Leaf thread material feeding process and equipment

A technology of feeding equipment and leaf shreds, which is applied in the field of tobacco processing, can solve the problems of agglomeration of feeding materials, large shredded tobacco sheets, etc., achieve less loss of feed liquid, absorb more feed liquid, and reduce sticking and drawing of shreds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

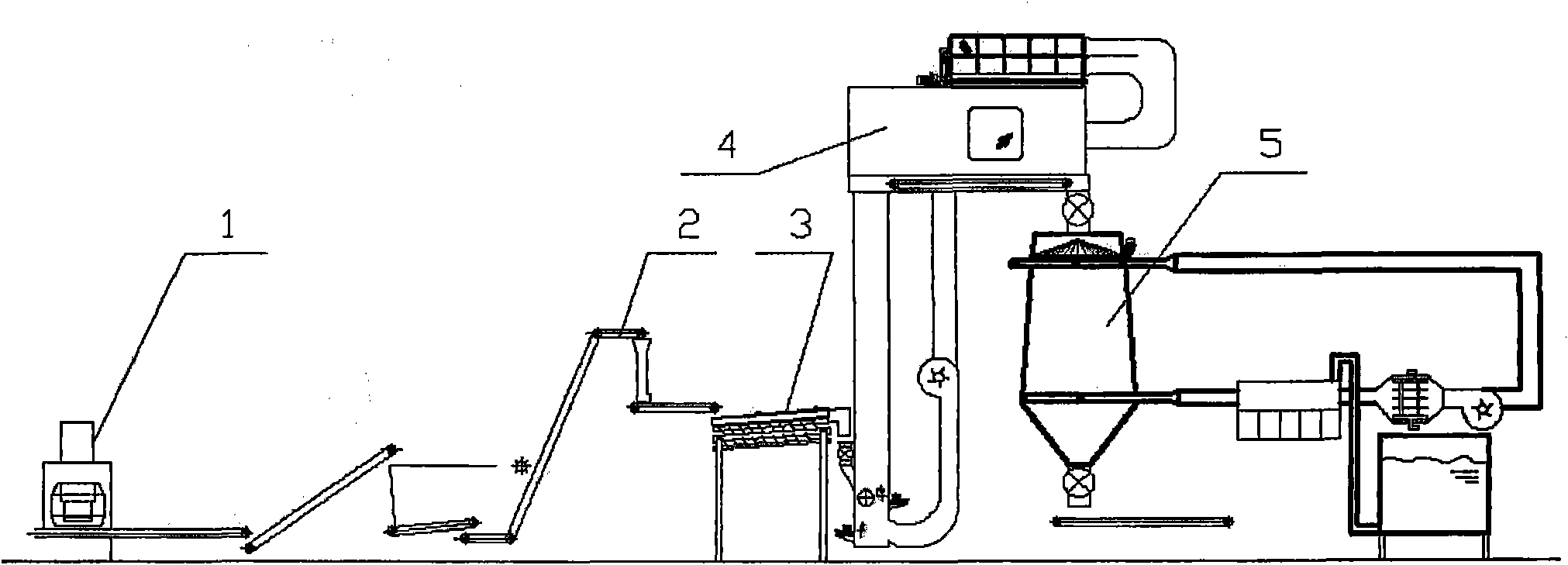

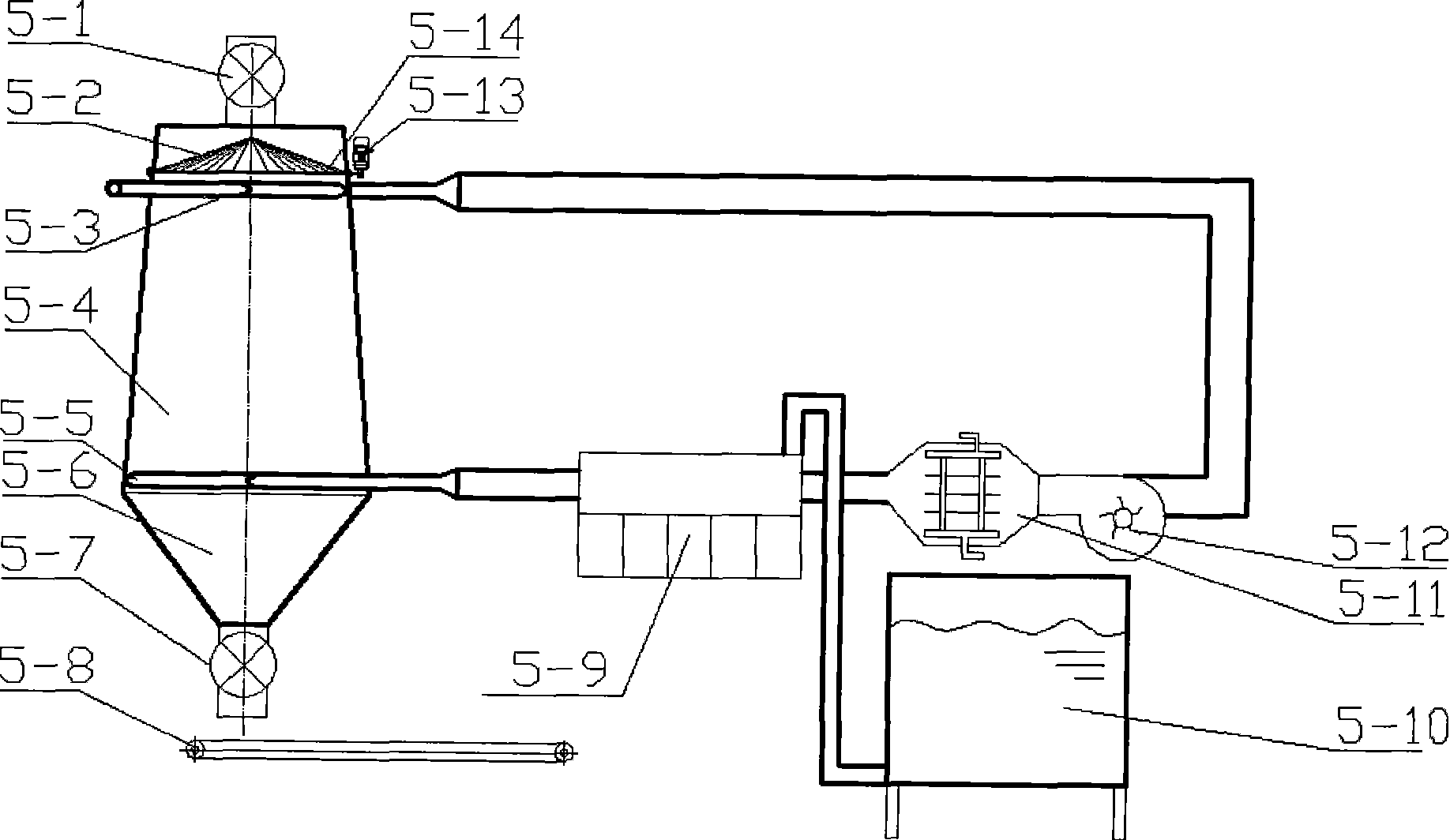

[0031] The present invention will further describe leaf silk feeding process and equipment below in conjunction with accompanying drawing:

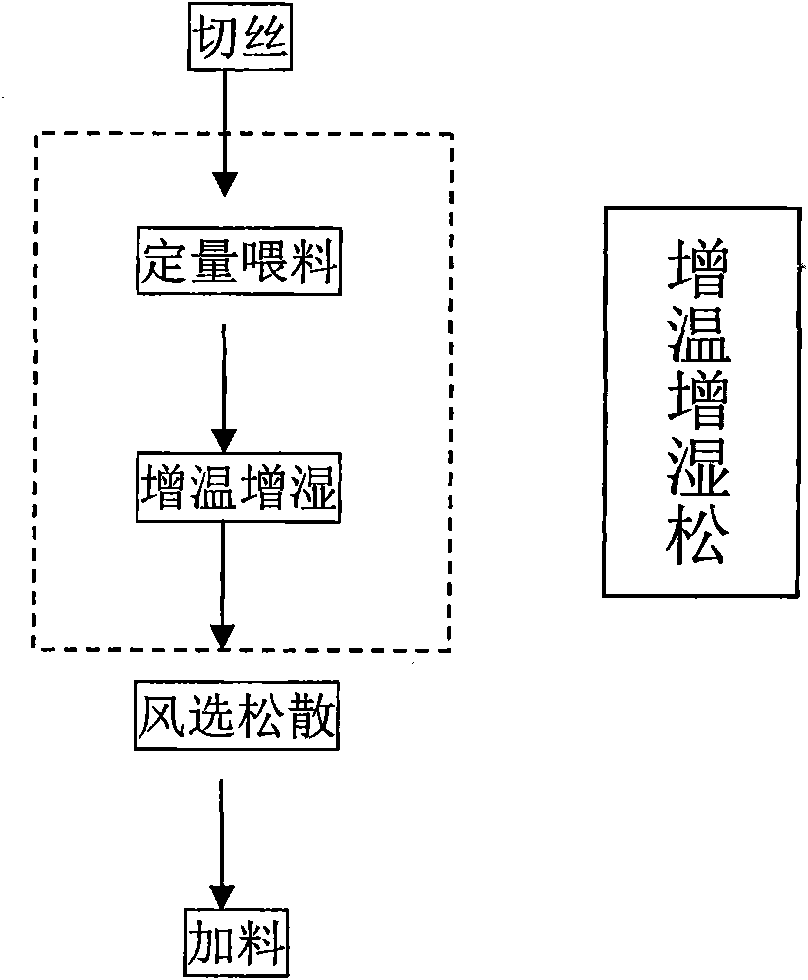

[0032] Such as figure 1 Shown: the shredded leaf feeding process of the present invention comprises four operations such as shredding, warming and humidification loosening, winnowing loosening and feeding, and the concrete steps of each operation are as follows:

[0033] 1. Shred: Send the raw tobacco sheet (moisture content 18.0% to 19.0% ± 1.0%) into the shredder for shredding. Low knife door pressure shredding machine (knife door pressure is 0.12-0.15MPa) for shredded, shredded width of 1.0±0.1mm.

[0034] 2. Warming and humidification loosening: In order to loosen the shredded leaves, pass the shredded leaf shreds through a quantitative feeder (the flow fluctuation of the quantitative feeder is less than 1.0%, and the electronic scale in the quantitative feeder measures Accuracy is less than 1.0%) transported to the vibrating fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com