Micro-ecological bedding material for raising aquatic birds and preparation method thereof

A technology of micro-ecology and microbial preparations, applied in poultry farming, poultry cages or houses, applications, etc., can solve the problems of poor waste disposal ability and easy hardening, so as to ensure the looseness of litter, broad application prospects, and overcome waste The effect of incompetence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

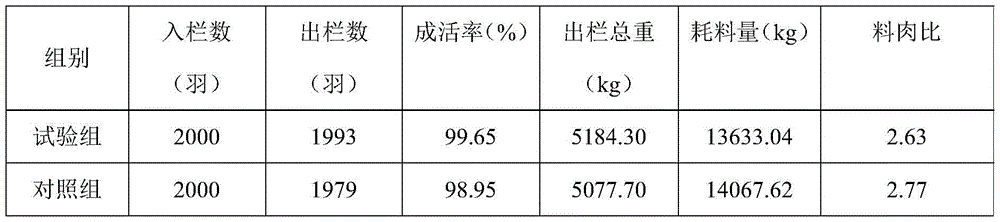

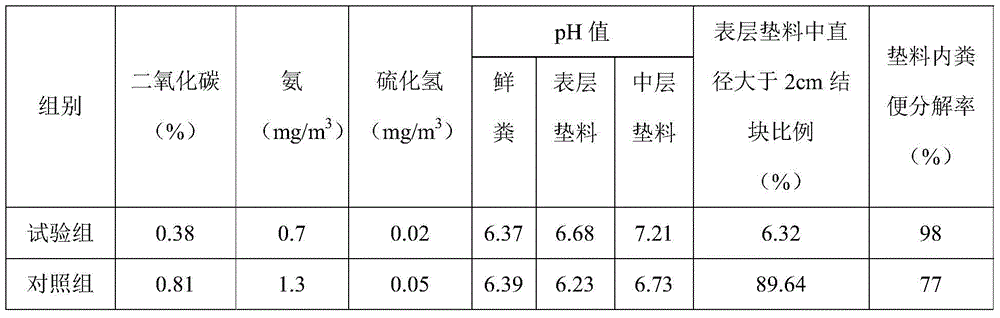

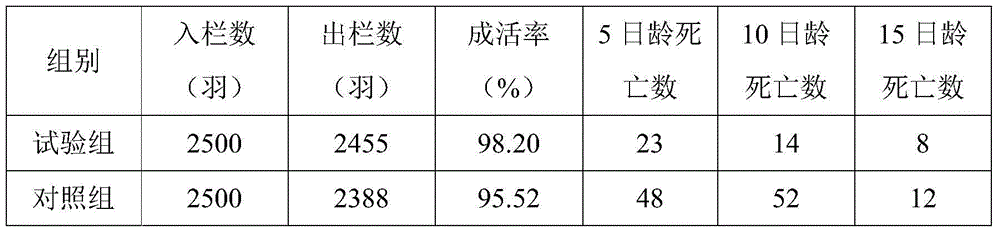

Examples

Embodiment 1

[0024] (1) Form A preparation: 1000kg of sawdust containing high lignin is pulverized to a particle size of 10mm, the moisture is adjusted to 40% (w / w), and the number of effective viable bacteria added is 2×10 8 Licheniformis and brewer's yeast mixture (weight ratio: 1:1) 10kg, urea 30kg and brown sugar 10kg, after fully mixing evenly, pile up and ferment for 48h; when the temperature in the center of the pile exceeds 55°C, fully overturn it Afterwards, heap again, ferment 48h; After this step is repeated once more, when heap body center temperature exceeds 55 ℃ for the third time, maintain 24h, make moisture content be 30% (w / w), carbon-nitrogen ratio ( C / N) is 65, the number of effective viable bacteria is 3×10 7 , the elimination of germs, insect eggs, and grass seeds is 99% of the A formulation;

[0025] (2) Form B preparation: 1000kg of sawdust containing high lignin is crushed to a particle size of 10mm, the moisture is adjusted to 10% (w / w), and the number of effectiv...

Embodiment 2

[0028] (1) Form A preparation: crush 1000kg of stalks containing high lignin to a particle size of 10mm, adjust the water content to 50% (w / w), and add an effective viable count of 3×10 8 10kg of the mixture of Bacillus subtilis and Candida utilis (weight ratio is 1:1), 30kg of ammonia water and 10kg of molasses, after fully mixing evenly, pile them into piles and ferment for 48h; when the temperature in the center of the pile exceeds 55°C, After being fully overturned, pile up again and ferment for 48 hours; after this step is repeated once more, when the temperature in the center of the pile exceeds 55°C for the third time, it is maintained for 50 hours, and the moisture content is 40% (w / w). The carbon-to-nitrogen ratio (C / N) is 45, and the effective number of viable bacteria is 4×10 7 , the elimination of germs, insect eggs and grass seeds is 100% A formulation;

[0029] (2) Formulation of agent B: crush 1000kg of straw containing high lignin to a particle size of 10mm, a...

Embodiment 3

[0032] (1) Form A preparation: crush 1000 kg of corn cobs containing high lignin to a particle size of 8 mm, adjust the moisture to 50% (w / w), and add effective viable bacteria to be 3 × 10 8The mixture of Bacillus licheniformis, brewer's yeast and plantarum lactobacillus (weight ratio is 1:1:1) 10kg, ammonia water 30kg and molasses 10kg, after mixing well, pile them up and ferment for 48h; ℃, fully overturned, piled up again, and fermented for 48 hours; after this step was repeated once more, when the temperature in the center of the pile exceeded 55℃ for the third time, it was maintained for 48 hours to make a moisture content of 50% (w / w), the carbon-to-nitrogen ratio (C / N) is 48, and the effective number of viable bacteria is 3×10 7 , the elimination of germs, insect eggs and grass seeds is 100% A formulation;

[0033] (2) Form B preparation: crush 1000 kg of corncobs containing high lignin to a particle size of 8 mm, adjust the moisture to 10% (w / w), and add an effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com