Anti-sticking and anti-dropping charging and flavoring device

A technology of feeding, flavoring and dripping, which is applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of uneven content of tobacco leaf material liquid, affecting product processing quality, waste of material liquid, etc., and achieves simple structure, practical function and convenient feeding good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

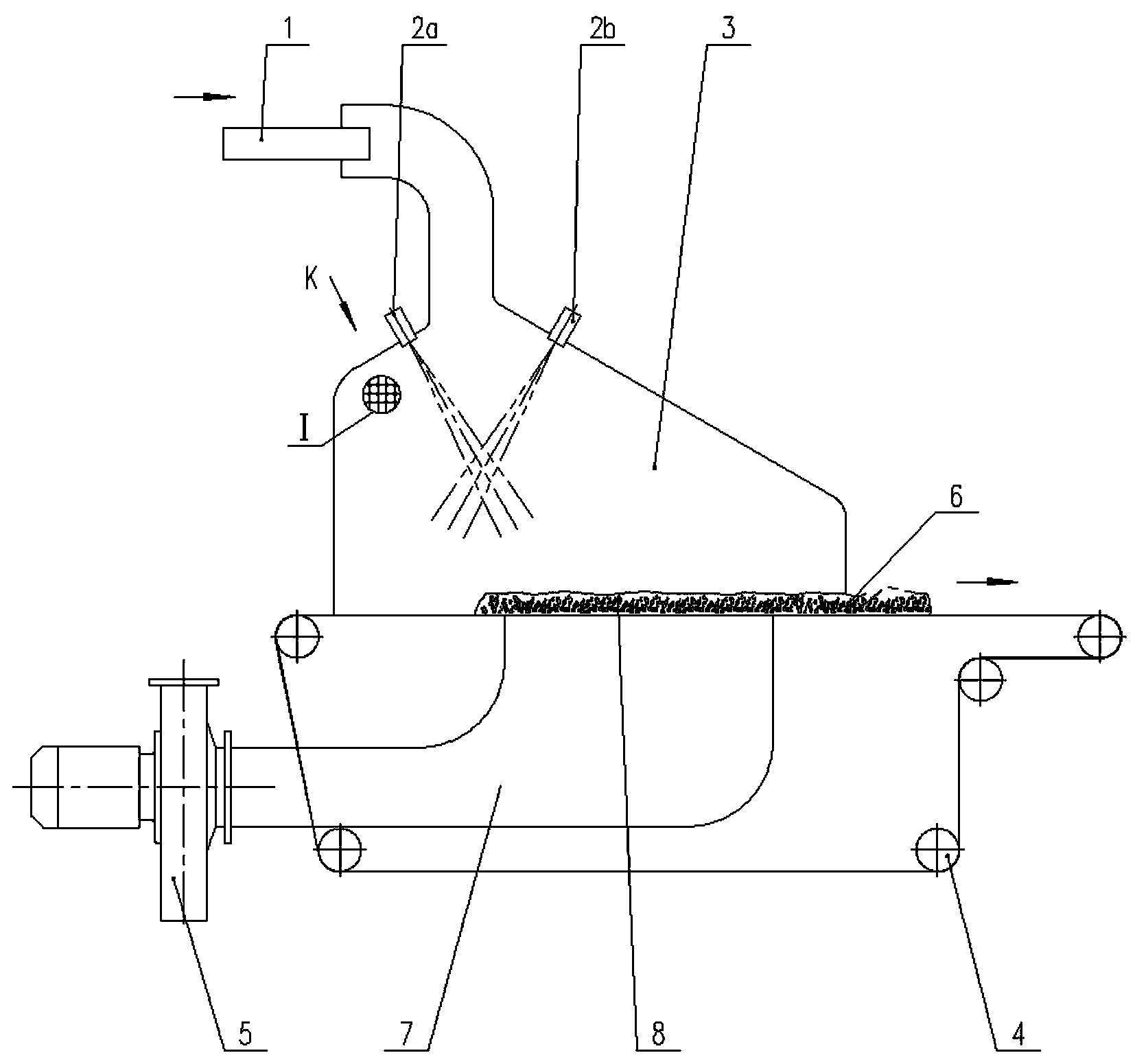

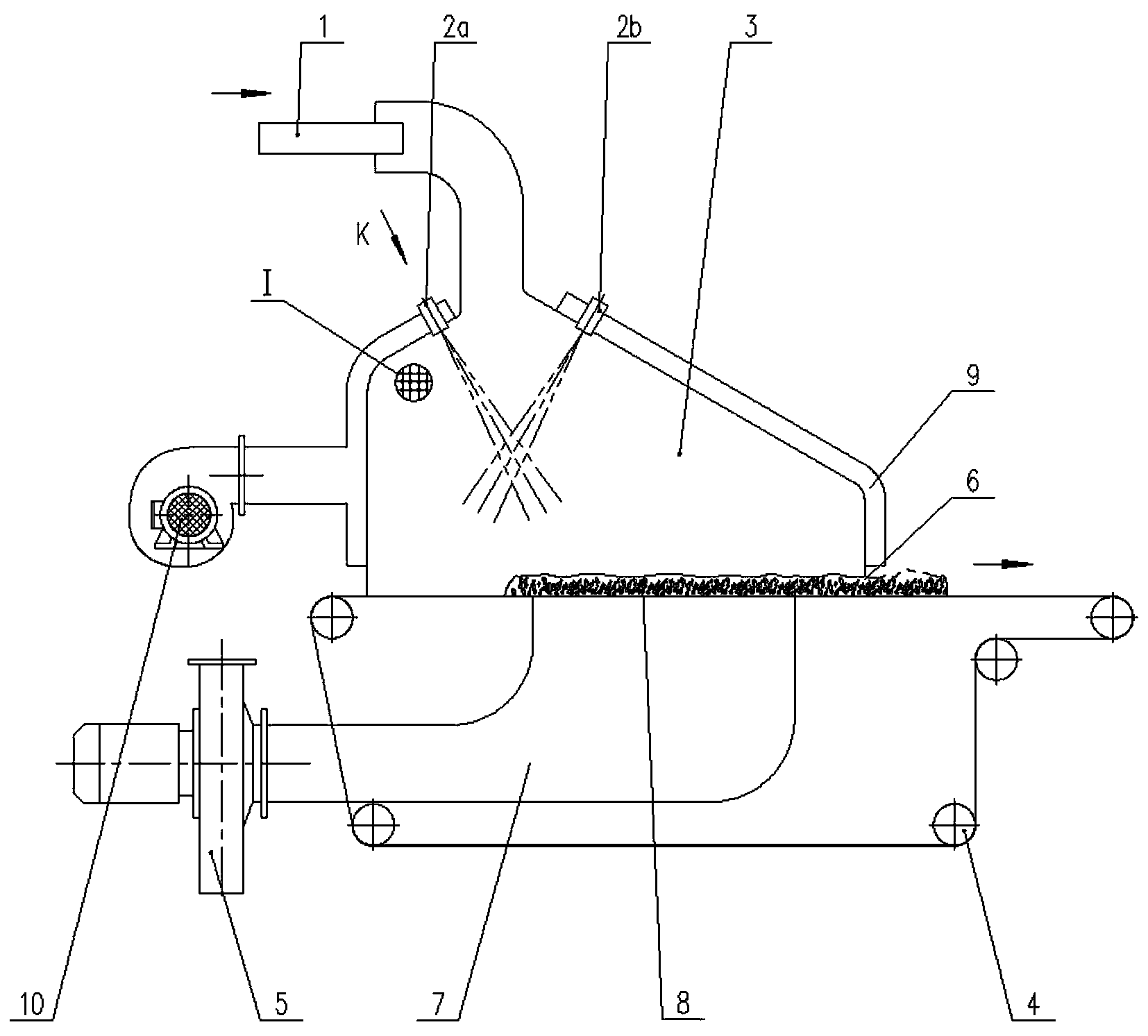

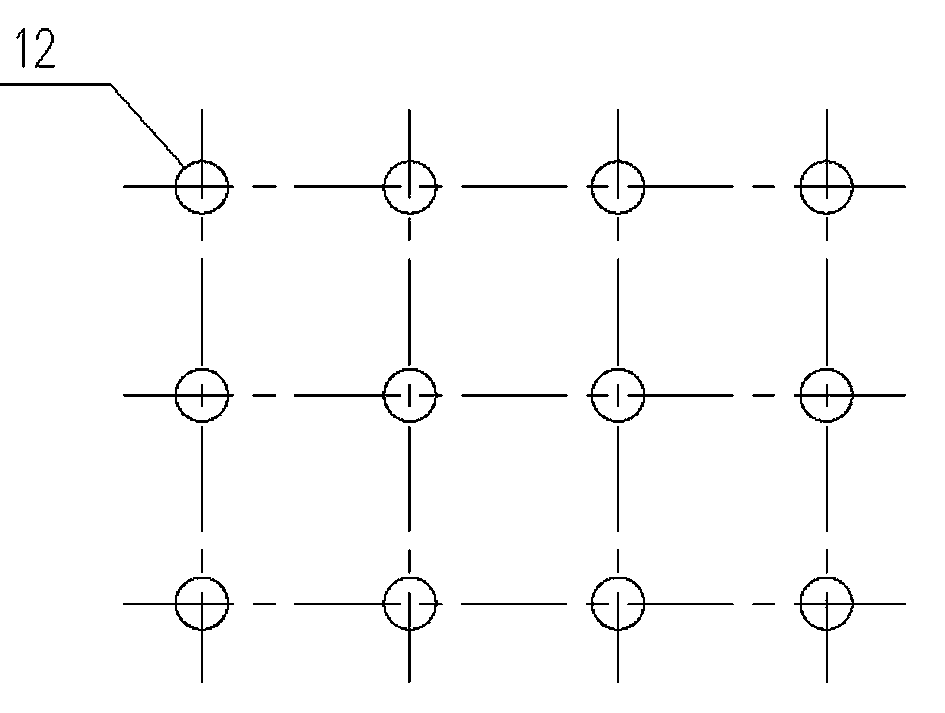

[0015] Example: such as figure 1 , 3 , shown in 4, a kind of feeding and perfuming device that prevents sticky material and dripping, comprises feeding cavity 3, and the top of feeding cavity 3 is connected with feeding conveyor belt, and feeding device 1 is arranged at the entrance of feeding conveyor belt; The lower side of the feeding cavity 3 is provided with a conveying device, and the conveying device includes a conveying platform, and a negative pressure cavity 7 is arranged below the conveying platform, and a negative pressure device 5 is provided on the wall of the negative pressure cavity 7; Nozzles 2a, 2b are arranged on the body, and vent holes 11 are arranged around the nozzles 2a, 2b. The negative pressure device 5 is an exhaust fan. The walls around the feeding cavity 3 are provided with cavity ventilation holes 12 . The vent hole 11 around the nozzle is annular, and the diameter of the outer circle of the vent hole 11 is 50-100 mm; the diameter of the cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com