TBS transformation and upgrading method

An underflow and box technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of TBS easily blocking the discharge port, running coal, frequent failure of the actuator, etc., to facilitate disassembly and maintenance. The effect of replacement, smooth discharge process and stable density control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

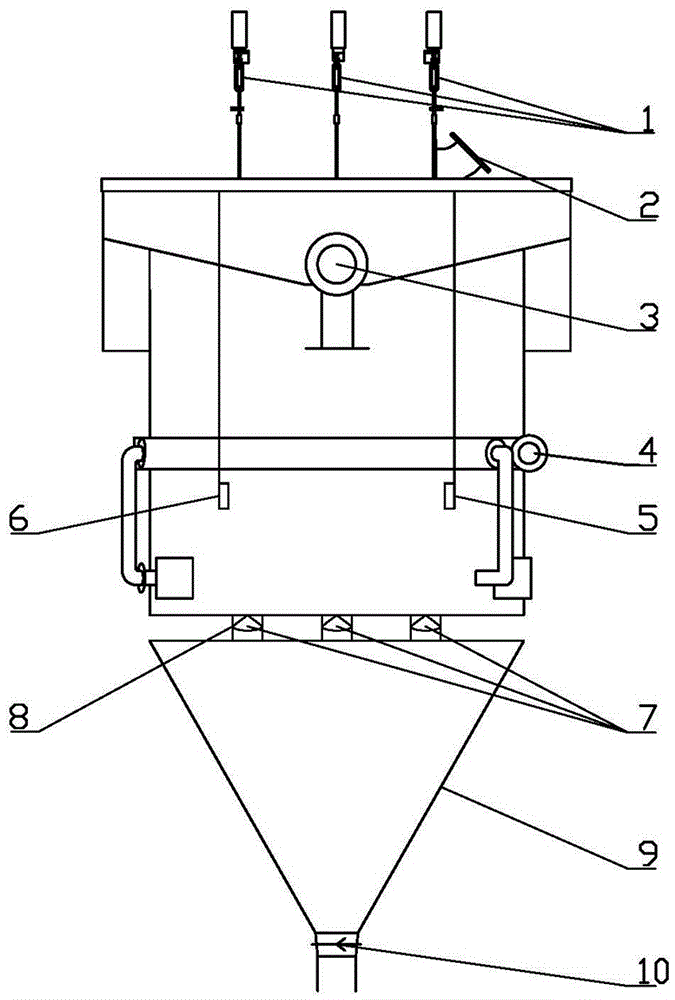

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the protection scope of the present invention.

[0036] During TBS production, the material is fed into the sorter tangentially from the material inlet 2, and moves downward under the action of gravity. The top water is fed through the top water hole 4, and moves upward under the action of pressure. The falling material and the rising water flow A self-generated medium bed is formed in the separator, and the small-density material enters the overflow under the action of the rising water flow and is discharged through the overflow port 3 to become concentrate, and the high-density gangue passes through the self-generated medium bed and enters the underflow. During this process, the actuator 1 Drive the bell-shaped discharge valve 7 to move downward to generate a discharge channel, and the gangue is discharged from the discharge channel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com