Tobacco lamina mixing processing method

A processing method and technology of sheet tobacco, applied in the fields of tobacco, tobacco preparation, manufacturing computing system, etc., can solve the problems of poor mixing uniformity, low mechanical degree, inconvenient operation, etc., reduce crushing and loss, and improve uniformity , the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

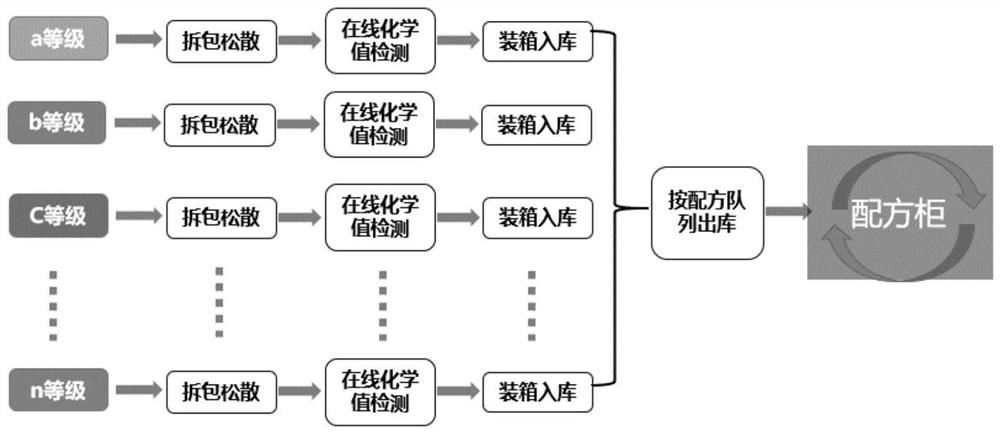

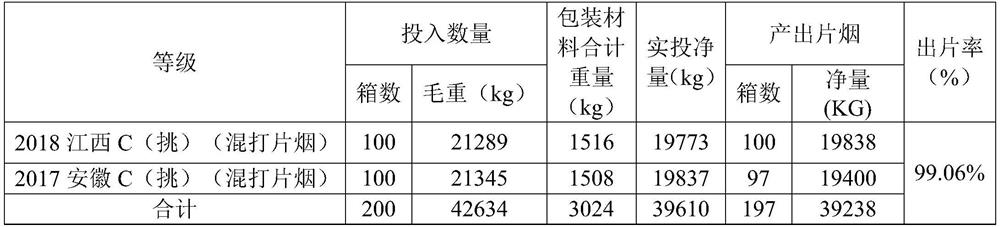

[0052] The plan for blending and processing of lamina in this example: "Origin-Anhui; grade-C (pick); year-2017; category-cured tobacco; ;Grade-C (pick); Year-2018; Category-Cured Tobacco; Form-Mixed Sheet Tobacco; Number of Boxes-100" Each batch of 200 boxes is combined into a raw material grade, and the combined name is "Origin-Jiangxi; Grade-C21; Year-2018; Category-Cured-cured Tobacco; Form-Mixed Tobacco".

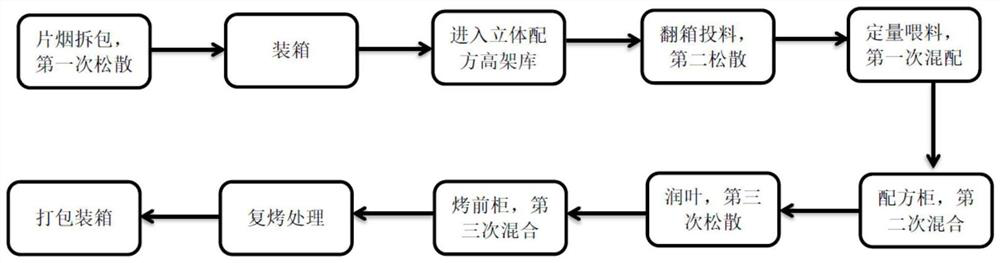

[0053] The sheet tobacco mixing processing method of the present embodiment comprises the following steps:

[0054] 1) Put the sliced cigarettes produced in Anhui or Jiangxi on the conveyor belt, and transport them to the turning device through the conveyor belt. First, the outer packing box is manually removed, and then the cigarette box is turned 180° by the turning equipment, and then the outer packing box is removed. The unpacked laminar stacks are layered and loosened by the unpacking and loosening device to complete the first loosening, and the debris and poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com