Density adjusting device of computer silk stockings machine

A density adjustment and stockings machine technology, which is applied in textiles and papermaking, weft knitting, knitting, etc. It can solve the problems of large density adjustment gap and slow response speed, so as to improve quality, stabilize density control, and meet diversified requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

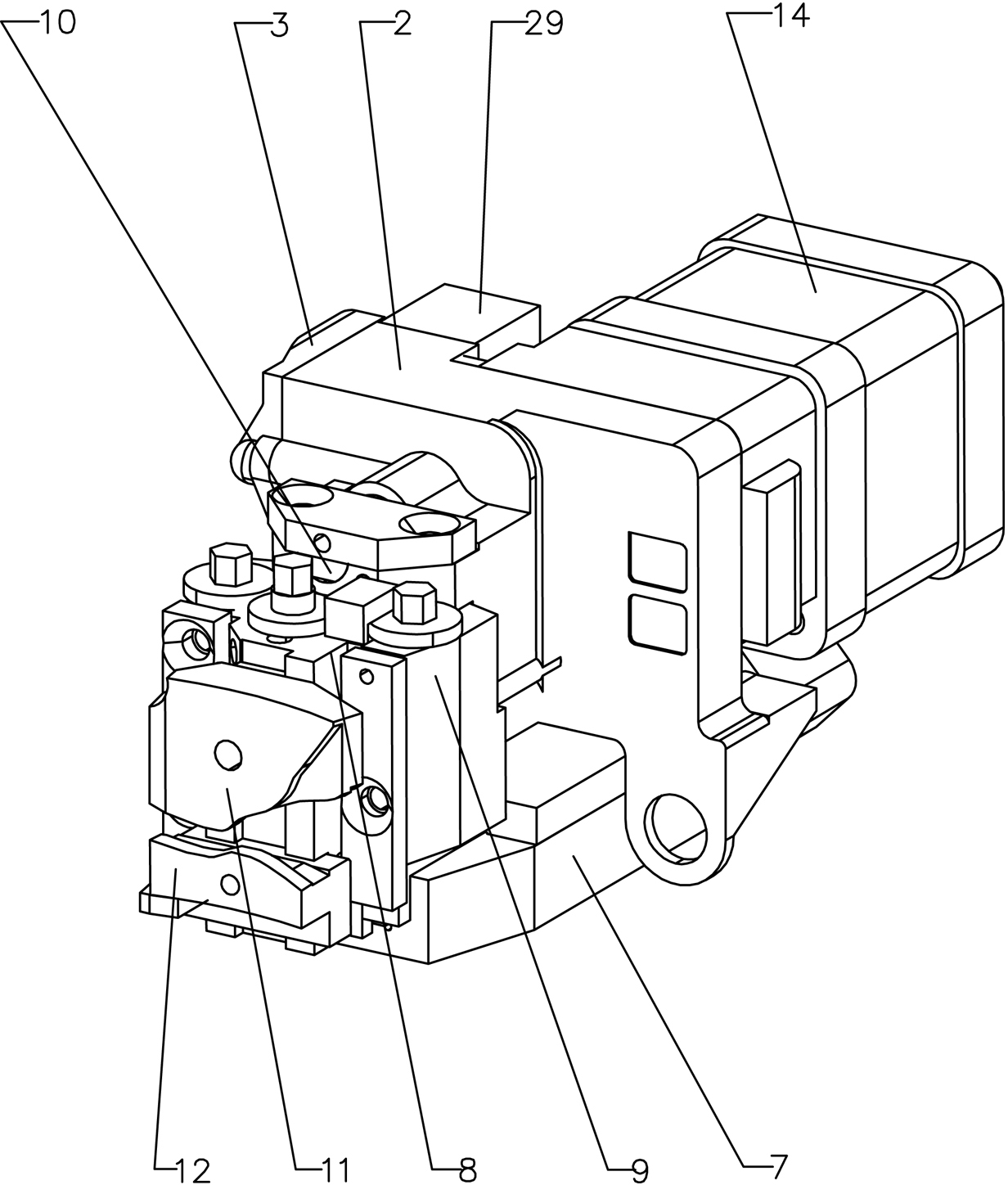

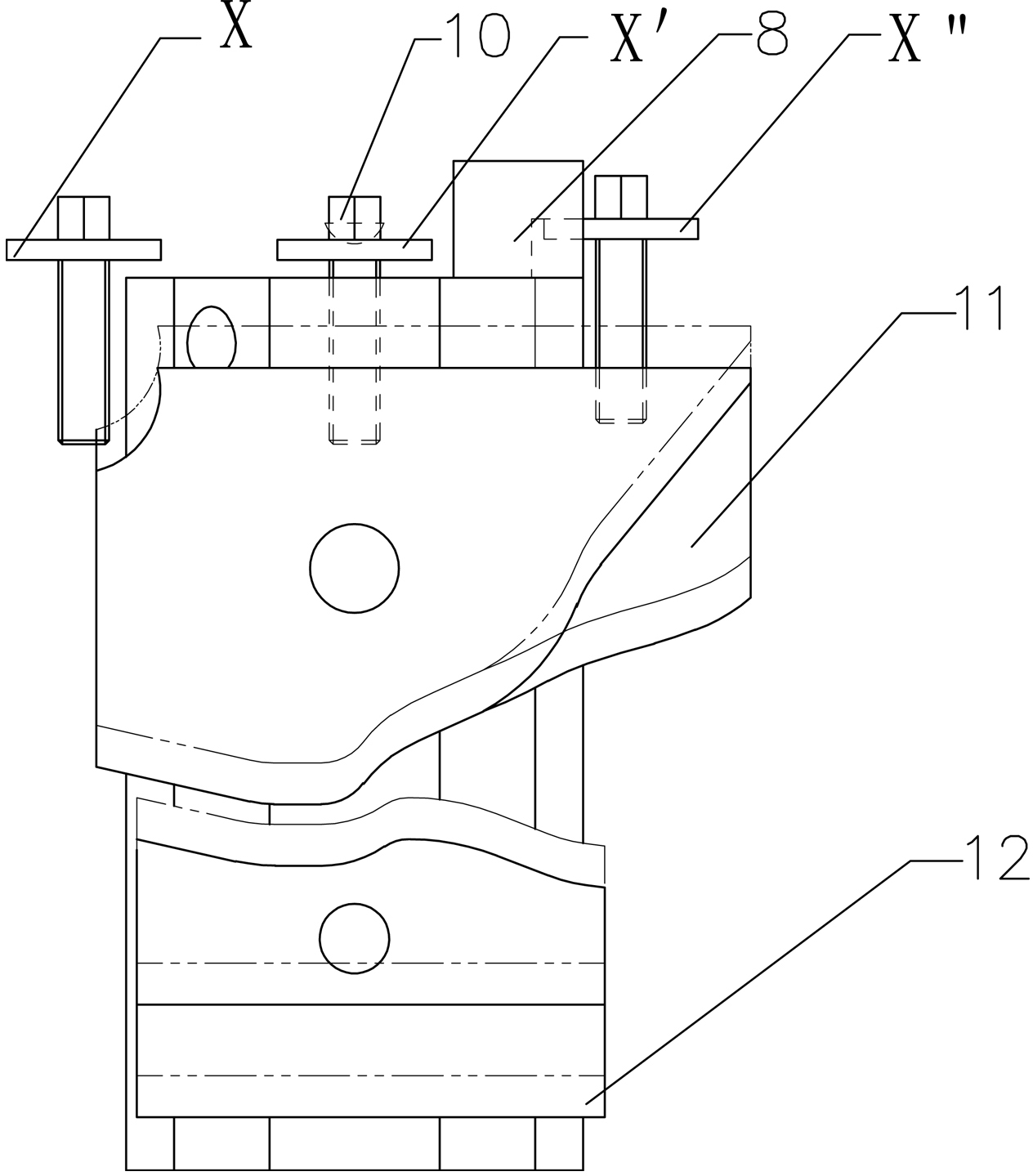

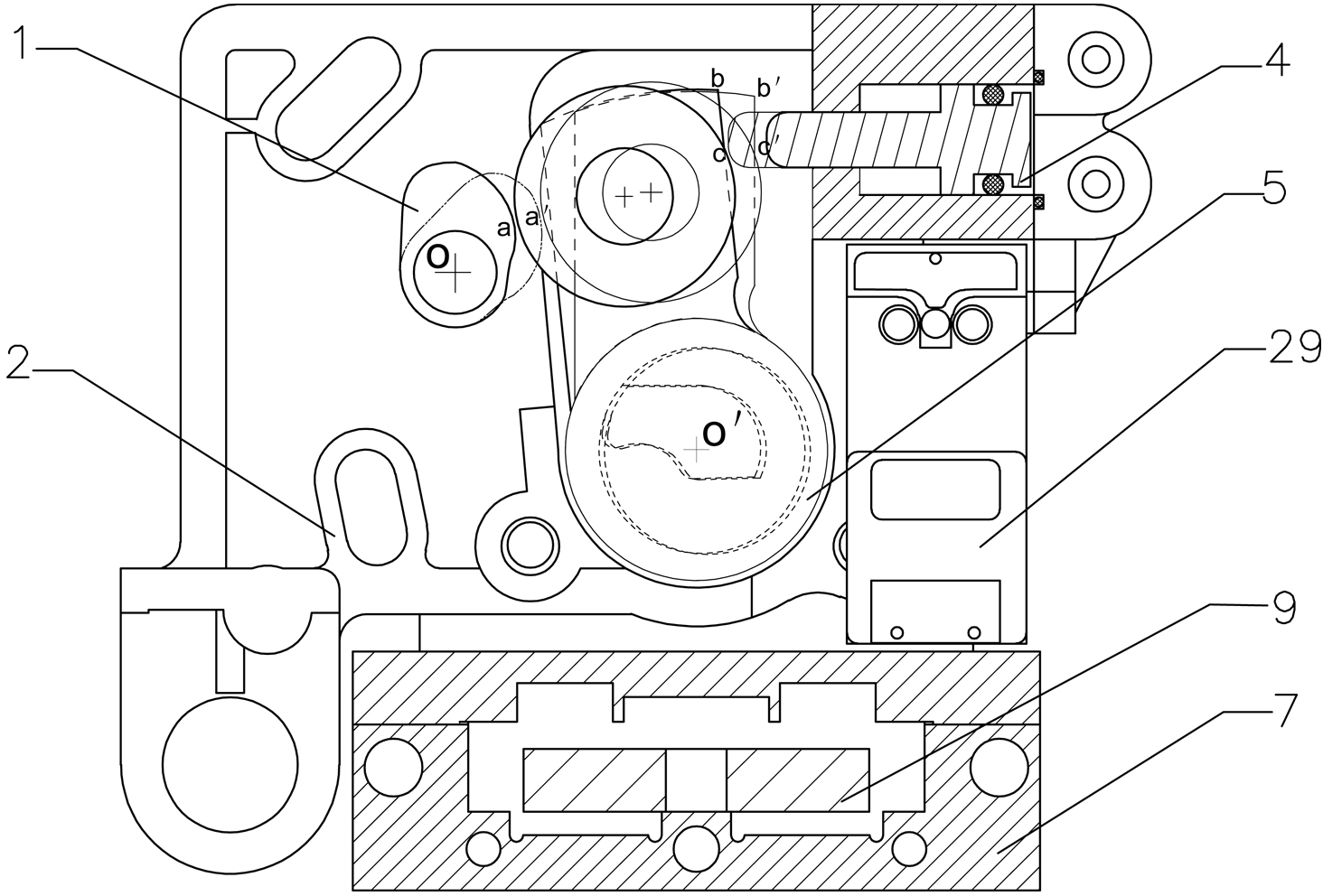

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0020] See attached picture. The present embodiment comprises the density adjusting device of computer stockings machine, comprises density triangular base 7, density triangular base 9 and triangular slider 8, density triangular base 7 is connected with density triangular base 9 by sliding, density triangular base 7 and triangular slider slide 8 Link to each other, also have pressing needle cam 11 and needle cam 12 on the cam slider 8; It also includes a base cylinder 24 and cylinder front frame 2, base cylinder 24 links to each other with density triangle seat 7, is provided with a full body in the base cylinder 24 A position piston 25 and a half-position piston 18 respectively promote the density triangular base 9 to move forward relative to the density triangular base 7; a return spring is provided between the density triangular base 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com