Process for accurately controlling stability of water content after shredding

A moisture content and stability technology, applied in the preparation of tobacco, tobacco, tobacco treatment, etc., can solve the problems of loss of feed liquid and lower quality of shredded tobacco, and achieve the effects of improving quality, improving uniformity of feeding, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

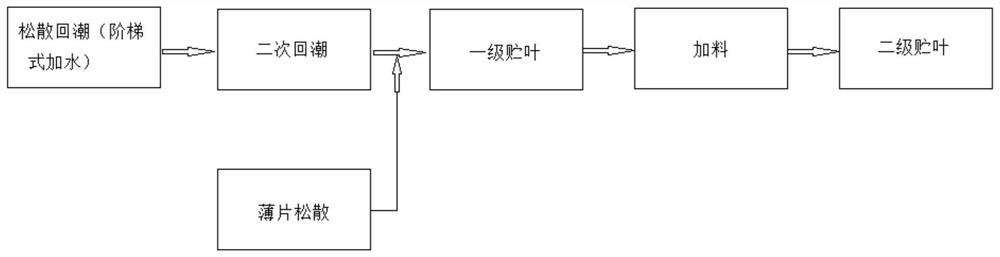

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

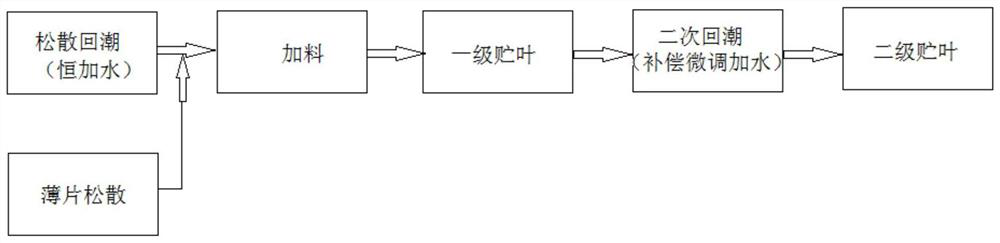

[0027] Such as figure 2 As shown, the present invention provides a process for precisely controlling the stability of moisture content after shredding, comprising the following steps:

[0028] By counting the water content data of the leaves before and after each process, the maximum value of the required water addition to the leaves within the set period of time is obtained, and the leaves with the determined batch weight are calculated after the second stage of storage under the condition of the maximum water content. Set the value of the amount of water that needs to be supplemented between the water contents, and the amount of add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com