Tobacco feeding mechanism

A technology of tobacco and material liquid, which is applied in the fields of tobacco, tobacco preparation, sustainable manufacturing/processing, etc., can solve the problems of difficult to control the precision of application material liquid, unstable tobacco quality, cumbersome operation, etc. the effect of ensuring looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

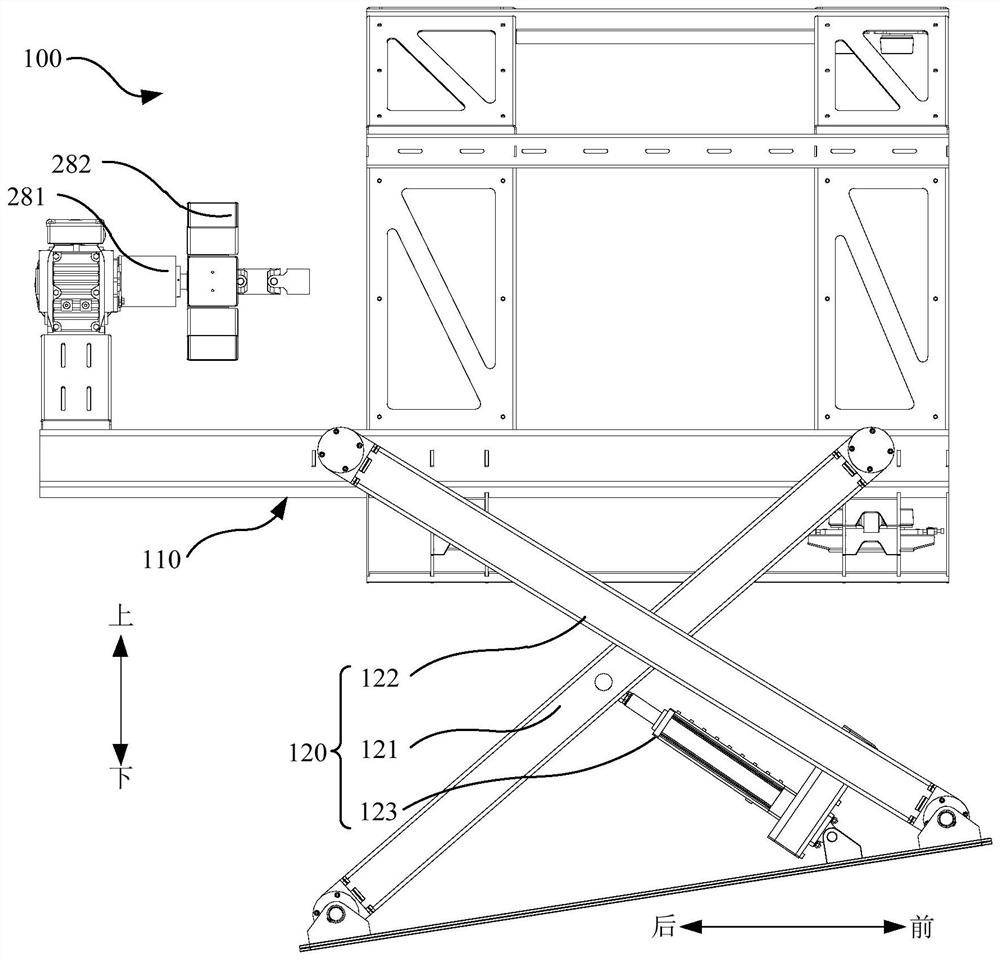

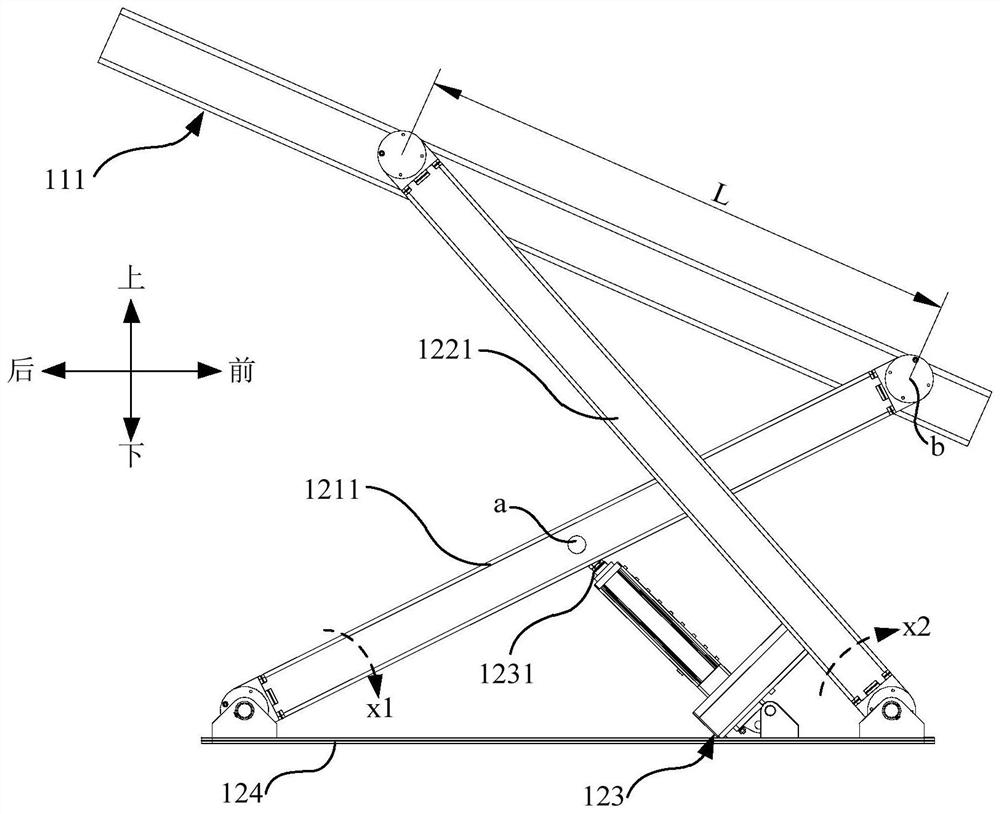

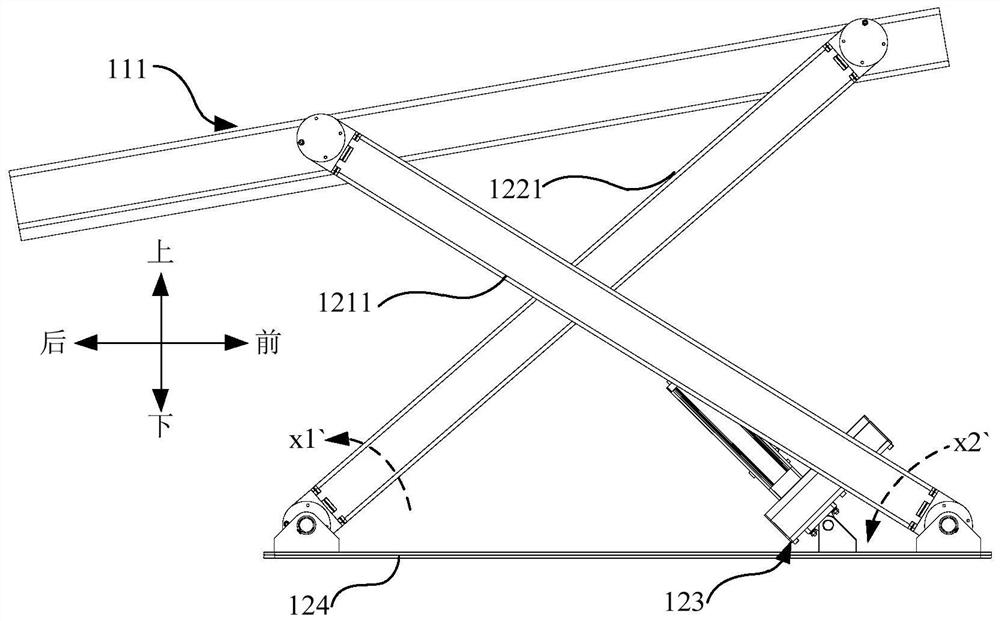

[0141] The present invention provides a tobacco feeding mechanism 200 suitable for laboratory conditions, specifically a tobacco feeding mechanism 200 capable of heating, humidifying, feeding and flavoring tobacco.

[0142] The tobacco feeding mechanism 200 mainly includes an electric heating drum 210, a frame 111, a discharge cover 220 and a pipeline system. The tobacco feeding mechanism 200 only needs power supply and compressed air as energy supply, and integrates the functions of stirring, loosening, heating, humidifying, feeding and flavoring. Compared with the production capacity of 40g-400g of other tobacco testing devices, the production capacity of this embodiment can reach 5kg-10kg.

[0143] The cylinder body 211 of the electric heating drum 210 is a polygonal cylinder body 211, and the silicon rubber electric heating sheet 2131 is pasted on the outer surface of the cylinder body 211 to heat the entire inner wall of the cylinder body 211 to realize the heating of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com