Patents

Literature

46results about How to "Improve feeding uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

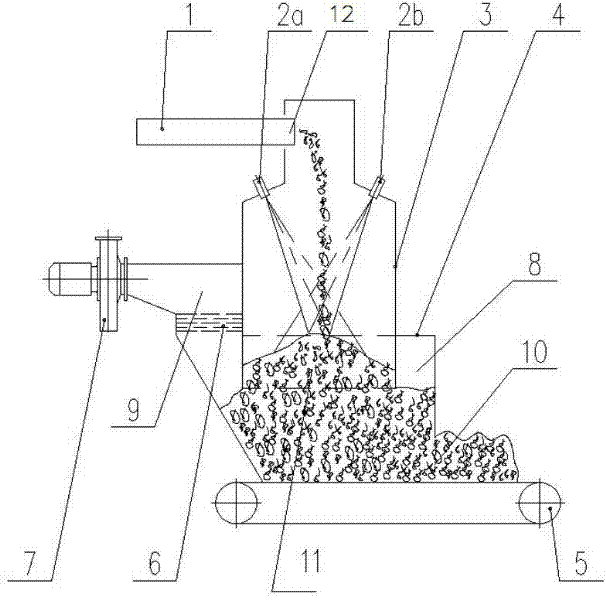

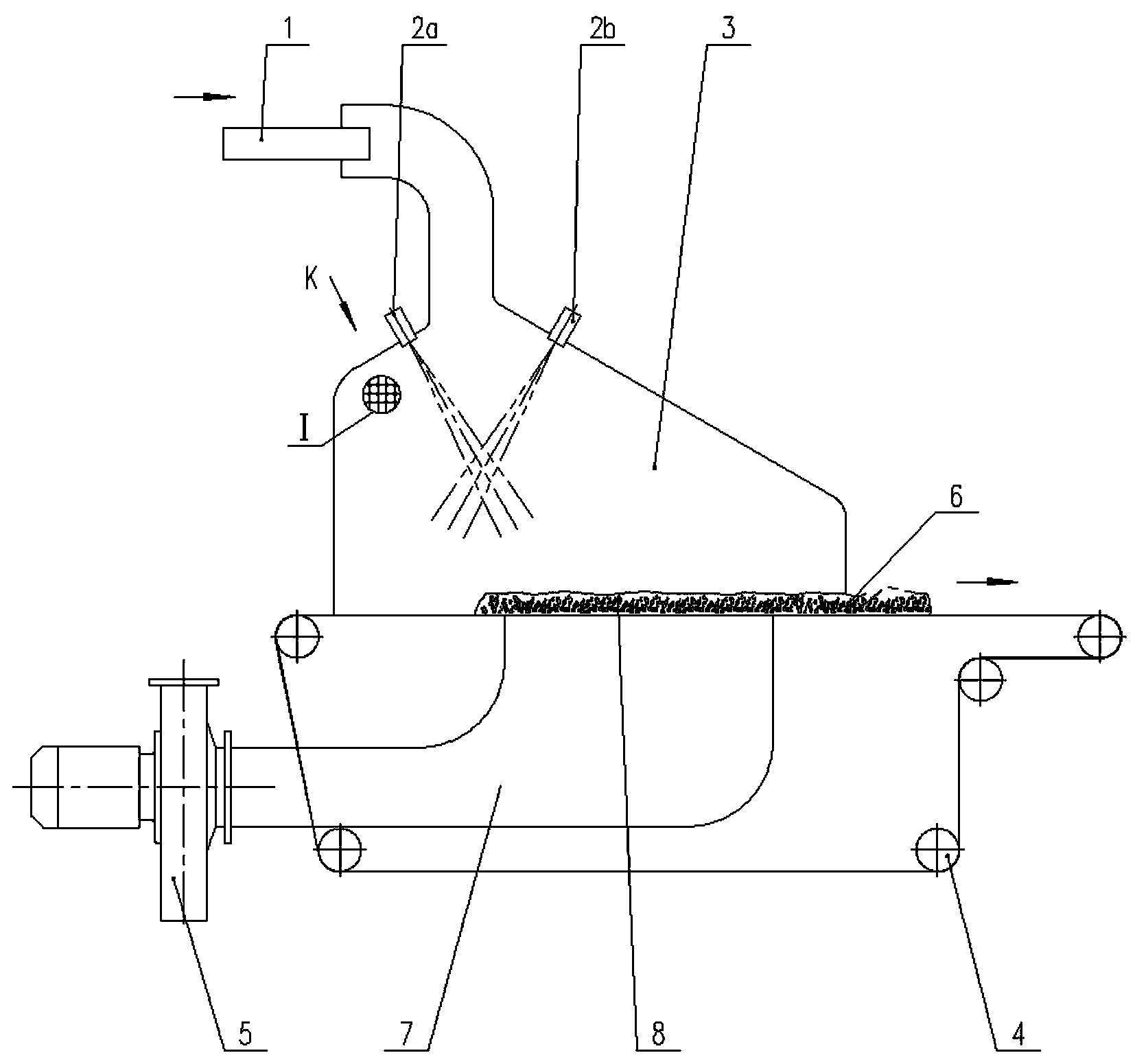

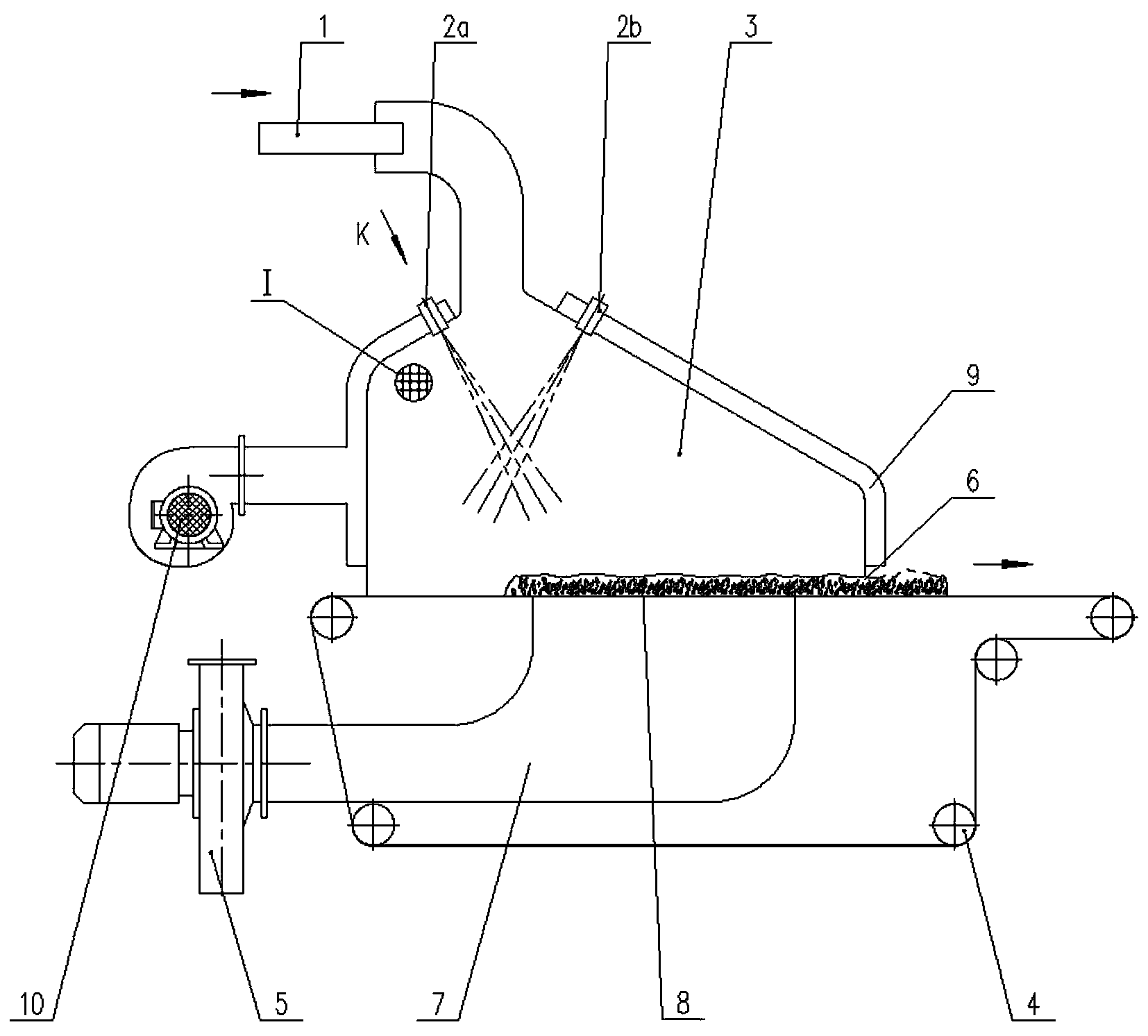

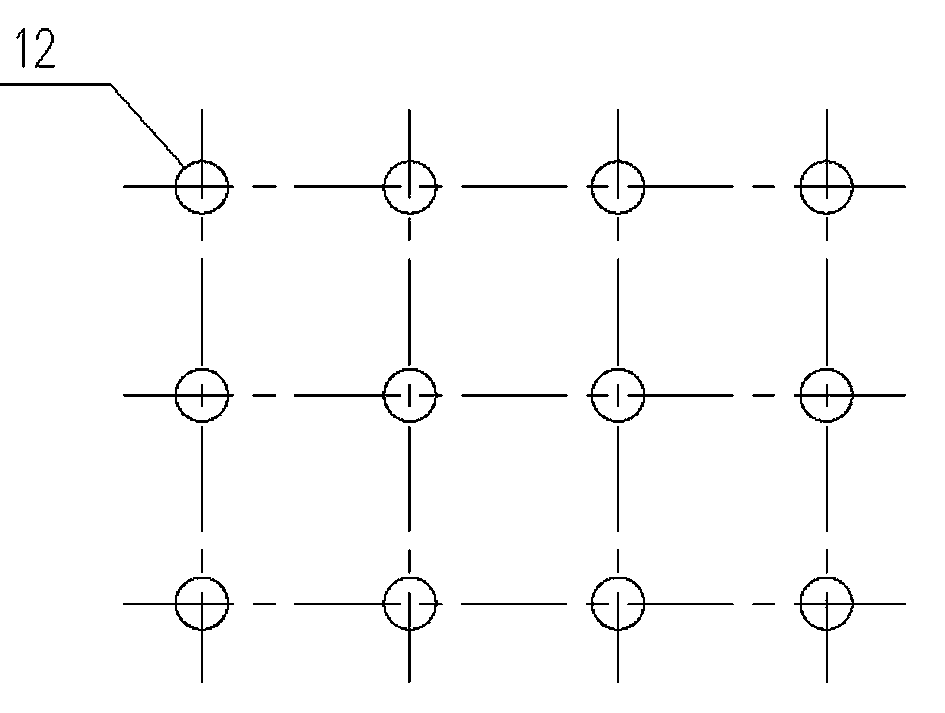

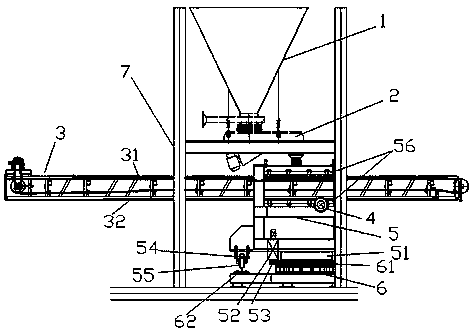

Material and flavor adding method and device capable of reducing liquid loss

The invention relates to a material and flavor adding method and a device capable of reducing liquid losses. Atomized liquid is sprayed to materials in a mixing chamber (3). Negative-pressure air is applied to suck atomized liquid particles which do not adhere to the materials and are suspended above a material layer to enable the atomized liquid particles to penetrate through the material layer, to be filtered and to be absorbed. The device comprises the mixing chamber (3) which is used for applying the liquid to the materials, a feeding device (1) which is arranged at the upper end of the mixing chamber (3) and leads to a feed inlet (12), and a discharge hopper (4) which is arranged below the mixing chamber (3). The lower end with a bottom outlet of the mixing chamber (3) partially stretches into the discharge hopper (4) to form a negative-pressure cavity (8). The negative-pressure cavity (8) is communicated with a negative-pressure device (7) through an air duct (9). A spray nozzle (2a) is arranged at the upper part of the mixing chamber (3) at a position above the feed inlet (12). A discharge outlet (10) is arranged at the bottom of the discharge hopper (4). By adopting the material and flavor adding method and the device capable of reducing liquid losses, the content of residual liquid in waste gas exhausted from the mixing chamber can be reduced to the utmost extent. The material and flavor adding method and the device capable of reducing liquid losses have the characteristics of low liquid losses, good added material evenness, high material adding accuracy and the like.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

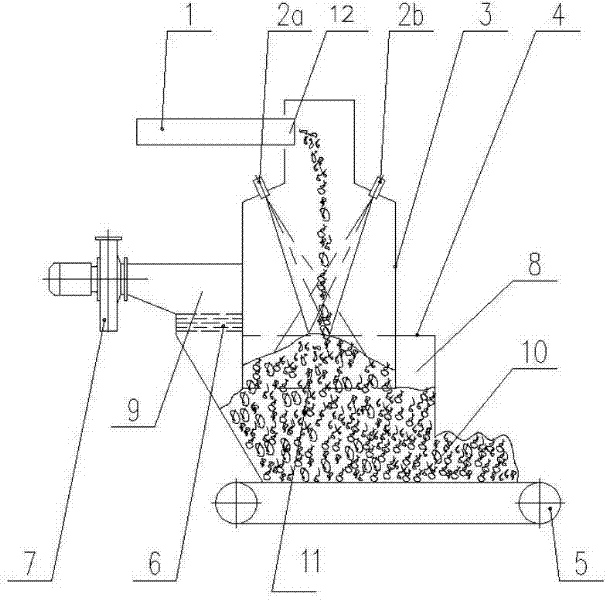

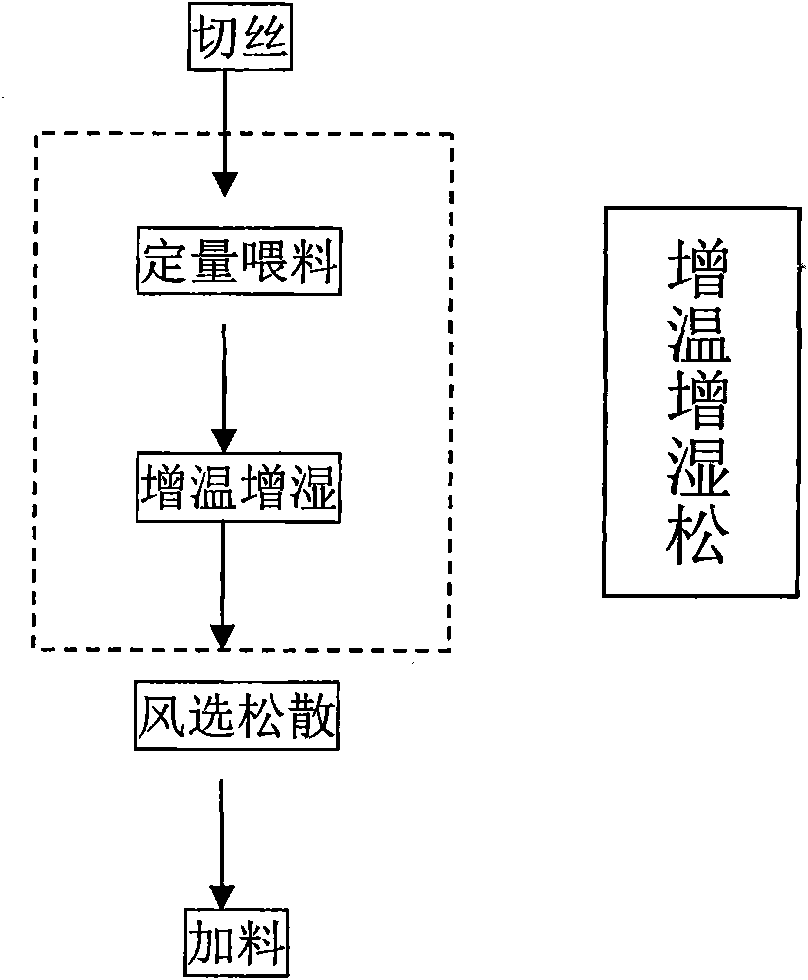

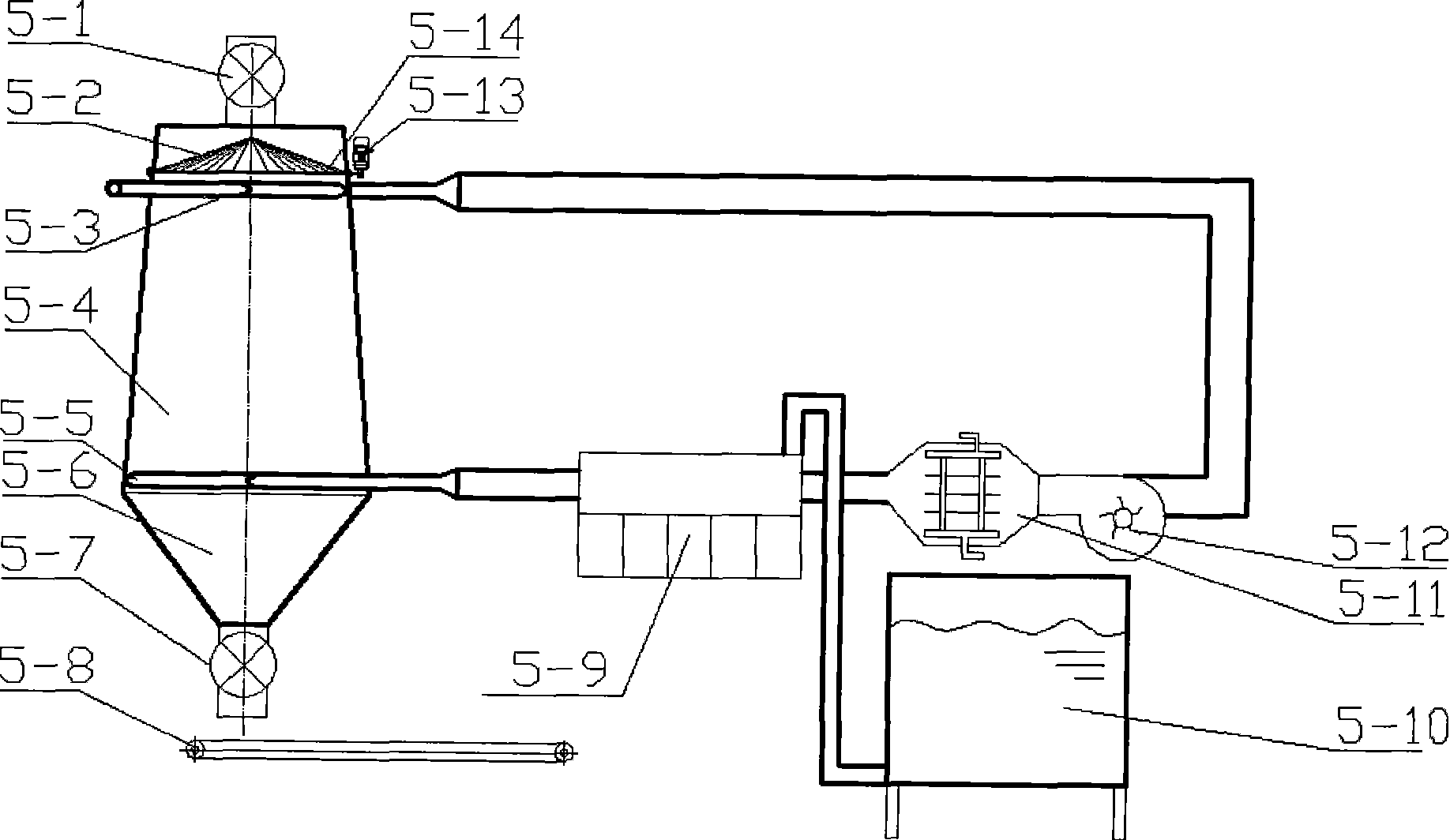

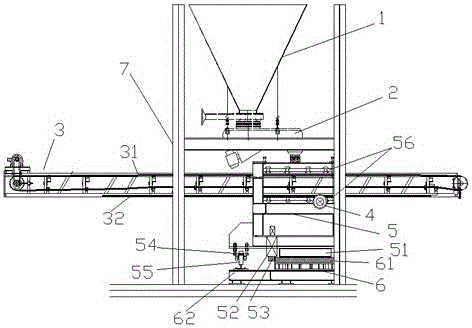

Leaf thread material feeding process and equipment

ActiveCN101773279AReduce sticking and drawingLoosely fullTobacco preparationTobacco treatmentVulcanizationMaterial scattering

The invention relates to a leaf thread material feeding process and equipment, which belong to the technical field of tobacco processing. The invention is characterized in that the leaf thread feeding process sequentially comprises the working procedures of thread cutting, temperature increasing and humidifying loosening, air separation loosening and material feeding. The equipment applicable to the process comprises a thread cutting machine, a quantitative material feeding machine, a vibration vulcanization bed, an air separation loosening device and a vertical material feeding machine which are sequentially ranged, wherein each equipment is connected through material conveying mechanisms, the vertical material feeding machine comprises a material feeding cavity, a material inlet airlock and a material outlet airlock are respectively arranged on the top and the bottom of the material feeding cavity, a material scattering mechanism is fixed on the upper part of the material feeding cavity, a material liquid atomizing system is communicated with the material feeding cavity through an air inlet pipe and a air return pipe of a hot air circulation system, and a sealed cyclic feeding system is formed. The process and the equipment can solve the problems of large thread cutting pulverization products of low-water-content tobacco flakes and material feeding aggregation of tobacco threads, the material liquid atomizing effect is good, the material liquid absorption velocity by the tobacco threads is high, the material feeding uniformity and the effectiveness are improved, in addition, the material storing time after the material feeding is shortened, and the production efficiency is high.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

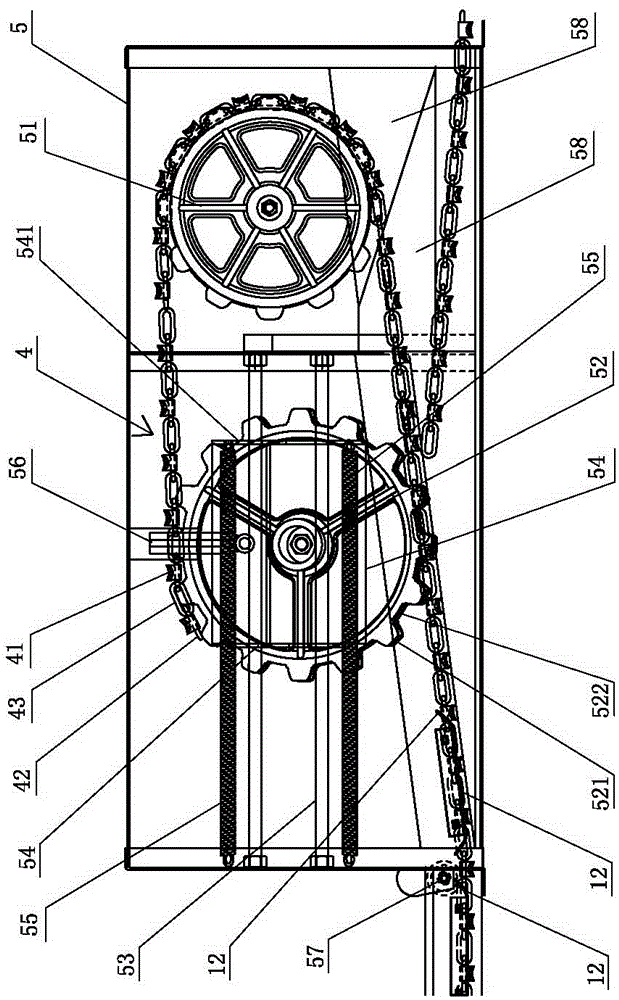

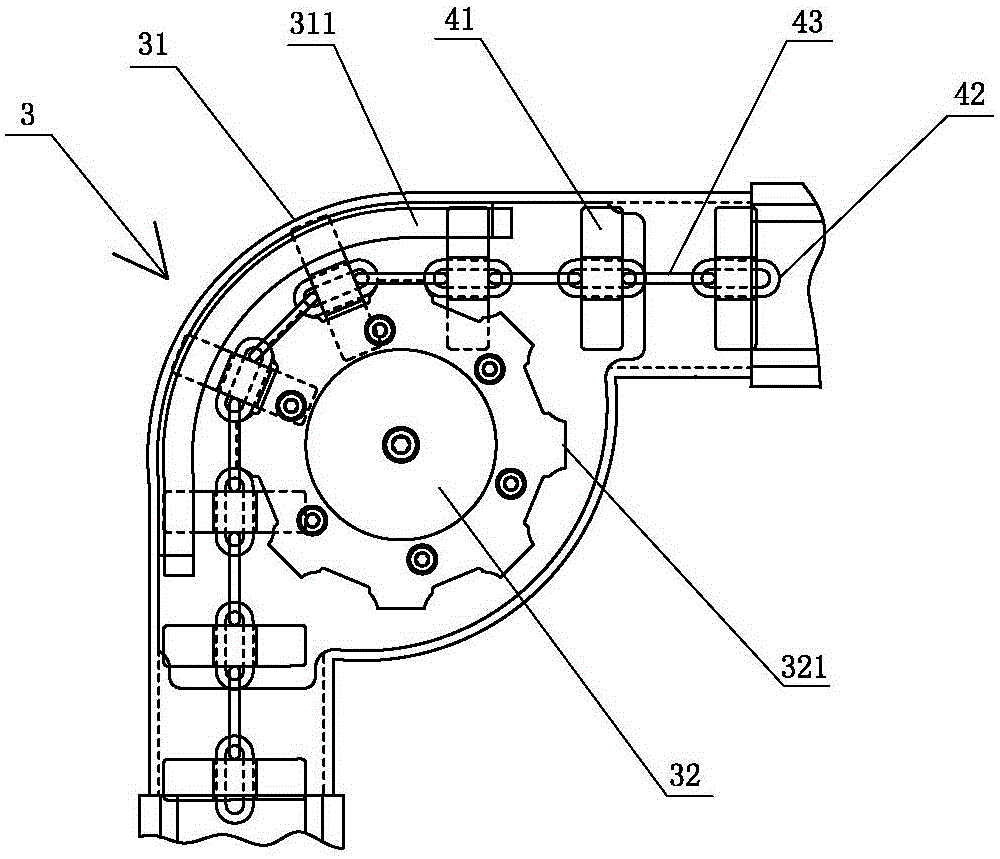

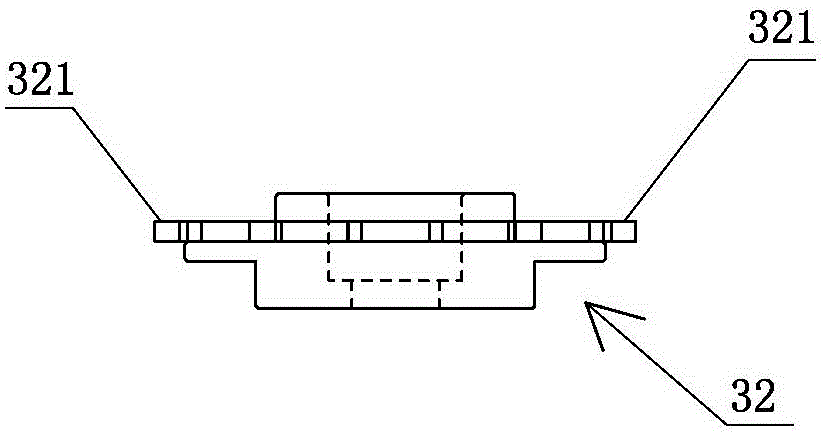

Rapid delivery poultry feeding machine

PendingCN105123559AIncrease delivery speedImprove feeding uniformityAviculturePoultry farmerEngineering

A rapid delivery poultry feeding machine includes a feeding tank, corner devices located in the corners of the feeding tank, a delivery chain operating in the feeding tank and provided with scraping plates, and a driving box driving the delivery chain to operate, wherein the delivery chain is formed by mutual fastening of horizontal chain clasps and vertical chain clasps which are arranged alternately; the upper part of the scraping plate is fixedly connected to the horizontal chain clasp, and the bottom of the scraping plate is tightly attached to the bottom surface of the feeding tank to operate; each corner device includes a corner housing and a corner tooth disc; the driving box is provided with a drive tooth disc, a driven tooth disc, and a tension device therein, wherein the tension device can tension the delivery chain to allow the delivery chain to normally operate. The rapid delivery poultry feeding machine has the advantages that the scraping plates match with the feeding tank, the operation is smooth, and the chain is not blocked; because convex teeth of the corner tooth disc abut against the vertical chain clasp, the chain cannot be stuck, and the operation is not affected; the operation speed is greatly improved, the delivery speed of fodder is improved, the feeding error of poultry is shortened, the uniformity of poultry farming is improved, and the delivery speed is improved by greater than one time when compared with the prior art.

Owner:QINGDAO MEICHAO MACHINERY

Crushing-screening integrated sorter

ActiveCN102716792AEasy to replaceImprove operational efficiencySievingScreeningOperation modeEngineering

The invention discloses a crushing-screening integrated sorter, the sorter comprises a cylinder body capable of rotating in an axial direction, an unit copy plate is provided on an internal surface of the cylinder body, the cylinder body is successively connected with a crushing cylinder, a screening cylinder and a discharging cylinder from left to right; a stirring and crushing shaft capable of operating in a rotary mode is arranged in an axial direction in an inner cavity of the cylinder body; a spray pipe body possessing a flushing function is arranged in the axial direction in the screening cylinder; an unit screening hole capable of externally leaking the screened matters is arranged on the circumferential wall surface of the screening cylinder; a technology flow of first crushing and then screening by water is employed, the technology has the advantages of reasonable design, complete screening and good effect; the rotary operation mode enables stable feeding and discharging operation, the uniformity of the discharged material is good; the rolling support wheels are symmetrically arranged at the lower side of the integrated cylinder body, the stable operation of the rotation of the cylinder body can be realized, and the reliability of the operation process can be guaranteed; a dual crushing technology of the cylinder body inner wall and the intermediate stirring crushing shaft are used, and the crushing effect is good and the crushing speed is fast.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

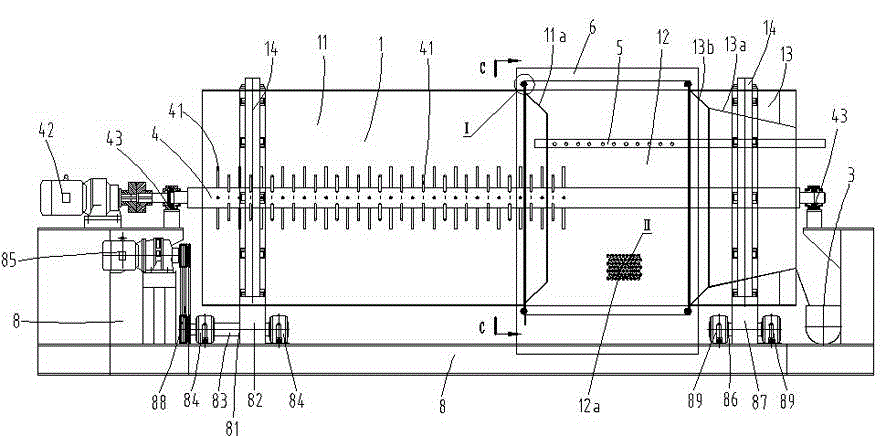

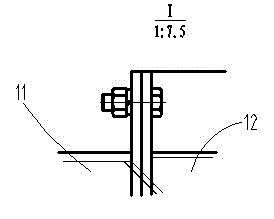

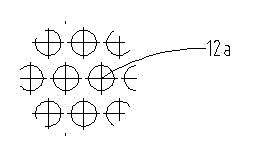

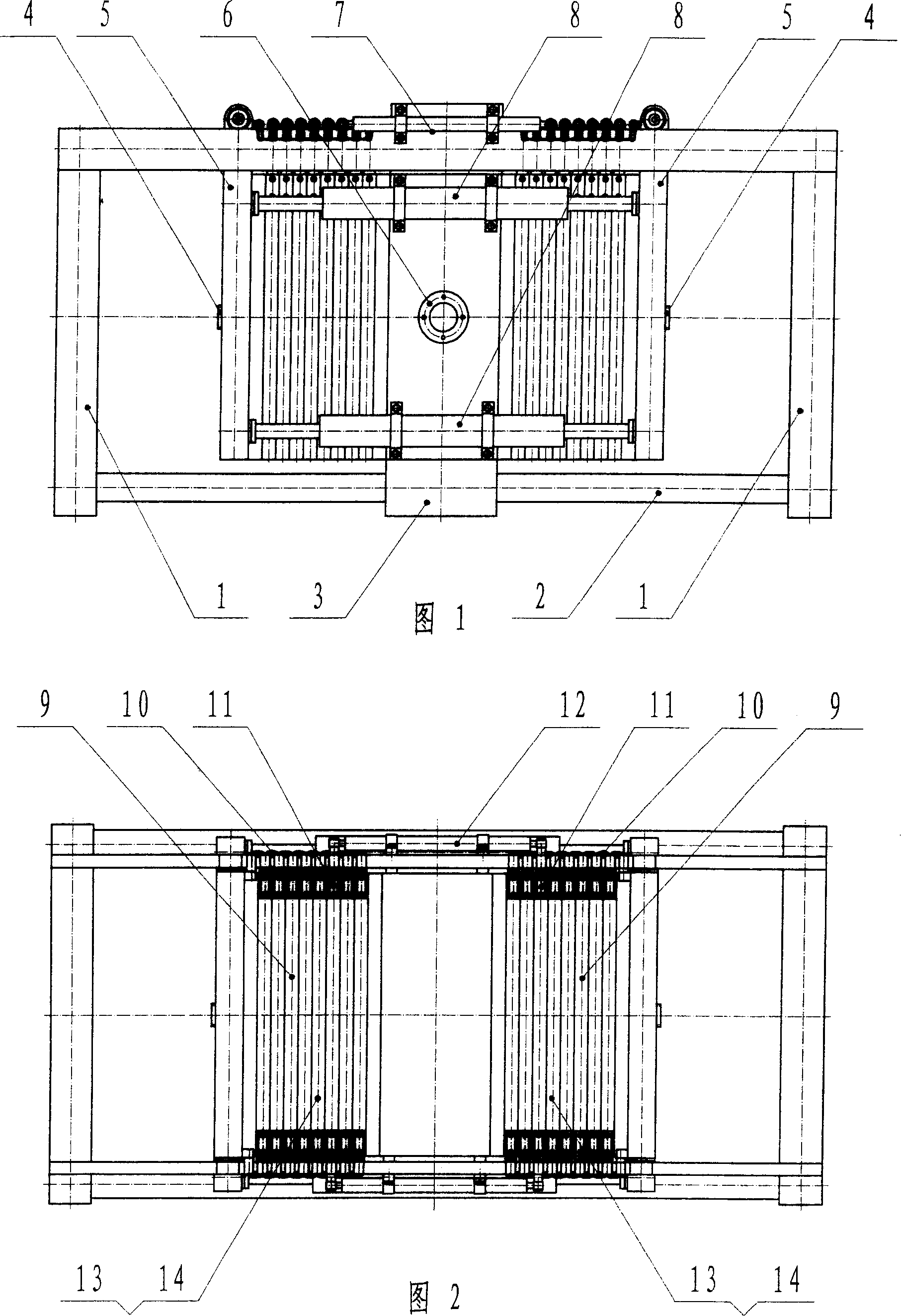

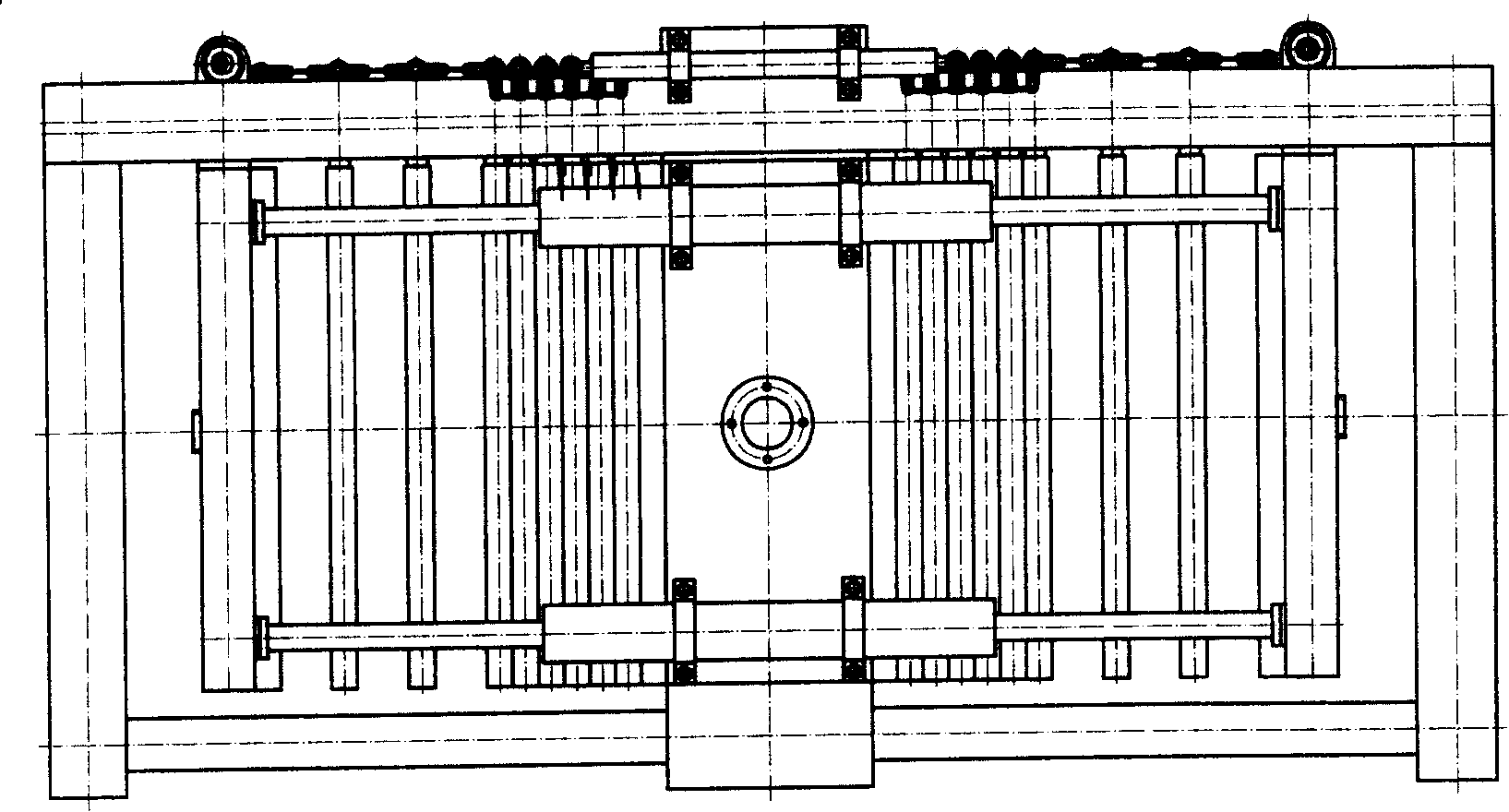

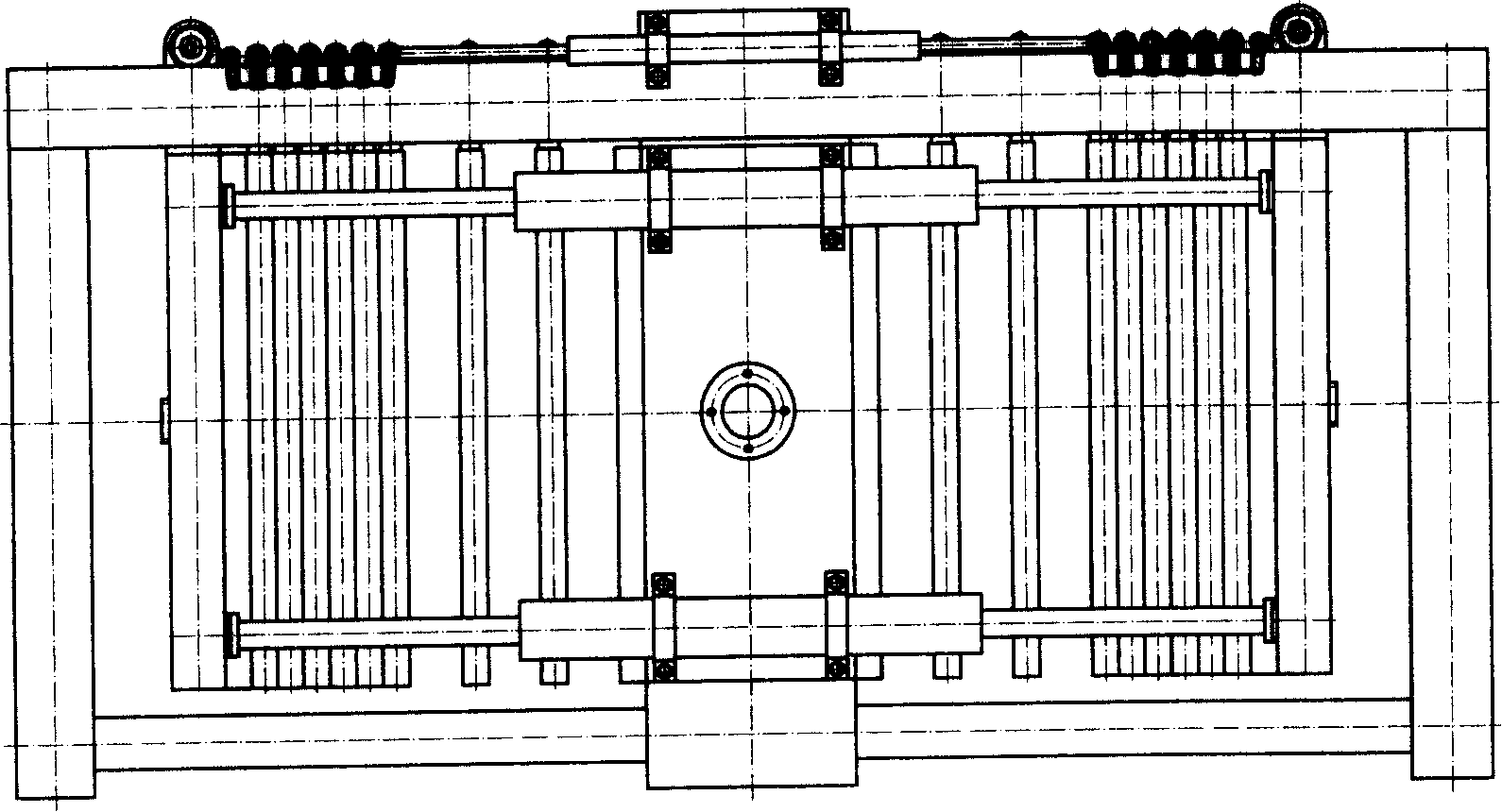

Rapid pressure filter

InactiveCN101172205AImprove stress conditionImprove reliabilityFiltration separationHydraulic cylinderEngineering

A fast filter press, which is composed of two end brackets, a middle plate, two top beams and two bottom beams connected by bolts to form a frame structure frame symmetrical to the middle plate, and the two sides of the middle plate are arranged symmetrically in sequence Filter unit and compression plate, all the filter plates in each filter unit are divided into three groups with the same number of filter plates with the connecting filter plate and the middle filter plate as the boundary, the filter plates and the filter plate and the compression plate are connected by hinges, The tensioning device and the pulling plate device composed of double-piston rod hydraulic cylinders are installed in the middle of the frame, and the piston rods at both ends of the respective hydraulic cylinders are respectively hinged with the compression plate and the connecting filter plate; the machine adopts symmetrical tension and compression The tensioning method of the plate presses the filter unit, the filter plate is divided into groups three times to unload and unload, and the two ends move and the middle is fixed. The problem of low efficiency and poor reliability caused by the inherent defects in the structural design of the machine.

Owner:王智民

Uniform feeding device with vibrating screen

InactiveCN102700929AIncrease profitImprove screening efficiencySievingScreeningEngineeringBelt machine

The invention relates to a uniform feeding device with a vibrating screen. The uniform feeding device comprises a belt machine, material spreading nets, an unloader, a platform, the vibrating screen and a material separating chute, wherein the material spreading nets are fixed to both sides of the belt machine; the unloader is arranged on the surface of the belt machine; the platform is positioned right above the belt machine; and the material separating chute is positioned right blow the material spreading nets and is fixedly connected with the platform. According to the uniform feeding device, the feeding uniformity of vibrating screen fed materials on the screen surface of the feed end and the utilization rate of the whole screen net are greatly improved. The uniform feeding device is particularly suitable for deeply screening sticky wet materials by a fine fraction dry method, improves the screening efficiency of the wet materials, solves the problem of deflection of fed materials, cleans soft sundries and has an obvious effect of improving the processing capability.

Owner:李大山

Anti-sticking and anti-dropping charging and flavoring device

ActiveCN104068461AReduce the amount of viscous liquidReduce the amount of sticky materialTobacco preparationEngineeringUtilization rate

Disclosed is an anti-sticking and anti-dropping charging and flavoring device. The anti-sticking and anti-dropping charging and flavoring device comprises a charging cavity, the top of the charging cavity is provided with a feeding conveyer belt, and a feeding device is arranged at the inlet of the feeding conveyer belt; a conveying device is arranged under the charging cavity and is a mesh conveyer and a porous belt conveyer, and the conveying device comprises a conveying platform, a negative pressure cavity is arranged under the conveying platform, and the wall of the negative pressure cavity is provided with a negative pressure device; the wall of the charging cavity is provided with a jet nozzle, and the circumference of the jet nozzle is provided with air holes. The anti-sticking and anti-dropping charging and flavoring device is simple in structure, practically in function, low in liquid material losses, low in tobacco absorption, good in charging uniformity and high in liquid material utilization rate.

Owner:CHINA TOBACCO HENAN IND +1

Method for preparing products of silk-shaped tobacco stalks

ActiveCN101720975AImprove inner qualityIncrease fill valueTobacco treatmentWater contentPre treatment

The invention provides a method for preparing products of silk-shaped tobacco stalks. The method is characterized by mainly comprising the following steps: 1) pre-treating the tobacco stalks; 2) the primary defibrination of the pre-treated tobacco stalks to make the water content of the tobacco stalks reach 30 to 60 percent; 3) twisting the tobacco stalks undergoing the primary defibrination into cut stems, of which the width is 1.2 to 2.0mm and the length is 2.0 to 30.0mm; and 4) drying the twisted cut stems until the water content of the cut stems reaches 10 to 13 percent, and perfuming the cut stems by process. In the method, an input-output ratio in actual production is high, and the prepared cut stems do not retain bad aftertaste after being smoked, so that the intrinsic quality is improved; the fill value is high, and the feeding uniformity is good; the colors and shapes of the products of silk-shaped tobacco stalks of the invention are close to the cut tobacco, the distribution of the products of the invention in cigarettes is more uniform than that of the conventional cut stems and tobacco stalk particles, and the rolling performance of the cut stems are improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

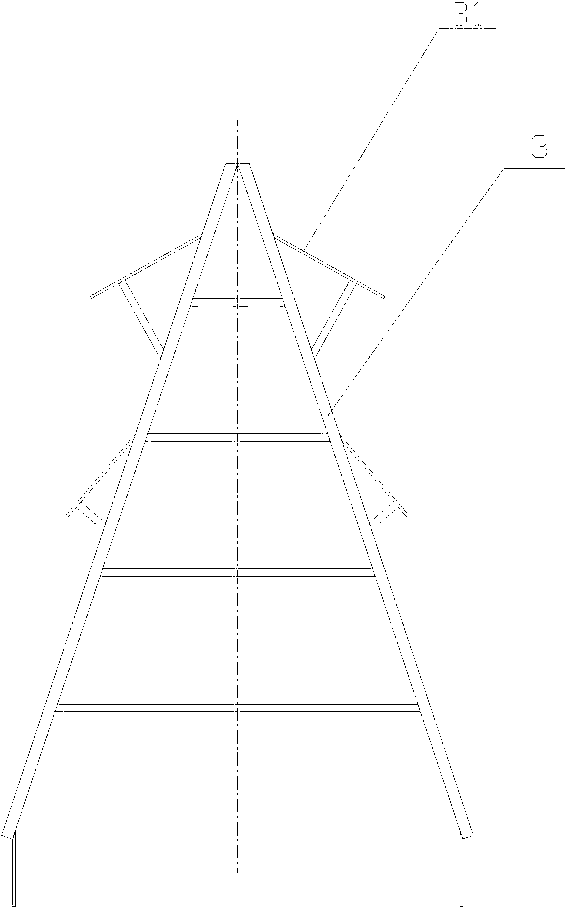

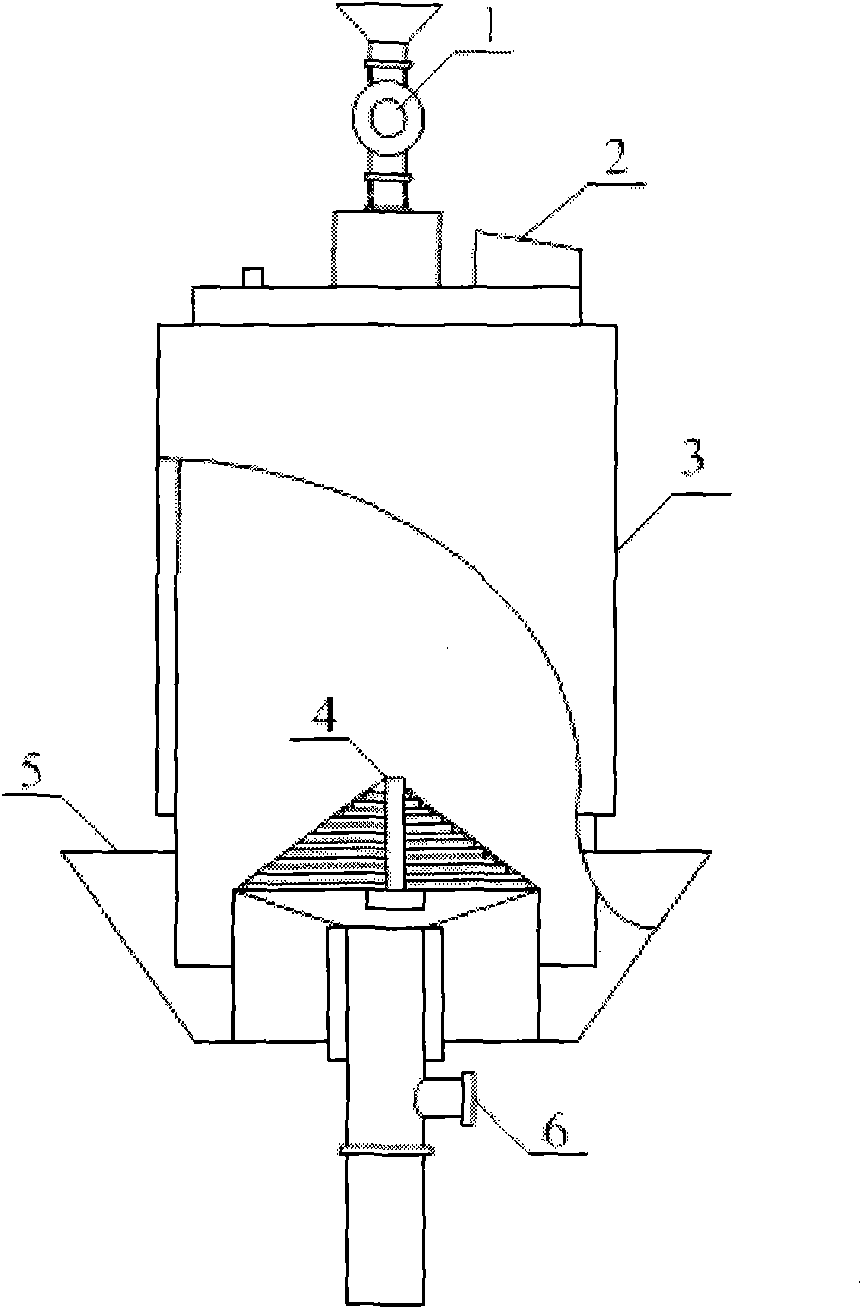

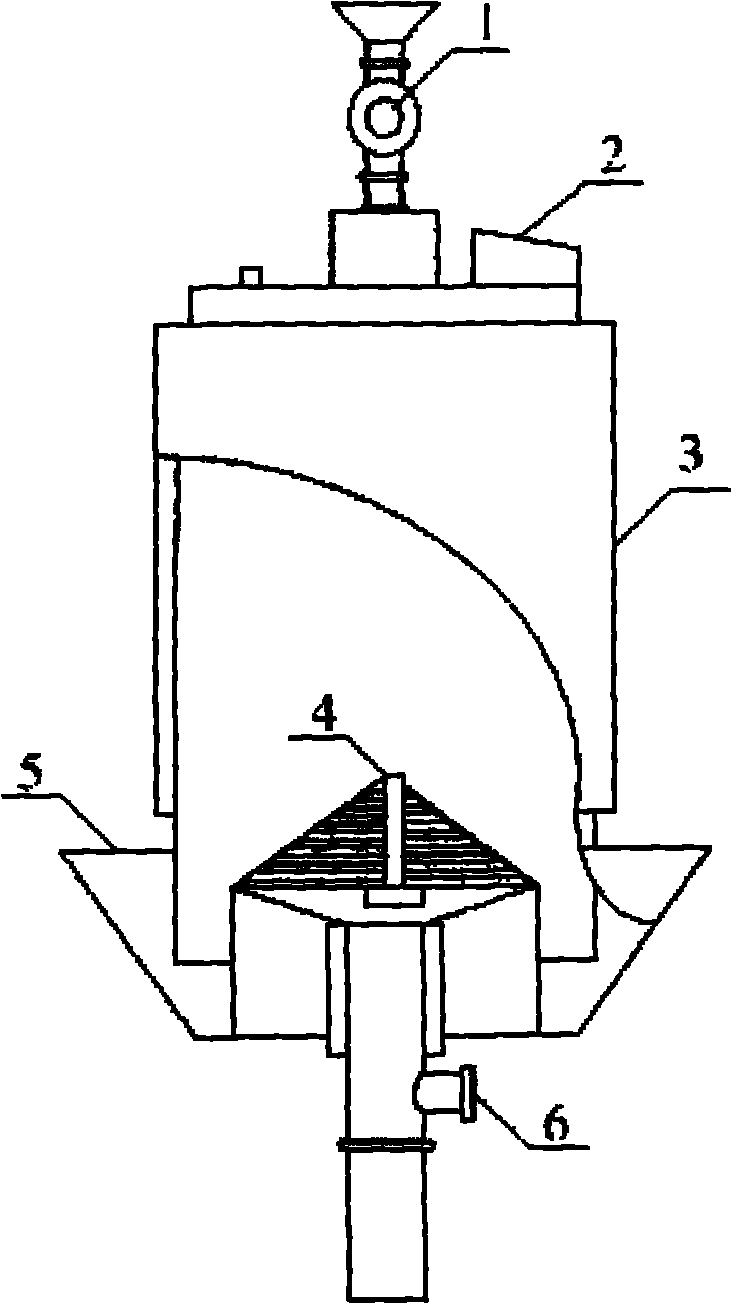

Large-scale fixed bed biomass gasification furnace and production process of gas with low oxygen content

InactiveCN101892084AOverall high thermal efficiencyImprove gasification efficiencyFixed-bed gasificationBriquetteCorrosion

The invention discloses a biomass (especially briquette straw) gasification furnace, in particular a fixed bed gasification furnace with an anticorrosion liner which can effectively prevent corrosion of alkali metals on the furnace wall. The gasification furnace comprises a charging device (1), a gas discharge port (2), a furnace body (3), a grate (4), a dust discharge port (5), an air inlet (6) and the like. The raw material is continuously added from the upper part and moves downwards under the action of gravitation to form a stable reduction layer (completely reacts with oxygen in air), and slag is discharged from the bottom; and air enters from the lower part, and gas is discharged from the upper part. The inner diameter of the gasification furnace is 3 m, the height is more than 3 m, and the gasification intensity is at least 100 m<3> / (m<2>h). The carbon conversion rate of the gasification furnace can reach 95%, and the oxygen content of gas can be below 0.6%. The invention has the advantages of high production capacity, long operating cycle and good gas quality, and can be used for combustion or power generation.

Owner:EAST CHINA UNIV OF SCI & TECH +2

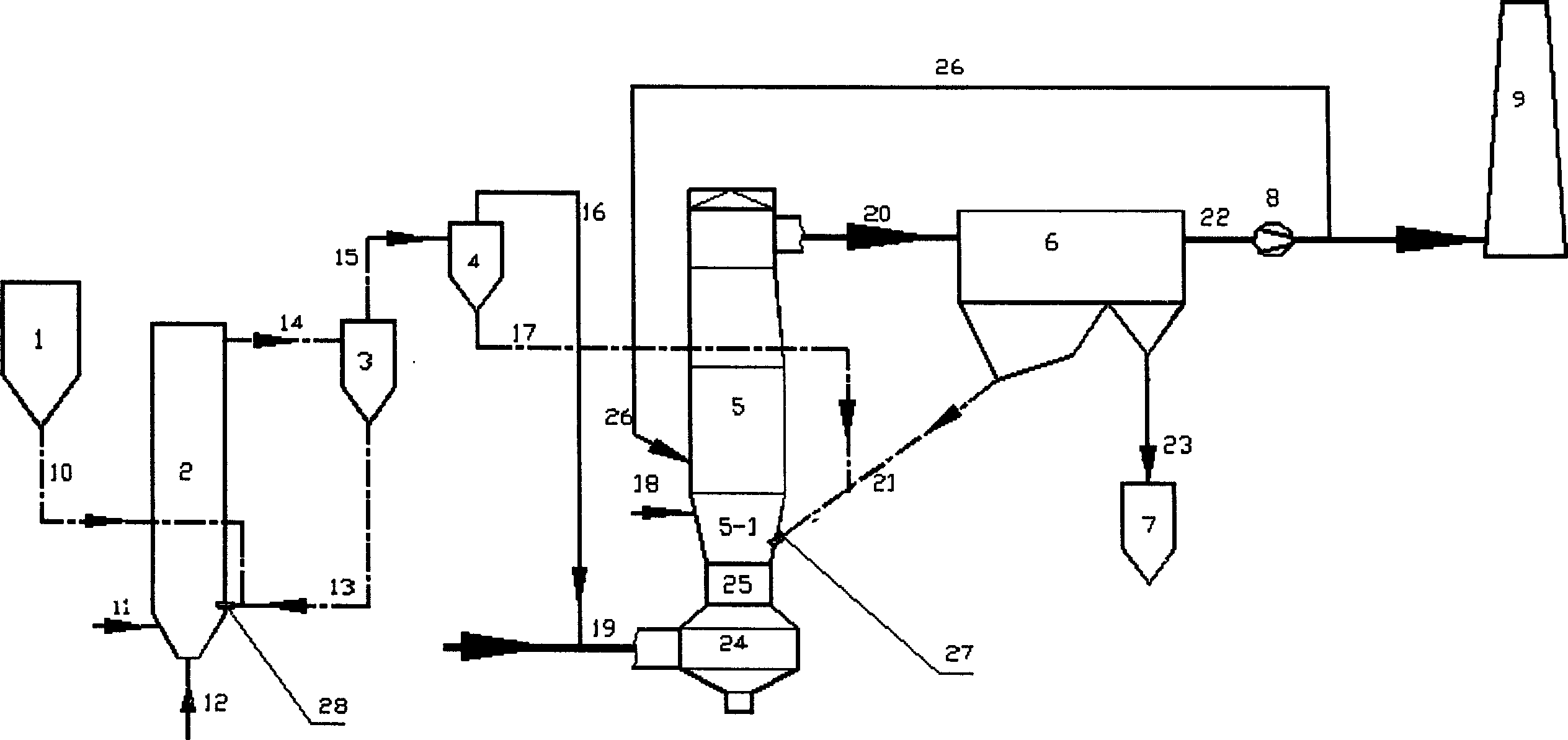

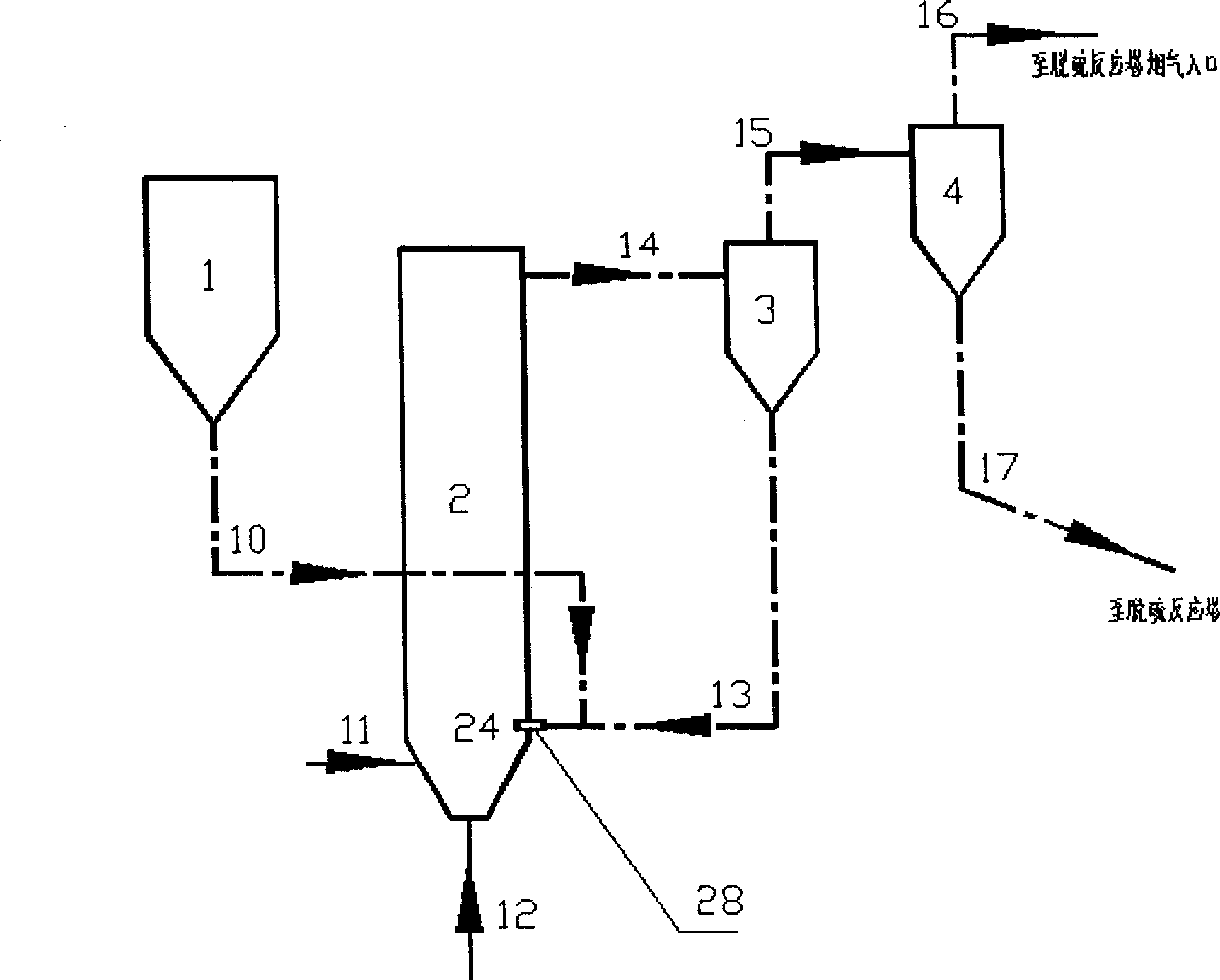

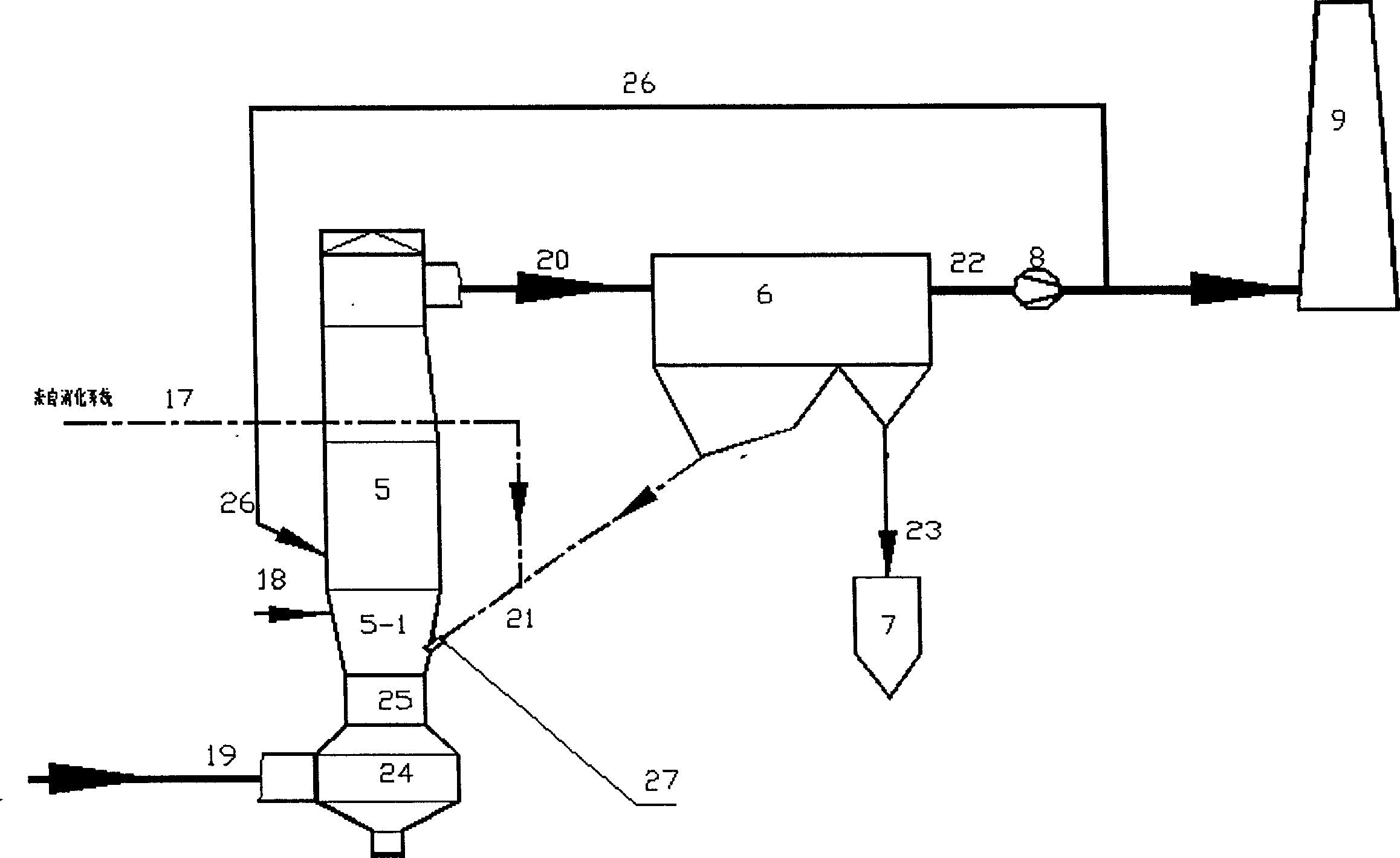

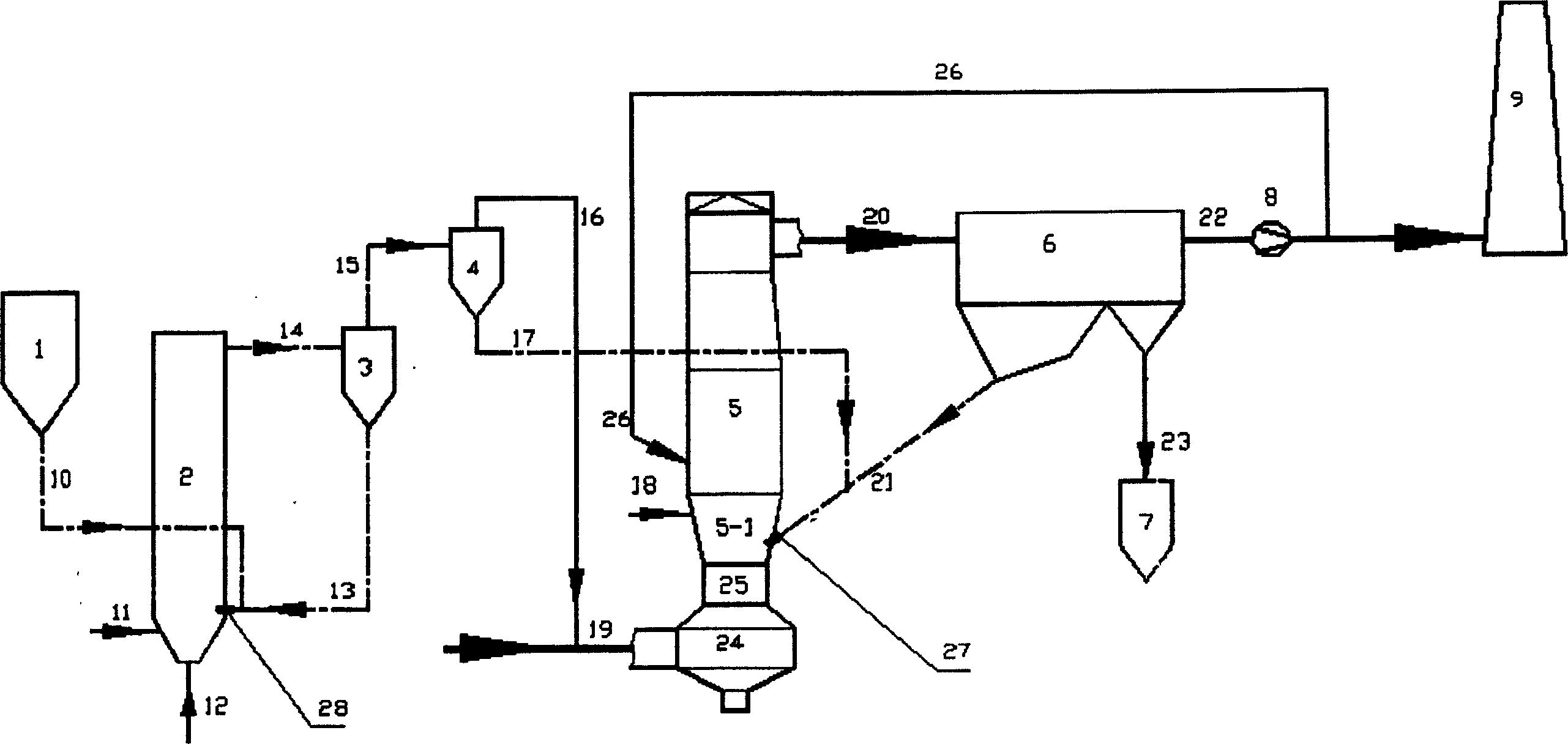

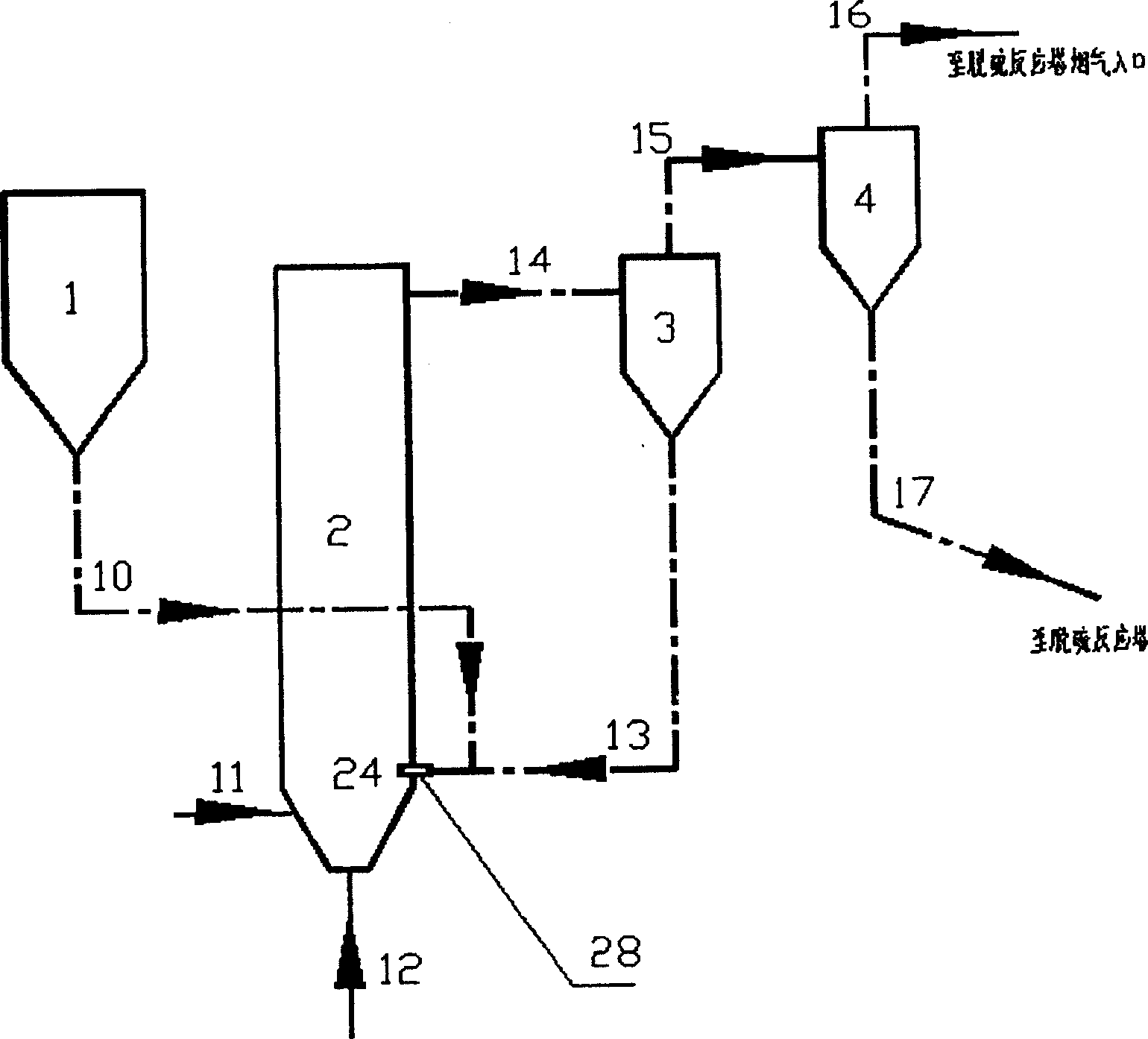

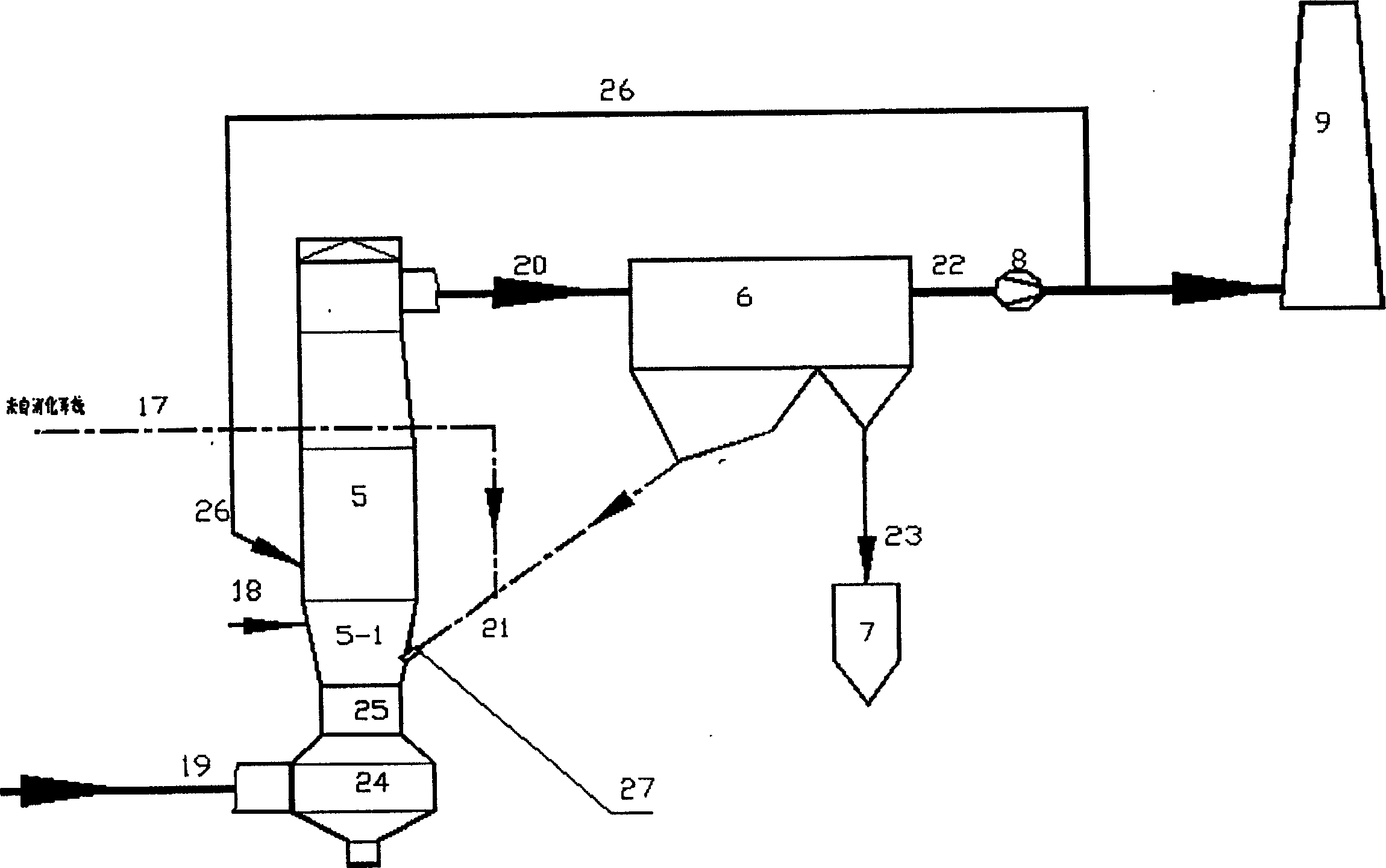

Circulation fluidized dry flue gas desulfurizing process by adopting mixed feeding mode

InactiveCN1515348AImprove space utilizationImprove desulfurization efficiencyDispersed particle separationChemical reactionFlue gas

The present invention discloses a circulating fluidized dry flue gas desulfurizing process adopting mixed feeding mode. It combines the fresh feeding modes of desulfurization reaction system and digestion reaction system with respective recirculating feeding back mode, i.e. adopts a mixed feeding mode to mix the initial feeding material and system circulating material to feed them into reaction tower, and at the position of mixed feeding hole a diffusion fan is placed so as to ensure the dispersed uniformity of the material in the reaction tower and can meet the concentration distributing characteristics required for desulfurization chemical reaction to raise reaction tower space utilization rate and raise the desulfurization or digestion efficiency.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

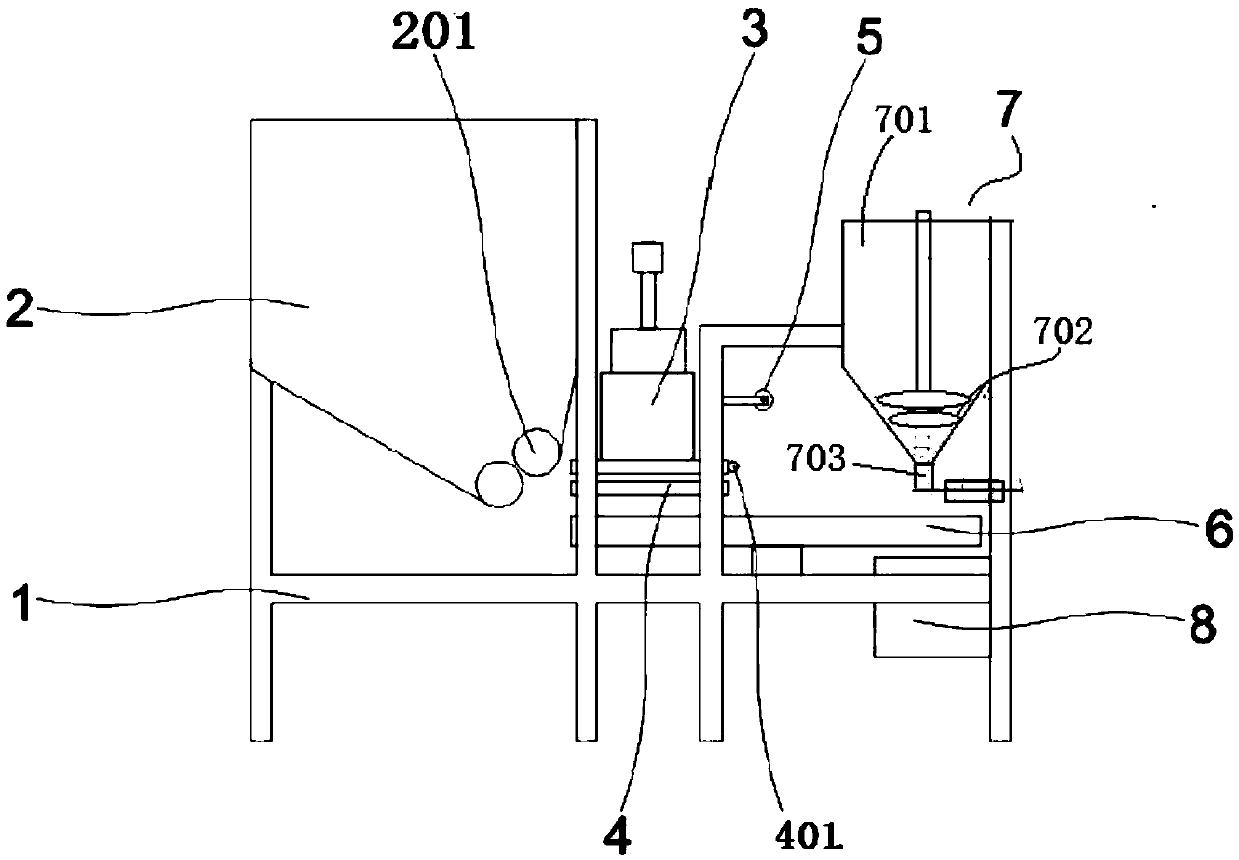

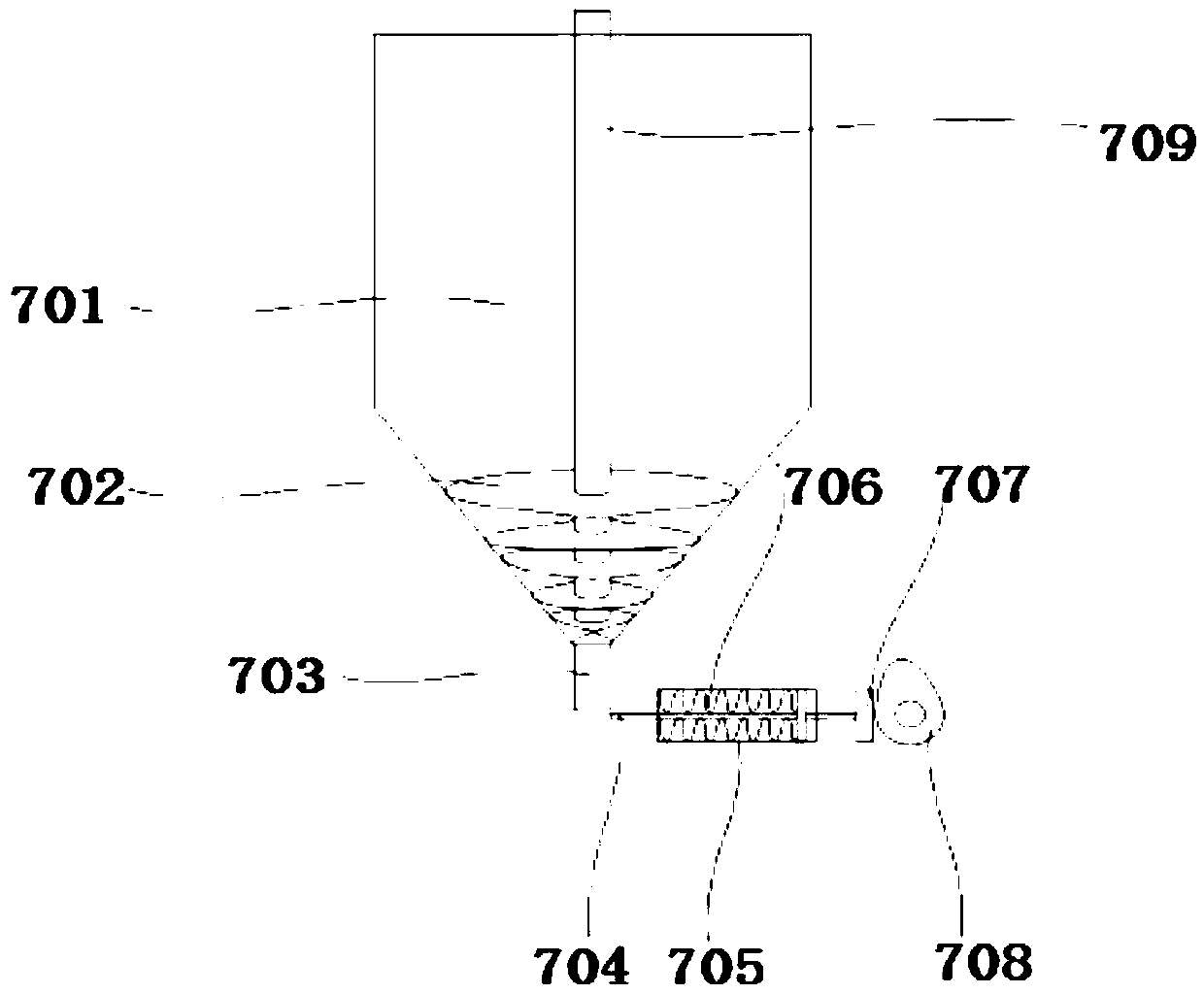

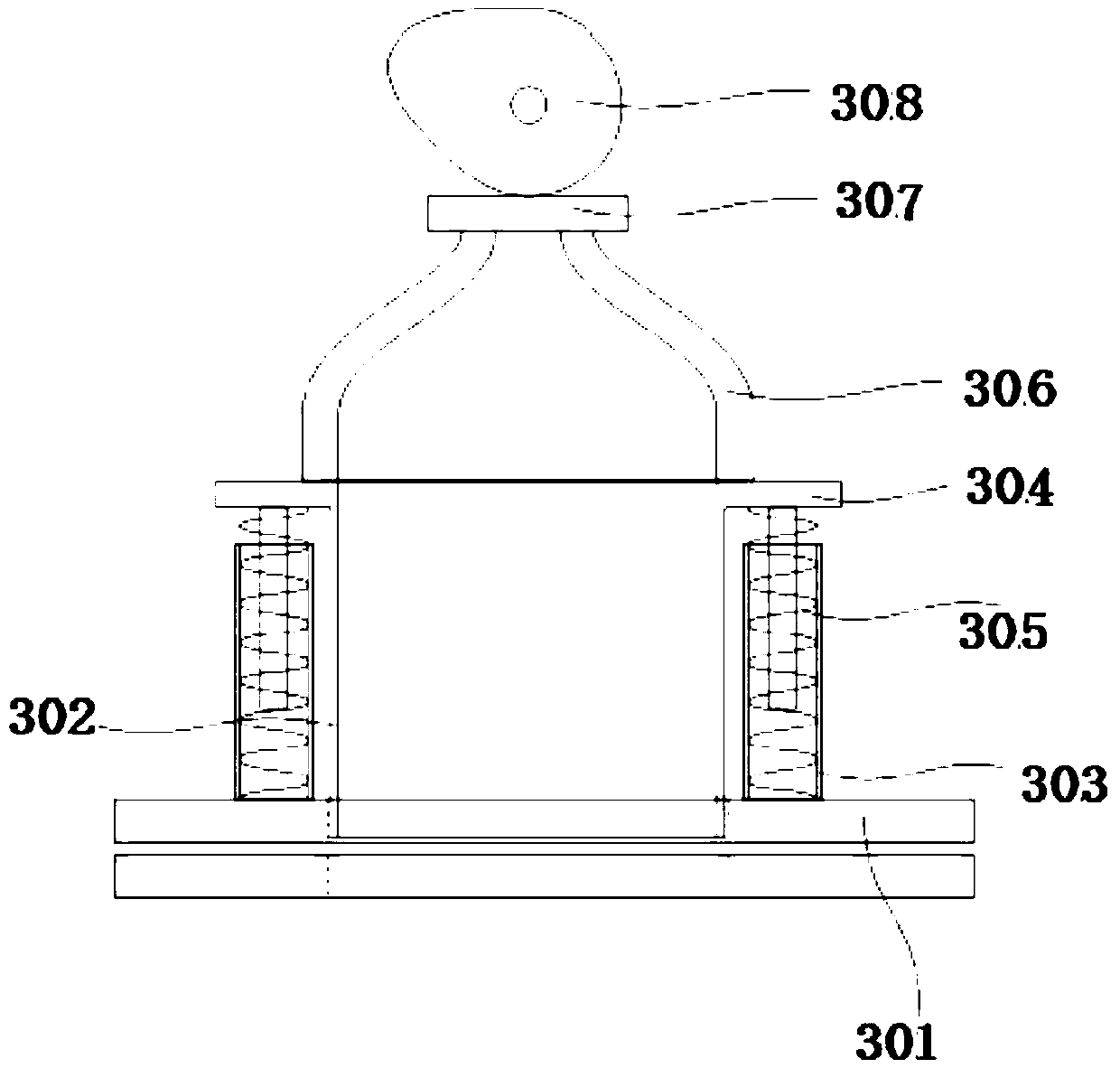

Automatic-stuffing-supply wonton producing device

InactiveCN105494505AReasonable designSimple structureDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusMechanical engineeringEngineering

The invention relates to an automatic-stuffing-supply wonton producing device, and belongs to the field of food devices. The producing device comprises a machine frame, a flour hopper, a wrapper pressing mechanism, a guide plate, a roller, a rotary mold, a stuffing barrel and an outlet groove. The stuffing barrel comprises a discharge tank, a discharge auger, a discharge port and a stuffing cutting mechanism. The lower end of the discharge tank is of a conical structure. The discharge auger is arranged in the discharge tank after being connected with a transmission rod. The shape of the discharge auger corresponds to the conical structure of the lower end of the discharge tank. The discharge port is connected with the bottom of the discharge tank. The discharge port is of a tubular structure. The stuffing cutting mechanism is arranged on the side face of the lower portion of the discharge port. Thus, the wonton producing device has the advantages that the device is reasonable in design, simple in structure, low in cost, completely practical and high in discharge uniformity, and pressed wrappers are thin and better in taste.

Owner:HUBEI GUDASAO FOOD

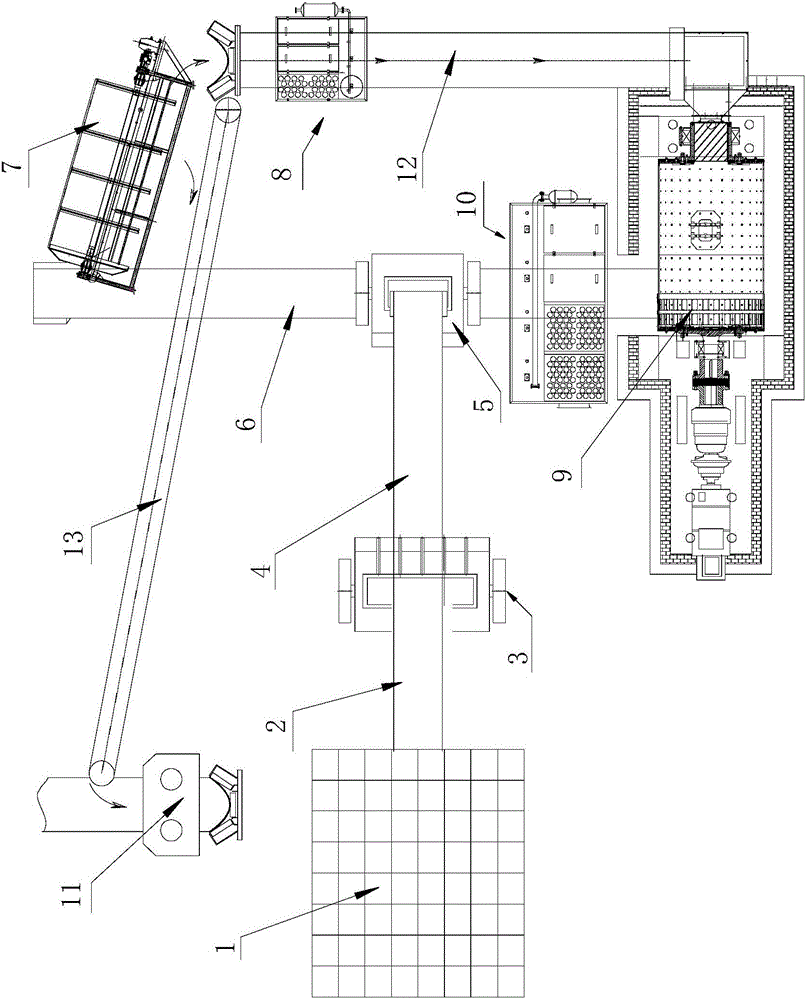

Crushing production line

InactiveCN106583000AAvoid cloggingLower feeding heightDirt cleaningGrain treatmentsProduction lineCrusher

The invention discloses a crushing production line. The crushing production line comprises a warehouse, a chain-plate feeder, a jaw crusher, a first conveying belt, a hammer crusher, a second conveying belt, a roller screen, a first dust remover, a rolling ball crusher, a second dust remover, a strong stirrer and a third conveying belt; the warehouse, the chain-plate feeder, the jaw crusher, the first conveying belt and the hammer crusher are sequentially connected; the hammer crusher is carried on the second conveying belt; the second conveying belt, the roller screen, the third conveying belt and the rolling ball crusher are connected circularly; the first dust remover is carried on the third conveying belt; the second dust remover is carried on the second conveying belt; the roller screen is further connected with a fourth conveying belt; the fourth conveying belt is connected with the strong mixer; and the warehouse is 6 m long and 5 m wide. With the crushing production line, materials are easy to pour, large stones are easy to convey, dust can be recovered, and the production efficiency is high.

Owner:ZHEJIANG YELI MACHINERY MFR

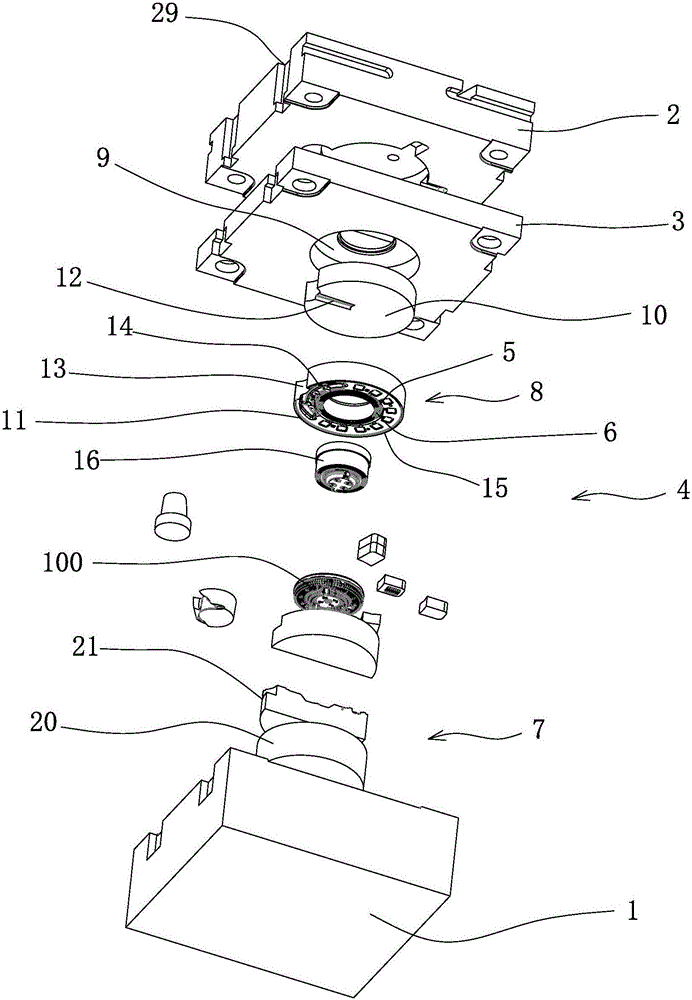

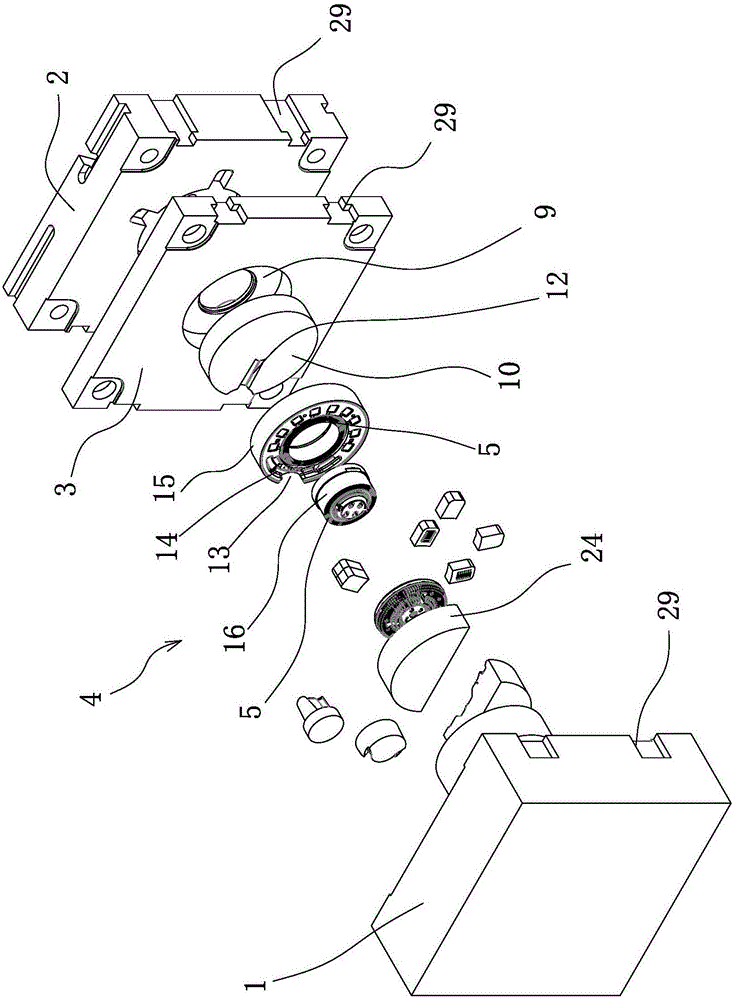

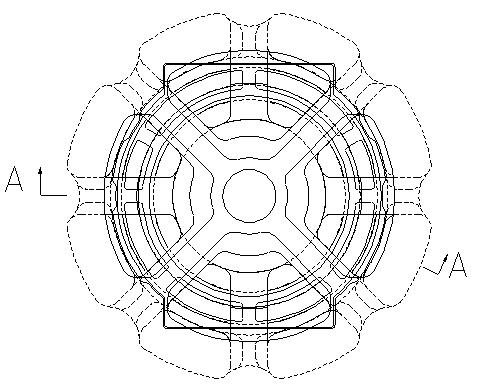

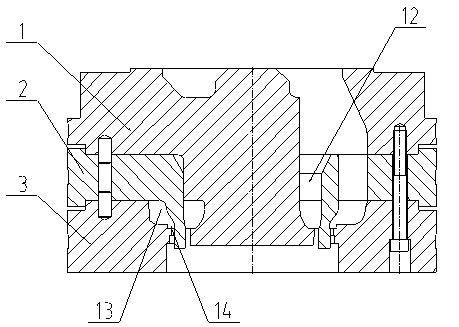

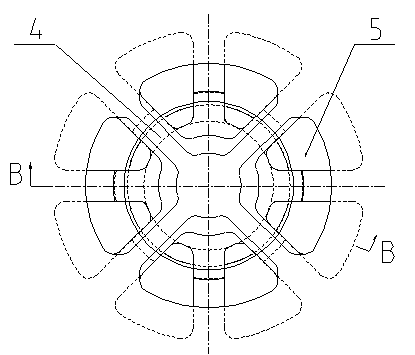

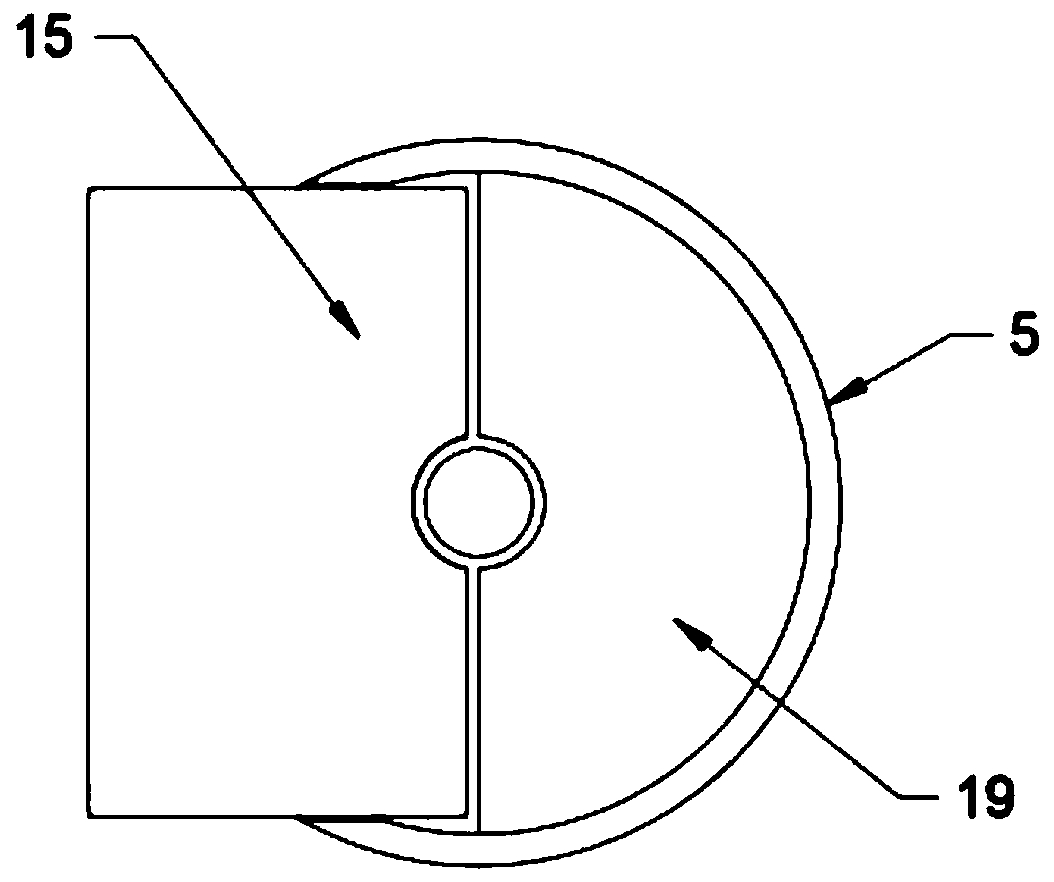

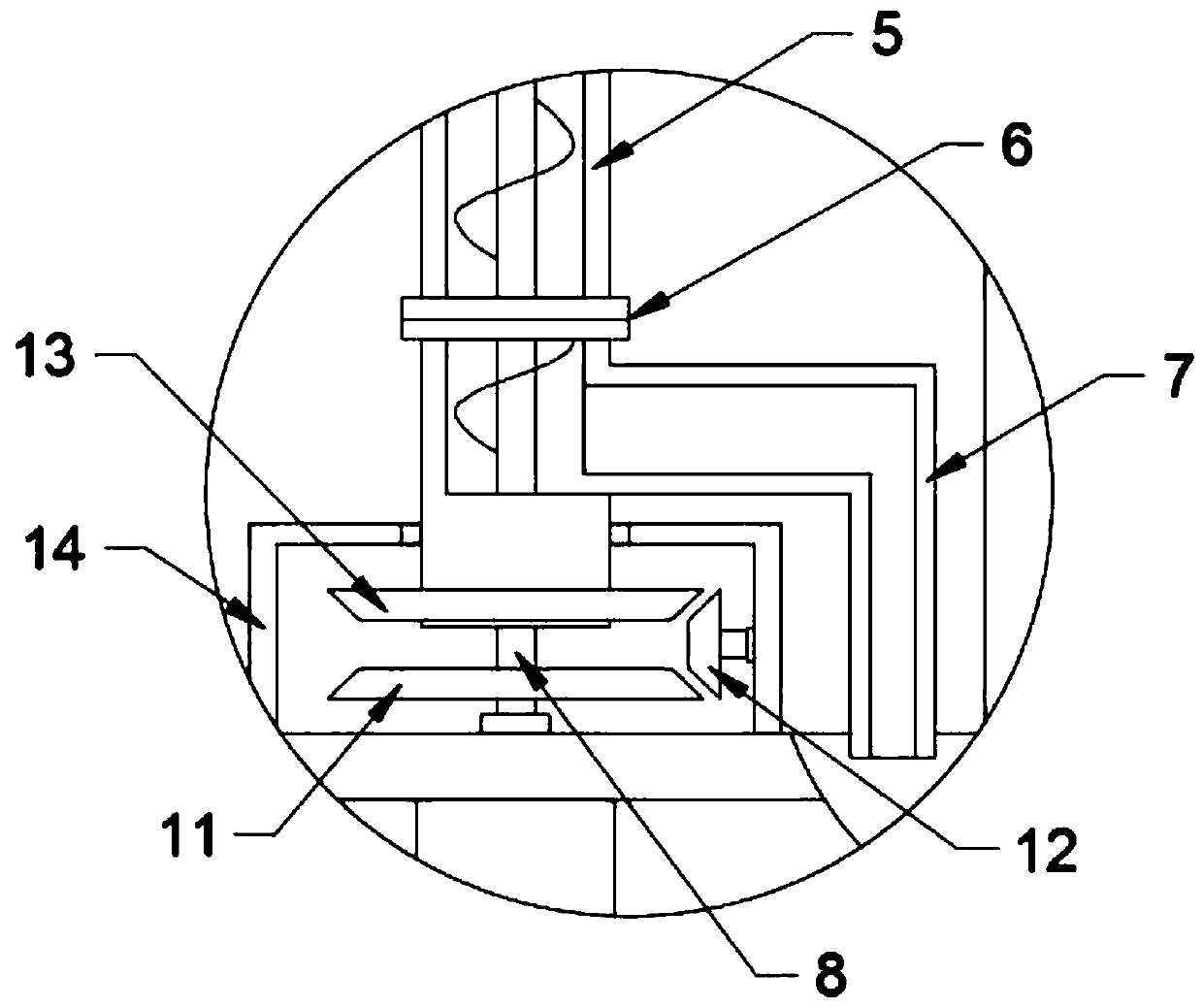

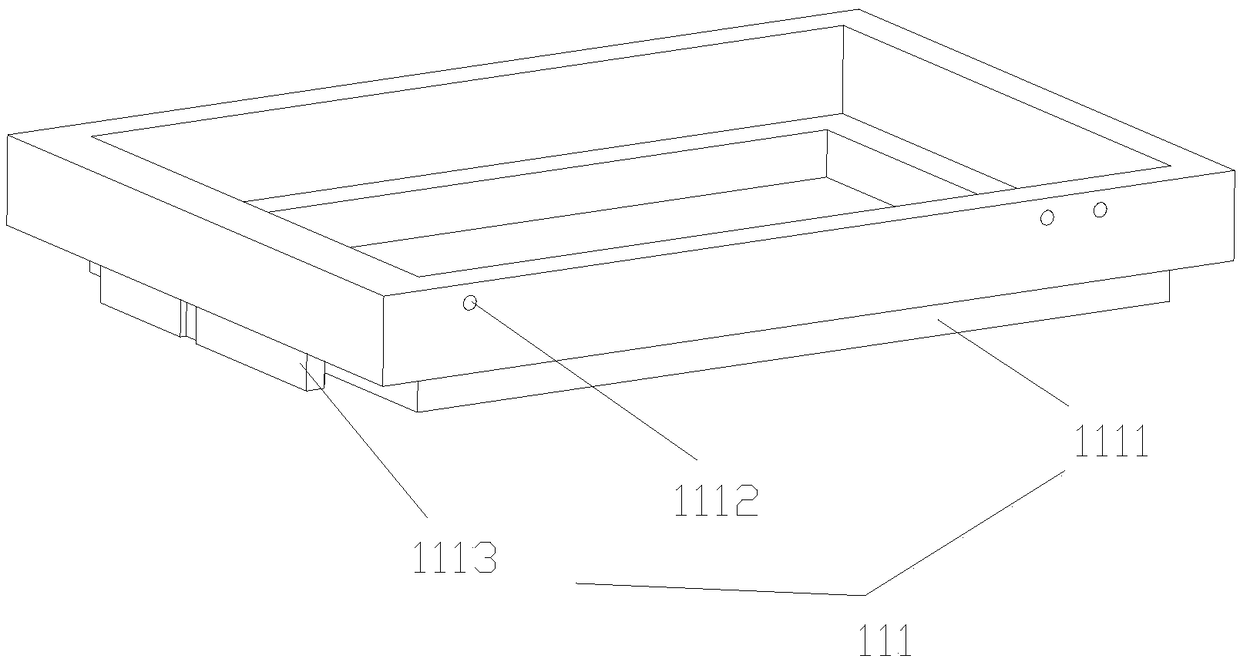

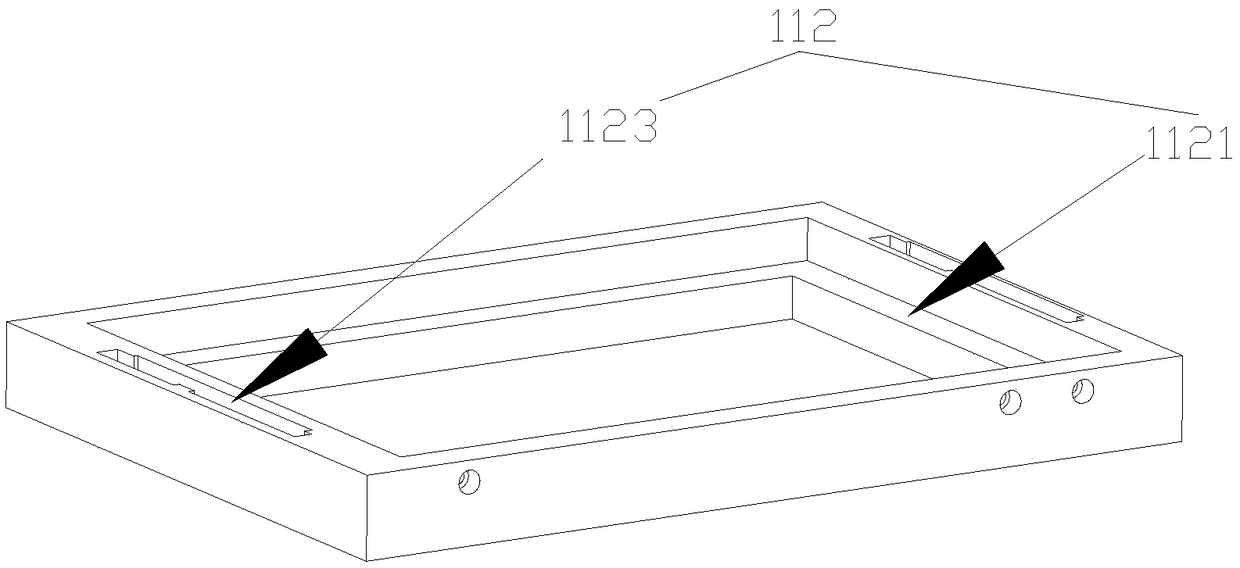

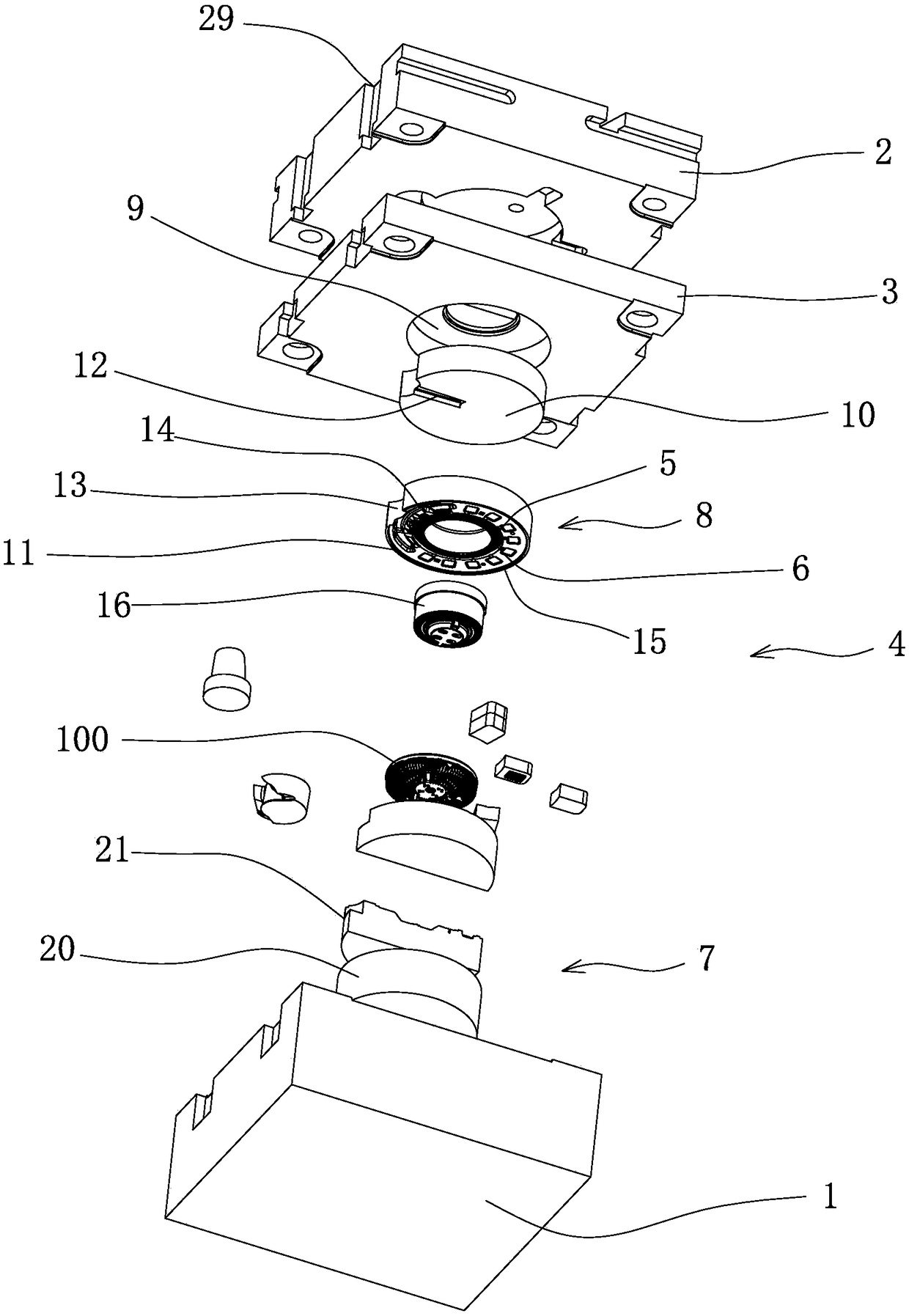

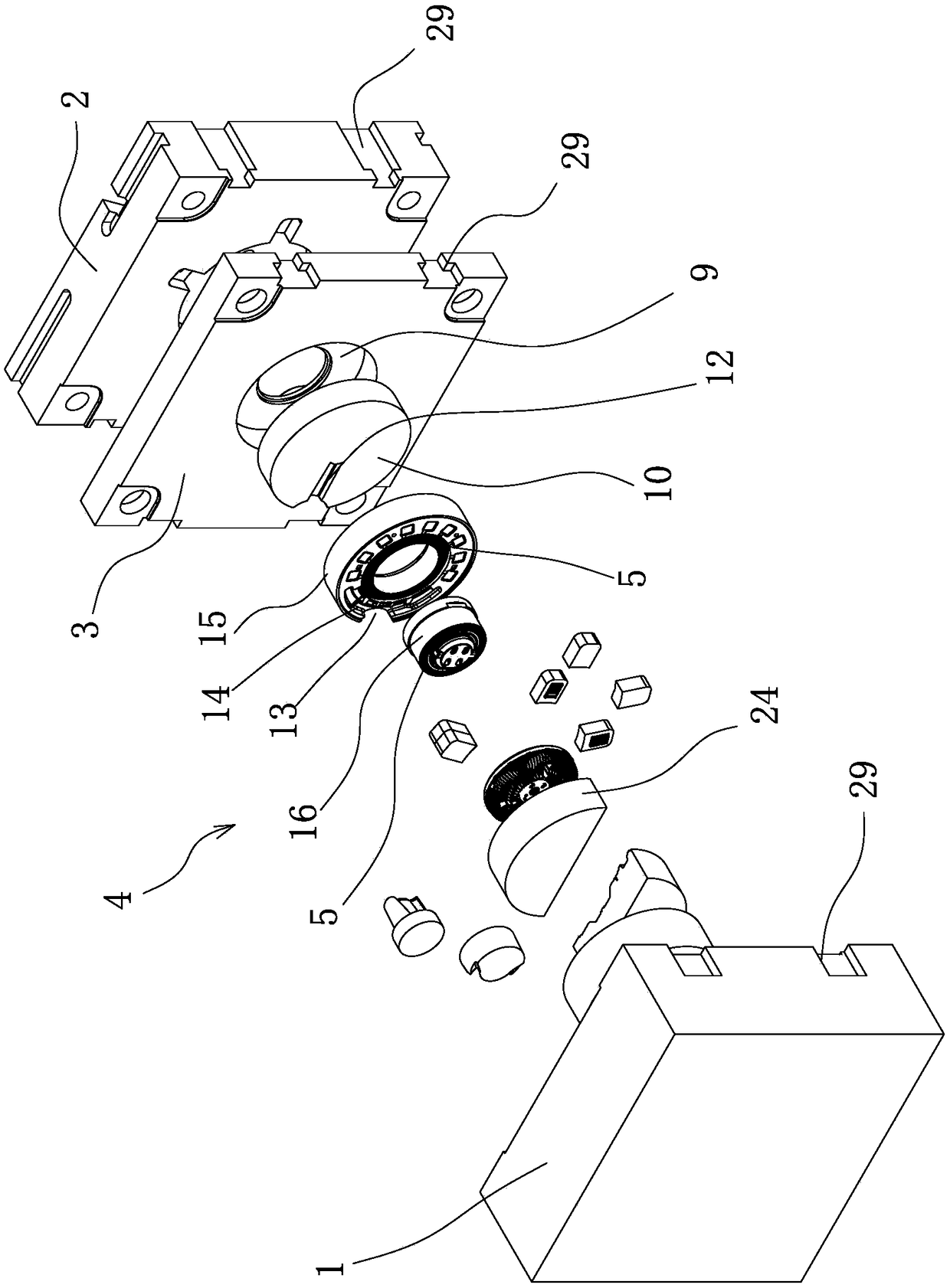

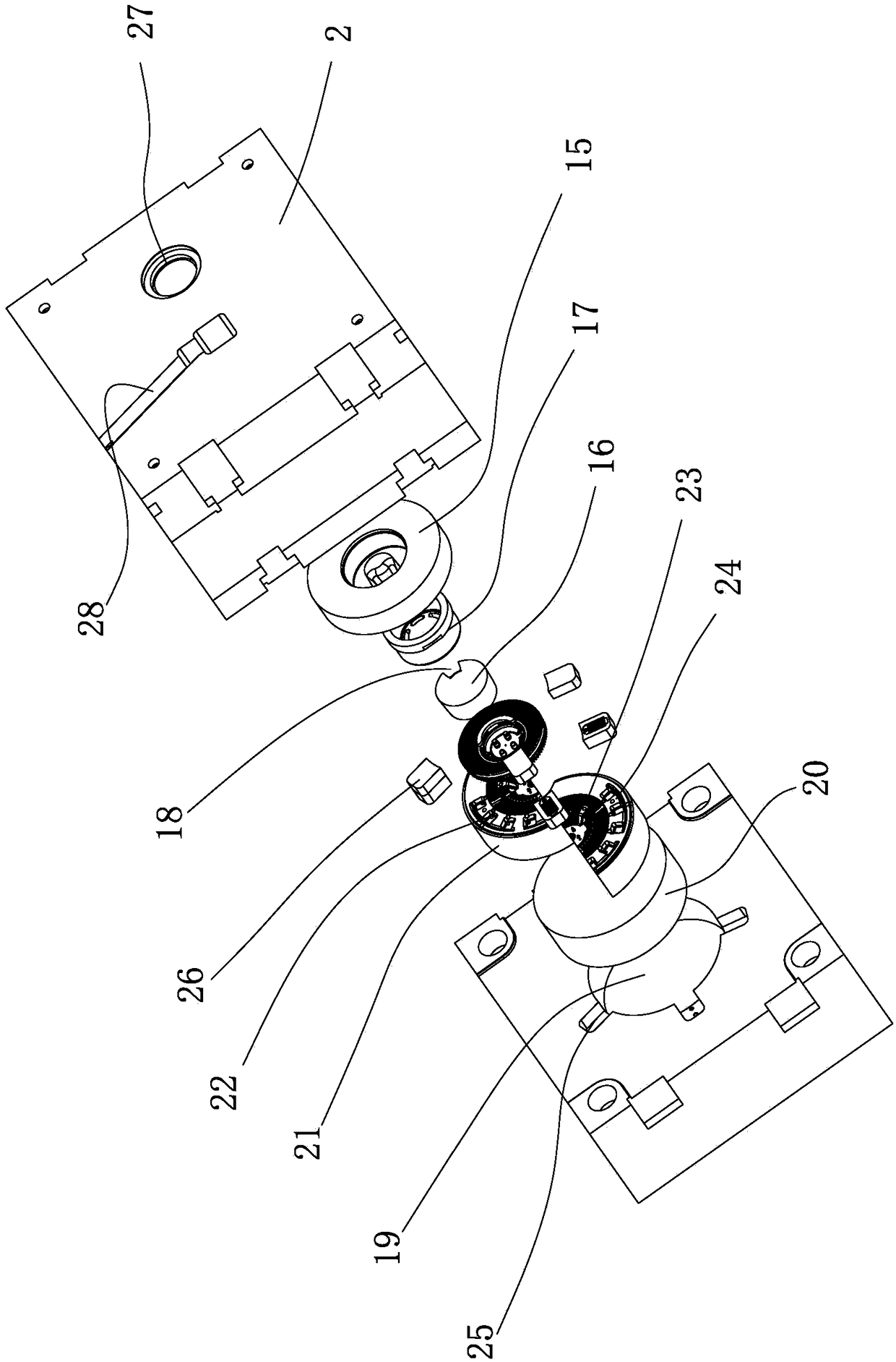

Die-cast molding mould of aluminum alloy front cover of automobile silicone oil fan clutch

The invention belongs to the technical field of die-cast molding, and relates to a die-cast molding mould of an aluminum alloy front cover of an automobile silicone oil fan clutch. The die-cast molding mould comprises a fixed mold, a movable mold and a middle mold located between the fixed mold and the movable mold, wherein the middle mold is movably connected with a core component; the core component is provided with a plurality of silicone oil feeding surface molding rings arranged concentrically; and an annular silicone oil feeding surface molding cavity is formed between every two adjacent silicone oil feeding surface molding rings. The wall thicknesses of oil guide rings are reduced, few bubbles are generated in a casting process, the overall quality of a product is uniform, and a rejection rate is low.

Owner:TAIZHOU SHUNYI AUTOMOBILE PARTS

Circulation fluidized dry flue gas desulfurizing process by adopting mixed feeding mode

InactiveCN1239234CImprove space utilizationImprove desulfurization efficiencyDispersed particle separationChemical reactionFlue gas

The present invention discloses a circulating fluidized dry flue gas desulfurizing process adopting mixed feeding mode. It combines the fresh feeding modes of desulfurization reaction system and digestion reaction system with respective recirculating feeding back mode, i.e. adopts a mixed feeding mode to mix the initial feeding material and system circulating material to feed them into reaction tower, and at the position of mixed feeding hole a diffusion fan is placed so as to ensure the dispersed uniformity of the material in the reaction tower and can meet the concentration distributing characteristics required for desulfurization chemical reaction to raise reaction tower space utilization rate and raise the desulfurization or digestion efficiency.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Aluminum profile extrusion die with complicated die core structure

ActiveCN103272873AEasy to shapeHigh dimensional accuracyExtrusion diesMaterial supplyProcessing accuracy

Owner:JIANGYIN GIANSUN MOLD

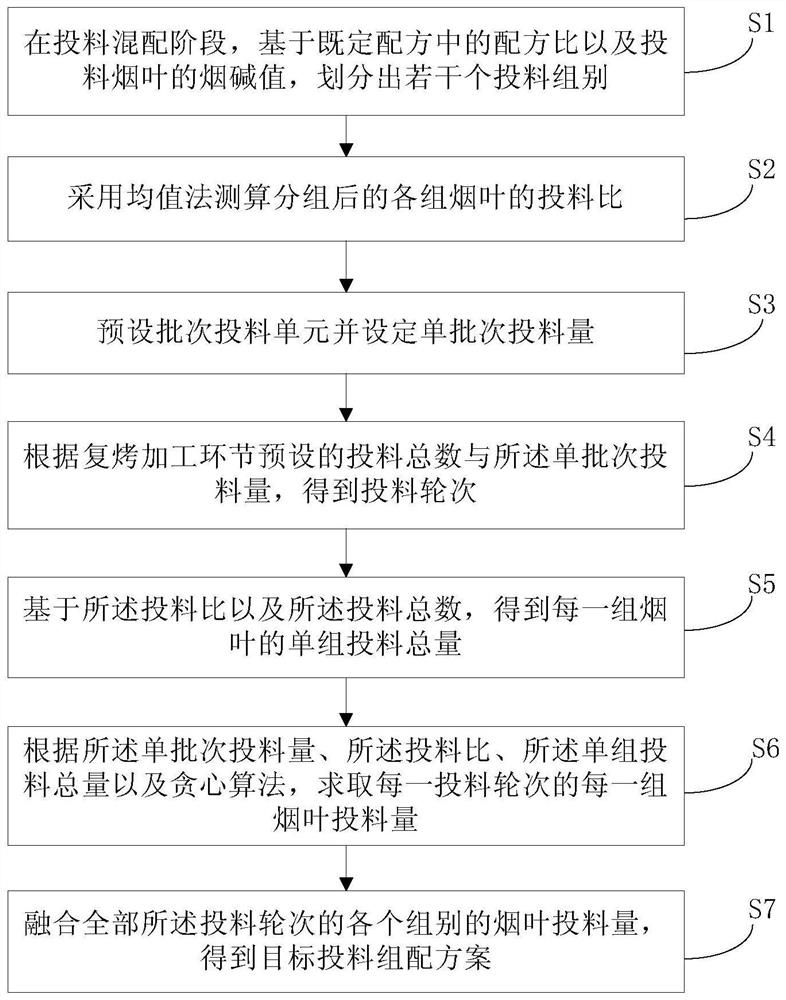

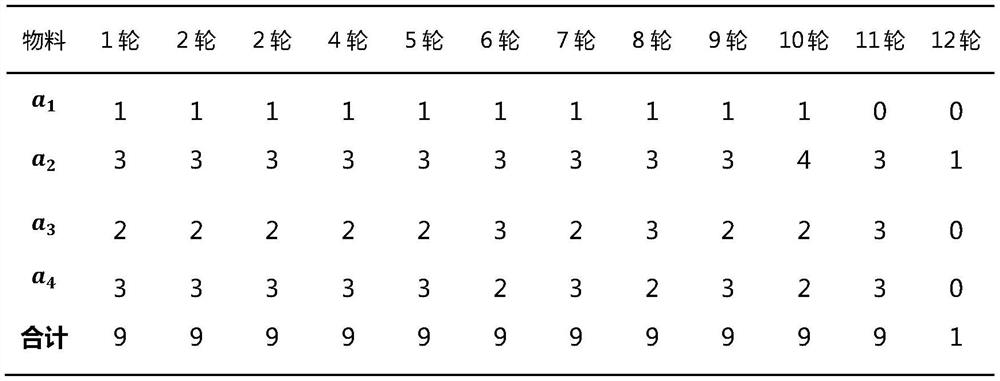

Uniform feeding control method for redrying production

ActiveCN113662230AAvoid early votingImprove quality stabilityTobacco preparationManufacturing computing systemsBiotechnologyAnimal science

The invention discloses a uniform feeding control method for redrying production. The method comprises the following steps of dividing a plurality of groups according to a formula ratio and a nicotine value in a feeding and mixing stage, measuring and calculating the feeding ratio of each group, and obtaining a feeding round based on the single-batch feeding amount corresponding to a minimum-batch feeding unit and the total feeding amount; meanwhile, based on the feeding ratio of each group and the total feeding amount, acquiring a single-group total feeding amount, predicting the feeding amount required by each group of tobacco leaves in each feeding process by using the single-batch feeding amount, the feeding ratio of each group and the total feeding amount of each group in combination with a recursion thought and a greedy algorithm, and finally, fusing the feeding amount prediction results of all groups of all feeding rounds; and obtaining a target feeding and assembling scheme. According to the method, the labor cost is effectively reduced, the method is more scientific, meanwhile, overall feeding and single batch of raw materials are ensured to be uniform, and therefore the feeding uniformity is improved, re-drying homogenization processing control is enhanced, and the quality stability of re-dried finished tobacco strips can be remarkably improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Small household aquaculture device

InactiveCN109892270AImprove survival rateSimple structureClimate change adaptationPisciculture and aquariaMobile vehicleEngineering

The invention discloses a small household aquaculture device. The device comprises a moving vehicle body and a feeding box disposed above the moving vehicle body, a ring groove is formed in the top end surface of the moving vehicle body, the ring groove is internally rotatably cooperatively provided with a plurality of rollers which abut against the bottom end surface of the feeding box, a stirring chamber is arranged in the top end surface of the feeding box, the inner top wall of the stirring chamber is provided with a feeding trough communicated with the outside, the top end surface of thefeeding box is fixedly provided with a feeding hopper communicated with the feeding trough, the top end surface of the feeding box is internally provided with a first transmission groove, and a stirring shaft is rotatably cooperatively mounted between the first transmission groove and the stirring chamber; the device has simple structure, high degree of automation and automatic feeding operation,greatly reduces labor intensity, improves work efficiency, has a swing function, can greatly improve feeding uniformity, improves fry survival rate, and is suitable for promotion and use.

Owner:嘉兴歆瑶新能源有限公司

Breeding feed feeding device

The invention discloses a breeding feed feeding device which comprises a feeding groove and a preparation barrel, wherein circumferentially distributed partition plates are fixedly connected onto theupper side of the feeding groove; the preparation barrel is fixedly connected onto the upper sides of the partition plates in a screw bolt fixing manner; and the lower end of a discharging pipe communicates with a swinging pipe through a rotating joint. Through the arrangement of the separation plates which are arranged at the edge positions of the feeding groove and can be dismounted for space regulation, the feeding groove can be subjected to space division, livestock feed fighting is avoided, and the uniform feeding development of the livestock is ensured; through the arrangement of a gateplate, the discharging pipe, the rotating joint, the swinging pipe, and a transmission gear set comprising an active bevel gear, a transmission bevel gear and a driven bevel gear, the circumferentialdischarging of the swinging pipe can be realized, manual feeding is replaced, the feeding efficiency is improved, and meanwhile, the feeding uniformity is improved; and a pollution discharging pump and pollution discharging branch pipes arranged at the bottom of the annular groove are arranged and cooperate with the swinging pipe, so that the annular groove is circumferentially flushed, the annular groove can be conveniently cleaned, and bacterium breeding is avoided.

Owner:郭娟

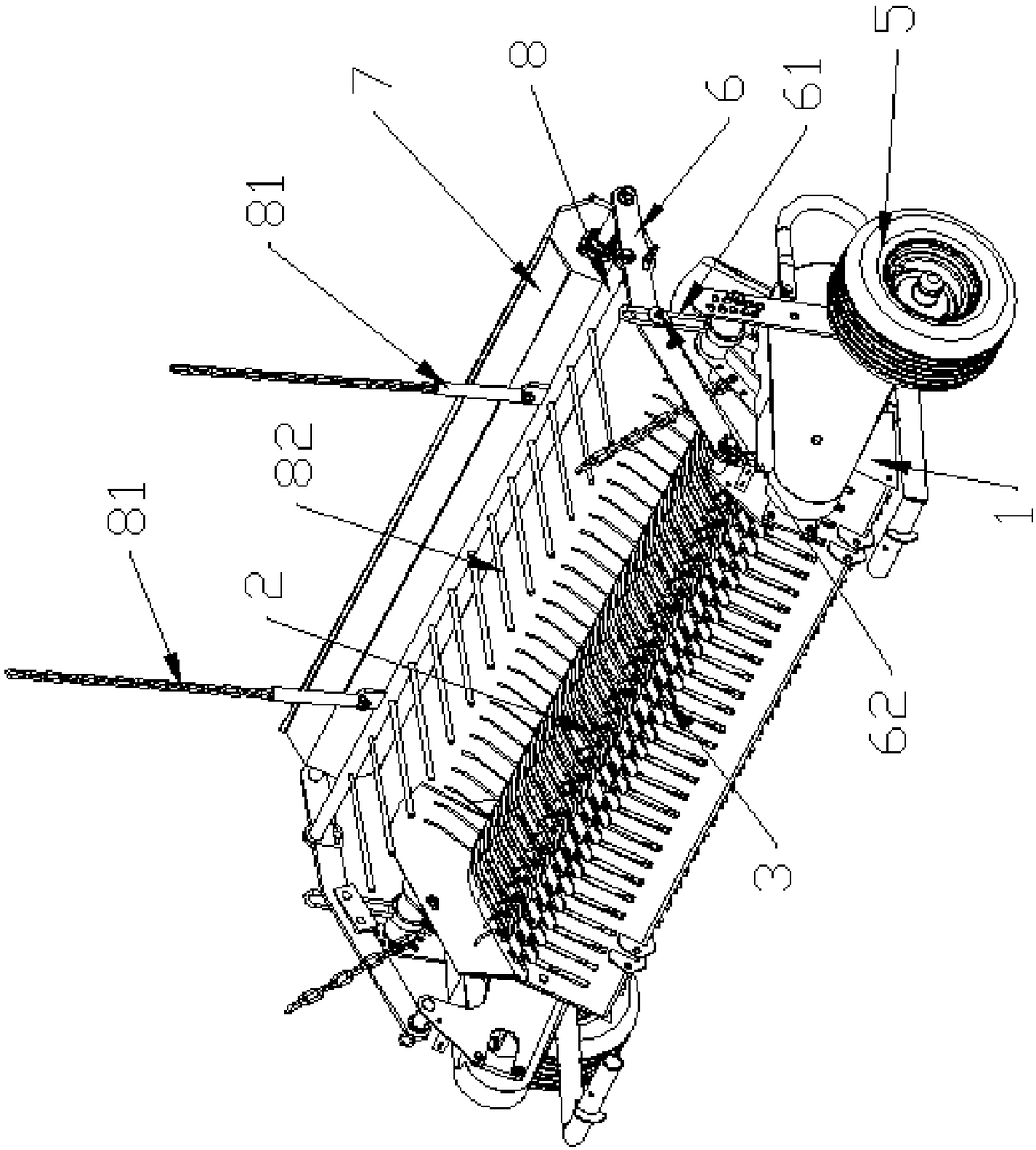

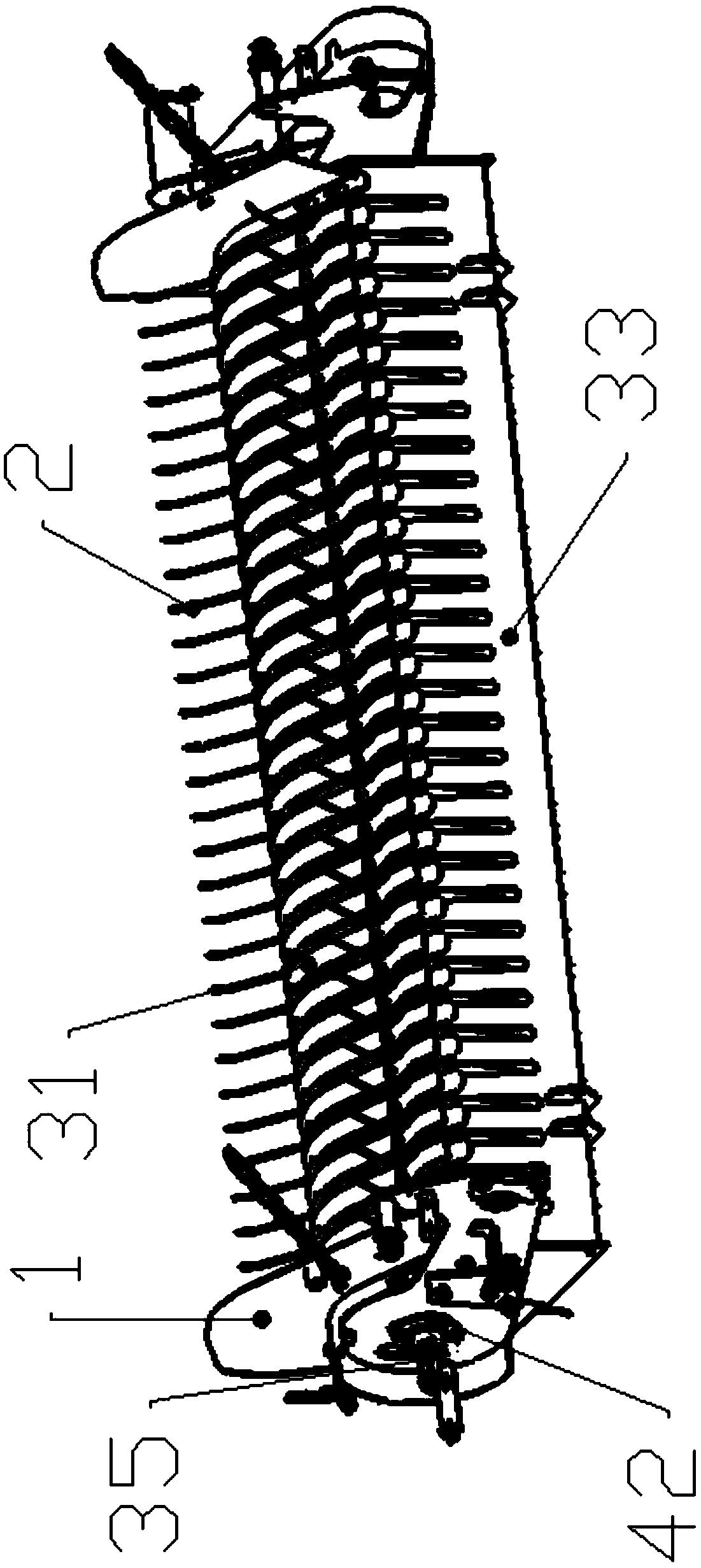

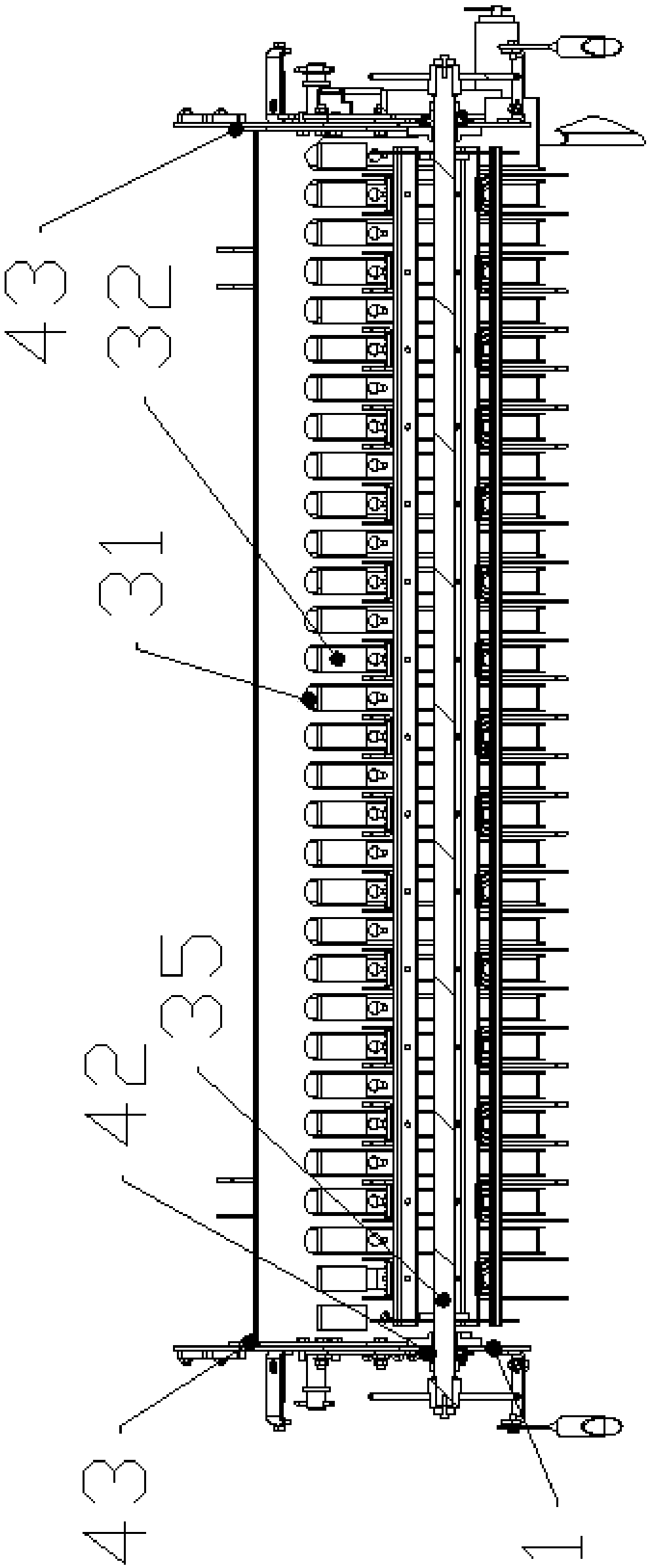

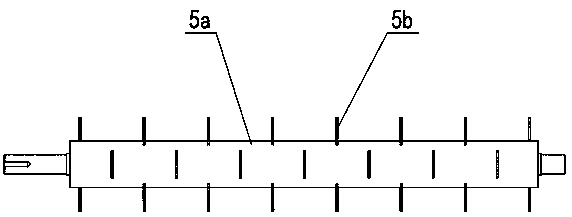

Pickup device for straw baler

PendingCN109328660APrevent upward scatterImprove work efficiencyLoadersEngineeringMechanical engineering

The invention provides a pickup device for a straw baler, and belongs to the field of agricultural baler devices. The pickup device comprises a machine frame, a rotating assembly, retainer assembliesand elastic claw assemblies. The rotating assembly is erected on the machine frame and rotationally connected with the machine frame. The elastic claw assemblies are fixedly arranged on the rotating assembly. The retainer assemblies are arranged on the outer ring of the rotating assembly. The retainer assemblies are arranged between every two adjacent elastic claw assemblies. A follower wheel assembly is arranged at the lower end of the machine frame. Supporting force arms are symmetrically arranged at the upper end of the machine frame. One end of each supporting force arm is hinged to the machine frame. The other end of each supporting force arm is provided with a floating wheel. A floating roller is erected on the symmetrical supporting force arms and rotationally connected with the supporting force arms. A positioning rod is arranged on each supporting force arm and provided with a plurality of comb teeth. The upper end of each positioning rod is provided with a limiting chain connected with a fixing piece. The pickup device is simple in structure, low in cost, high in carding efficiency, not prone to getting stuck, low in failure rate and stable in performance.

Owner:天津威猛机械制造有限公司

Knitted sweater spraying device

InactiveCN108787280AFully loadedImprove feeding uniformitySpray boothsAgricultural engineeringEngineering

The invention discloses a knitted sweater spraying device. The technology processes sequentially comprise a knitted grey cloth mounting frame, a knitted gray cloth mounting frame stacking cylinder, aknitted gray cloth mounting frame stacking cylinder conveying device, a knitted gray cloth mounting frame lifting device, a knitted gray cloth mounting frame push-out device, a knitted gray cloth mounting frame reversing device, a knitted gray cloth mounting frame conveying device and a spraying bin. The knitted sweater spraying device has the advantages that the spraying uniformity is good, the fabric shrinkage caused by difficulty in tension control is reduced, the polluted probability of the fabric during feeding of the fabric is reduced, the processing line is short, and double-sided simultaneous feeding can be met.

Owner:安徽京威纺织服饰有限公司

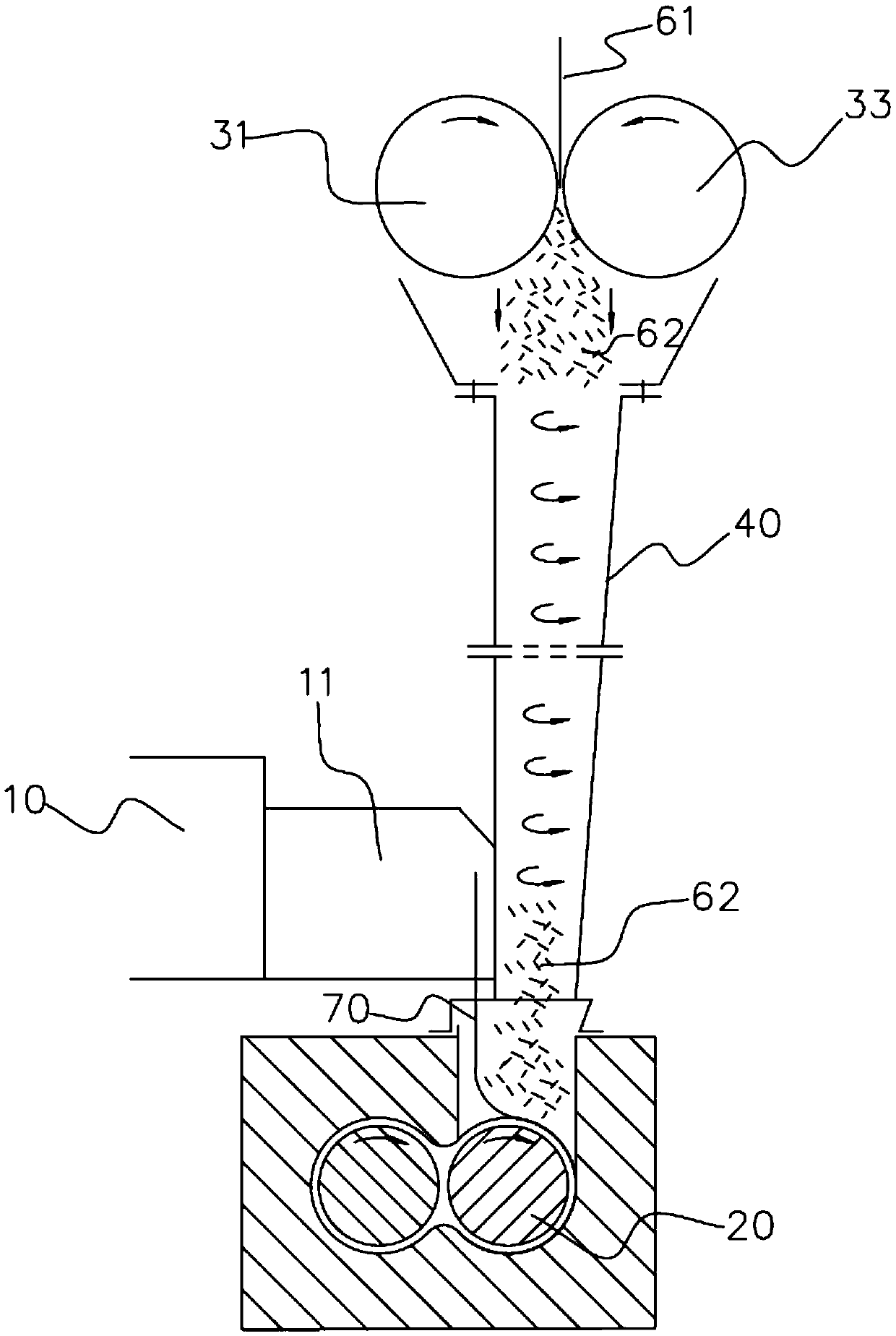

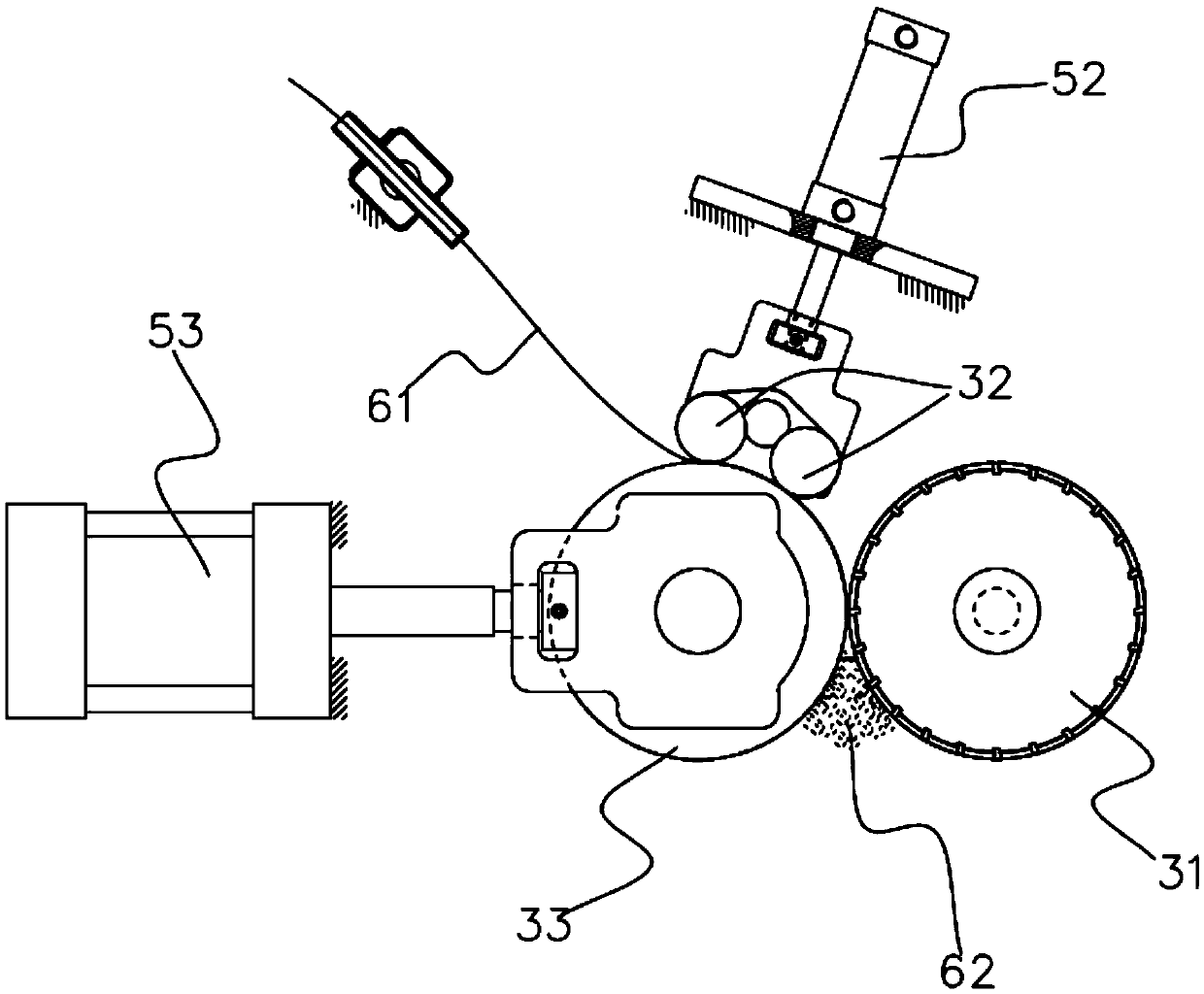

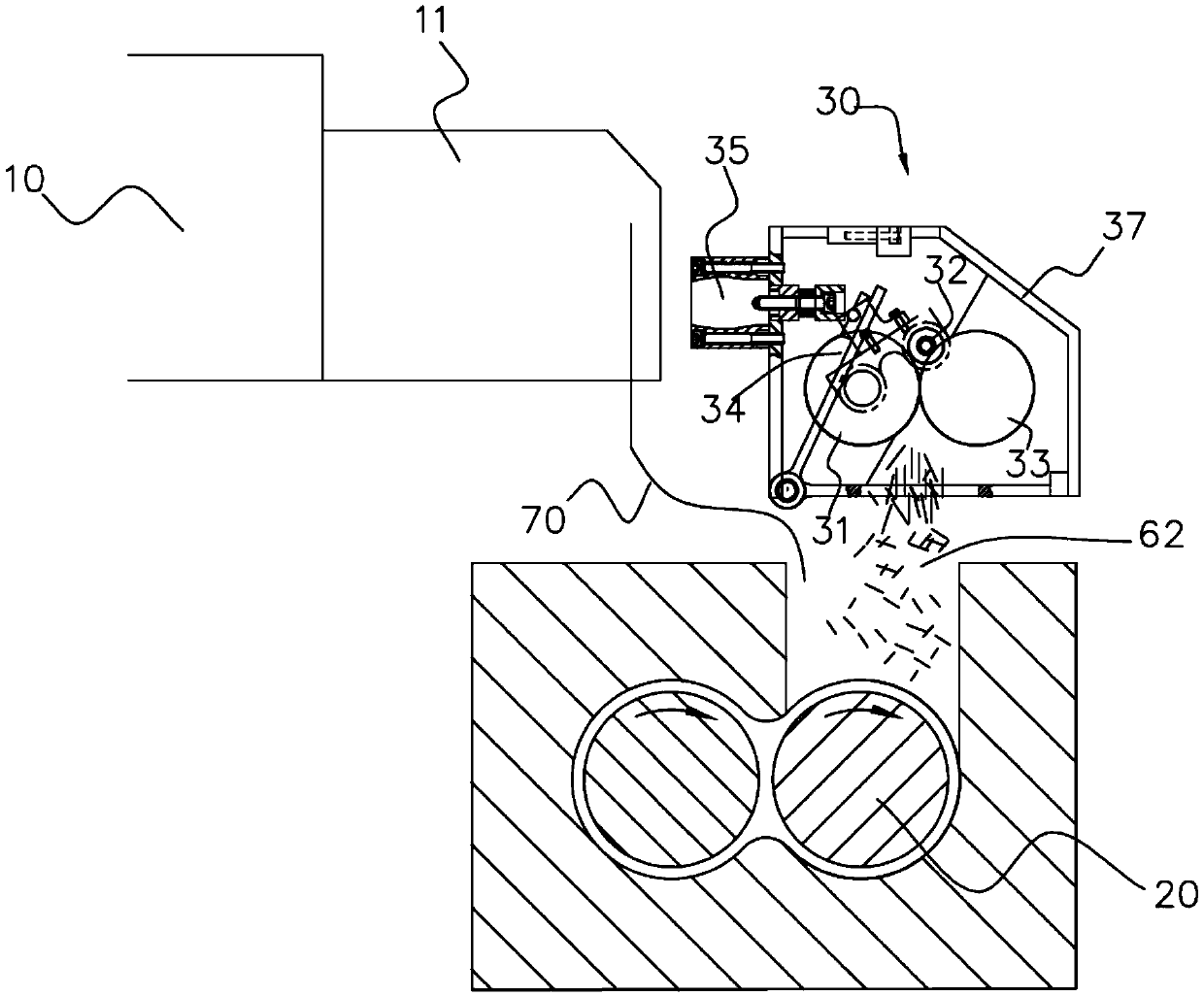

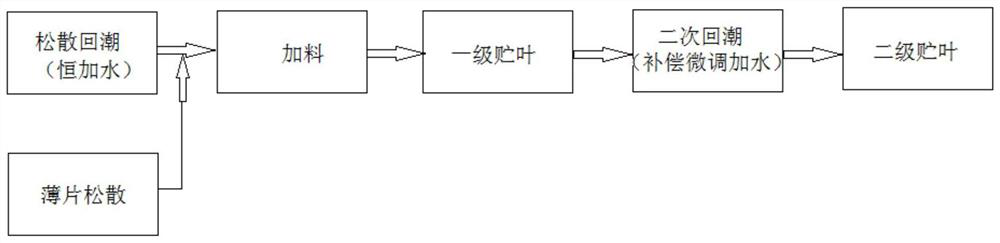

Fiber cutting device and fiber reinforced composite material mixing equipment

ActiveCN105500668AQuality improvementReduce distanceMetal working apparatusEngineeringFiber-reinforced composite

The inventor provides a fiber cutting device which comprises a cutter roller, a pressing roller, a rubber roller, a pressing support, a pressing mechanism and a power mechanism, wherein the pressing mechanism drives the pressing support to move close to or away from the rubber roller, the power mechanism is in transmission connection with a driving roller to drive the driving roller to rotate, when the pressing support driven by the pressing mechanism is close to the rubber roller, the driving roller driven by the power mechanism drives a driven roller to rotate by friction force, and a short fiber outlet is formed below a device shell or a device outer frame, and is located below the gap between the cutter roller and the rubber roller. In the fiber reinforced composite material mixing equipment, the distance between the fiber cutting device and a feeding port of a second-stage extrusion device is shortened as far as possible, the short fiber cut by the cutter roller directly falls to the feeding port of the second-stage extrusion device as soon as possible, the cluster falling of the short fiber is avoided, and the raw material feeding uniformity of the second-stage extrusion device is improved.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

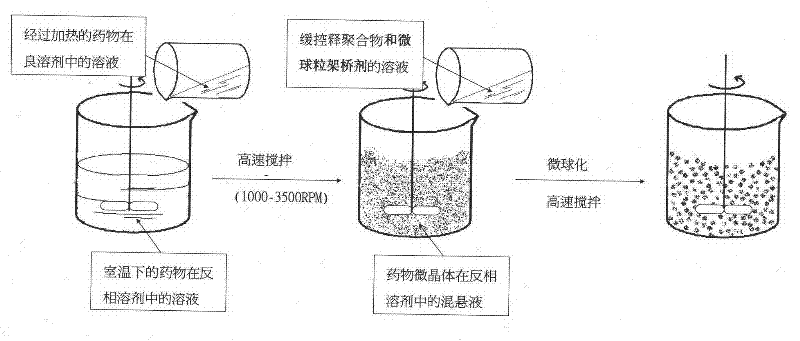

Precipitation and crystallization drug sustained and controlled release microspheres and preparation method thereof

ActiveCN101874784BShorten the timeImprove dry powder flowabilityOrganic active ingredientsGranular deliveryDrugs solutionControl release

The invention discloses a crystal separating drug sustained-release microspherule comprising the following components in parts by weight: 4-9 parts of water-insoluble drug, 0.1-2 parts of sustained-release polymer and 1-4 parts of microspherule bridging agent. In addition, the invention also discloses a preparation method of the crystal separating drug sustained-release microspherule, comprising the following steps: 1) dissolving water-insoluble drug into good solvent to form drug solution; 2) adding the drug solution into the opposite phase solvent of the drug, and stirring; 3) after the injectable suspension of drug microcrystal in the opposite phase solvent is completely formed and stabilized, adding solution containing the sustained-release polymer, the microspherule bridging agent and the solvent, and stirring; and 4) after the drug microspherule is completely formed and the solvent for dissolving the sustained-release polymer and the microspherule bridging agent is completely volatilized, stopping stirring, and filtering and drying the drug microspherule. The method can obtain the granule diameter with wider range, more regular and smooth surface and more controllable inner and outer releasing rate of drug.

Owner:PIVOT PHARMA TECH SHANGHAI

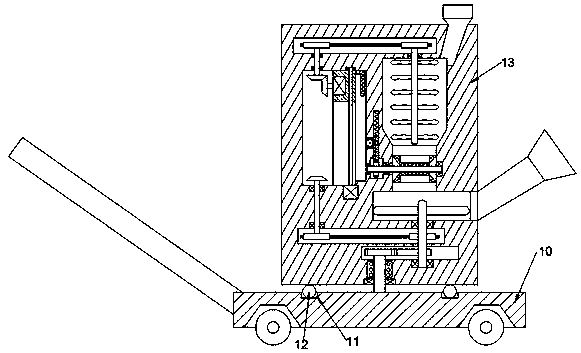

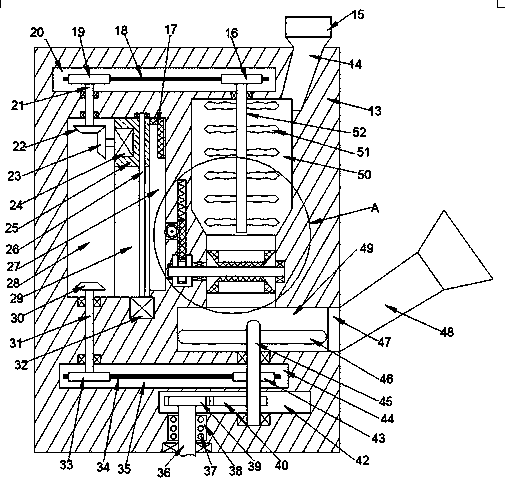

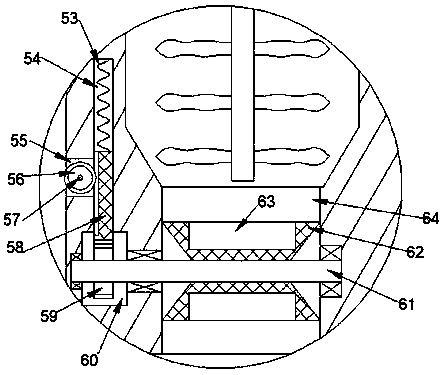

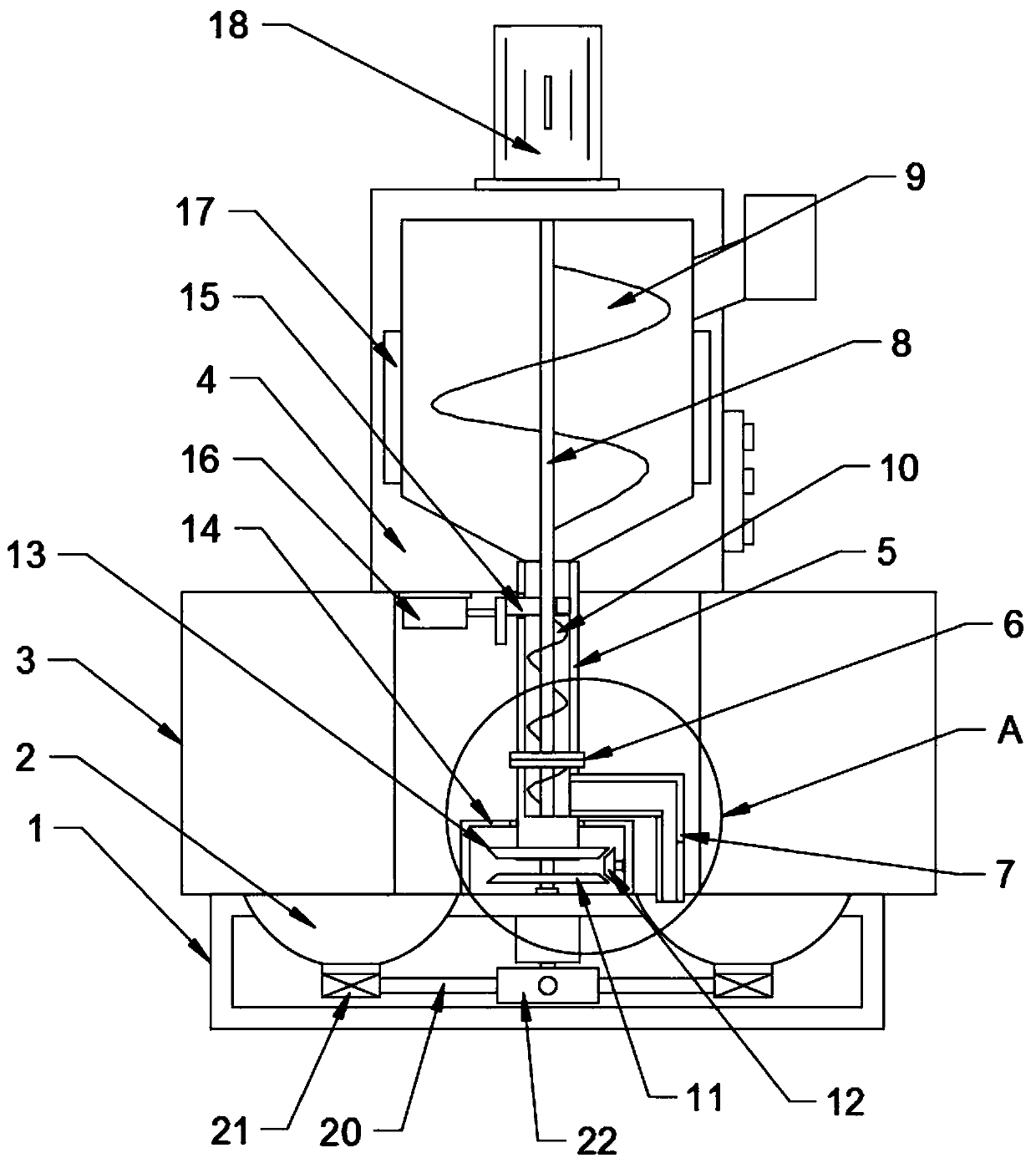

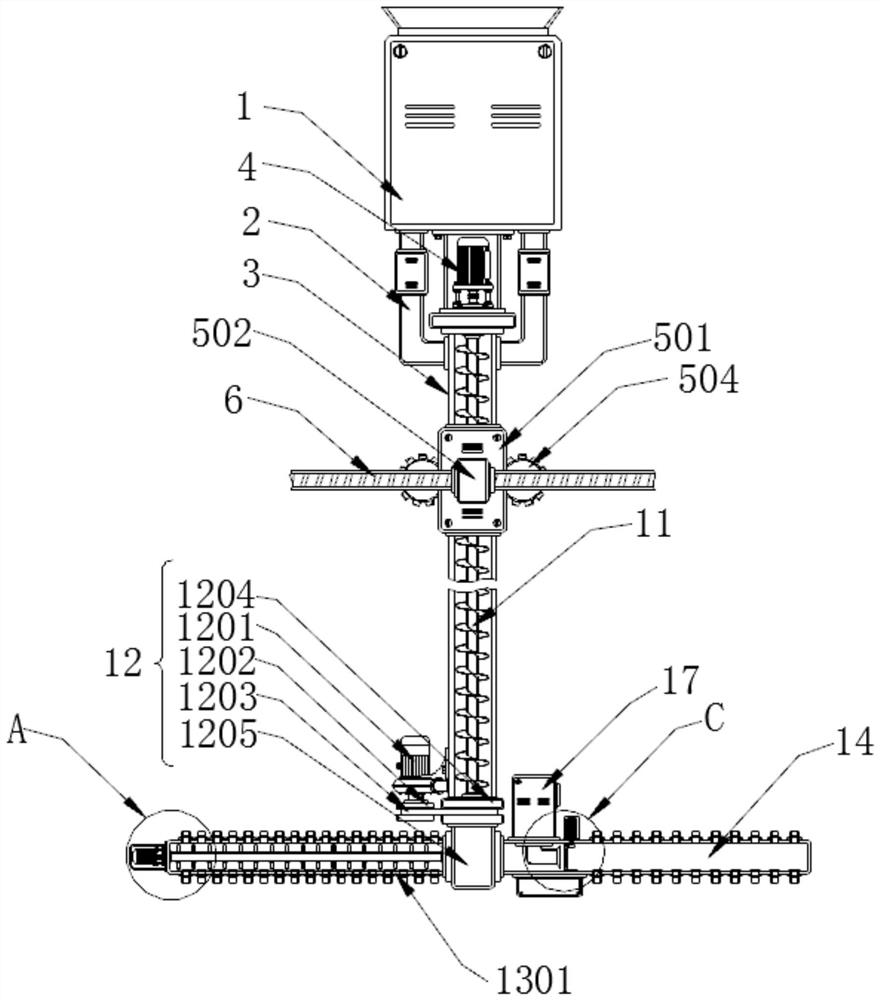

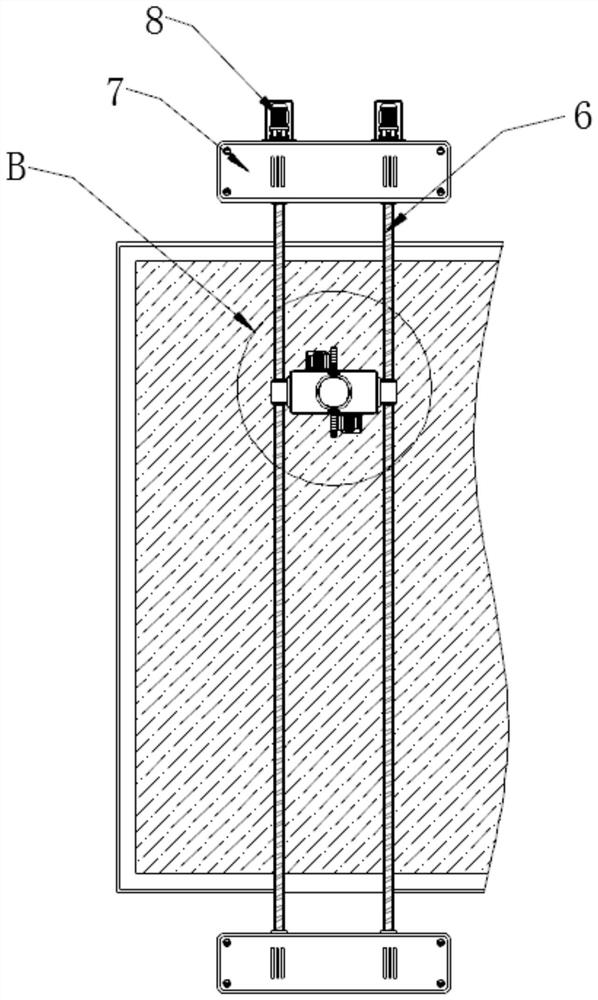

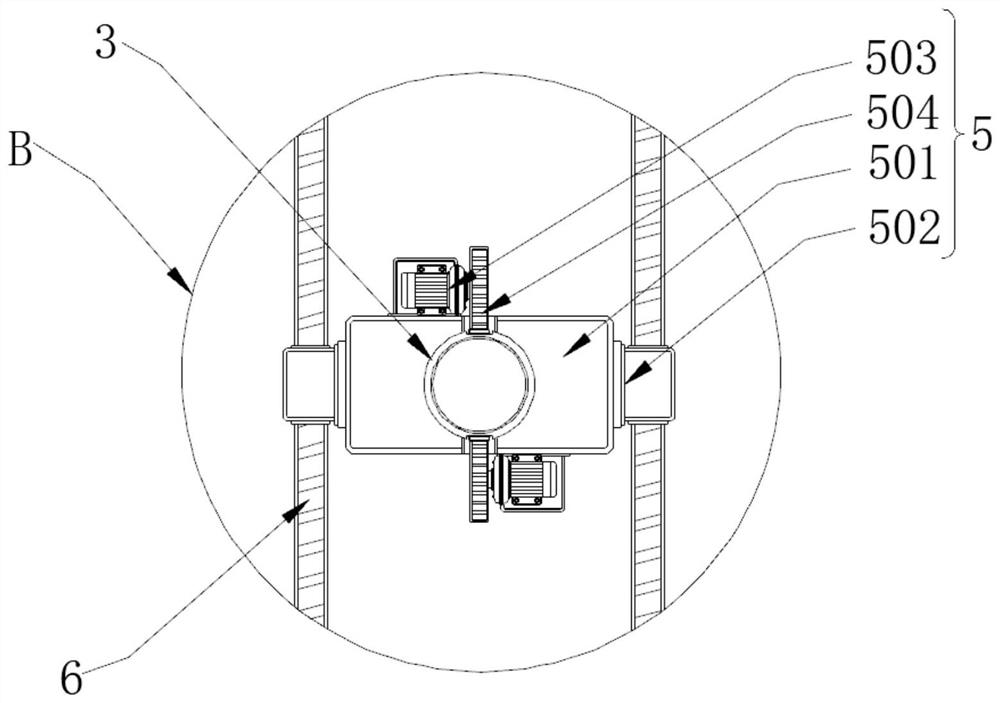

Uniform feeding device for biomass boiler

PendingCN111536546AAvoid material jamsReduce the temperatureFuel supply regulationFuel feeding arrangementsElectric machineryEnvironmental engineering

The invention discloses a uniform feeding device for a biomass boiler, and relates to the technical field of boilers. The device comprises a feeding hopper, a bin connected with the feeding hopper anda discharging hopper connected with the bin, wherein the discharging hopper is used for being connected with a boiler, the feeding hopper is connected with the rear part of the top end of the bin, and the discharging hopper is connected with the front part of the bottom end of the bin; a conveying belt and a homogenizer are arranged in the bin, the conveying belt is in transmission connection with a transmission roller, the transmission roller is in transmission connection with a conveying motor through a speed reducer, and the homogenizer is positioned between the conveying belt and the feeding hopper; a water spraying pipe is arranged in the bin, the water spraying pipe is positioned at the upper part of the front side of the bin, the water spraying pipe is parallel to the width direction of the conveying belt, and a plurality of nozzles are uniformly distributed on the pipe wall of the water spraying pipe; and the outer wall of the discharge hopper is coated with a water-cooling jacket, and the water-cooling jacket is provided with a water inlet and a water outlet. According to the device, the feeding uniformity is better, and the conditions of material blocking and tempering combustion in the feeding device can be prevented to a great extent.

Owner:HUNAN CHANGHONG BOILER

Seaweed feed for river crabs and automatic feeding equipment thereof

InactiveCN114711343AImprove the immunityReduce deathFood processingAnimal feeding stuffFisheryElectric machinery

The invention discloses seaweed feed for river crabs and automatic feeding equipment of the seaweed feed, and relates to the technical field of river crab breeding, the seaweed feed comprises a feeding box, a feed conveying pipe and a feeding assembly, feeding pipes are connected to the two sides of the outer portion of the feeding box, the feed conveying pipe is connected to the tail ends of the bottoms of the feeding pipes, and a first motor is arranged on the outer side of the top of each feeding pipe; a displacement assembly is arranged at the outer end of the conveying pipe, and lead screws are arranged on the two sides of the outer portion of the displacement assembly. A third motor works, a rotating gear can be driven to rotate, the rotating gear is meshed with butt joint tooth grooves in the two ends of the outer portion of a material conveying pipe, and therefore in the rotating process of the rotating gear, the material conveying pipe can be driven to ascend and descend on the inner side of a connecting box; the feed conveying pipe can drive the feeding pipe to move to the bottommost part of the crab pond, and due to the fact that the growth environment of river crabs is located at the pond bottom, the situation that feed is grabbed by fish in a lake due to the fact that the feed is directly fed on the lake surface can be effectively avoided by feeding the river crabs at the lake bottom.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

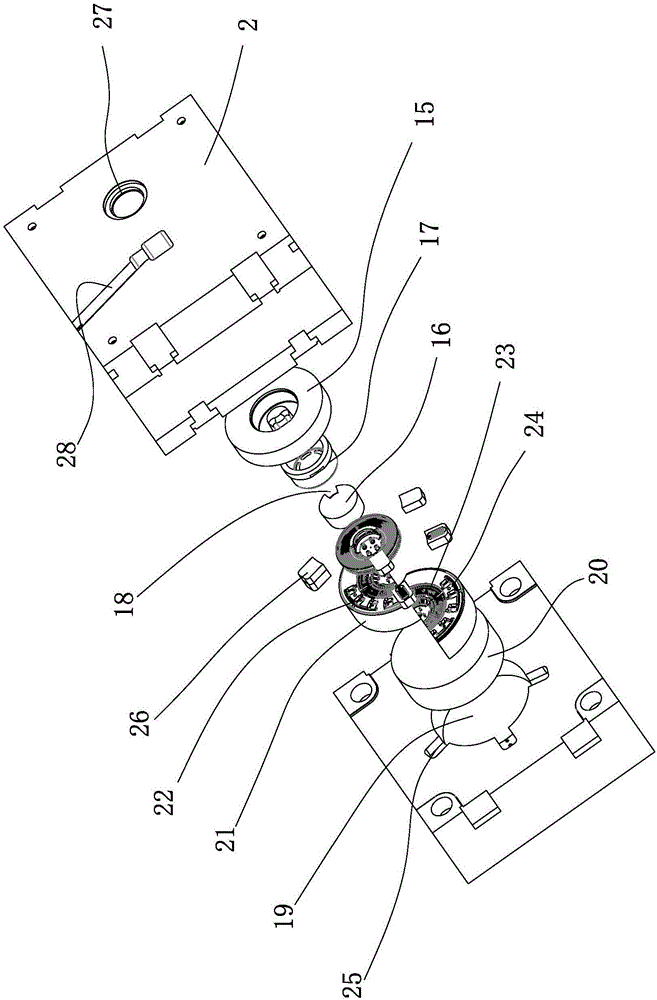

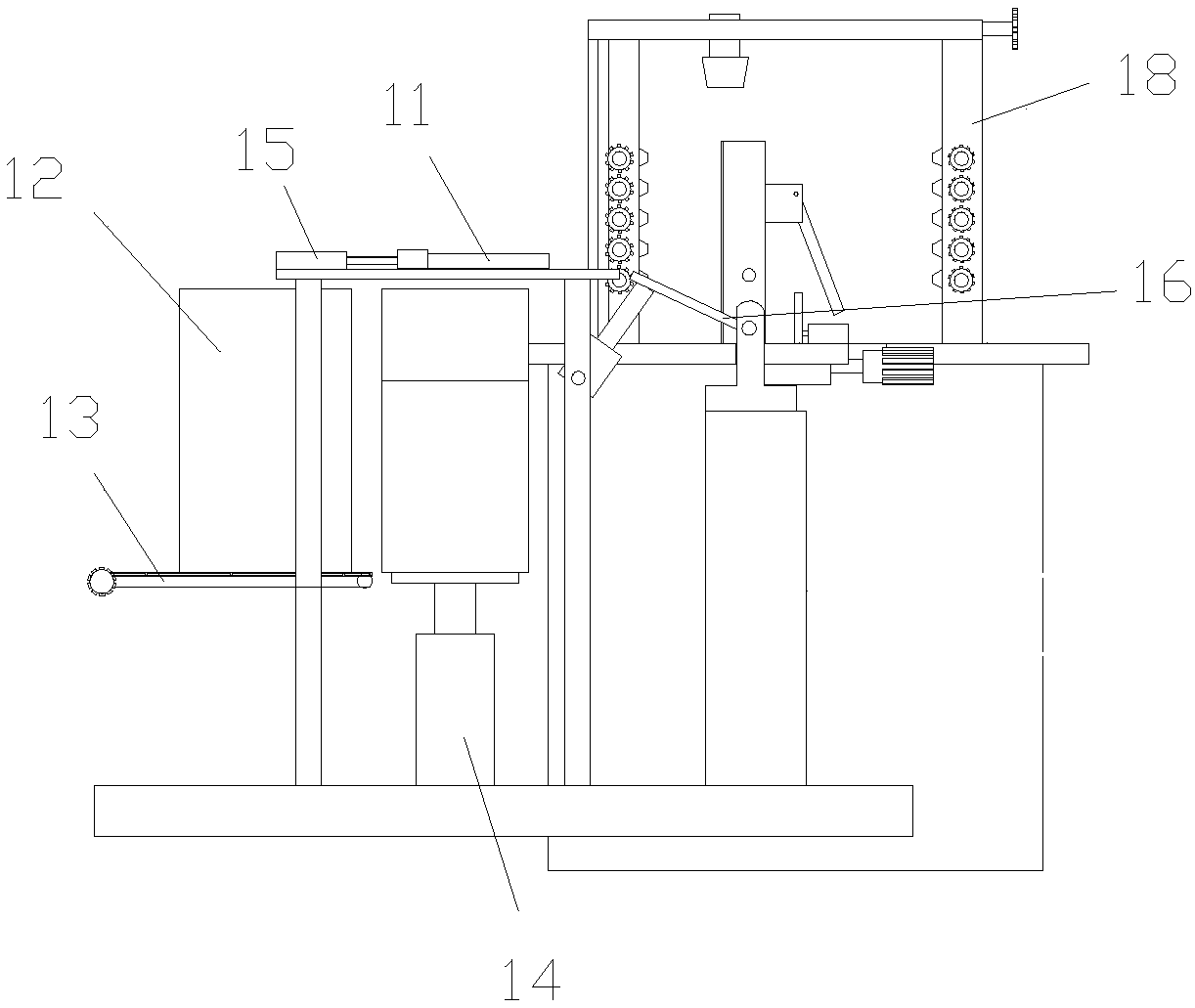

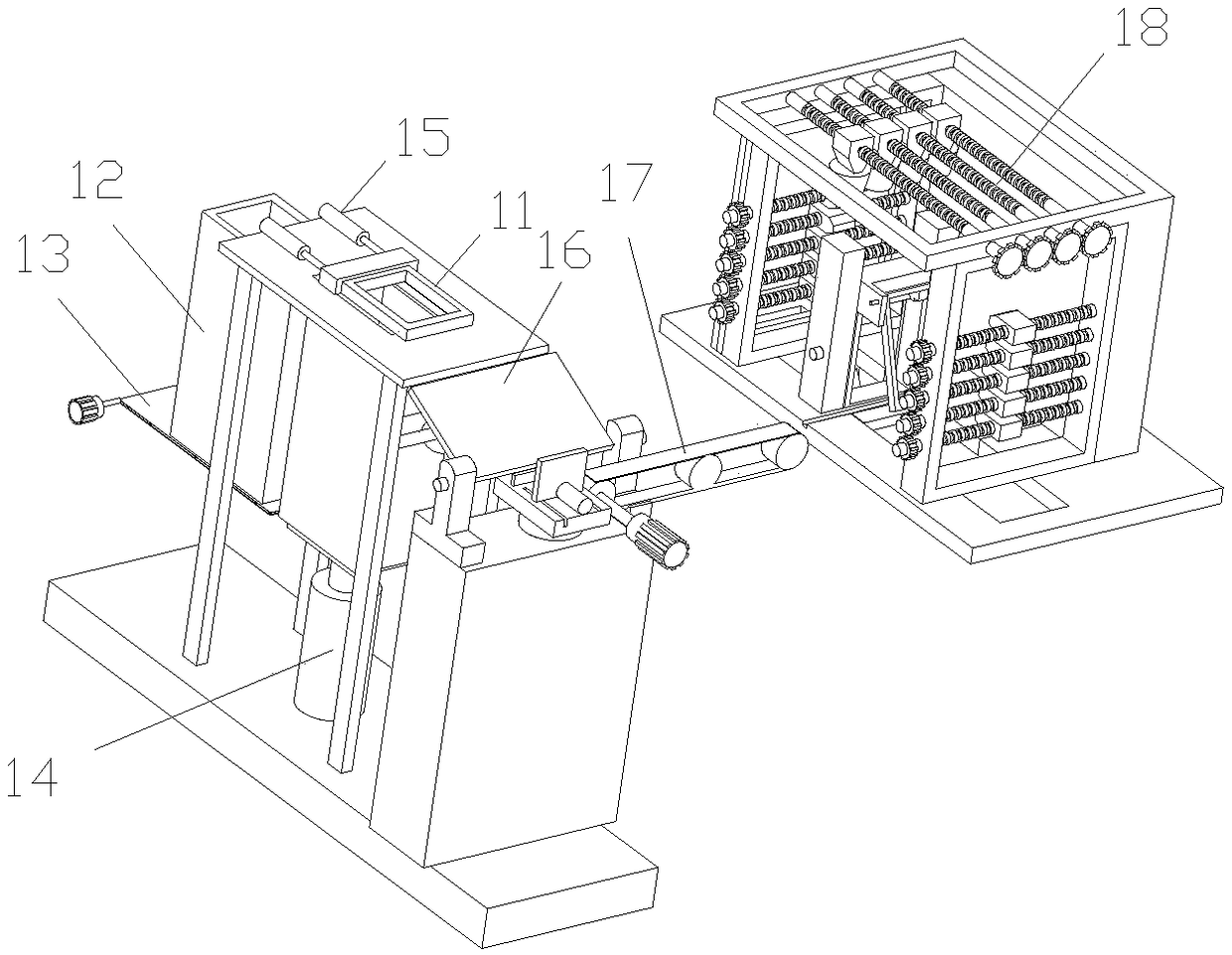

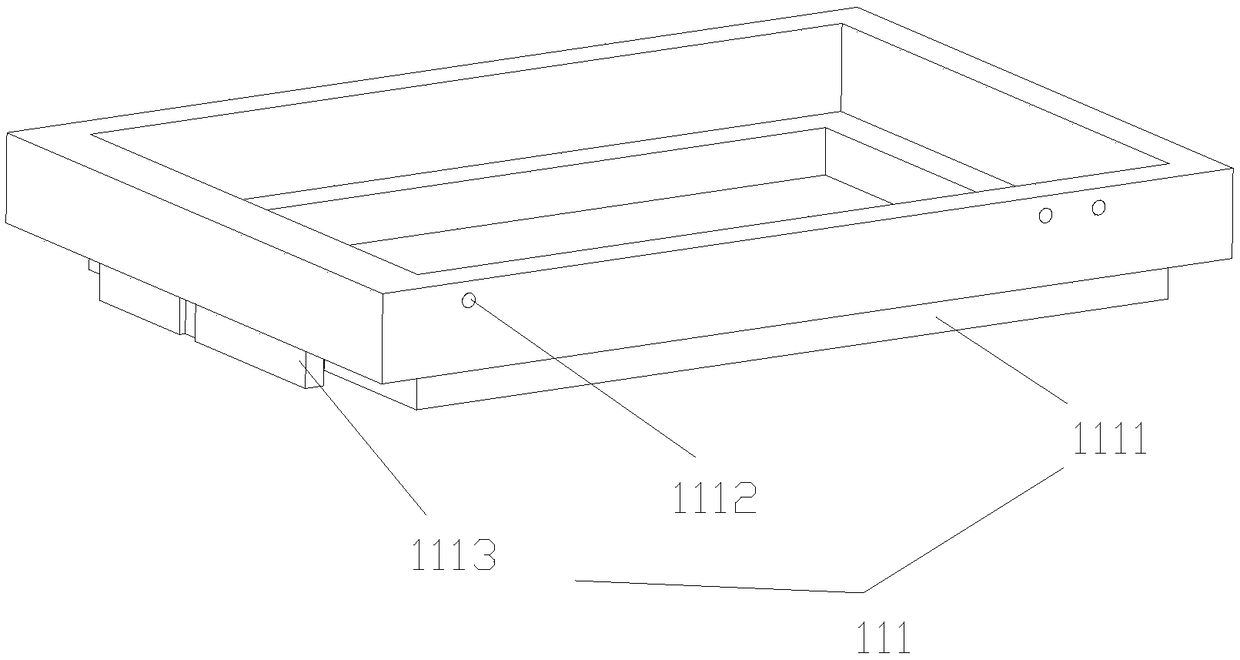

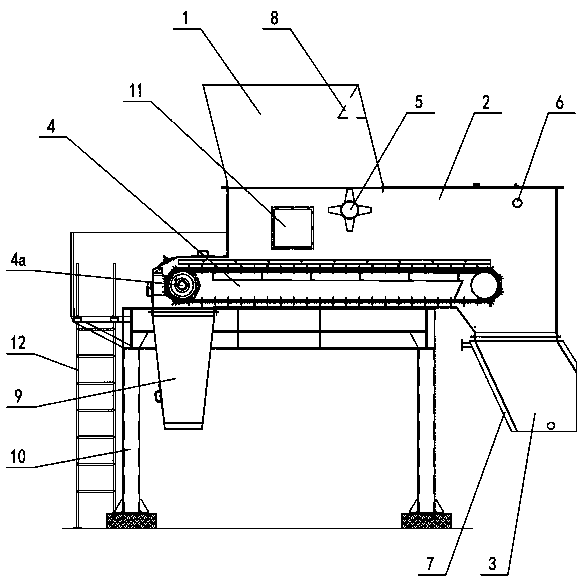

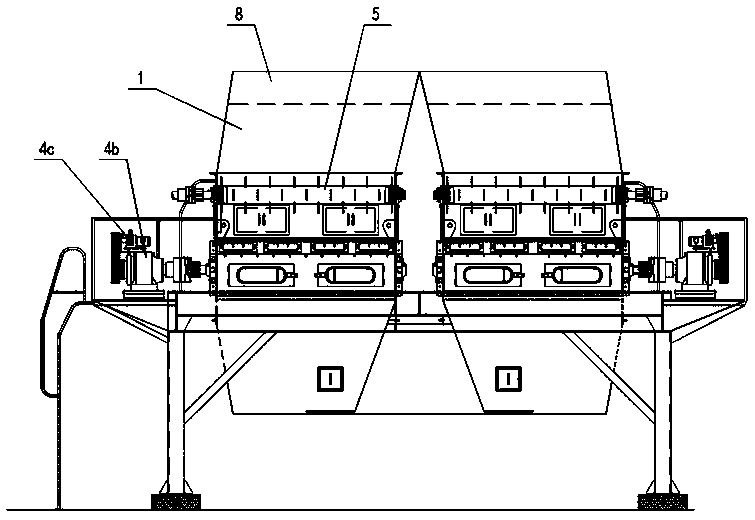

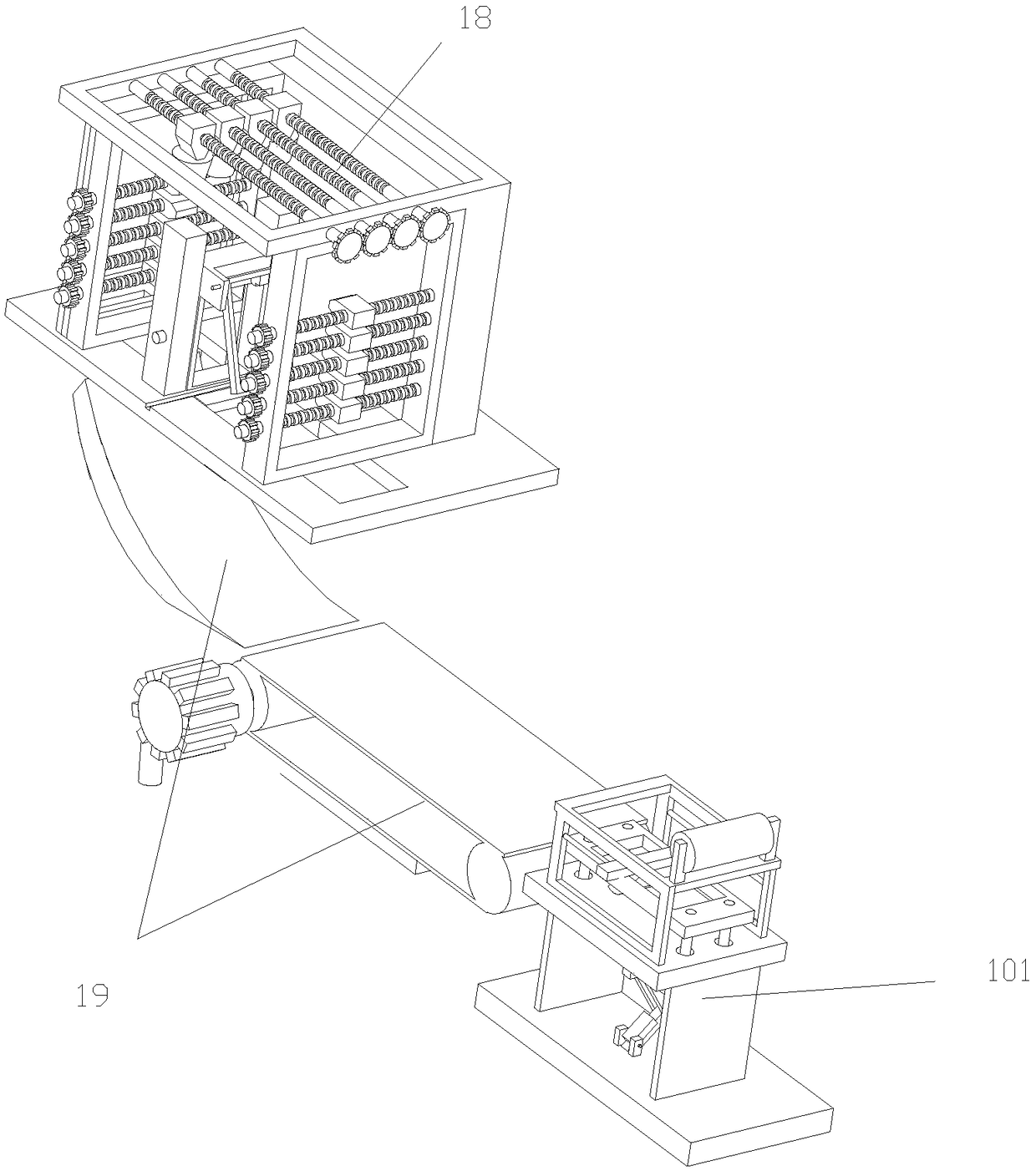

Emulsion opal glass charging machine

ActiveCN104176903AReduce the impactGood feeding uniformityCharging furnaceGlass productionEmulsionEngineering

The invention discloses an emulsion opal glass charging machine comprising a material storage bin, a vibrating feeder, a horizontal conveying frame, a conveying frame displacement driving motor, a rotary working frame, a fixed base and a foundation supporting frame, wherein the vibrating feeder is arranged at the upper part of the foundation supporting frame, the bottom discharge opening of the material storage bin is connected with the material input end of the vibrating feeder, the bottom of the rotary working frame is provided with a movable rotating shaft and is connected with the fixed base, the fixed base is provided with a fixed gear plate, the bottom of the rotary working frame is provided with a gear driving motor, and the conveying frame displacement driving motor is arranged on the rotary working frame. By virtue of the mode, the emulsion opal glass charging machine disclosed by the invention can charge materials to an all-electric-melting furnace without dead angles along with the back-and-forth movement and swing of the horizontal conveying frame; the emulsion opal glass charging machine disclosed by the invention is good in material feeding uniformity, can be used for improving the production efficiency, and is small in floor area and convenient to operate.

Owner:江苏宝恒新材料科技有限公司

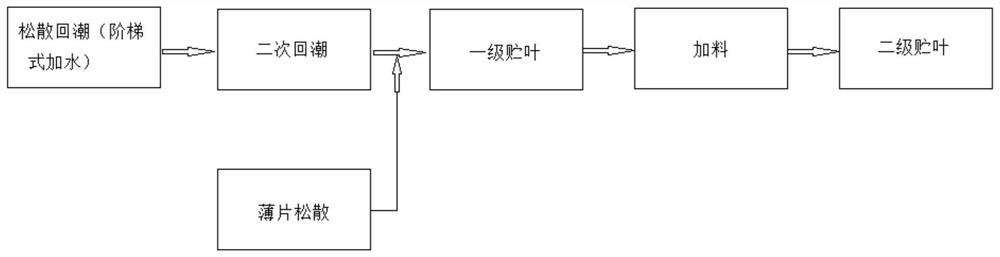

Process for accurately controlling stability of water content after shredding

ActiveCN112075658AStrong water absorptionIncrease moisture contentTobacco preparationTobacco treatmentSoil scienceEnvironmental engineering

The invention relates to a process for accurately controlling the stability of the water content after shredding. The process comprises the steps that a set amount of water is added into leaves; a setamount of feed liquid is added into the leaves with the water added through a feeding procedure; the leaves with the feed liquid added are stored under the conventional leaf storage condition; the current instant water content of the leaves subjected to primary leaf storage is detected, the difference value between the current instant water content and the set water content is calculated througha control system, and the amount of water corresponding to the difference value added into the leaves through a water adding system is controlled; and secondary leaf storage is conducted, and the leaves with the water added again are stored under the conventional leaf storage condition and then enter the subsequent procedure. According to the process, the volatilization amount of the feed liquid is far smaller than that of feed liquid in an existing production process, the difference value between the water content obtained after primary material storage and the set water content is obtained by detecting the water content, secondary storage is conducted after the amount of water for supplementing the difference value is controlled, the stability of the water content of shredded tobacco isguaranteed, the feeding uniformity is improved, and the quality of the shredded tobacco is improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Compound lining production assembly line of functional jacket

InactiveCN108943975AImprove feeding uniformityShorten processing timeLamination ancillary operationsLaminationAssembly lineTension control

The invention discloses a compound lining production assembly line of a functional jacket. The assembly line sequentially comprises a knitted fabric mounting frame, a spraying cabin, a knitted sprayedcloth mounting frame conveying device and a knitted sprayed cloth compound device successively according to sequences of process flows; the knitted fabric mounting frame is used for mounting a knitted fabric therein; the spraying cabin is used for spraying the knitted fabric in the knitted fabric mounting frame; and the knitted sprayed cloth mounting frame conveying device is used for conveying the sprayed knitted fabric mounting frame to the knitted sprayed cloth compound device, and the knitted sprayed cloth compound device is used for compounding and finishing the sprayed knitted fabric. The assembly line has the advantages of being good in spraying uniformity, reducing shell fabric shrinkage caused by difficulty in controlling tension and being capable of feeding the fabric on two sides at the same time.

Owner:安徽京威纺织服饰有限公司

Method for preparing products of silk-shaped tobacco stalks

ActiveCN101720975BIncrease fill valueImprove inner qualityTobacco treatmentPulp and paper industryPre treatment

The invention provides a method for preparing products of silk-shaped tobacco stalks. The method is characterized by mainly comprising the following steps: 1) pre-treating the tobacco stalks; 2) the primary defibrination of the pre-treated tobacco stalks to make the water content of the tobacco stalks reach 30 to 60 percent; 3) twisting the tobacco stalks undergoing the primary defibrination intocut stems, of which the width is 1.2 to 2.0mm and the length is 2.0 to 30.0mm; and 4) drying the twisted cut stems until the water content of the cut stems reaches 10 to 13 percent, and perfuming thecut stems by process. In the method, an input-output ratio in actual production is high, and the prepared cut stems do not retain bad aftertaste after being smoked, so that the intrinsic quality is improved; the fill value is high, and the feeding uniformity is good; the colors and shapes of the products of silk-shaped tobacco stalks of the invention are close to the cut tobacco, the distributionof the products of the invention in cigarettes is more uniform than that of the conventional cut stems and tobacco stalk particles, and the rolling performance of the cut stems are improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Automotive silicon oil fan clutch aluminum alloy front cover die-casting mold

Owner:TAIZHOU SHUNYI AUTOMOBILE PARTS

A kind of opacity glass feeding machine

ActiveCN104176903BImprove feeding uniformityIncrease productivityCharging furnaceGlass productionElectricityDrive motor

The invention discloses an opaque glass feeder, which comprises: a storage bin, a vibrating feeder, a horizontal conveying frame, a displacement drive motor for the conveying frame, a rotating work frame, a fixed base and a foundation support. The vibrating feeder is provided with On the upper part of the base support, the bottom outlet of the storage bin is connected with the material input end of the vibrating feeder, and the bottom of the rotating work frame is provided with a movable shaft connected with a fixed base, on which A fixed gear plate is provided, a gear drive motor is provided at the bottom of the rotating working frame, and the displacement driving motor of the conveying frame is arranged on the rotating working frame. Through the above method, the opacity glass feeding machine pointed out by the present invention can feed the all-electric melting furnace without dead angle along with the back and forth movement and swing of the horizontal conveying frame, the uniformity of feeding is good, and the production efficiency is improved. The floor area is small and the operation is convenient.

Owner:江苏宝恒新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com