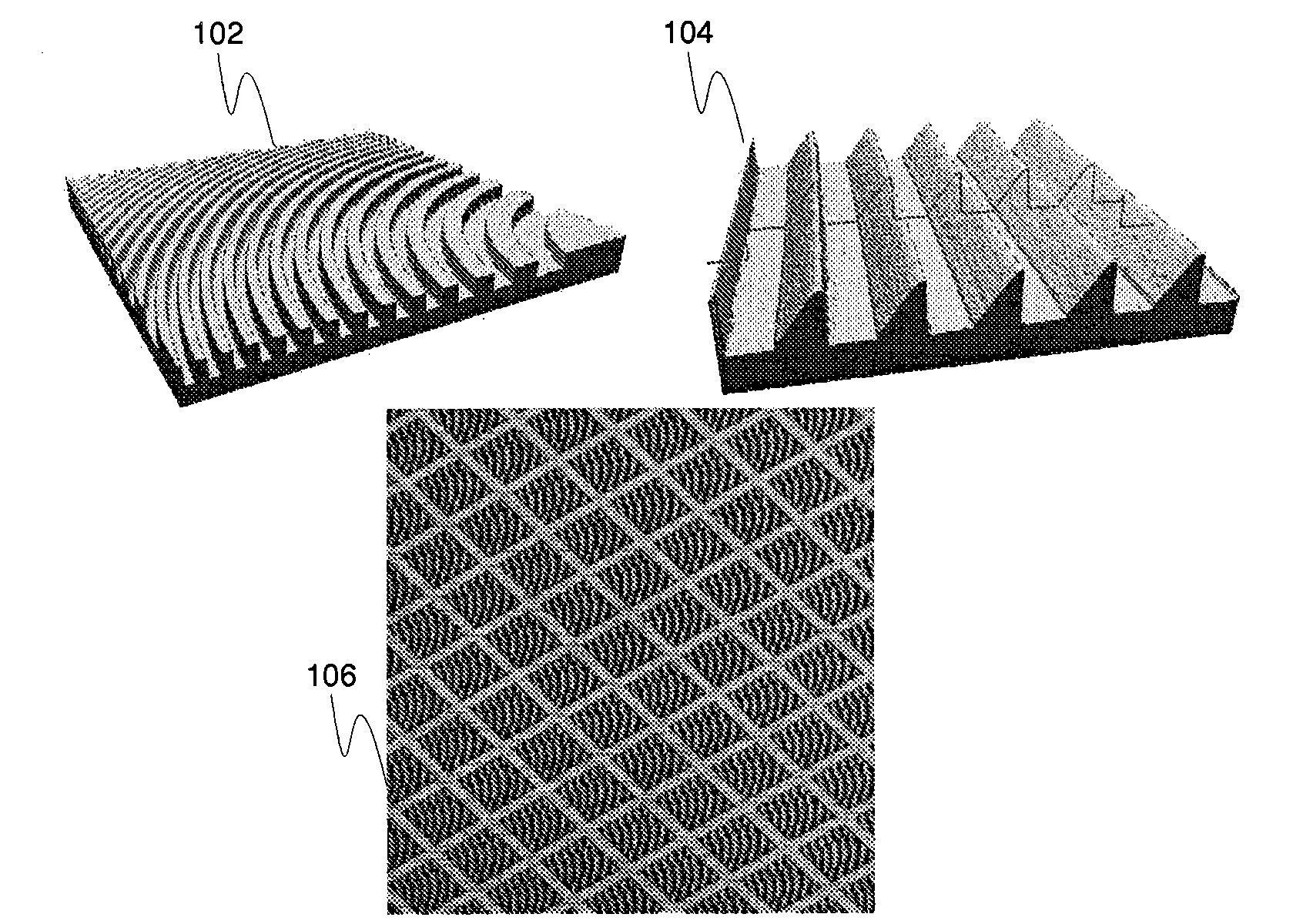

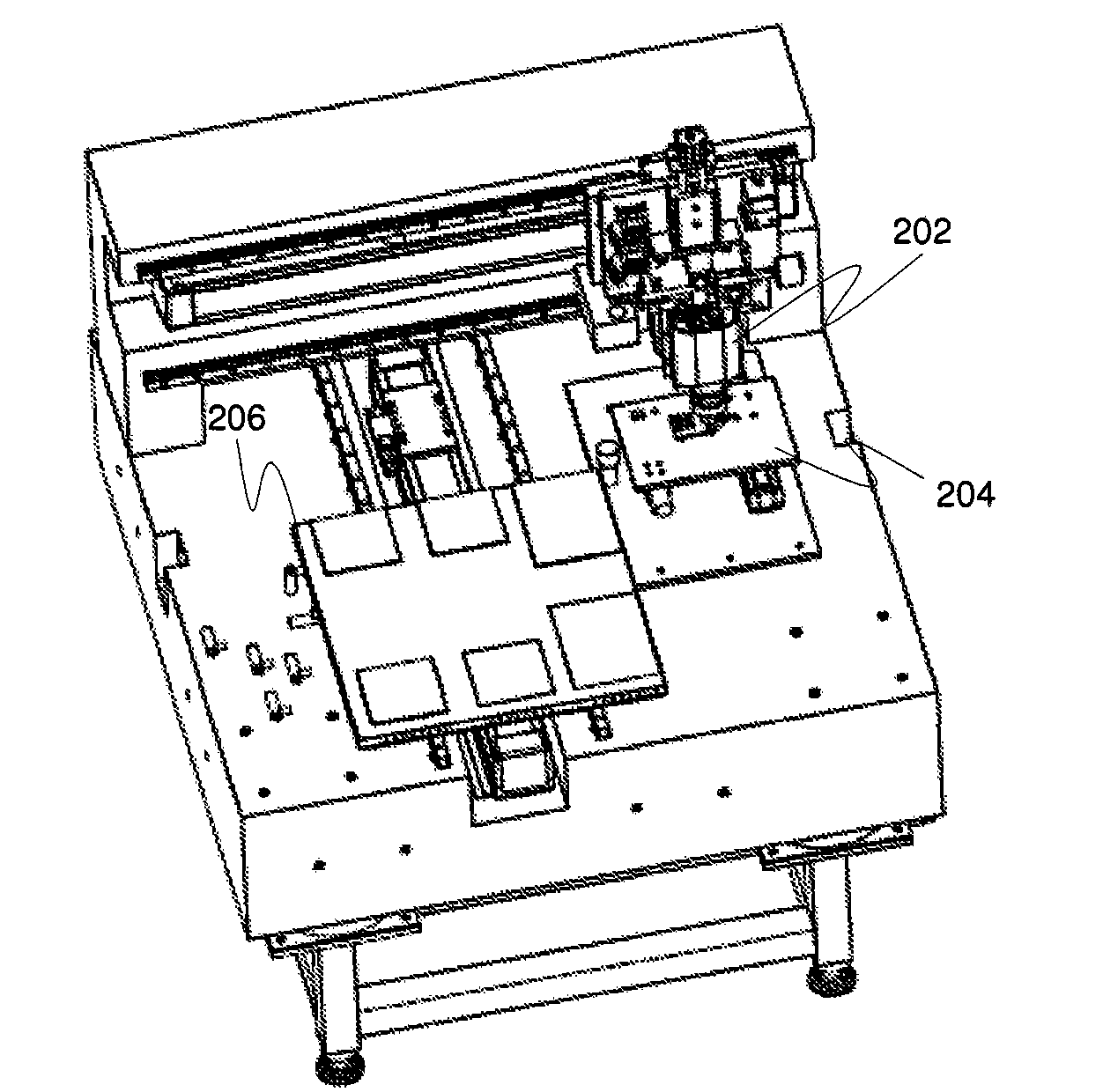

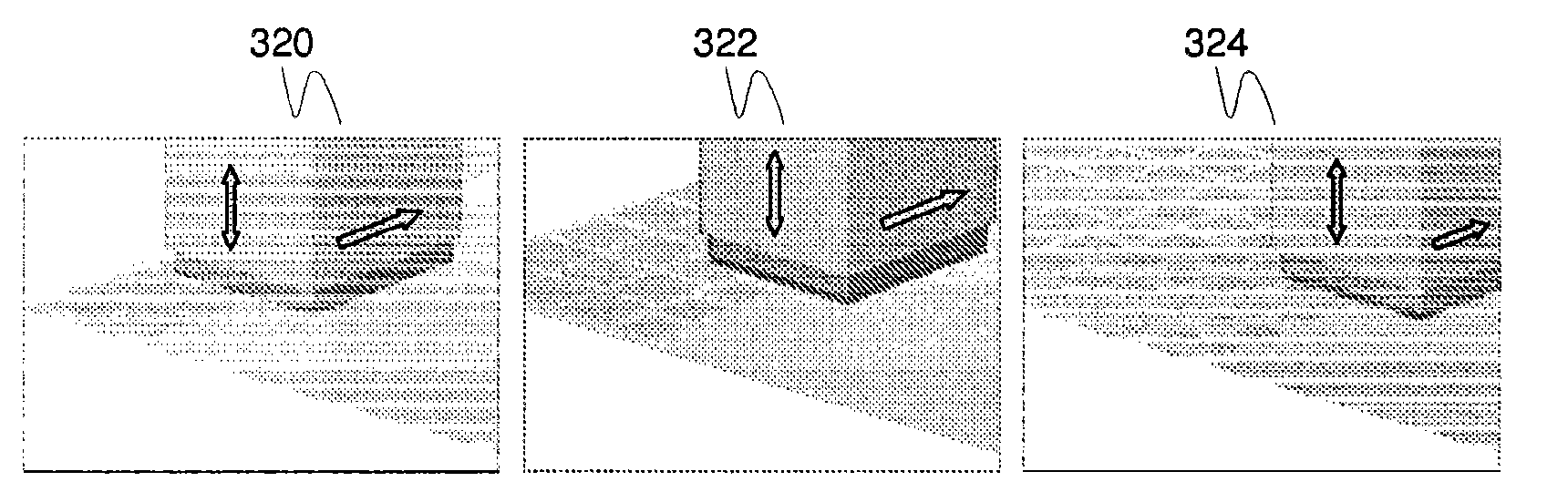

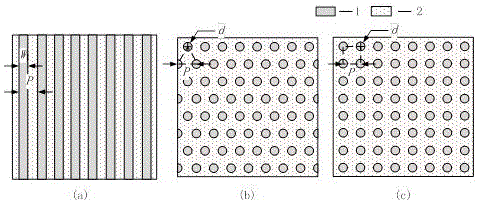

Method and arrangement for manufacturing optical products with complex three-dimensional forms

ActiveCN101594980ADensity adjustmentEasy to manageSemiconductor/solid-state device manufacturingEngineeringComputer software

A method and an arrangement for manufacturing microoptic surface design with complex, variable three-dimensional forms. The method comprises obtaining (302) a step embossing, step imprinting, a chip bonding or a corresponding device capable of patterning the surface of a target substrate, obtaining the target substrate (304) whereto the micro-optic structures shall be patterned, obtaining a plurality of different stamping tools (306) operable with said device, each stamping tool comprising one or more surface relief forms defining one or more micro-optic structures, selecting (310) a stampingtool from said plurality of stamping tools by said device, embossing (312) the target substrate with said selected stamping tool as controlled by said device, wherein said selected stamping tool is optionally heated or assisted by UV (Ultraviolet) source so as to form and / or cure the target substrate during or after the embossing, and repeating (314) said selecting and embossing steps until the micro-optic surface design has been completed on the substrate. A related computer software product for control purposes is also disclosed.

Owner:MODILIS HLDG LLC

Quick controllable manufacturing method of large-area micron/nanometer texture on metal material surface

InactiveCN105081488AEasy to achieve large area exposureAvoid makingElectrical-based auxillary apparatusElectrolysisImage resolution

The invention provides a quick controllable manufacturing method of a large-area micron / nanometer texture on a metal material surface; and the method realizes the preparation of simple-complex, large-area and controllable-size micron / nanometer structures on metal surfaces with low cost and high efficiency through combining with the characteristic that the laser interference photoetching and the micro electrolytic machining both can reach submicron-level and nanometer-level resolutions and by using the characteristics that the laser interference photoetching is easy to realize large-area exposure and the micro electrolytic machining can machine all electric conducting materials. The method can reduce the machining cost and largely shorten the machining period, and has significant meaning on the research of tribological properties of textured surfaces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

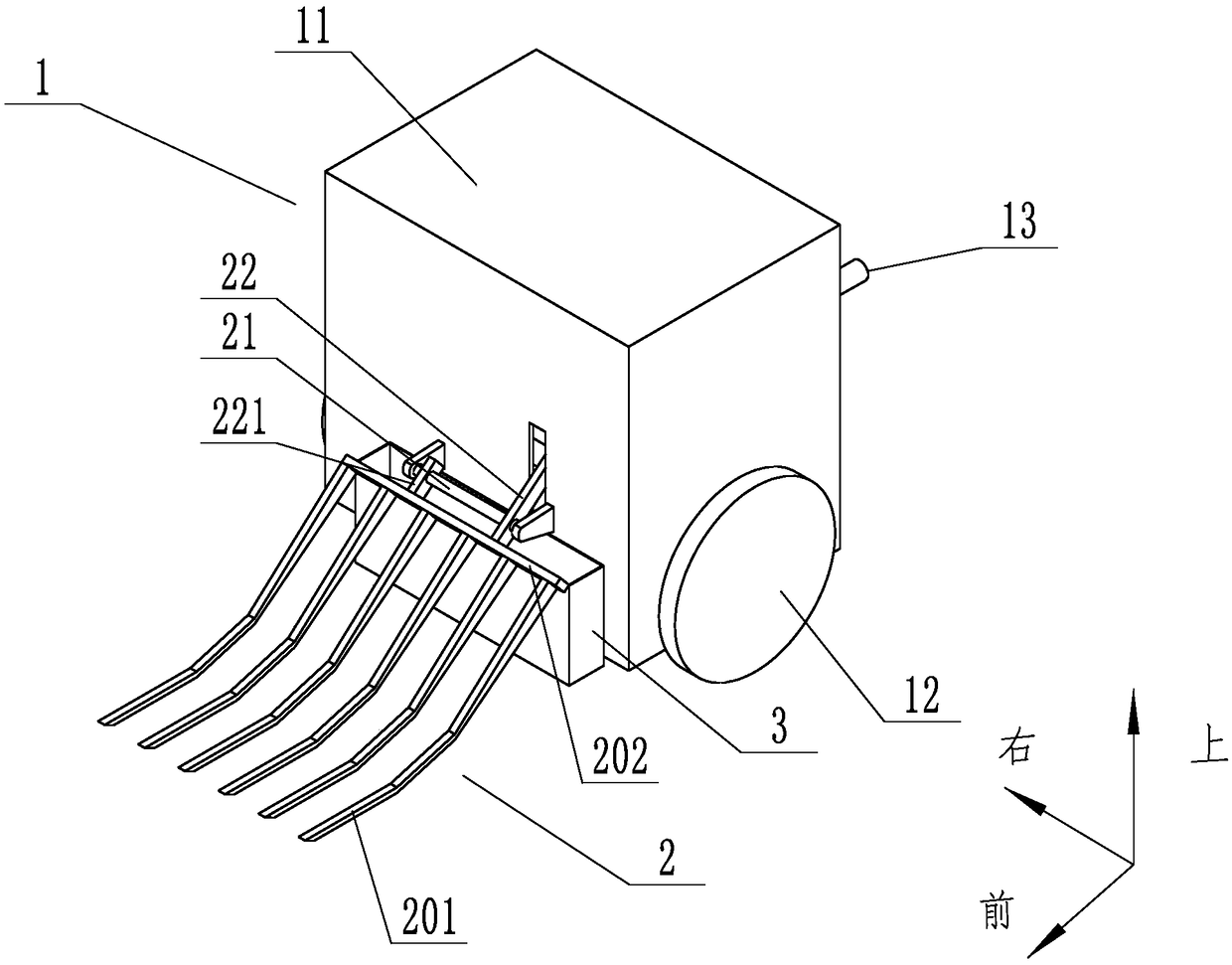

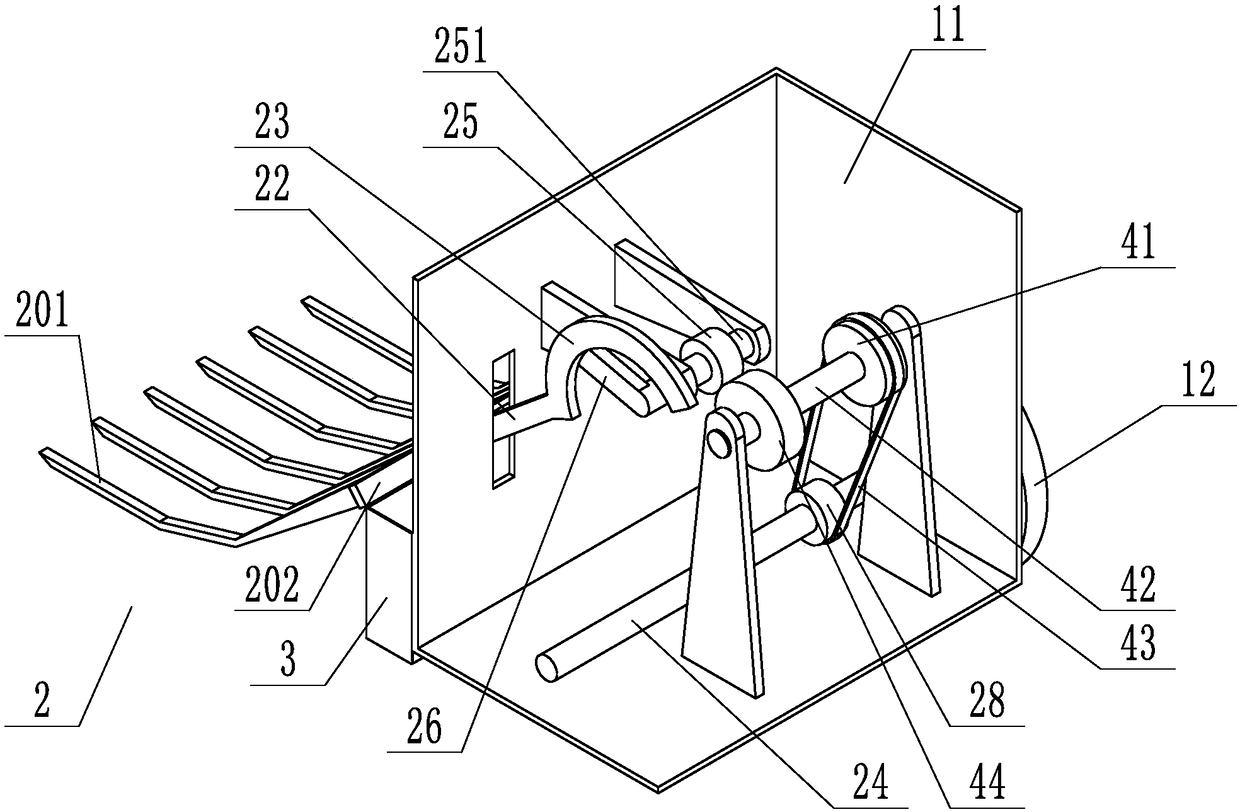

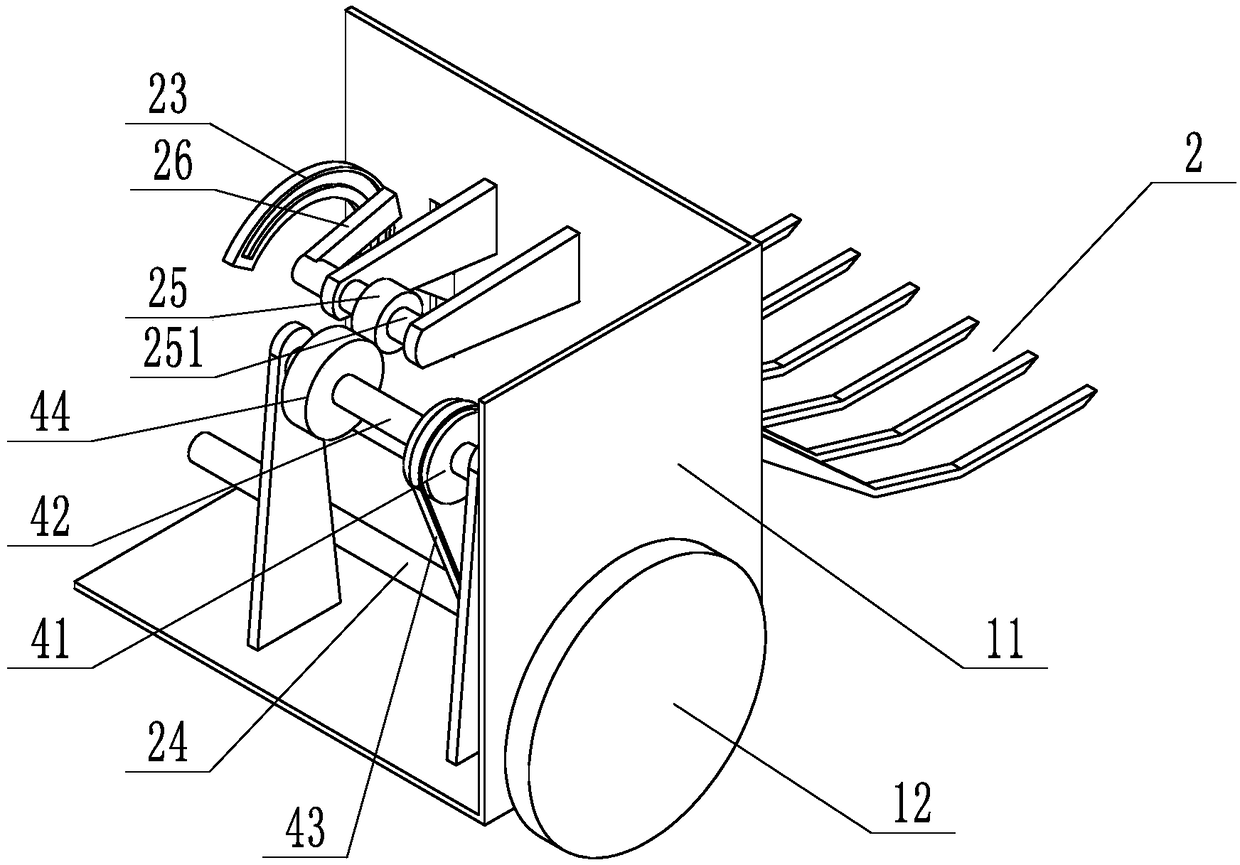

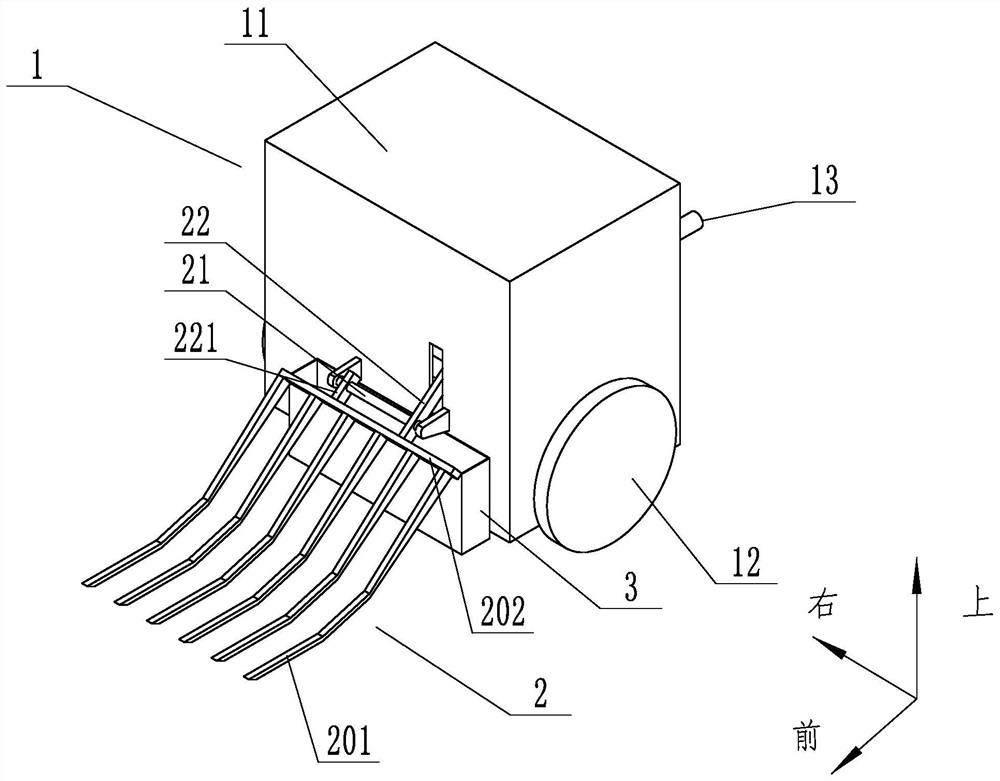

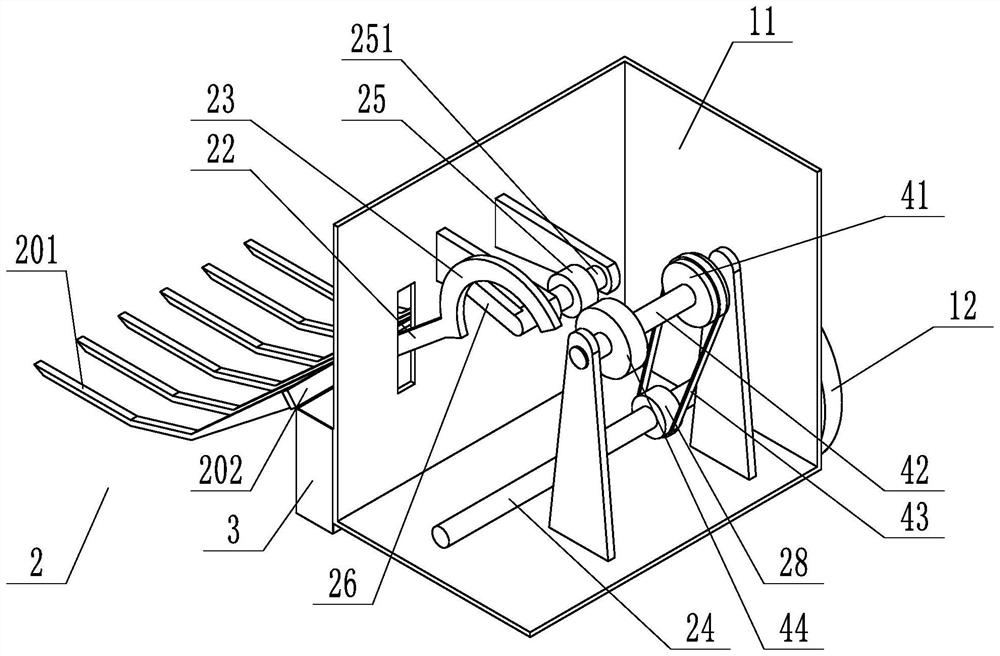

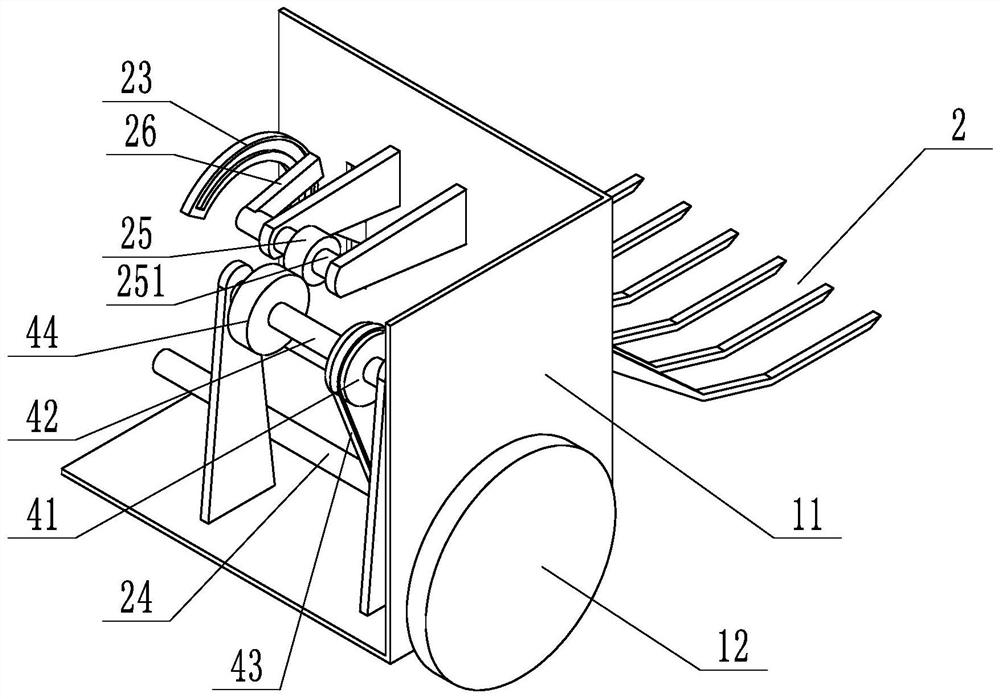

Energy-saving and environment-friendly withered leaf collecting device

ActiveCN109479628AAvoid destructionImplement the dumping actionHops/wine cultivationTurf growingEngineering

The invention discloses an energy-saving and environment-friendly withered leaf collecting device. The device comprises a cart, the cart comprises a compartment and wheels, a collecting claw is rotatably arranged at the front end of the compartment, a first rotating shaft is rotatably arranged at the front end of the compartment through a bearing, and the collecting claw is fixedly arranged on thefirst rotating shaft through a first connecting rod and a second connecting rod; the front end of the collecting claw is short, and the rear end of the collecting claw is high; the first connecting rod and the second connecting rod are fixedly disposed on the rear side of a connecting plate, the end of the first connecting rod is disposed in the compartment and fixedly provided with an arc-shapedguide rod, the arc-shaped guide rod is provided with a semicircular guide rail, the wheels are fixedly disposed on a second rotating shaft, and the second rotating shaft is fixedly provided with a second gear; the second gear is connected to a first gear through a transmission mechanism, the first gear is coaxially provided with a swing rod, a roller is slidably disposed in the guide rail of thearc-shaped guide rod, and the front end of the compartment is further provided with a collecting basket which is arranged below the collecting claw. Energy is saved, the efficiency of collecting withered leaves on a lawn is improved, and the environment is improved.

Owner:兰昊宇

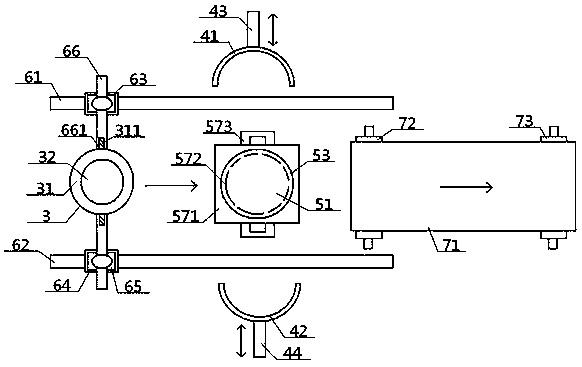

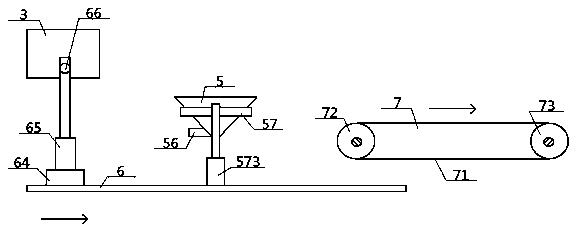

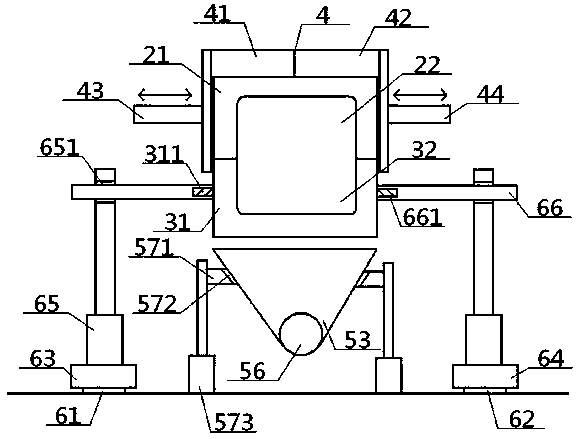

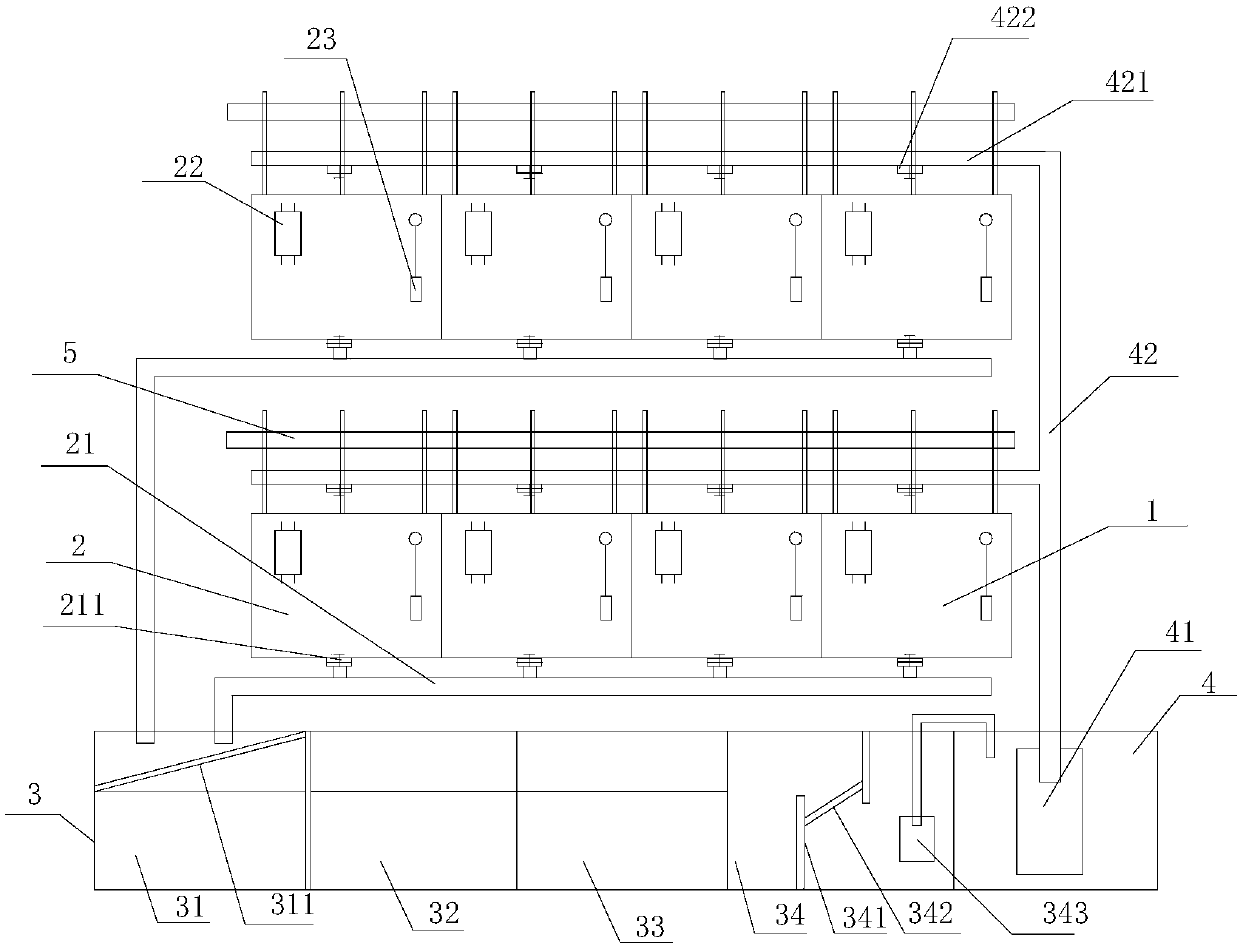

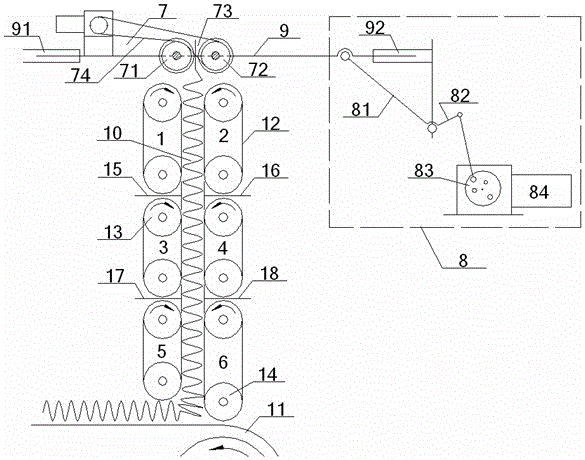

Linear straight-rail-type production system for textile bodies

ActiveCN109898237AGood equipment connectivityIncrease productivityNon-woven fabricsEngineeringInjection air

A linear straight-rail-type production system for textile bodies comprises an upper mold, a lower mold, an outer sleeve, an air injection device, linear guide rails and a conveying device. Each of theupper mold and the lower mold comprises an external mold body, a mold cavity and an air passage, and the mold cavities and the air passages are formed in the mold bodies and communicated with each other. The outer sleeve is higher than the upper mold. The linear guide rails include a first guide rail, and a second guide rail parallel to the first guide rail. The top ends of the first guide rail and the second guide rail are in sliding fit with the bottom surfaces of first and second sliding seats respectively. The top surfaces of the first sliding seat and the second sliding seat are connected with bottoms of mold lifting cylinders respectively. The output ends of the mold lifting cylinders are connected with the lateral portion of the lower mold through support shafts. An air outlet corresponding to an air inlet region is arranged at the top of the air injection device, and is clamped between the middle portions of the first guide rail and the second guide rail. The conveying deviceis arranged between the tail ends of the first guide rail and the second guide rail. The linear straight-rail-type production system has the advantages that streamline operation can be realized, and the production efficiency is high; the shapes of the textile bodies are not limited, and the utilization rate of materials can be increased.

Owner:武汉博瑞智信科技有限公司

Preparation method of density-adjustable hollow strontium titanate material

InactiveCN106348339ADensity adjustmentHigh activityAlkaline earth titanatesStrontium titanateHigh pressure

The invention provides a preparation method of a density-adjustable hollow strontium titanate material. A foam core material is prepared. The preparation method comprises the following steps: preparing a solution from ethanol, tetra-tert isopropylamine, ethyl silicate, deionized water, a guiding agent S-81 and a stabilizer T 123 in a high-pressure reactor at the temperature of 220 DEG C, and insulating for 72 hours; strontium titanate coating: preparing mixed liquor from tetra-n-butyl titanate, ethanol, butanediol, a guiding agent R-53, the foam core material, strontium nitrate, deionized water and a surfactant AP-9 in the high-pressure reactor at the temperature of 180 DEG C, and insulating for 24 hours; and aperture modified treatment: calcining in a programmed electric box furnace at the temperature of 700-900 DEG C. Foamed core materials with different aperture distribution features are prepared, and the density of the hollow strontium titanate material can be adjusted.

Owner:SHENYANG LIGONG UNIV

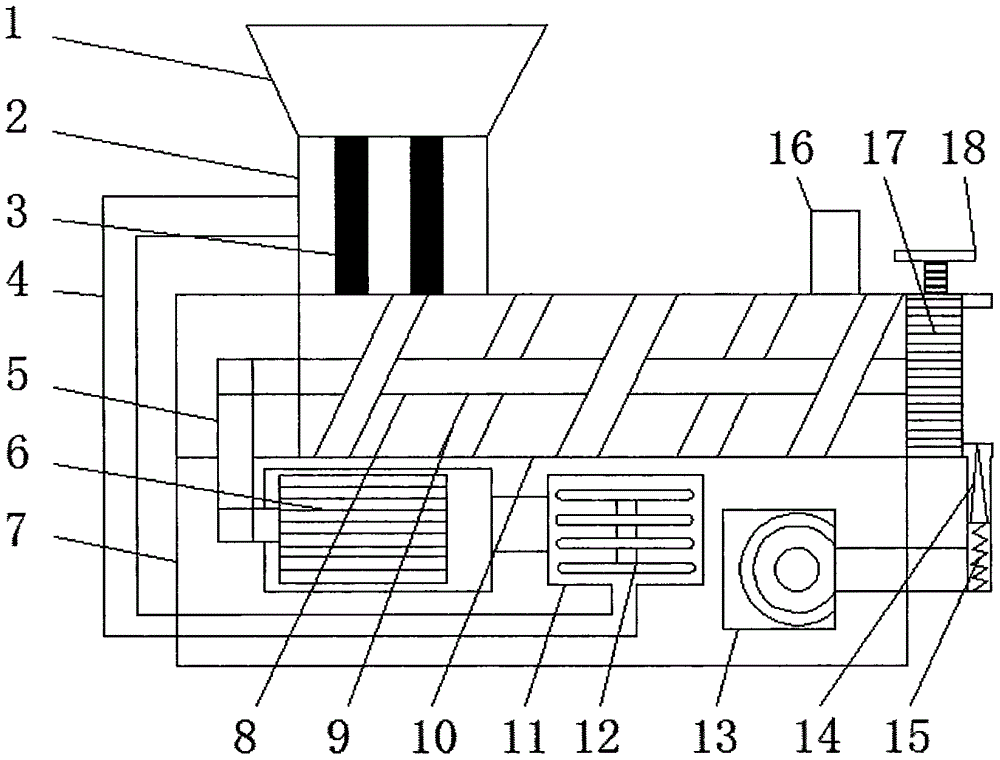

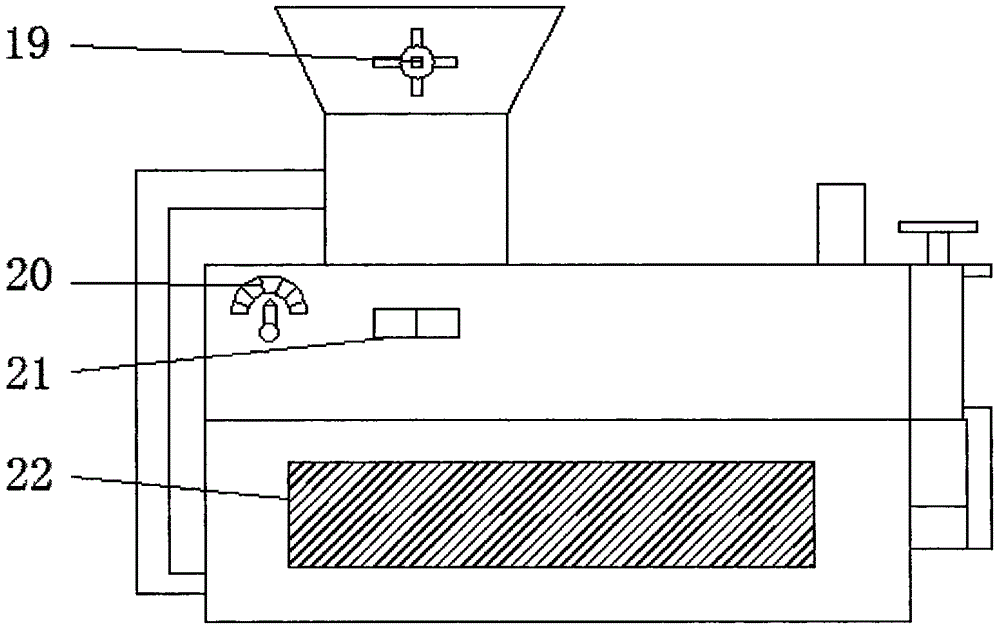

Paddy feed granulator

The invention discloses a rice feed granulator, which comprises a drying box, a base, a pushing box and a discharge plate. A feeding funnel is installed above the drying box, and a feeding adjustment knob is installed on the surface of the feeding funnel. The drying A drying pipe is installed inside the drying box, a propulsion box is installed under the drying box, and an air outlet is installed above the propulsion box, a rotating shaft is installed inside the pushing box, and a screw propeller is installed on the surface of the rotating shaft, and the right side of the pushing box A discharge plate is installed, a base is installed under the push box, a motor is installed inside the base, and the motor is connected to the rotating shaft through a linkage rod, a heat recovery device is installed inside the base, and a heat recovery device is installed inside the heat recovery device. An exchange pipe, and a hydraulic pump is installed inside the base. In the present invention, the drying box is connected with the heat recovery device through the return pipe, and the heat generated by the motor can be recovered and acted in the drying box, thereby reducing energy waste and saving electricity consumption.

Owner:新昌县羽林街道金庭机械厂

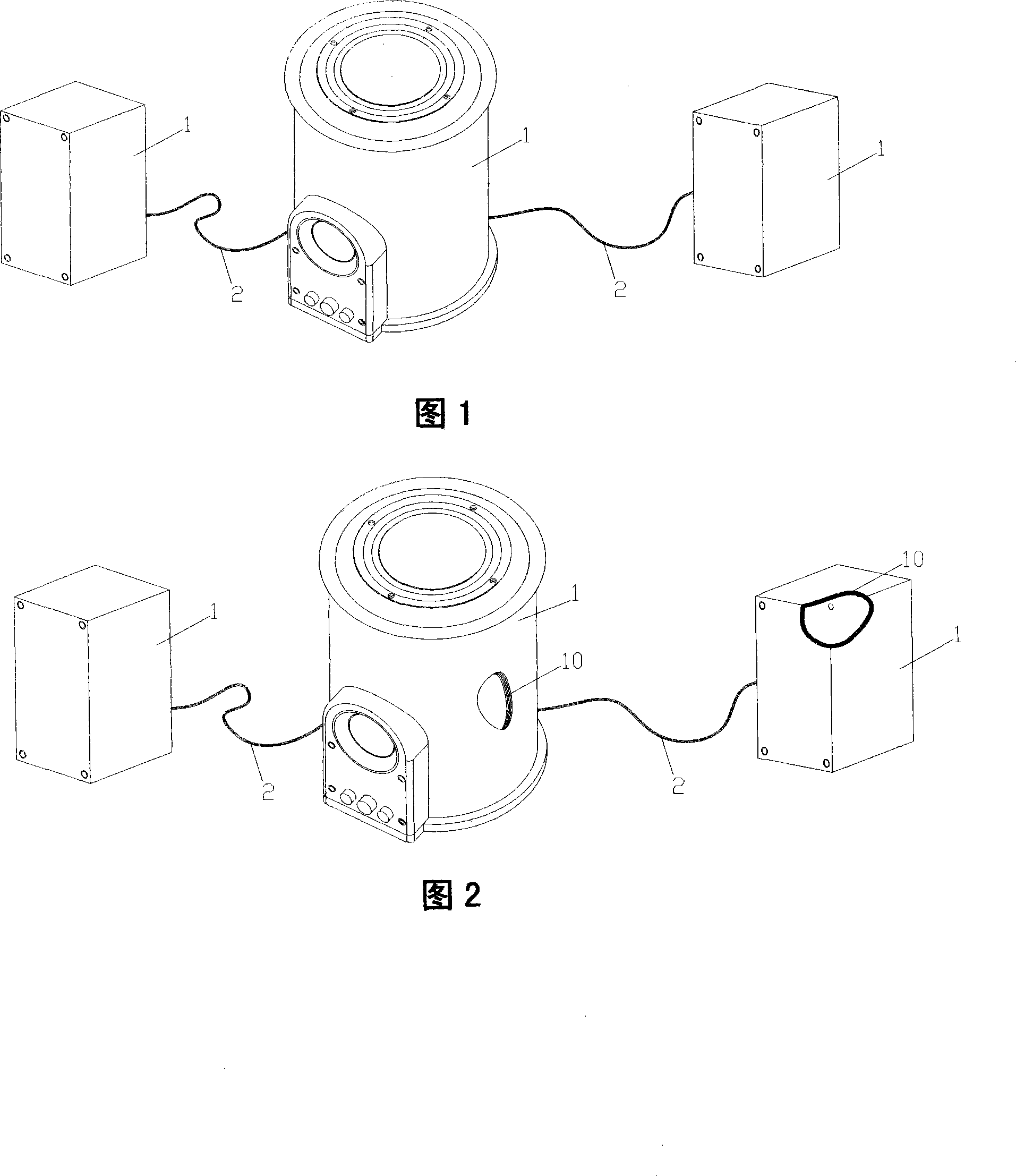

Sound box made of paper

InactiveCN101203055ADensity adjustmentGood effectTransducer detailsHigh intensityPulp and paper industry

The invention relates to a paper sound box, comprising an articulation unit, a connection cable connected with the articulation unit, and a paper sound box body covering the articulation unit. The paper sound box body is made of high strength paper, the density of which can be adjusted. The invention not only is easy to manufacture but also can reduce the cost effectively. Furthermore, the shape of the paper sound box has various forms. The invention can realize high-quality sound effect output.

Owner:WEIGE ELECTRONICSSHENZHEN

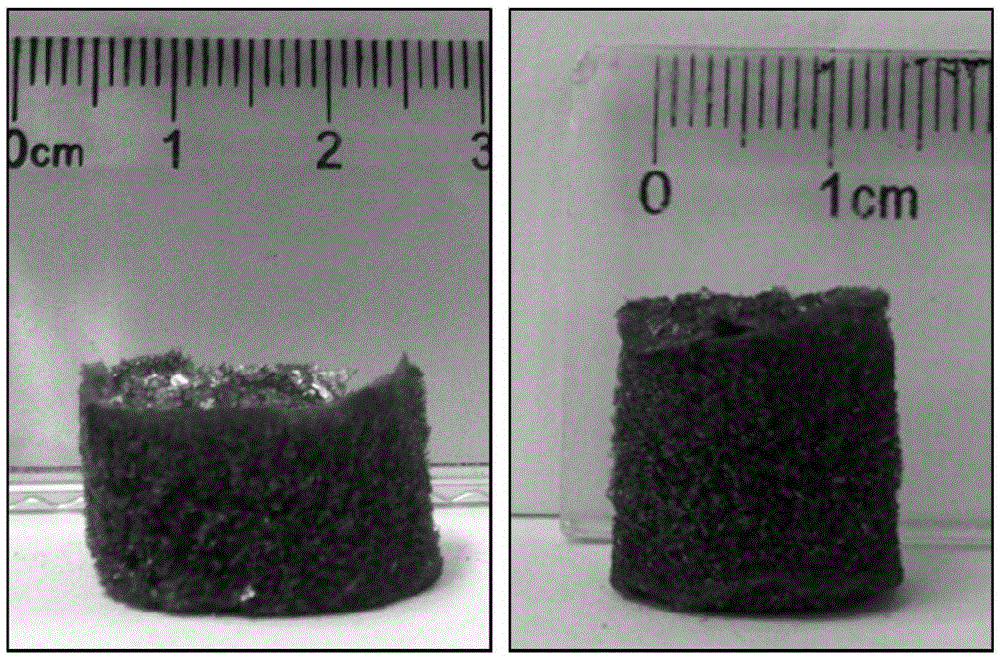

Method for weaving net composite catalytic material from nanometer titania and polytetrafluoroethylene in mixing manner, and application of net composite catalytic material

InactiveCN103100425AAdjustable densityDensity adjustmentWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsWastewaterVolumetric Mass Density

The invention discloses a method for weaving a net composite catalytic material from nanometer titania and polytetrafluoroethylene in a mixing manner, and an application of the net composite catalytic material. The nanometer titania is directly loaded on the polytetrafluoroethylene by a ball-milling method. The method comprises the following steps of 1) putting a polytetrafluoroethylene cylinder into a cylindrical ball-milling tank; 2) putting the ball and the nanometer titania into a polytetrafluoroethylene cylinder cavity according to the ball-to-material ratio of (10-30) to 1; and 3) adjusting the rotating speed and the ball-milling time of a ball grinder so as to obtain the net nanometer titania-polytetrafluoroethylene composite catalytic material. The mixed weaving method disclosed by the invention is simple in process, simple in equipment, low in cost, and easy to control; the application of the net composite catalytic material is that a loading body of the net composite catalytic material can float in different densities of waste water bodies to carry out wastewater treatment; the specific surface area of the titanium dioxide on the loading body is larger than that loaded on the plate; but the cost is lower and the operation is simpler.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Novel low-detonation velocity explosive suitable for titanium material compounding, and preparation method thereof

InactiveCN105384588AMeet the needs of the development of domestic chemical industry and other industriesDensity adjustmentNon-explosive/non-thermic compositionsEffective densityEmulsion explosive

The invention discloses a novel low-detonation velocity explosive suitable for titanium material compounding, and a preparation method thereof. The method comprises the following steps: taking 40 parts by weight of a rock powdery emulsion explosive with the bulk density of 0.58-0.62g.cm<-3>, the detonation velocity of 3500-3700m / s, the brisance of 15-17mm, the gap distance of 9-11cm and the work capacity of 360 / ml, taking 45 parts of sands with the bulk density of 1.40g.cm<-3> and the particle size of 300 meshes, putting above taken materials in a medicine mixer, stirring the materials for 3-5min, taking 7 parts of bran with the bulk density of 0.50g.cm<-3> and the particle size of 300 meshes, putting the taken bran in the medicine mixer, stirring the obtained mixture for 20min until fullness and uniformity, and detecting the density and the detonation velocity of the above obtained product. The sands are used to reduce the detonation velocity, and the bran is used as a density adjusting agent to adjust the density of the obtained mixed explosive; and the effective density of the rock powdery emulsion explosive is reduced through synergism of the sands and the bran, and the novel low-detonation velocity explosive prepared through mixing above materials in proportion can improve the production efficiency, and solves the problem of lack-of-fit of large-area titanium-steel composite plates.

Owner:安徽宝泰特种材料有限公司

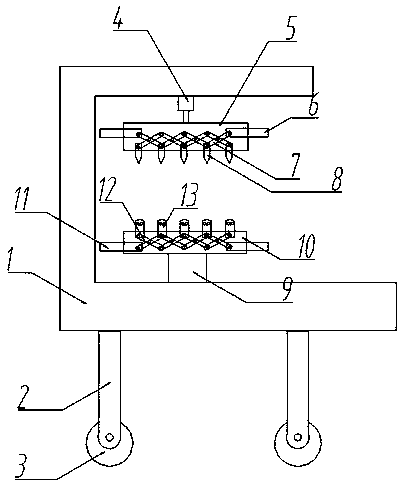

Eyelet equipment with adjustable eyelet density

The invention discloses eyelet equipment with an adjustable eyelet density. The equipment comprises a rack, an eyelet hole punching mechanism and a fixing mechanism, the eyelet hole punching mechanismis fixed to the lower portion of the rack and comprises an air cylinder, a supporting frame, a first adjusting mechanism, a first telescopic mechanism and hole punching heads, the fixing mechanism isinstalled above the bottom of the rack and comprises a supporting block, a fixing frame, a second regulating mechanism, a second telescopic mechanism and a shoe ring platform. According to the eyeletequipment, the structure is scientific and reasonable, the use is safe and convenient, multiple hole punching heads are arranged, the eyelet punching speed is rapid, the production efficiency is improved, a telescopic mechanism is arranged in a cutter frame and a shoe fixing device, the distance between the hole punching heads and the fixing device is regulated according to specific demands of the eyelets to regulate the density of the eyelets, unequal length of the eyelet spacing is prevented, and the use is more convenient.

Owner:江苏又一城智能科技有限公司

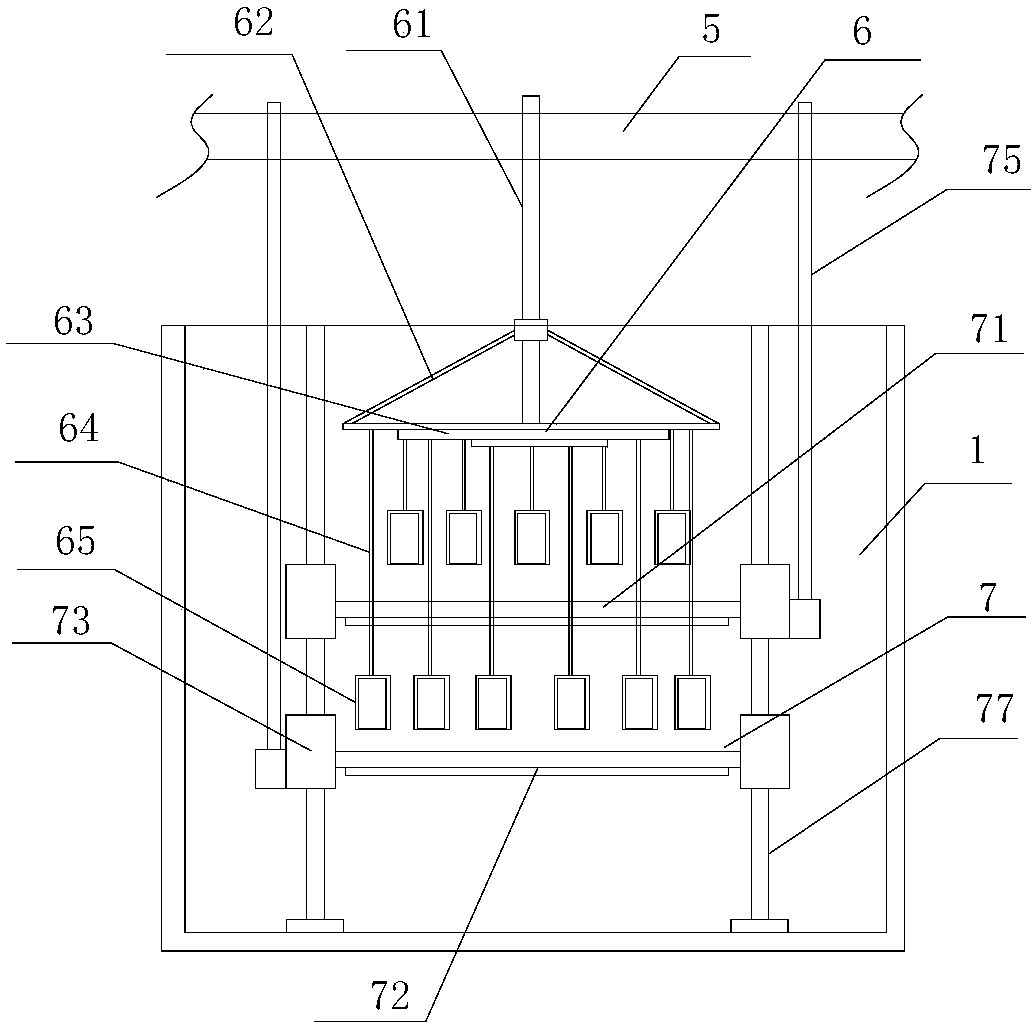

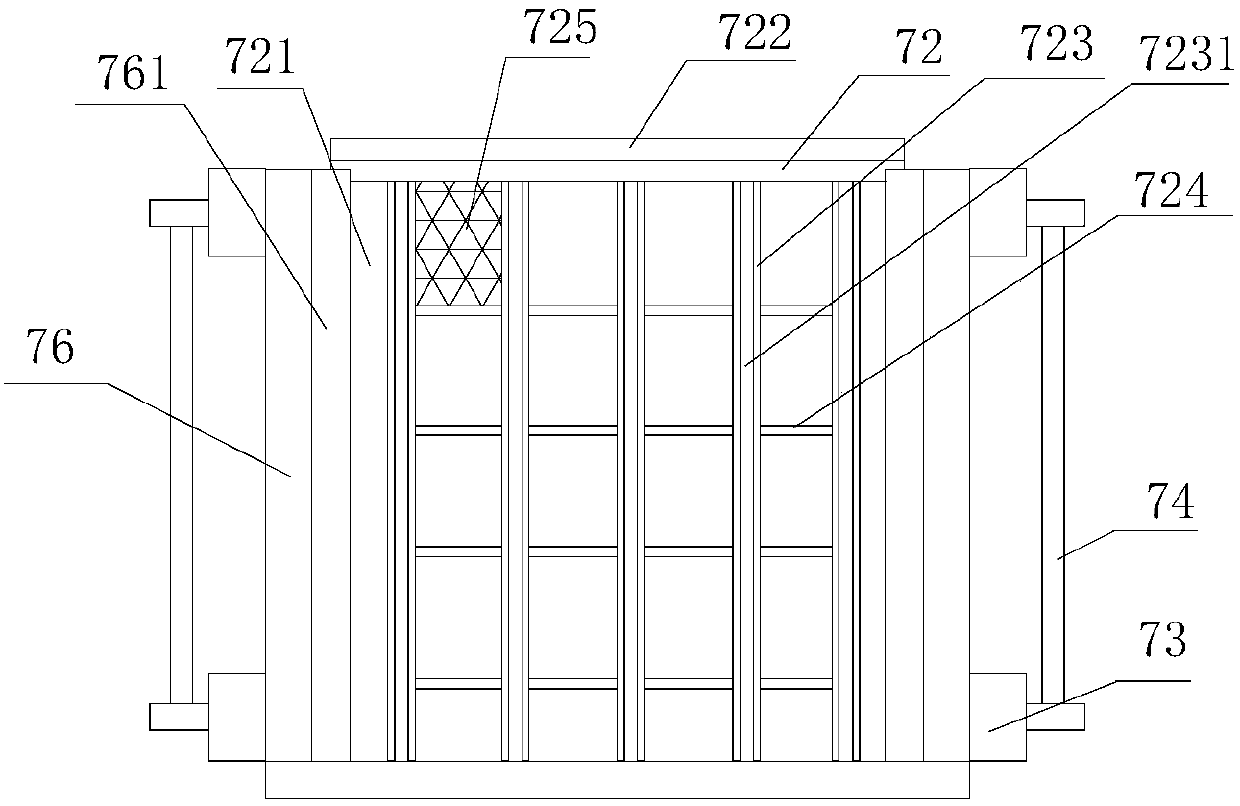

Industrialized freshwater pearl culture system

ActiveCN107549069AQuality improvementHigh densityClimate change adaptationPisciculture and aquariaEcological environmentFresh water

The invention provides an industrialized freshwater pearl culture system. The system comprises culture units, a plurality of culture pools, a drainage and purification system, a water supply system, suspended fixing brackets, culture bag devices and lifting mechanisms; the culture pools are horizontally distributed on each culture unit, the lower portion of each culture pool is communicated with the drainage and purification system, the water supply system is communicated with the culture pools, the suspended fixing brackets are arranged above the culture units, the lifting mechanisms are arranged in the culture pools and matched with the culture bag devices, each lifting mechanism is provided with a first lifting mechanism and a second lifting mechanism which are connected with traction cables respectively, and the end portions of the traction cables are connected to the suspended fixing brackets; a good ecological environment for culturing shellfish and pearls is conveniently created, and the environmental pollution is reduced; by arranging two culture bag suspending units, the space is fully utilized, it is avoided that the density of pearl mussels is too high, and the survivalrate of the pearl mussels is increased.

Owner:浙江梵沛珍珠股份有限公司

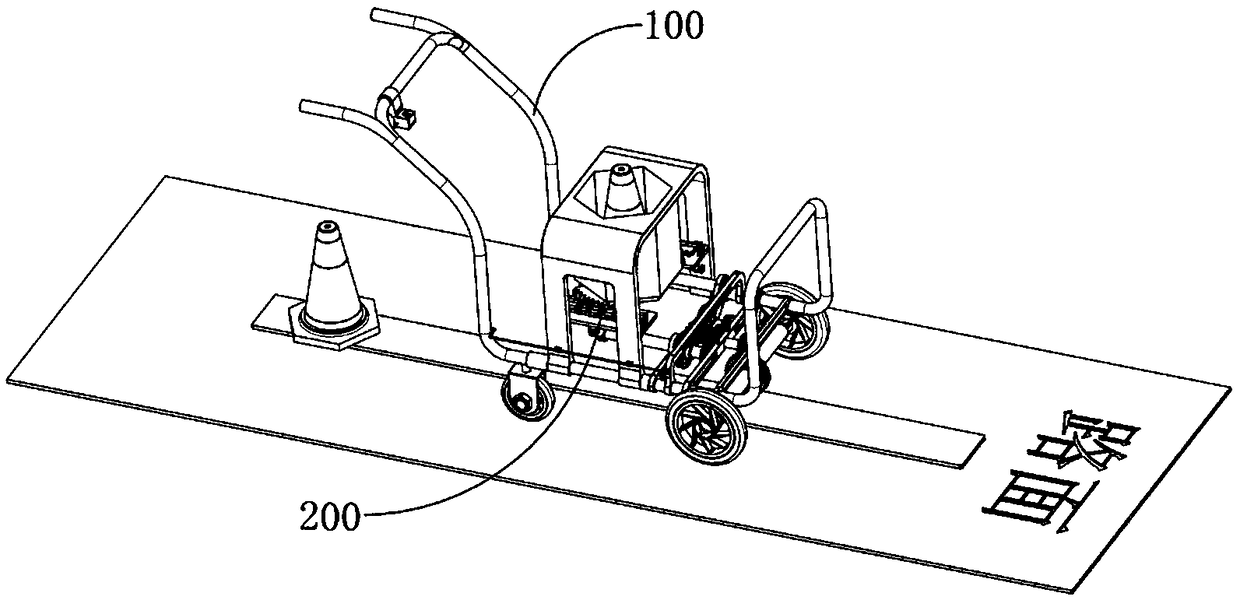

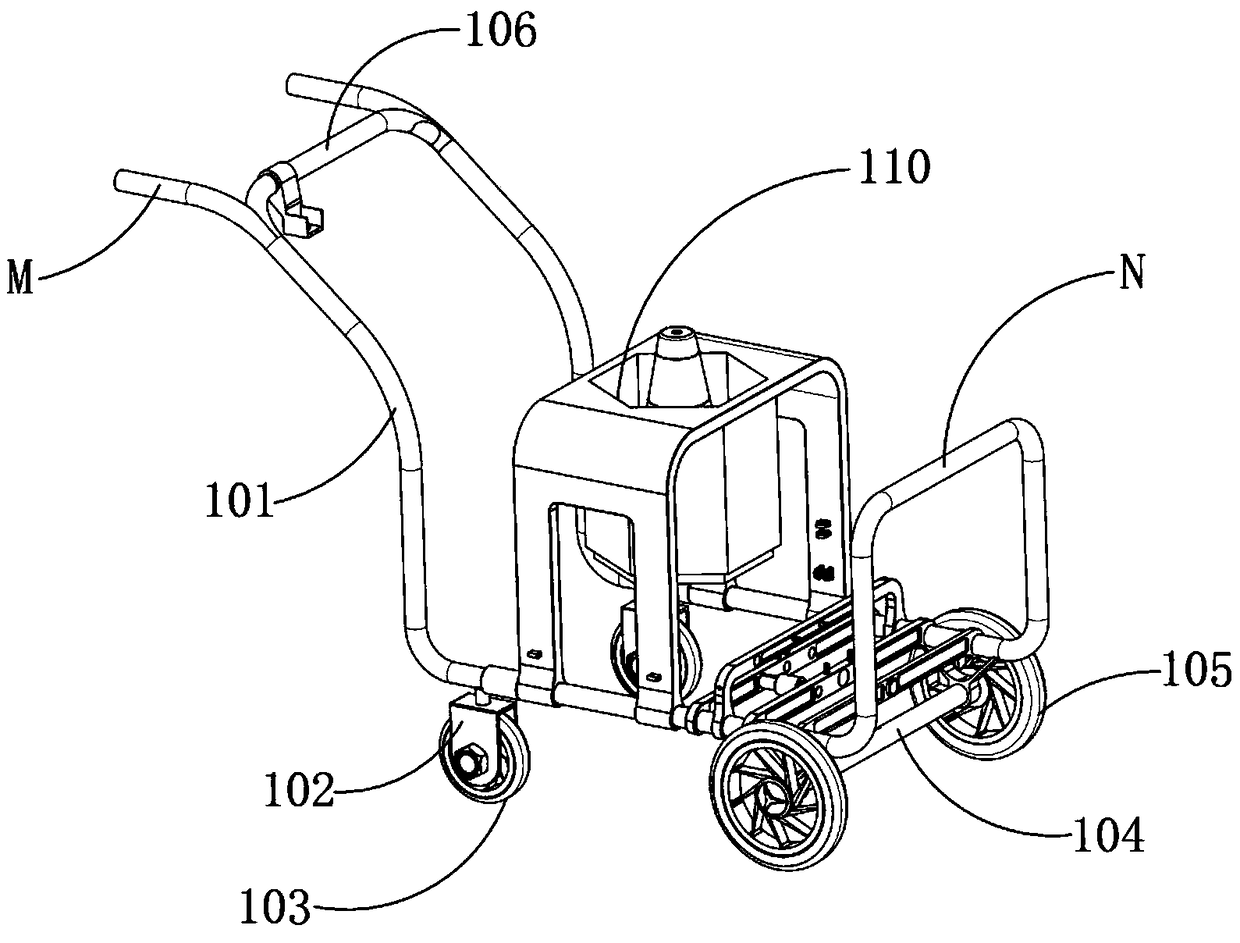

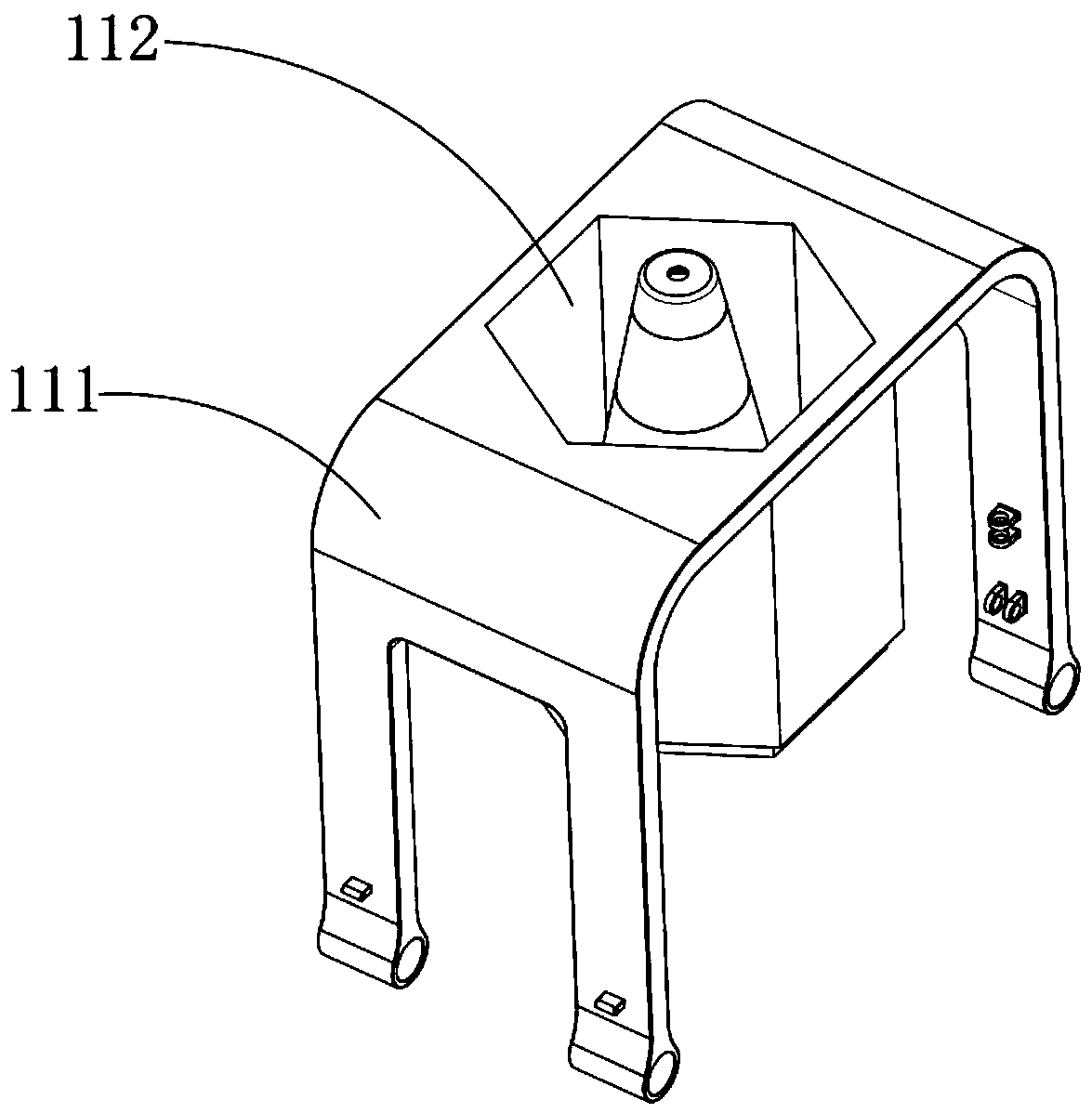

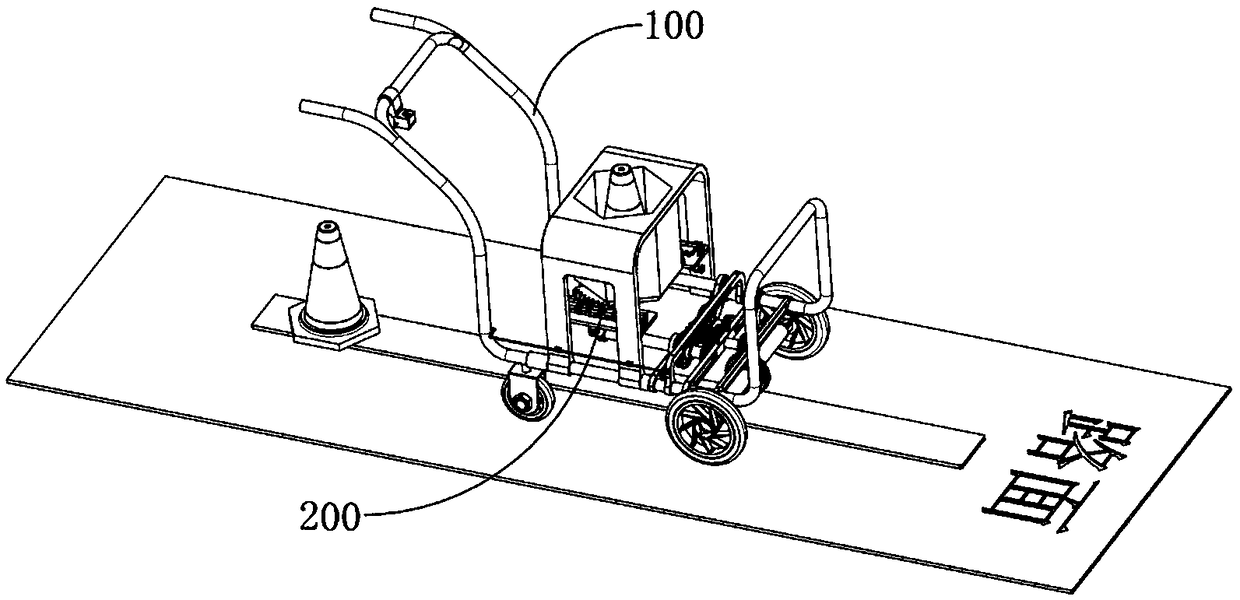

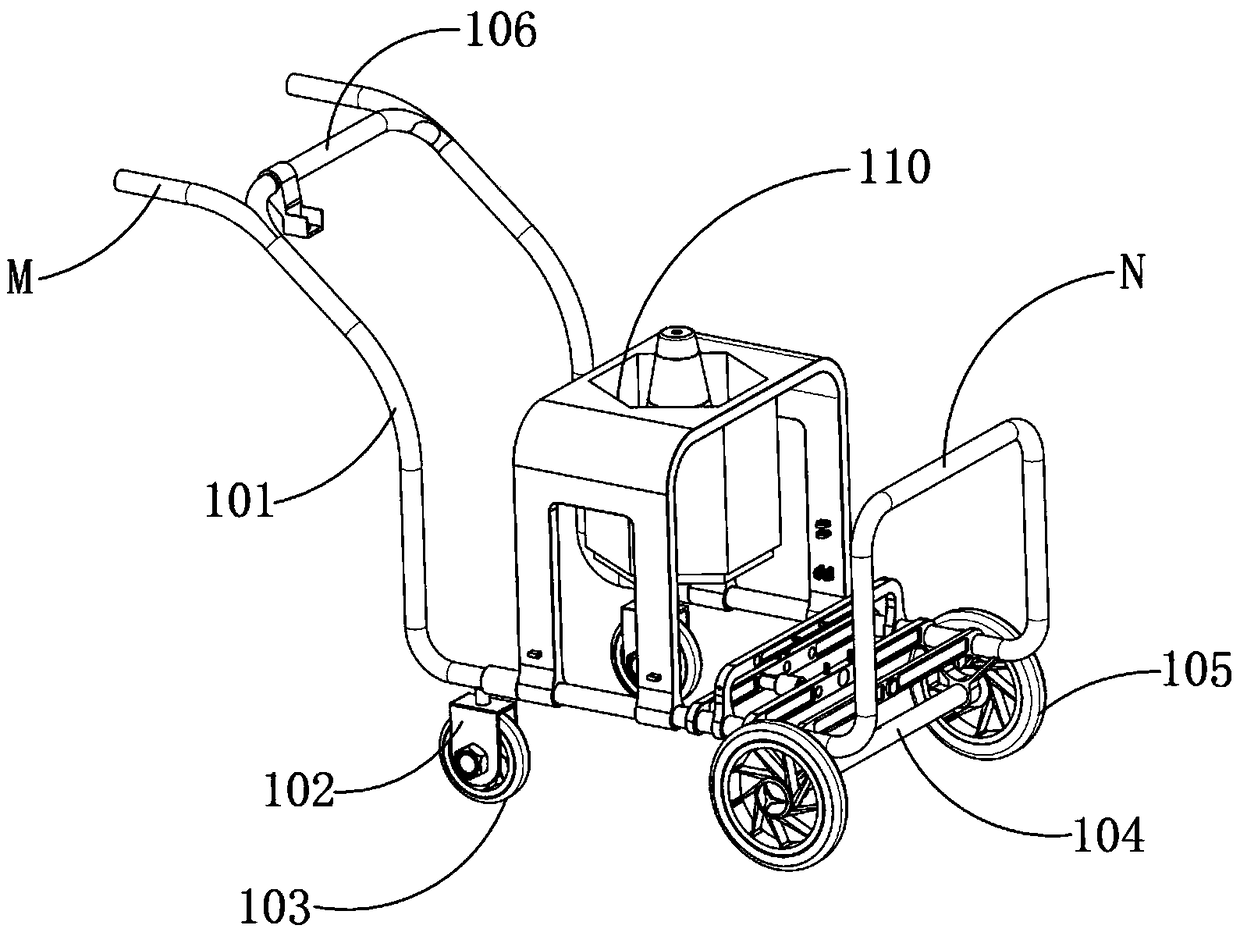

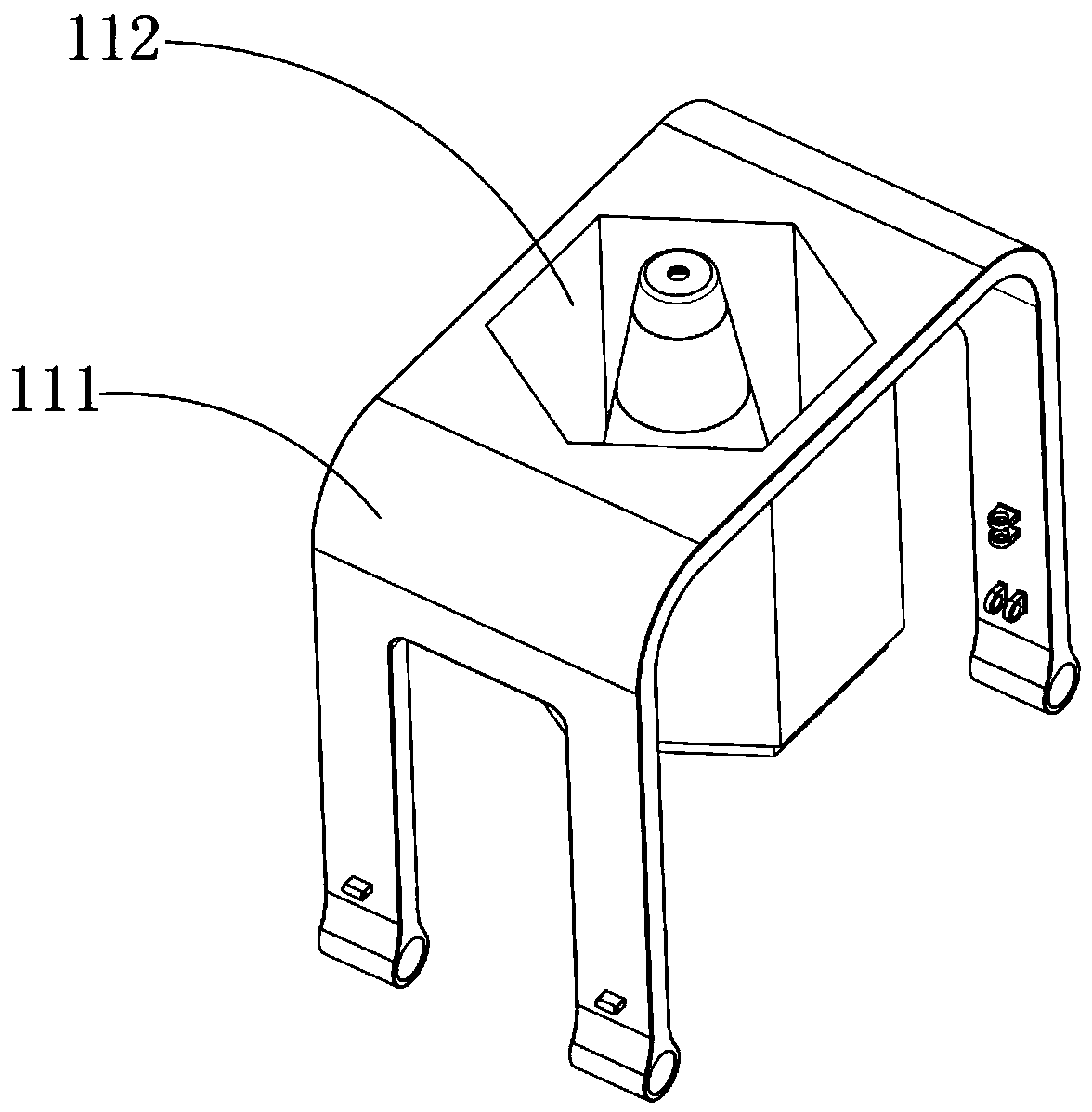

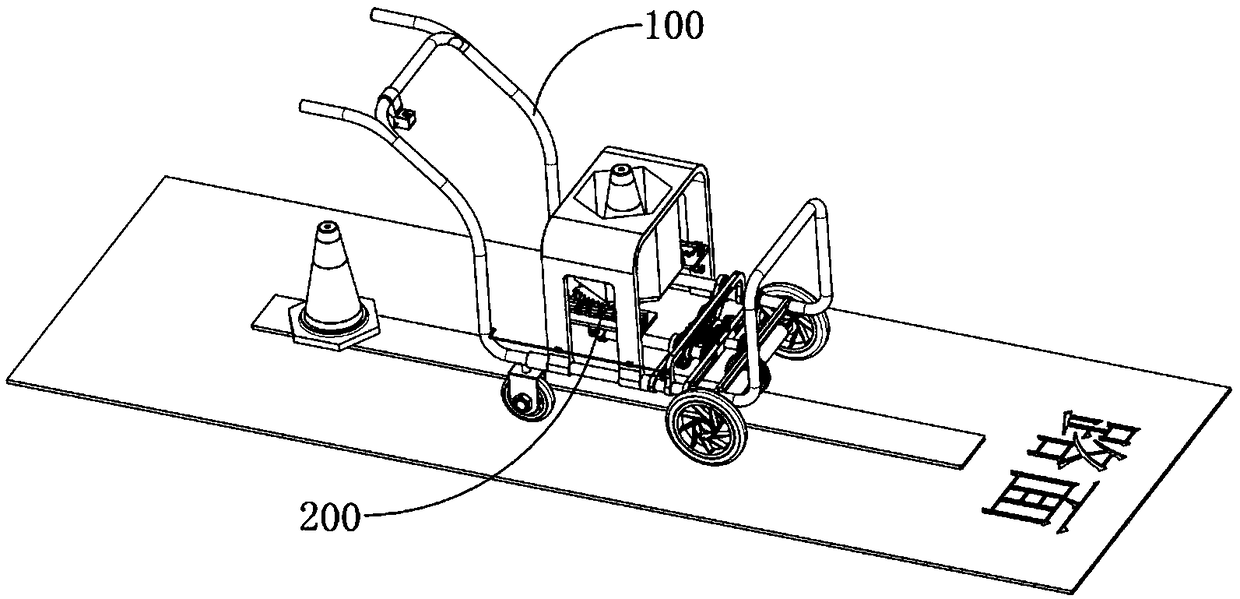

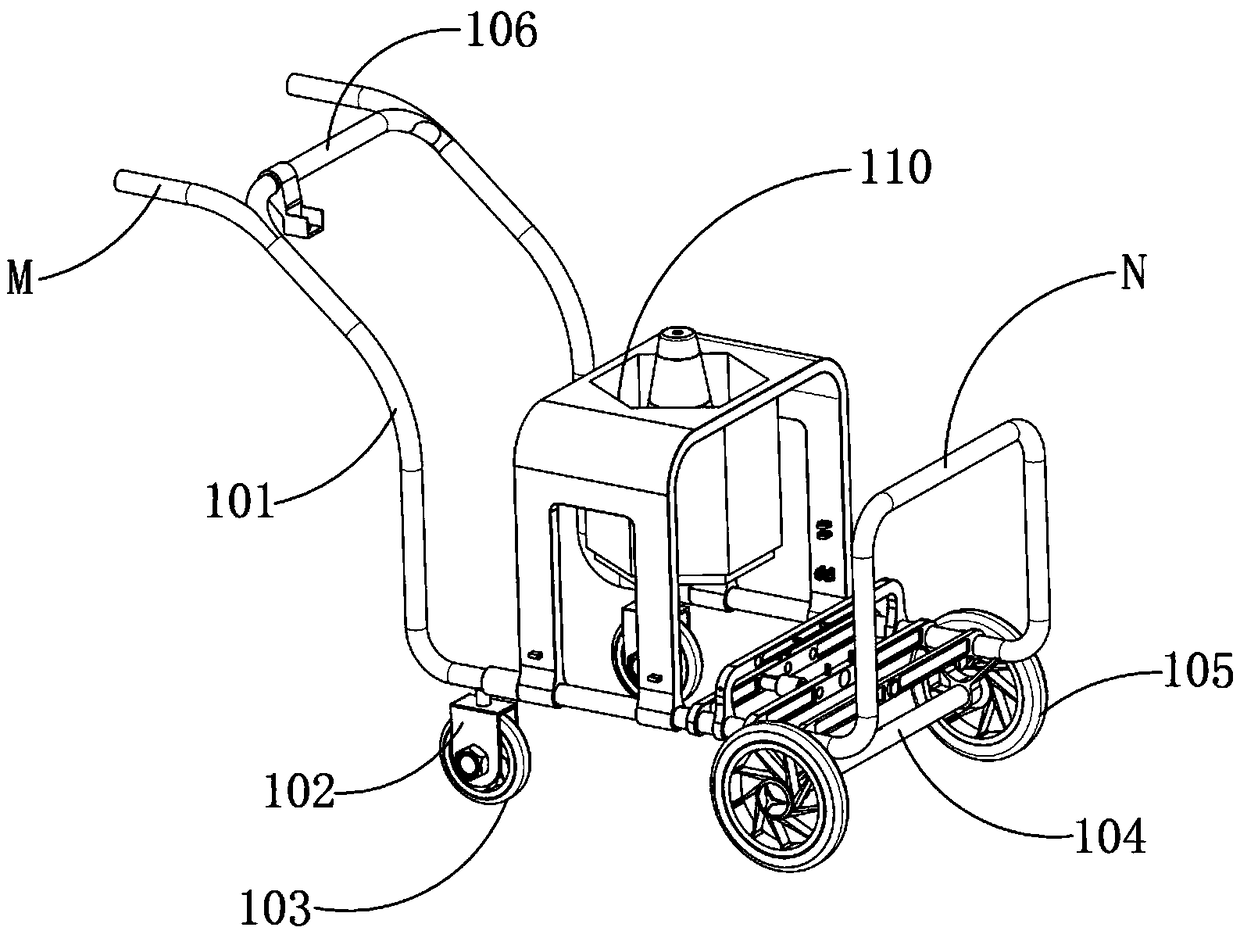

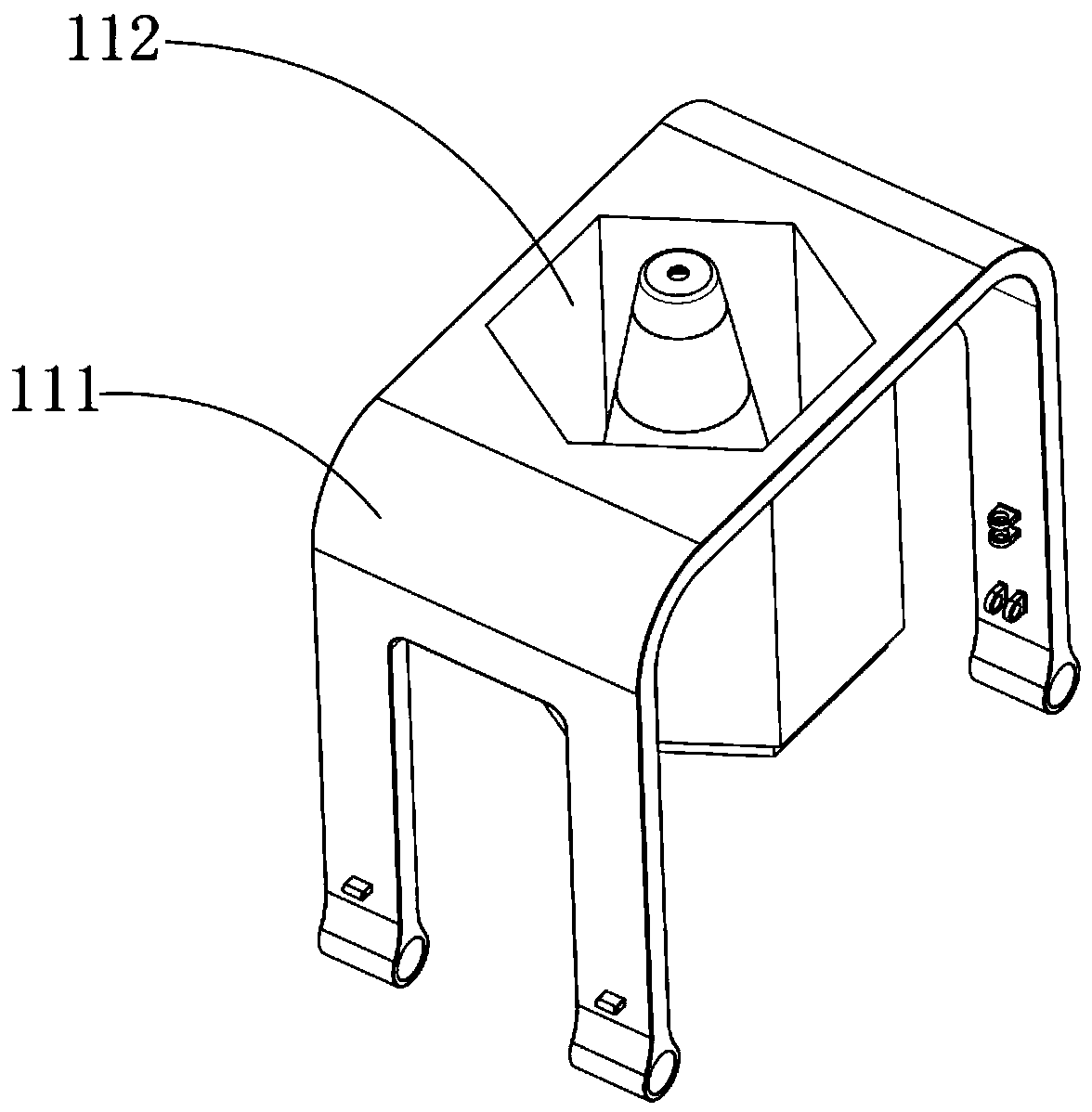

Road cone automatic placement device applied to municipal roads

InactiveCN109252466ADensity adjustmentIngenious structureTraffic signalsRoad signsAcceleration UnitCart

The invention provides a road cone automatic placement device applied to a municipal road, which includes a cart body provided with front and rear wheels, the cart body is provided with a receiving member for receiving a road cone, an automatic lowering device for placing the road cones in the receiving member one by one, the automatic lowering device comprises a limit support mechanism for supporting the road cone, a drive mechanism for driving the limit support mechanism to undo the support of the road cone one by one and a power source for supplying power to the drive mechanism; the drive mechanism is arranged to an idle state, a speed increase state, a deceleration state, and an initial state in which the initial state is an idle state and the drive mechanism can be switched between every two of the states. A control device is arranged on the cart body and is used for controlling the drive mechanism to switch between the idle state, the acceleration state and the deceleration state; the power source comprises a helical gear III fixedly connected with an input end of a drive mechanism, a helical gear IV fixedly sleeved on a front wheel / a rear wheel coaxially, and the helical gear III meshes with the helical gear IV.

Owner:张伟

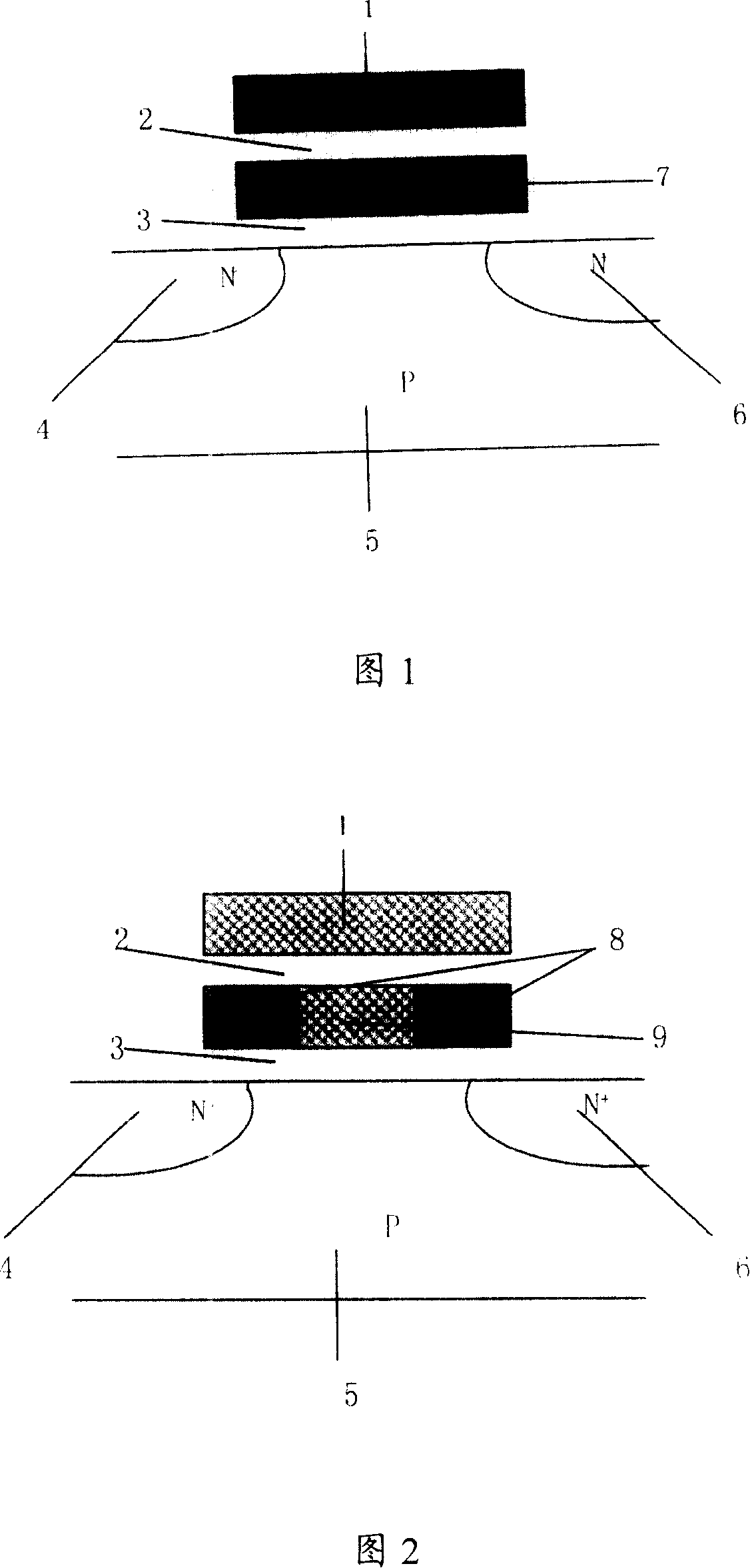

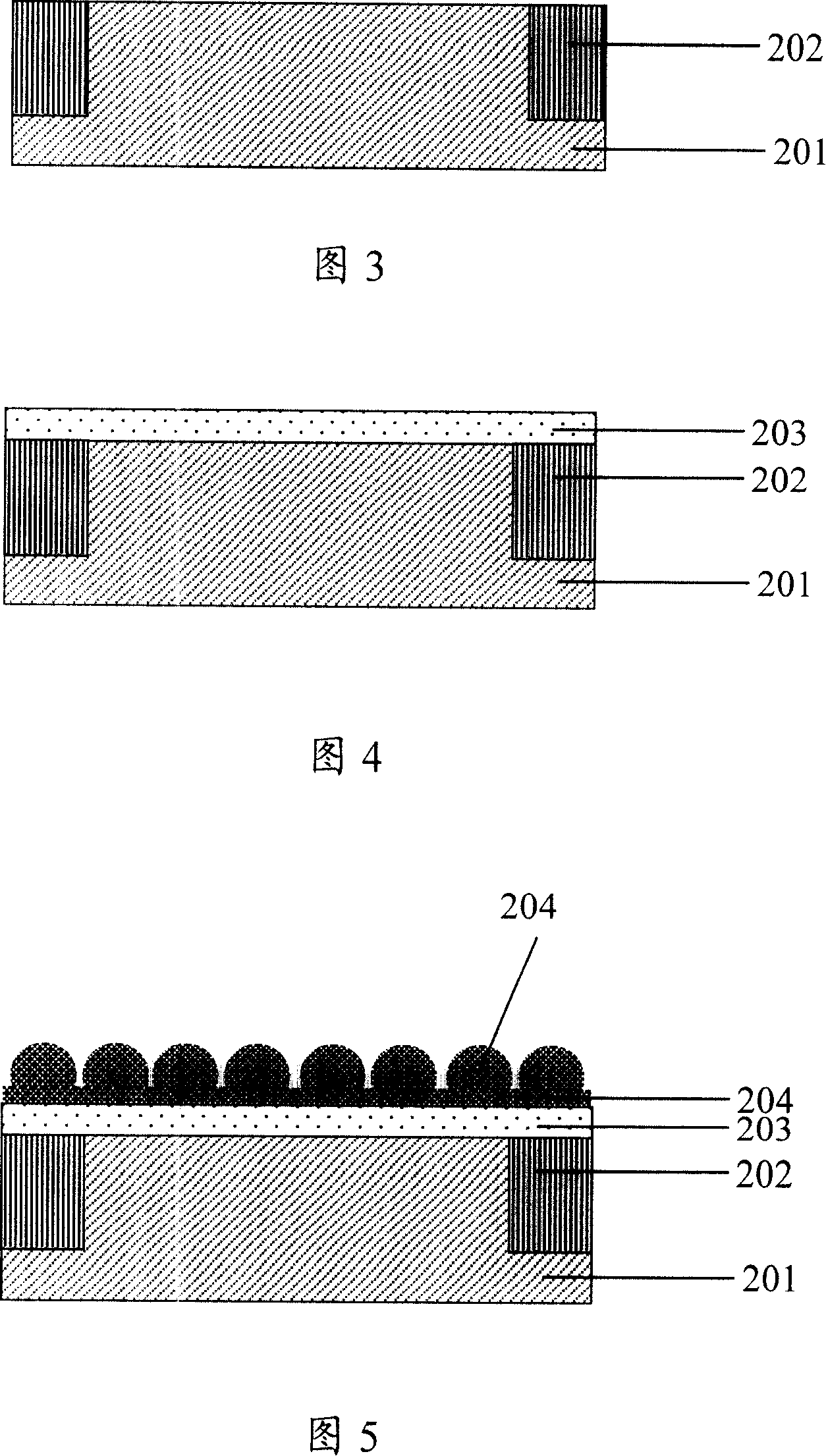

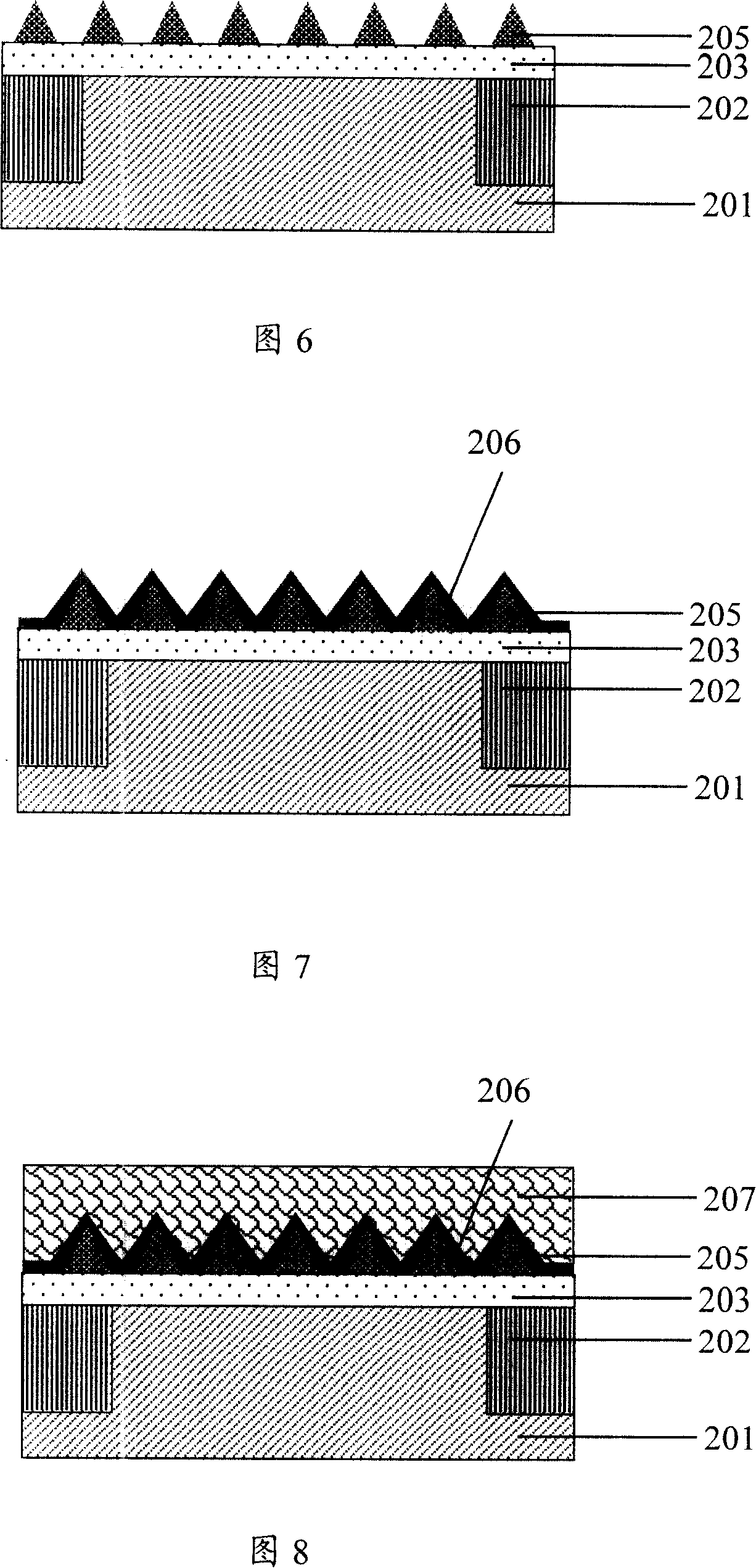

Non-volatile semiconductor memory and manufacturing method thereof

ActiveCN101154592AReduce current densityAchieve erasureTransistorSolid-state devicesSingle electronDielectric layer

The present invention provides a non-volatile semiconductor memory and the manufacturing method thereof. The non-volatile semiconductor memory adopts a nanometer single crystal silicon floating gate to realize single-electron storage, and nanometer single crystal silicon ion in the nanometer single crystal silicon floating gate is high in density and strong in storage capacity. The manufacturing method of the non-volatile semiconductor memory comprises that: a tunnel oxide layer is formed on a semiconductor matrix; a nanometer single crystal silicon layer is formed on the tunnel oxide layer; the nanometer single crystal silicon layer is formed by nanometer single crystal silicon particles in knoll shape; an interlayer dielectric layer covering the nanometer single crystal silicon layer is formed; a polysilicon layer is formed on the interlayer dielectric layer; the polysilicon layer is patterned to form a control grid; the interlayer dielectric layer is patterned to form a barrier oxide layer; the nanometer single crystal silicon layer is patterned to form a floating gate; the semiconductor basal plate is intermingled to form a separate source electrode and a drain electrode; the tunnel oxide layer is patterned to form a thin gate oxide.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

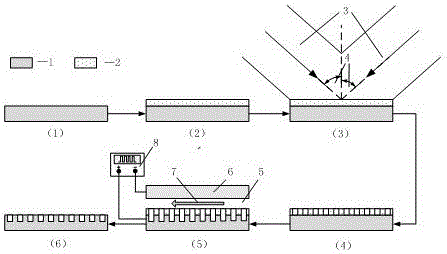

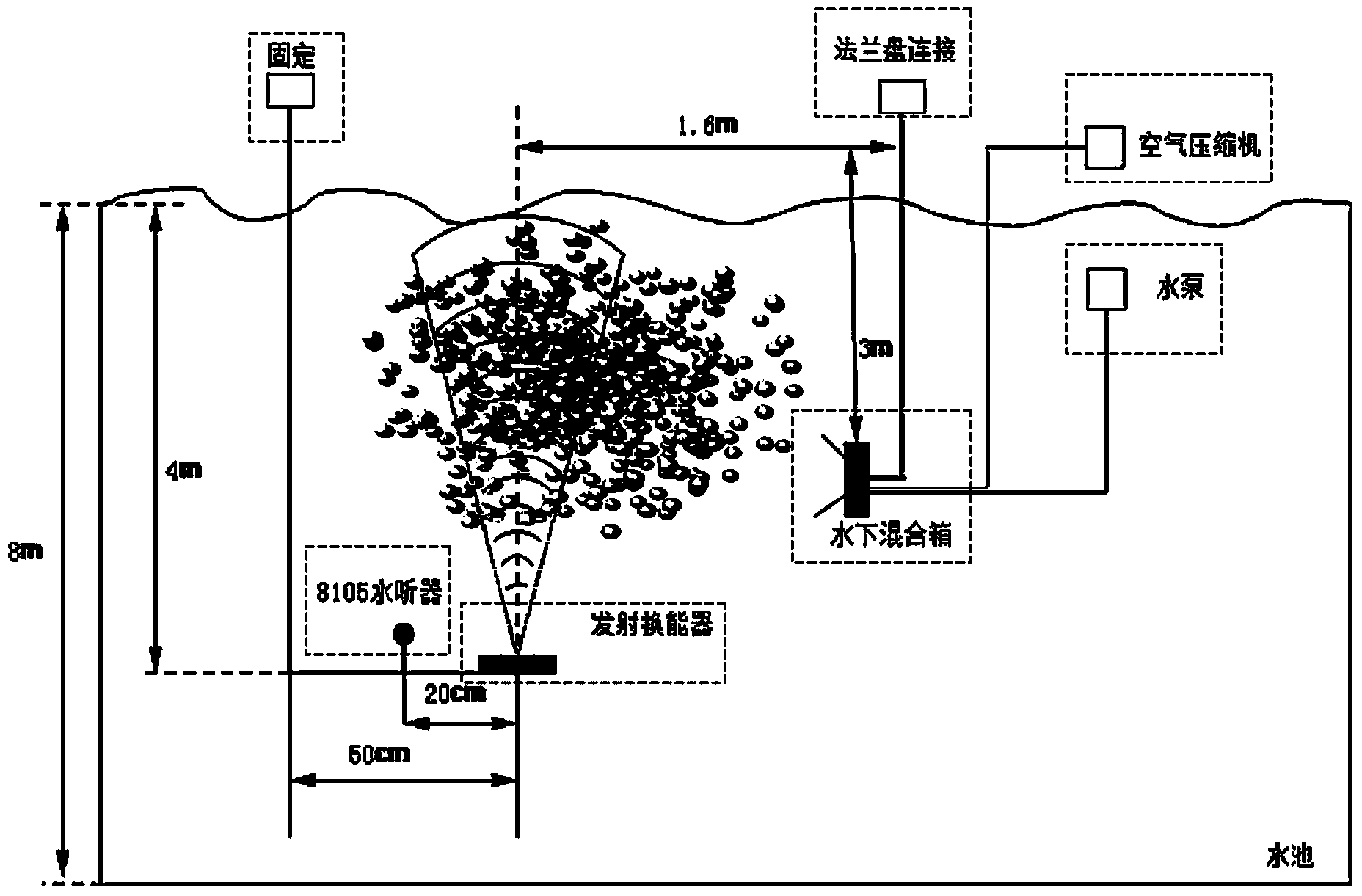

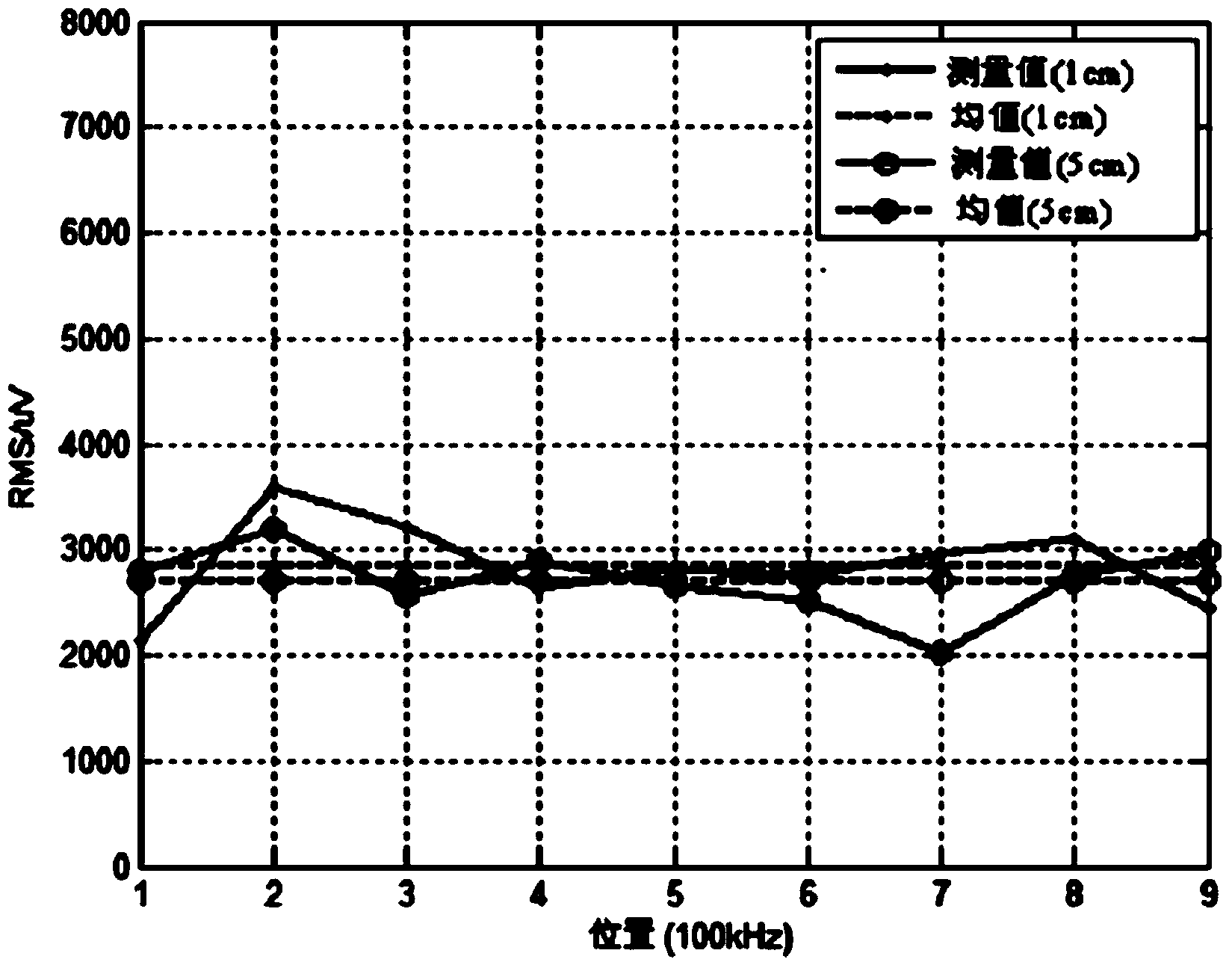

Ship wake flow realistic simulation method allowing bubble density to be adjusted

ActiveCN103712772ADensity adjustmentBubble Density AdjustmentHydrodynamic testingTest measurementEngineering

The invention provides a ship wake flow realistic simulation method allowing bubble density to be adjusted. The method comprises the following steps: (1) setting the pressure intensity range of air output by an air compressor, (2) setting the flow quantity of water flow output by a water pump, (3) adjusting the width of a rectangular nozzle of a metal box, (4) performing optimization design on parameters of the width of the nozzle of the metal box according to test measurement values, and (5) detecting the effect of ship wake flow realistic simulation. The ship wake flow realistic simulation method can be easily achieved in a water pool; the adjustment of the bubble density in the ship wake flow realistic simulation is achieved by changing the width of the nozzle, and therefore the ship wake flow realistic simulation method has important significance for acoustic characteristic studying of wake flow.

Owner:中国船舶重工集团公司第七二六研究所

Road cone placement method capable of adjusting spacing

InactiveCN109252463ADensity adjustmentIngenious structureTraffic signalsRoad signsCartAutomotive engineering

The invention provides a road cone placement method capable of adjusting spacing, which comprises the following steps: first, when the road cone is required to be arranged on the road surface, the road cones are stacked on an accommodating member on the cart body. Second, a transmission mechanism is switched from an idle state to an increasing state / decelerating state by a control device. According to the invention, a user pushes the cart body along the road surface; the power source receives the power generated in the process of the cart body travel and transmits the power to the transmissionmechanism, the transmission mechanism transmits the power to the limit support mechanism, the limit support mechanism withdraws the support to the road cone one by one, the road cone drops to the ground one by one under the action of its own gravity, and the road cone is arranged along the track of the cart body travel with intervals. Third, in the process of the second step, the control device switches the transmission mechanism to the deceleration state when it is necessary to make the placed path cone sparse.

Owner:张伟

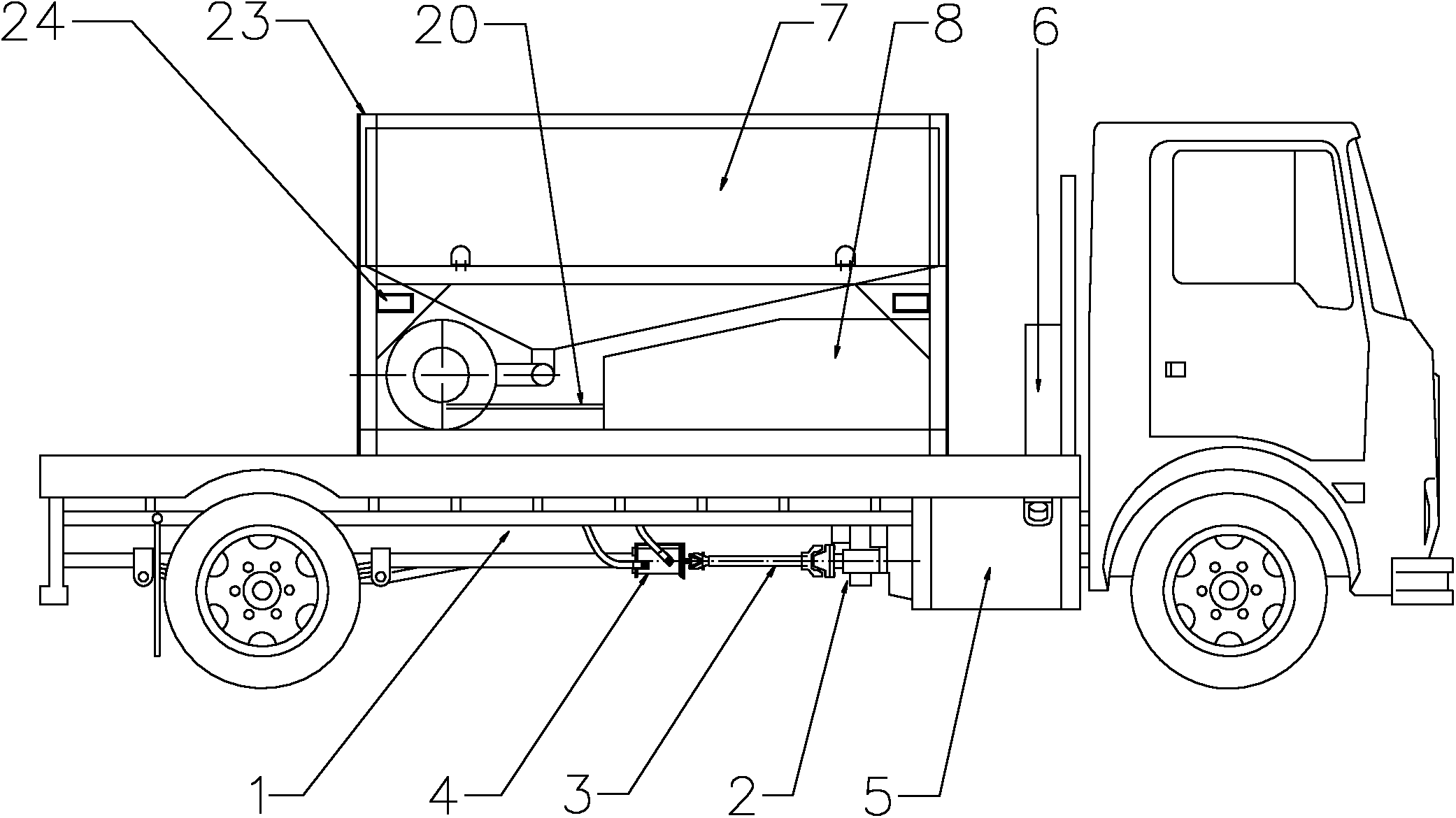

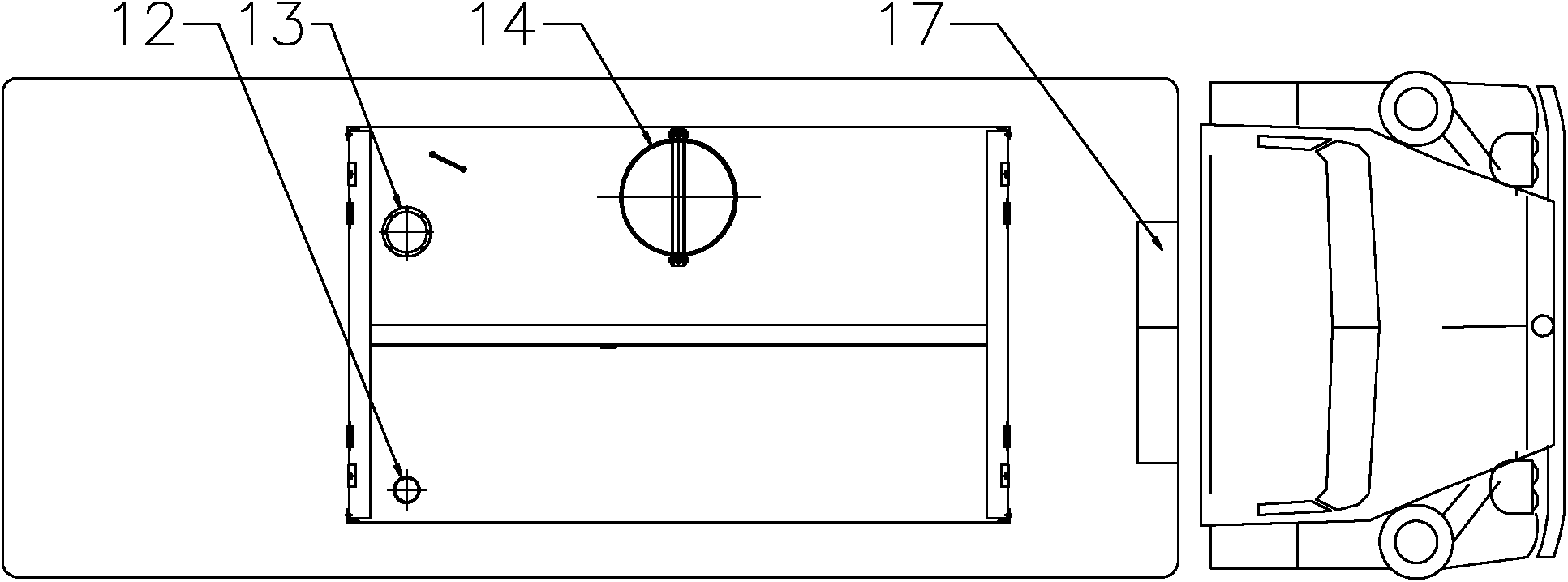

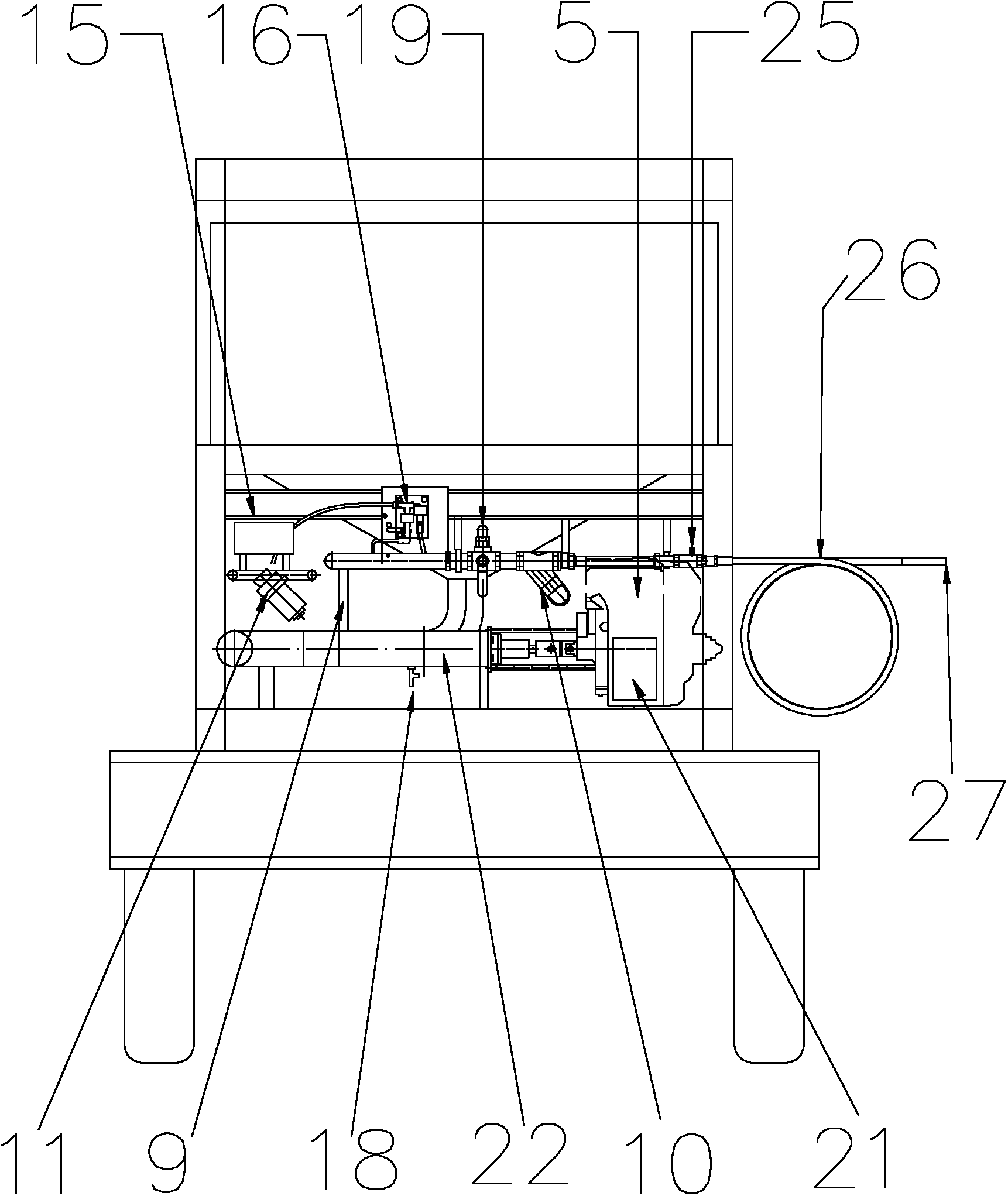

Special vehicle for filling strip mine bulk emulsifying bases

The invention relates to a special vehicle for filling strip mine bulk emulsifying bases, which comprises an automatic chassis, a device framework and an emulsifying base pumping device, wherein the device framework is installed on the automatic chassis, and the emulsifying base pumping device is installed on the device framework. The emulsifying base pumping device comprises an emulsifying base and sensitizing solution linkage plunger pump, an emulsifying base storing and delivering device, a sensitizing solution storing and delivering device, a cleaning water storing and delivering device, an injector for injecting the emulsifying bases and sensitizing solution, a base output hose and a mixer and further comprises a power take-off transmitting device and a hydraulic transmission system which are arranged on a gearbox installed at the bottom of the automatic chassis. Due to the optimized design and the structure, the special vehicle has the advantages of being wide in applied range, small in equipment volume, simple in power source, safe and reliable in production process, low in burst cost, low-carbon, environment-friendly and the like.

Owner:薛世忠

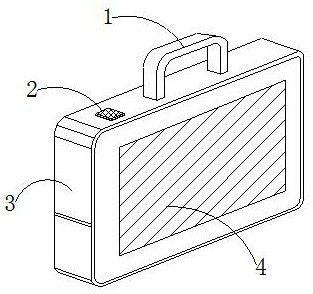

Movable light-guide fiber display

InactiveCN112289204AImprove stabilityDensity adjustmentIdentification meansDisplay deviceEngineering

The invention discloses a movable light-guide fiber display which structurally comprises a handle, a control switch, a movable box and a display screen. The movable box is provided with a light sourceplate, a fixed plate, a scaling mechanism and a transparent plate. A pressure block in a blocking mechanism is scaled through a controller in a telescopic device, when a telescopic mechanism is retracted, a bent rod is stressed and bent inwards to block light, so that the irradiation range in an irradiation hole is prevented from being too dense, the intensity of the light is adjusted, the diffraction phenomenon caused by too dense irradiation is avoided, and the visual effect at the edge of the pattern is prevented from being influenced by light cross; and the refractivity of a light sourceemitted by a bent mirror is controlled, so that light rays are in a good uniform scattering state, the light rays are prevented from forming a cross phenomenon, the light rays enter a reverse transparent mirror in a scattering structure and are refracted and diffused from rhombic holes after being focused, the light rays reach a uniform state, light sources are scattered orderly, and the problem of non-uniform brightness caused by scattering deviation is solved.

Owner:广州优易机械科技有限公司

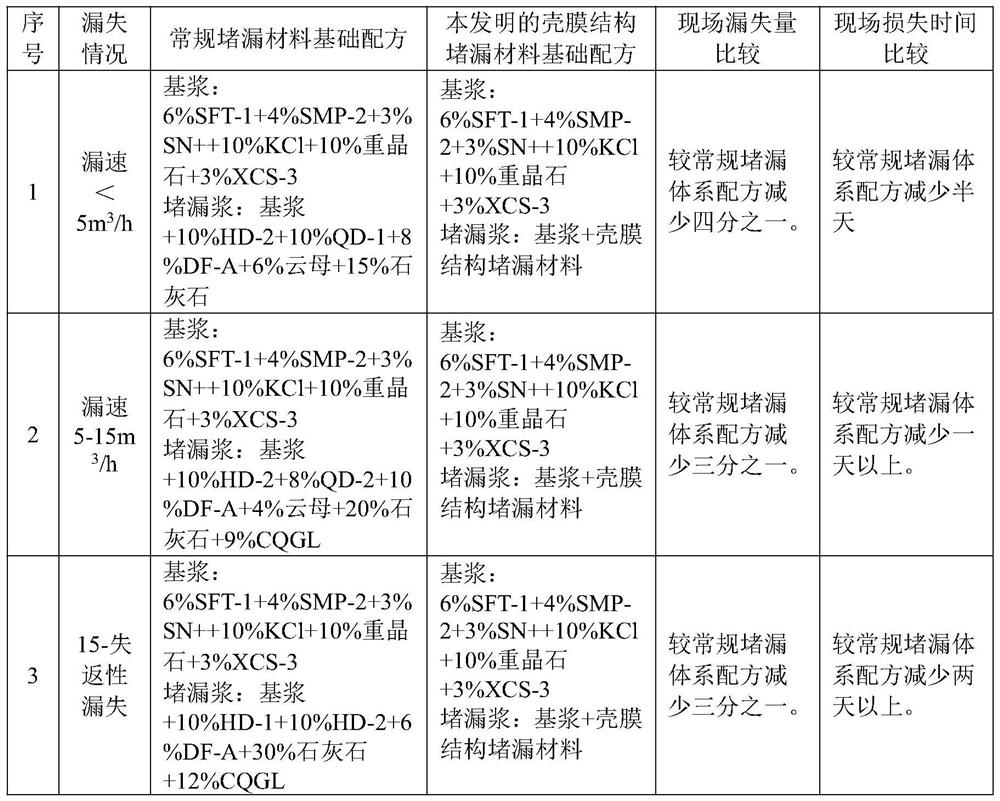

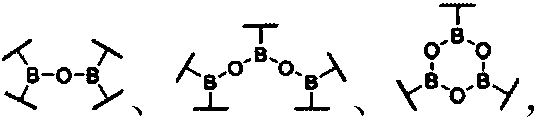

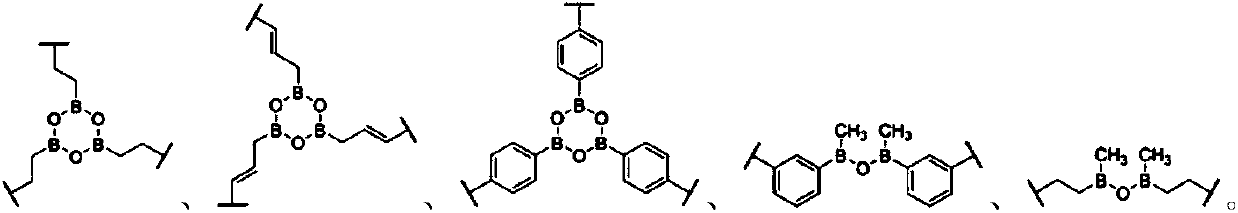

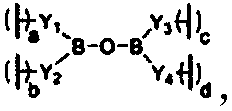

Shell-membrane structure plugging material as well as preparation method and use method thereof

ActiveCN112480884AShort timeLow costDrilling compositionMicroballoon preparationChemistryComposite material

The invention belongs to the technical field of oil and gas drilling engineering, and particularly relates to a shell-membrane structure plugging material as well as a preparation method and a use method thereof. The composite material comprises an aluminum film, Fe3O4 and gelatin, the Fe3O4 is coated with a layer of gelatin, the Fe3O4 coated with the gelatin is coated with the aluminum film, andthe aluminum film is coated with a layer of gelatin. According to the invention, under the action of an earth magnetic field, magnetic media Fe3O4 with different shapes, different proportions and different particle grades injected into cracks are rapidly magnetized to rapidly form a relatively stable netty three-dimensional plugging framework with certain pressure bearing capacity, the cracks arefilled with the magnetic media Fe3O4, and the magnetic media Fe3O4 are matched with a liquid-phase plugging agent to realize rapid plugging, so that not only is the plugging time saved, but also the cost is saved.

Owner:PETROCHINA CO LTD

Vitrified dilatant polymer foam hybrid material

The invention discloses a vitrified dilatant polymer foam hybrid material. The hybrid material is characterized by comprising a dilatant polymer and polymer foam particles, wherein the dilatant polymer is at least selected from a vitrified dilatant polymer; the polymer foam particles are compounded with the dilatant polymer and other optional components to form the hybrid material. The hybrid material has the characteristics of low density, heat insulation, sound insulation, buffering, shock absorption, dilatancy, slow resilience and the like, and can be widely applied to manufacturing of packaging materials, building materials, impact-resistant protective materials, shock absorption materials, buffering materials, silencing materials, heat preservation materials, shape memory materials, electronic and electric appliance materials, medical supplies and the like.

Owner:厦门天策材料科技有限公司

A dead leaf collection device

ActiveCN109479628BAvoid destructionImplement the dumping actionHops/wine cultivationTurf growingGear wheelCart

The invention discloses an energy-saving and environment-friendly withered leaf collecting device. The device comprises a cart, the cart comprises a compartment and wheels, a collecting claw is rotatably arranged at the front end of the compartment, a first rotating shaft is rotatably arranged at the front end of the compartment through a bearing, and the collecting claw is fixedly arranged on thefirst rotating shaft through a first connecting rod and a second connecting rod; the front end of the collecting claw is short, and the rear end of the collecting claw is high; the first connecting rod and the second connecting rod are fixedly disposed on the rear side of a connecting plate, the end of the first connecting rod is disposed in the compartment and fixedly provided with an arc-shapedguide rod, the arc-shaped guide rod is provided with a semicircular guide rail, the wheels are fixedly disposed on a second rotating shaft, and the second rotating shaft is fixedly provided with a second gear; the second gear is connected to a first gear through a transmission mechanism, the first gear is coaxially provided with a swing rod, a roller is slidably disposed in the guide rail of thearc-shaped guide rod, and the front end of the compartment is further provided with a collecting basket which is arranged below the collecting claw. Energy is saved, the efficiency of collecting withered leaves on a lawn is improved, and the environment is improved.

Owner:兰昊宇

A vertical web laying device with adjustable density of upright cotton

ActiveCN104805597BDensity adjustmentGood for changing speedNon-woven fabricsEngineeringMechanical engineering

The invention discloses a vertical type net laying device capable of adjusting upright cotton density. The vertical type net laying device capable of adjusting the upright cotton density comprises a reciprocating type cotton feeding system, a vertical type cotton arrangement system and a horizontal conveying belt, the reciprocating type cotton feeding system comprises a reciprocating power part and a cotton feeding part mutually connected, a cotton feeding groove is formed in the middle of the cotton feeding part, the outlet of the cotton feeding groove is communicated with the inlet of a forming tunnel in the vertical type cotton arrangement system, the outlet of the forming tunnel is communicated with the horizontal conveying belt below the outlet, the vertical type cotton arrangement system comprises three layers, and each layer comprises a left cotton arrangement roll set and a right cotton arrangement roll set bilaterally symmetrical to the forming tunnel. When using, the density of a final product can be changed through setting different running speeds for left and right cotton arrangement roll sets in each layer. The vertical type net laying device capable of adjusting the upright cotton density is capable of adjusting the density and width of the upright cotton, and moreover, the structure is simple, and the operation is facilitated.

Owner:TENGFEI TECH CO LTD

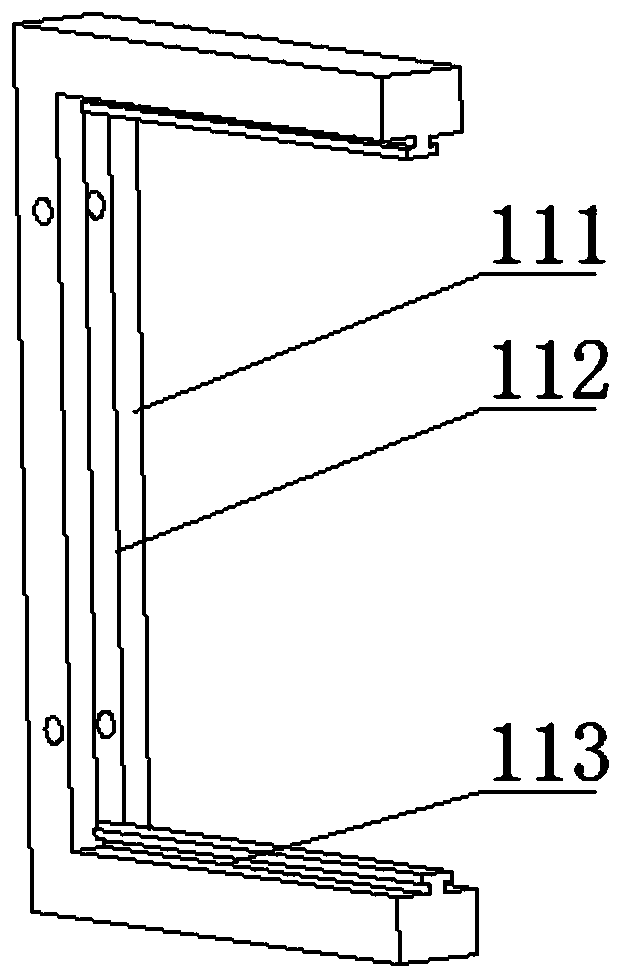

Dong brocade weaving tool allowing for increased warp-weft density

PendingCN110607595AIncrease warp and weft densityIncreased sealing and articulationLoomsTextileMechanical engineering

The invention relates to the technical field of textile tools, and discloses a Dong brocade weaving tool allowing for increased warp-weft density, which comprises a length adjusting device. Accordingto the Dong brocade weaving tool allowing for increased warp-weft density, the length adjusting device mutually cooperates with a density adjusting mechanism and reed teeth, so that a distance betweena first adjusting frame and a second adjusting frame can be adjusted by rotating an adjusting nut, the exposed length of the density adjusting mechanism is changed, and the whole length of the devicecan be conveniently adjusted as required; the density adjusting mechanism mutually cooperates with a bolt and a lock nut, so that it is convenient to fixedly connect the density adjusting mechanism with the first adjusting frame, and the device is convenient to disassemble and mount; uniformly distributed clamping grooves are arranged in the density adjusting mechanism, so that it is convenient to insert different numbers of clamping grooves and adjust the space between reed teeth as required, thereby adjusting the warp density.

Owner:通道侗族自治县呀啰耶侗锦织艺发展有限公司

Construction cart for automatic traffic cone arrangement and placement

InactiveCN109371876ADensity adjustmentIngenious structureTraffic signalsRoad signsDrive shaftEngineering

The invention provides a construction cart for automatic traffic cone arrangement and placement. The construction cart comprises a cart body. The cart body is provided with a storage component for storing traffic cones and an automatic placing and falling device for placing the traffic cones in the storage component one by one. The automatic placing and falling device comprises a limiting supporting mechanism for supporting the traffic cones, a transmission mechanism used for driving the limiting supporting mechanism not to support the traffic cones one by one, and a power source for providingpower for the transmission mechanism. The transmission mechanism is set into an idling state, an acceleration state and a deceleration state, all of which can be mutually switched, wherein the initial state is the idling state. The transmission mechanism comprises a transmission shaft connected with the power source and a speed changing shaft connected with the limiting supporting mechanism. A speed changing component is arranged between the transmission shaft and the speed changing shaft and comprises an acceleration component and a deceleration component. The transmission mechanism furthercomprises a combination control component for controlling transmission of the acceleration component or transmission of the deceleration component.

Owner:张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com