Automotive silicon oil fan clutch aluminum alloy front cover die-casting mold

A die-casting molding and clutch technology, applied in the field of die-casting molding, can solve the problems of increasing product scrap rate, not taking into account, etc., and achieve the effect of low scrap rate, less air bubbles, and uniform overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

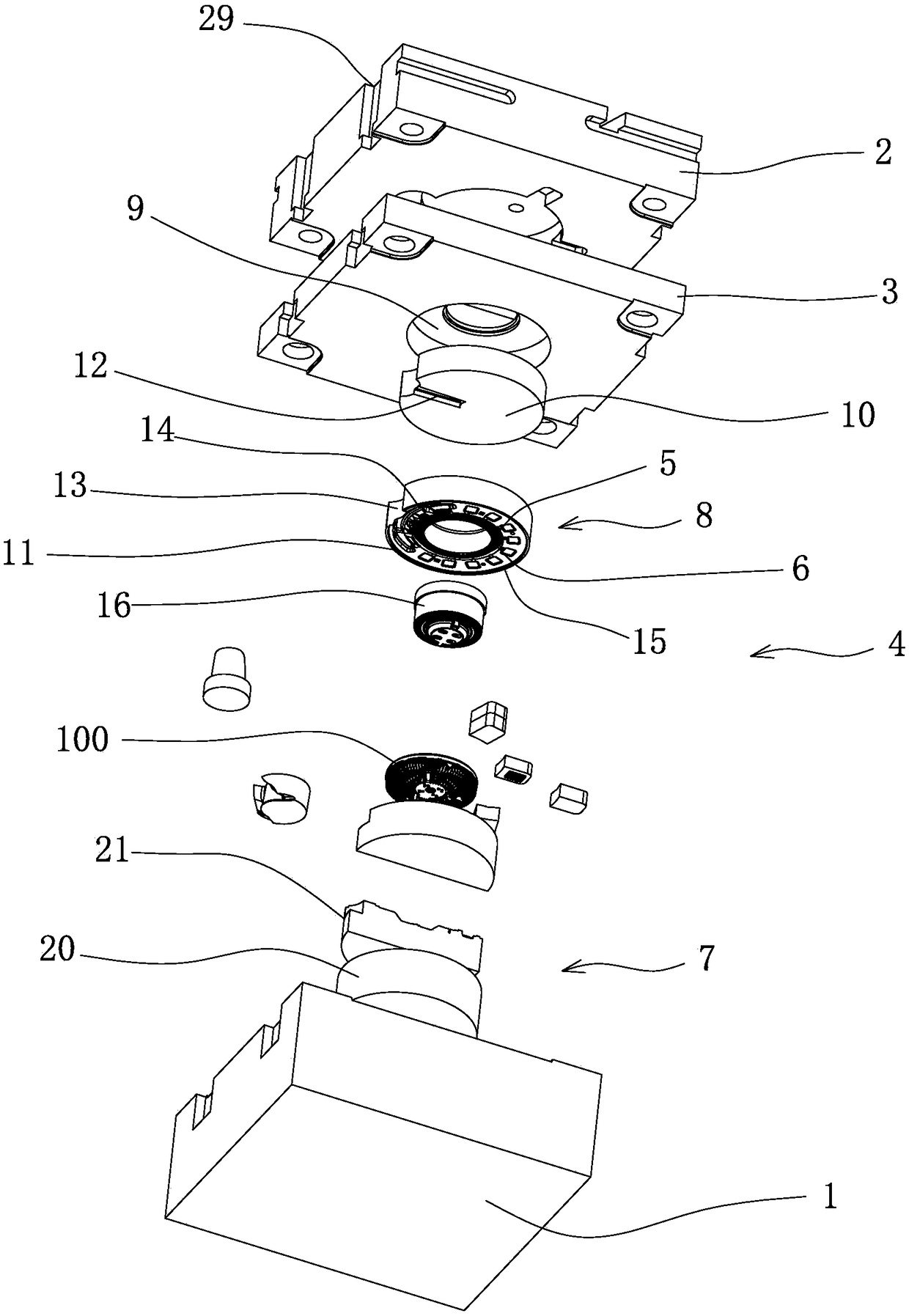

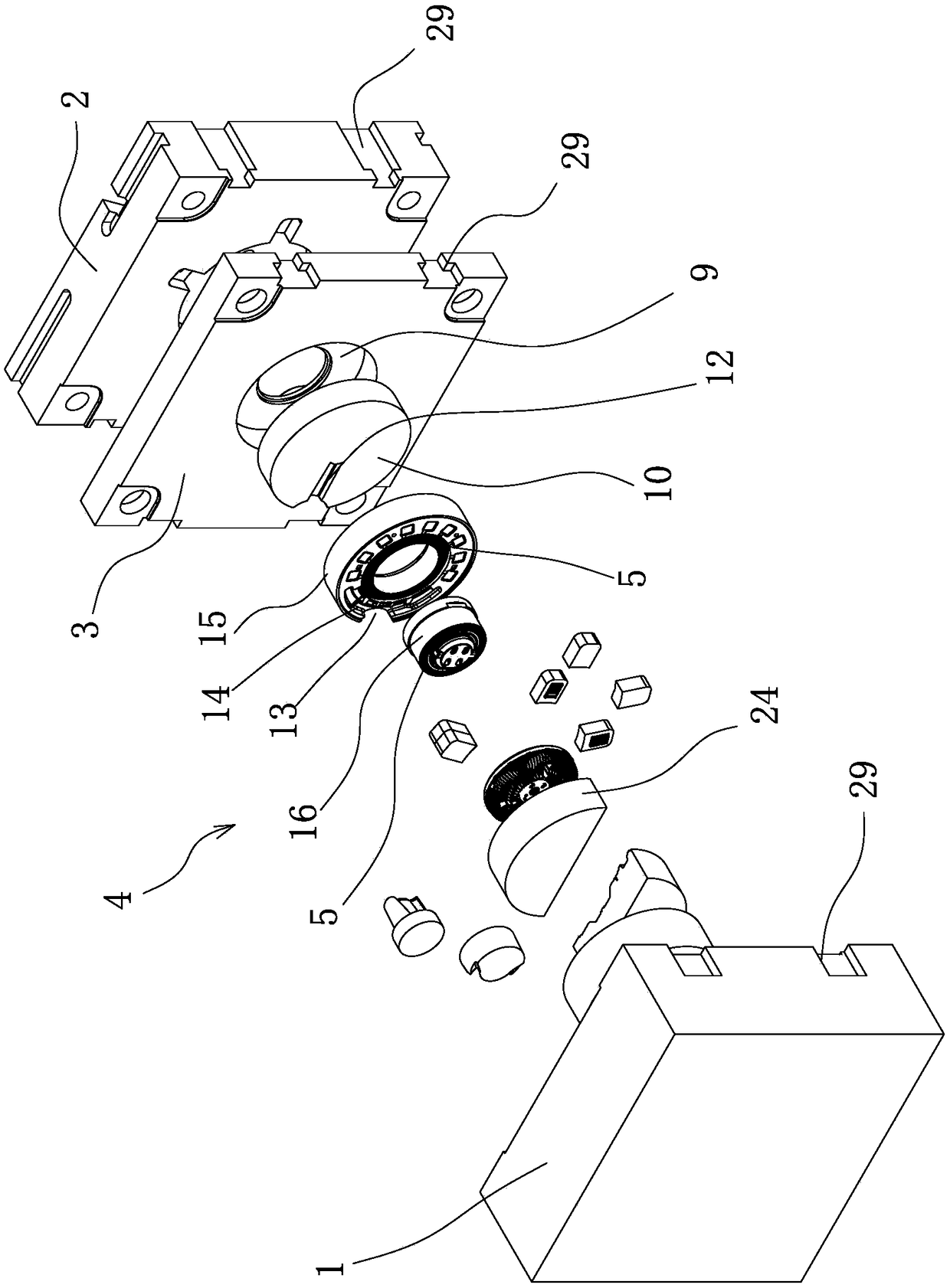

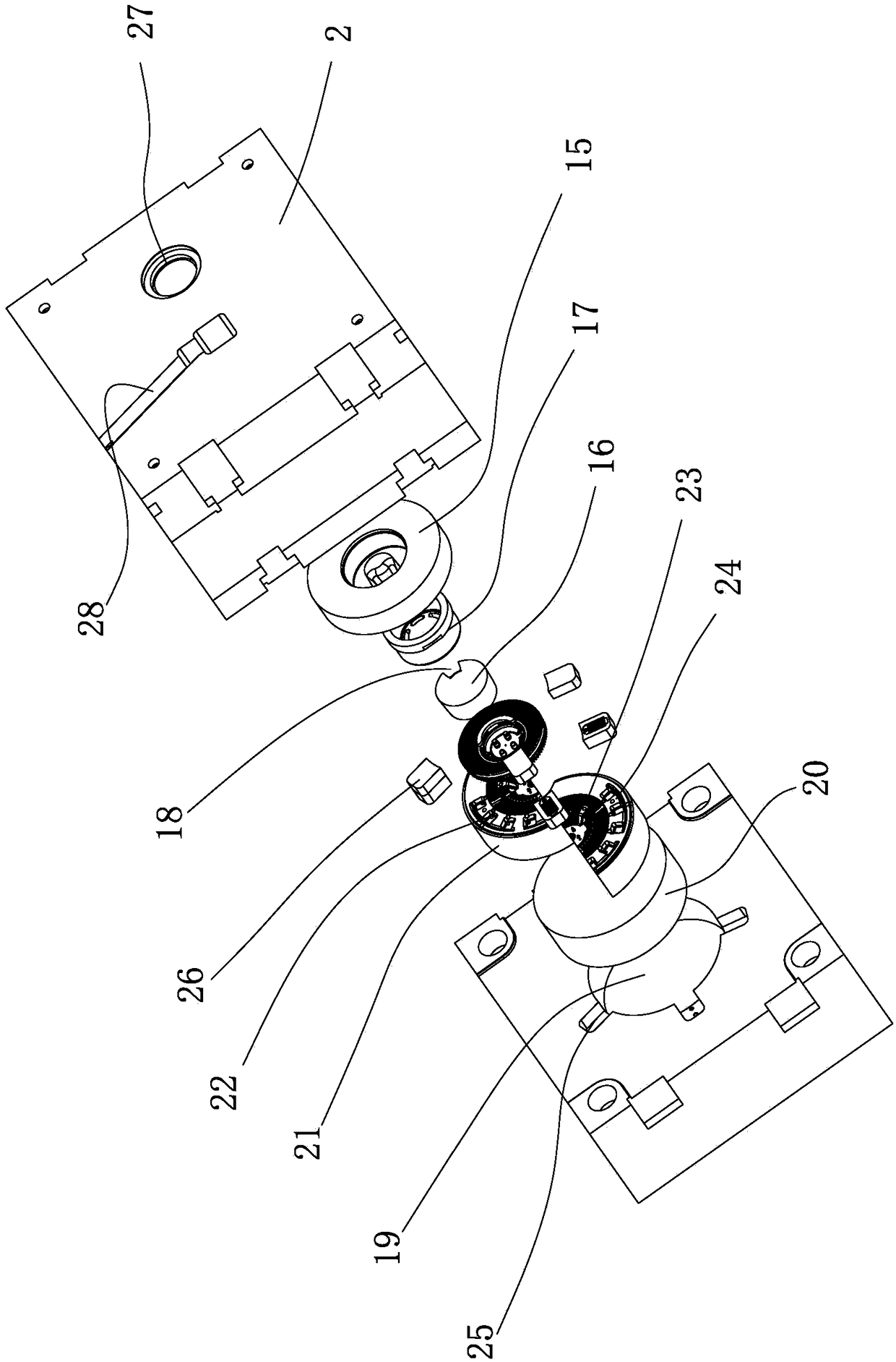

[0028] Such as figure 1 with Figure 5 As shown, a die-casting mold for an aluminum alloy front cover of an automobile silicone oil fan clutch includes a fixed mold 1, a movable mold 2, and a middle mold 3 located between the fixed mold 1 and the movable mold 2. The middle mold 3 is movably connected There is a core assembly 4, on which there are several concentrically arranged silicone oil feed surface forming rings 5, and an annular silicone oil feed surface molding is formed between every two adjacent silicone oil feed surface forming rings 5 Cavity 6.

[0029] In the prior art, the common practice is that the front teeth of the product, that is, the inner side of the silicone oil fan clutch front cover 100, adopt an overall circular block shape, and then use machining methods to process the required ring shape in the later stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com