Coarse slime column type sorting device and method

A sorting device and coarse coal slime technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of poor sorting stability, poor adaptability, and low sorting precision, and achieve improved income. The uniformity of materials, the improvement of economic benefits, and the effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

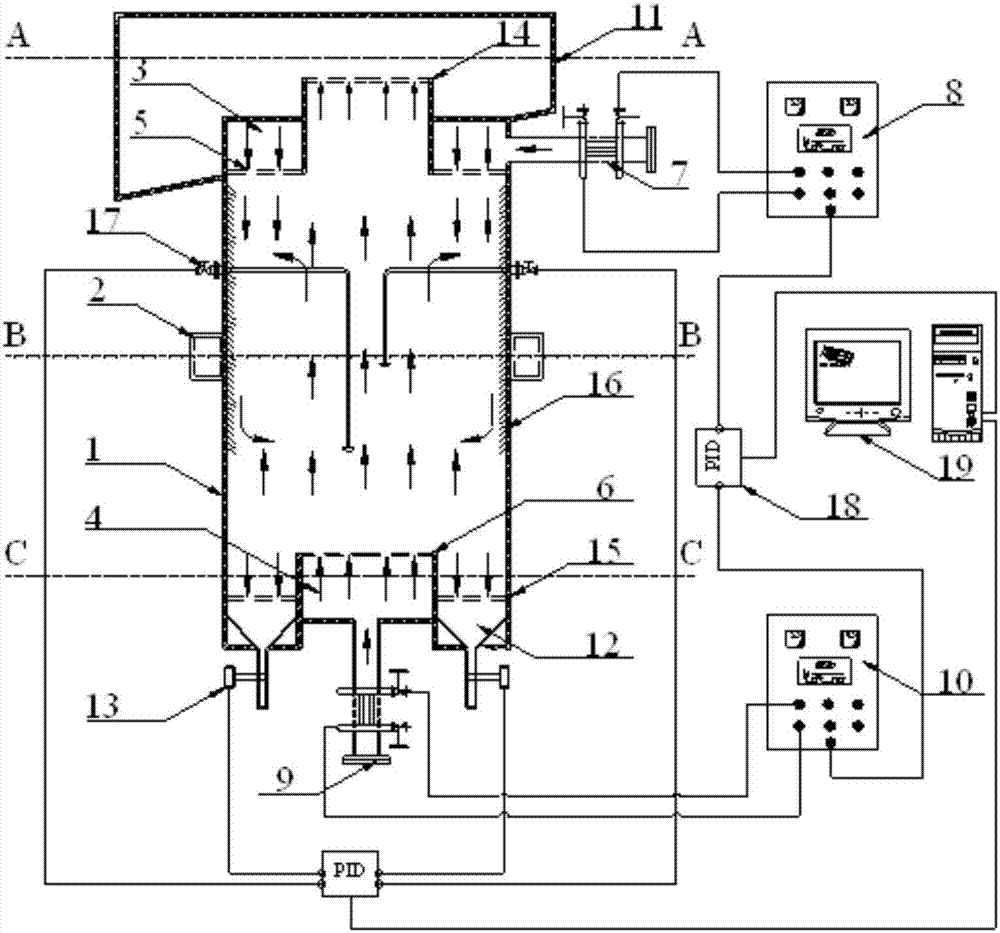

[0043] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

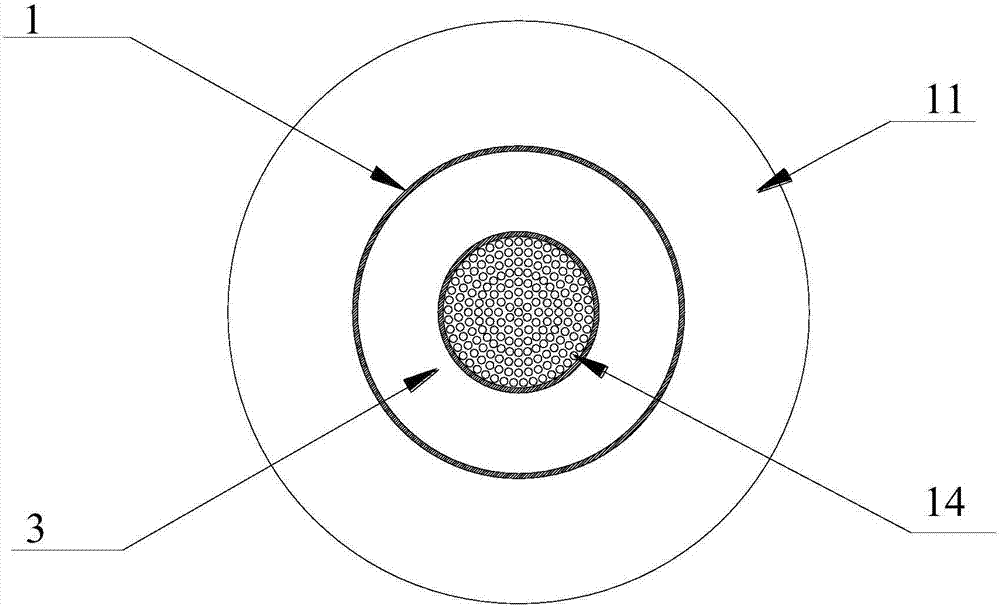

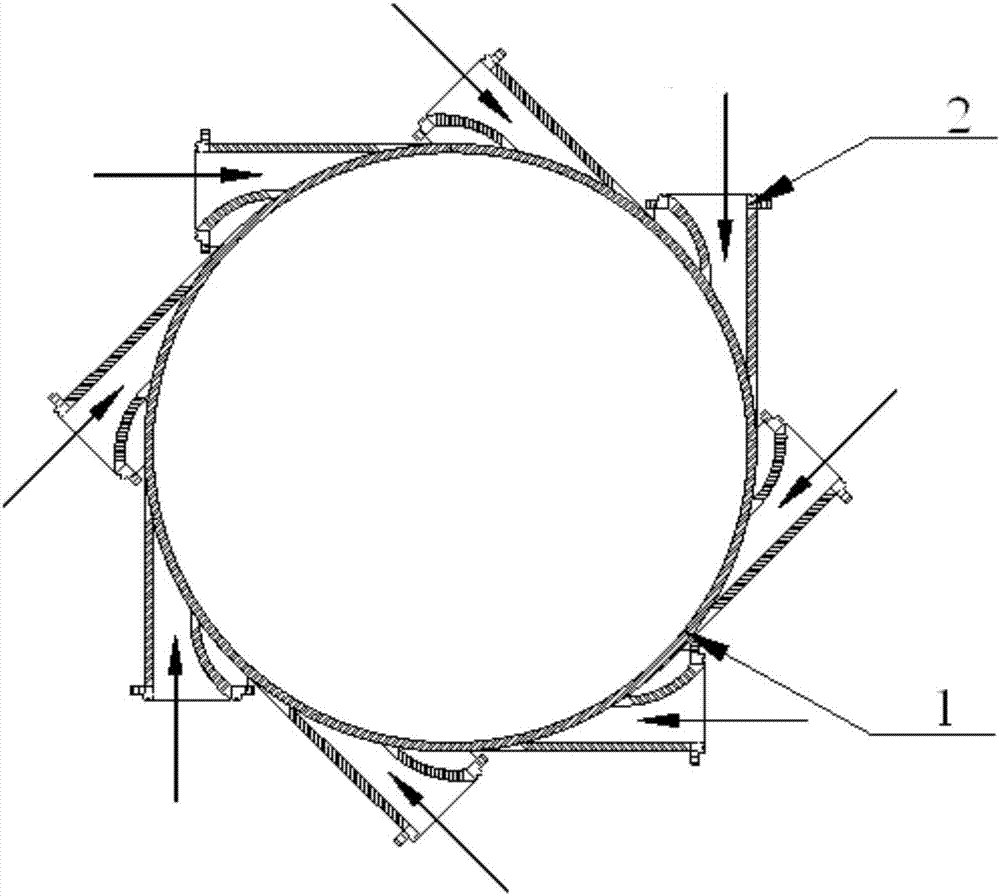

[0044] A coarse coal slime column type separation device, such as figure 1 As shown, it mainly includes fluidized bed column 1, ring cylinder feeder 2, top water supply buffer tank 3, bottom water supply buffer tank 4, top water supply steady flow plate 5, bottom water supply steady flow plate 6, top water supply device 7 , top water supply frequency conversion controller 8, bottom water supply device 9, bottom water supply frequency conversion controller 10, floating object overflow tank 11, sinking object discharge tank 12, underflow flow control valve 13, overflow steady flow plate 14, underflow steady flow Plate 15, inclined blades 16 around the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com