Circulation fluidized dry flue gas desulfurizing process by adopting mixed feeding mode

A dry flue gas desulfurization and mixed feeding technology, applied in the field of dry flue gas desulfurization process and dry desulfurization system, can solve the problems of low concentration and affect the reaction efficiency, so as to increase the amount of feed and increase the amount of feed. The effect of uniformity and improved space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

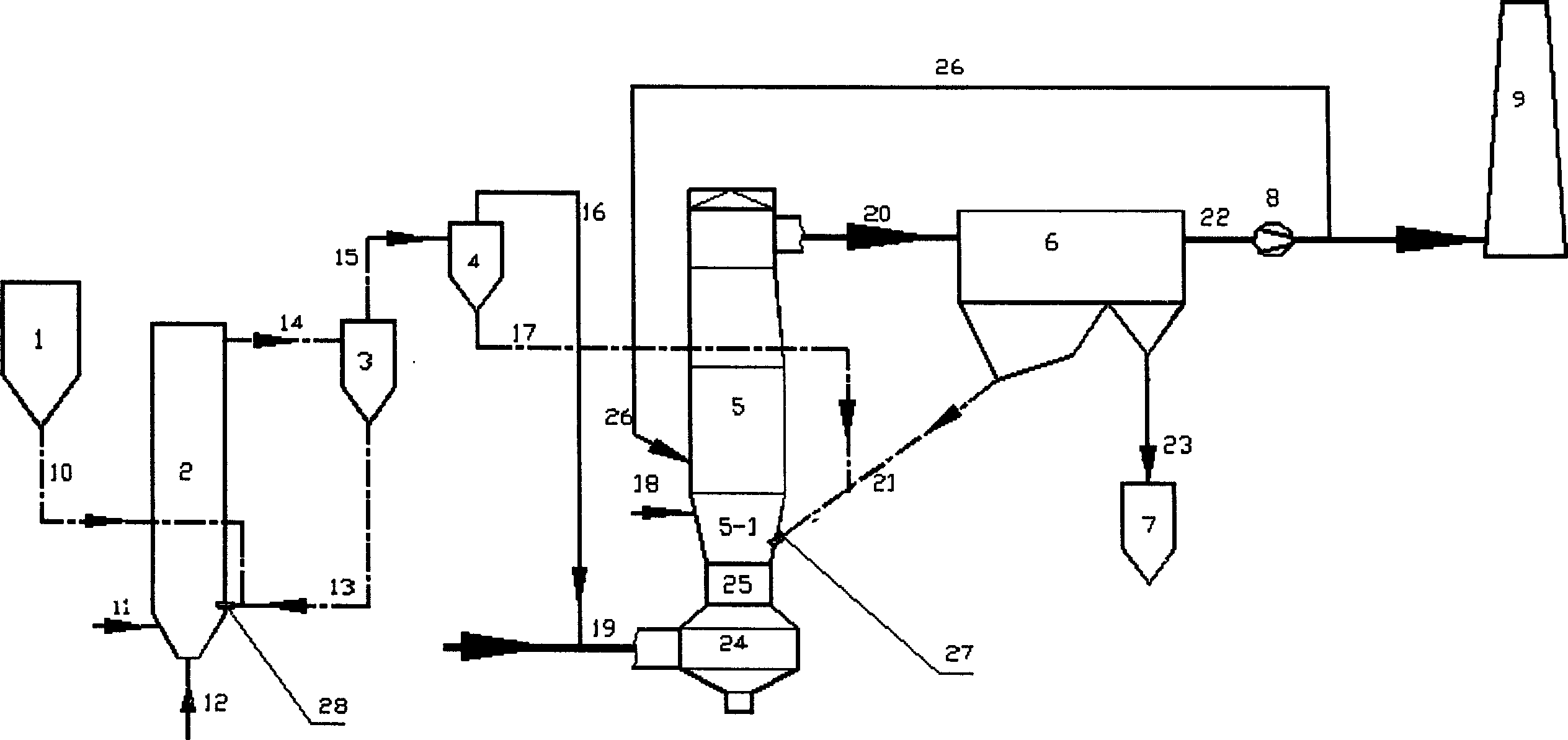

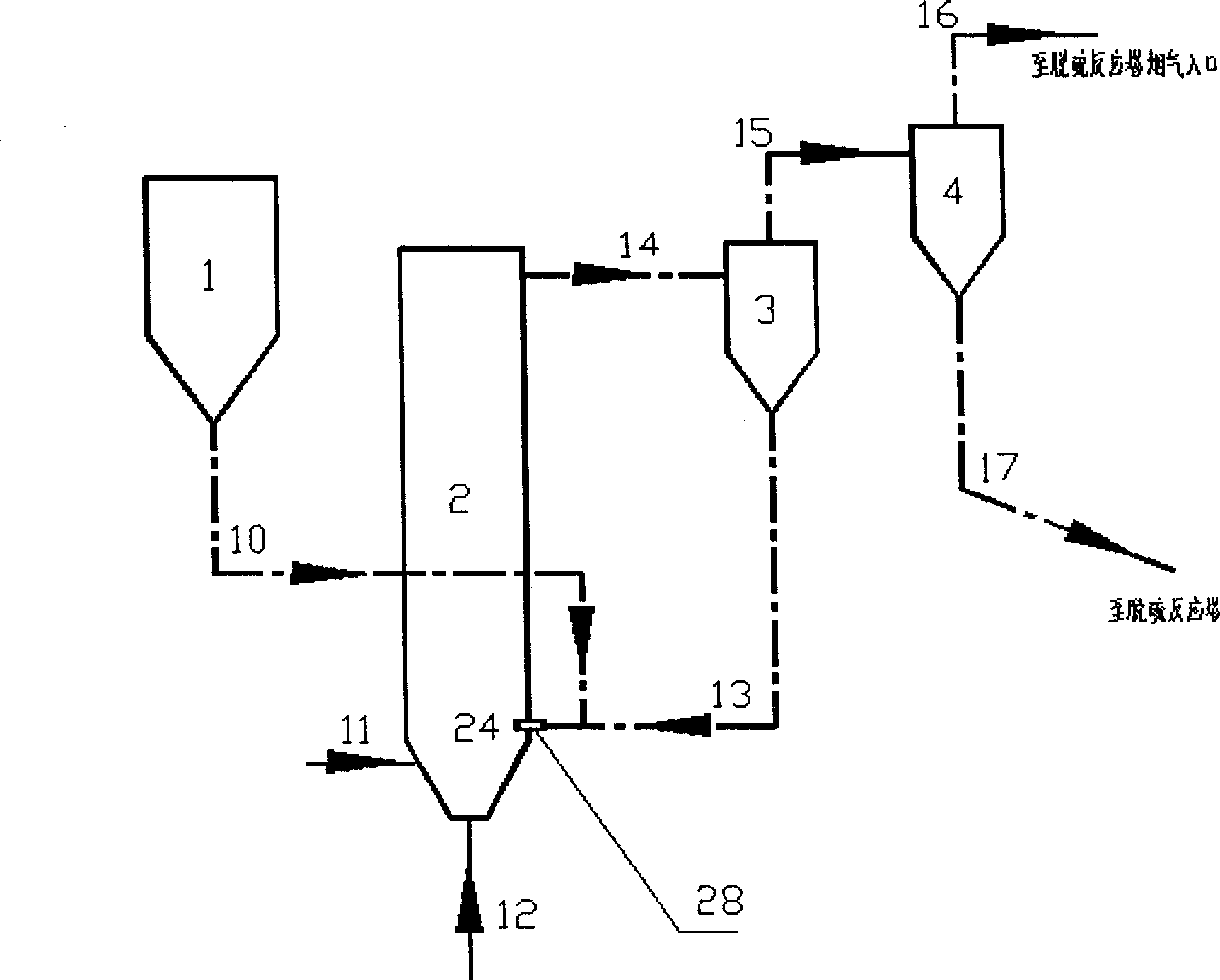

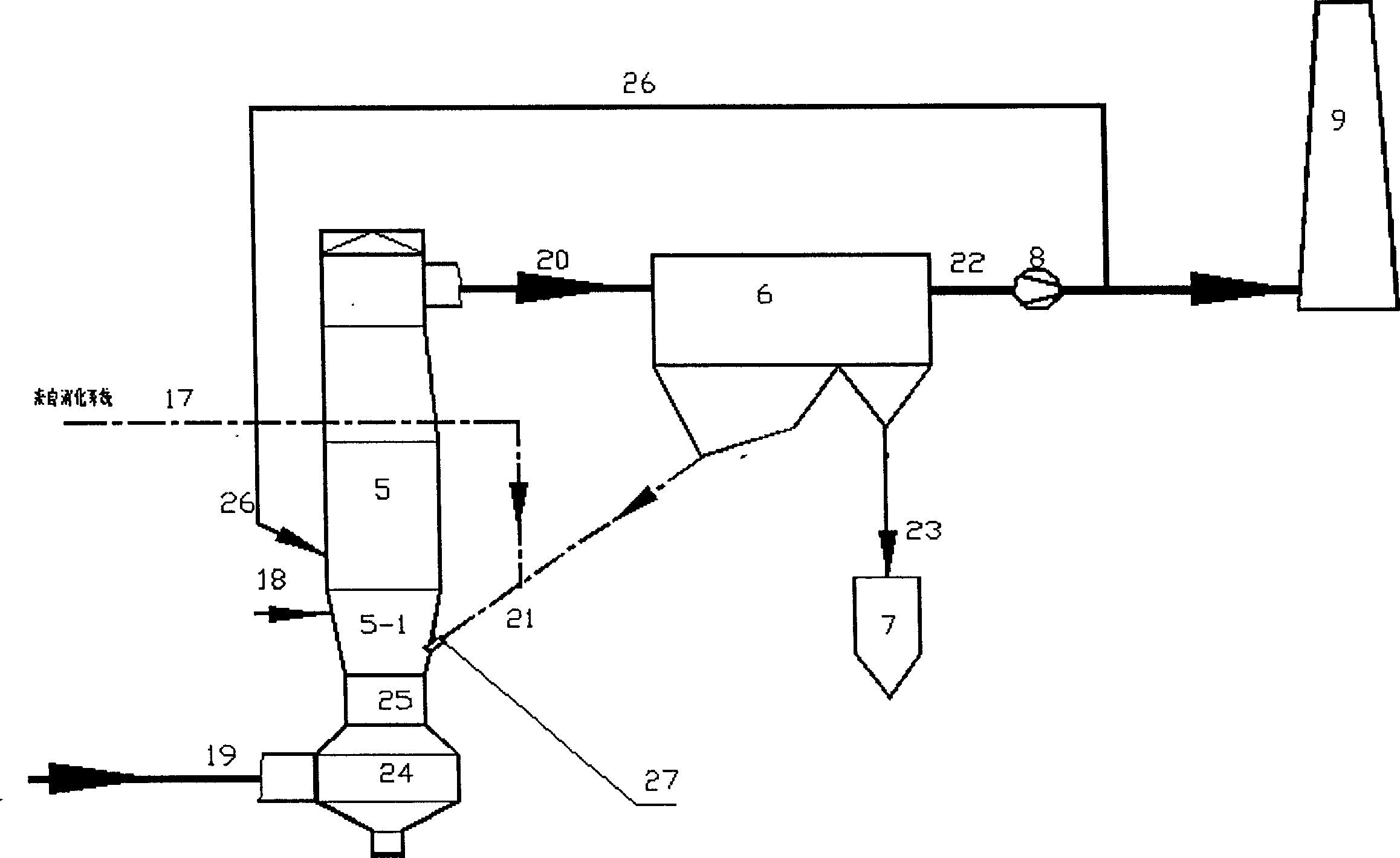

[0028] Below in conjunction with accompanying drawing, specifically illustrate embodiment, technological process and system arrangement structure of the present invention:

[0029] Such as figure 1 : The present invention includes a digestion reaction system for desulfurization agent preparation, a desulfurization reaction tower and a desulfurization reaction system, and a separation and recirculation system for external desulfurization agent particles.

[0030] In the digestion reaction system, the raw material feed pipe 10 for the desulfurizer and the recirculation pipe 13 of the recirculation material separated by the separation device 3 of the digestion system after passing through the digestion tower are combined outside the tower, and fed into the digestion system through a feed nozzle 28. Reaction tower 2.1 is the desulfurizer raw material quicklime warehouse. In the digestion reaction system, the separation device adopts two stages 3 and 4. There are also digestion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com