Crushing production line

A production line and hammer crusher technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, grain processing, etc., can solve the problems of narrow storage of crushing production line, difficult recovery of dust collectors, and difficulty in conveying large stones, etc. Grinding time, increased output and fineness, low feed height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but they are not limitations to the technical solution of the present invention, and any changes made based on the teachings of the present invention all fall within the scope of protection of the present invention.

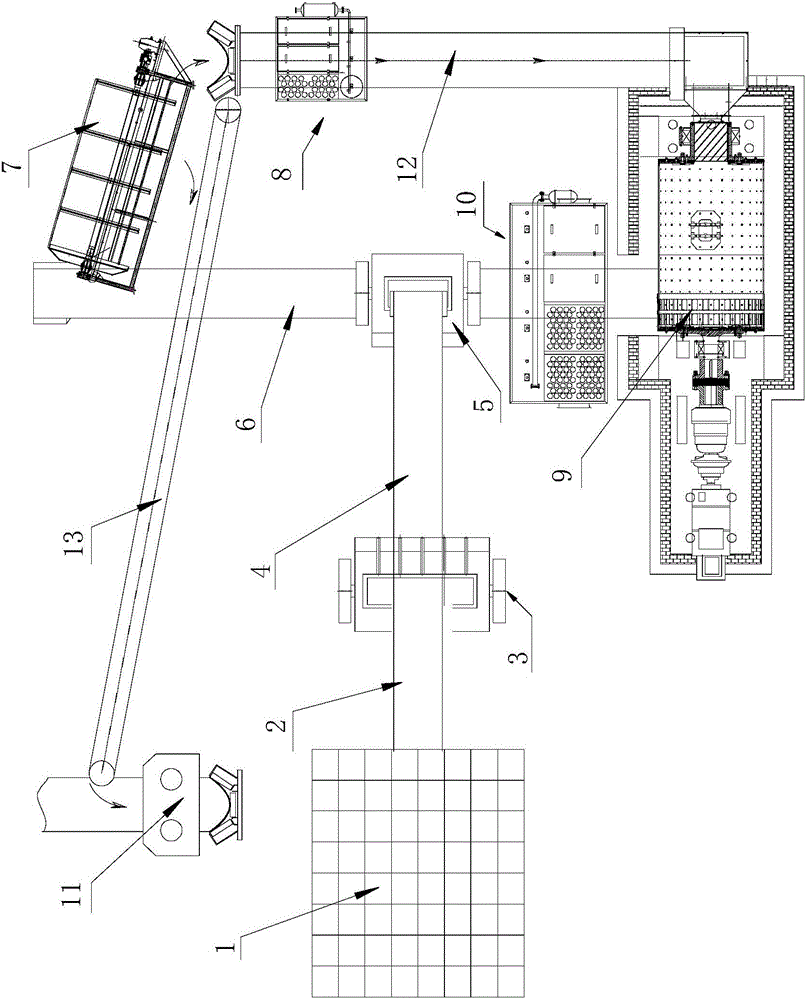

[0016] Referring to 1, a crushing production line includes a material warehouse 1, a chain plate feeder 2, a jaw crusher 3, a first conveyor belt 4, a hammer crusher 5, a second conveyor belt 6, a trommel screen 7, a first A dust collector 8, a rolling ball crusher 9, a second dust collector 10, a powerful mixer 11 and a third conveyor belt 12, the material warehouse 1, the chain plate feeder 2, the jaw crusher 3, and the first conveyor belt 4 and the hammer crusher 5 are sequentially connected, the hammer crusher 5 is mounted on the second conveyor belt 6, the second conveyor belt 6, the drum screen 7, the third conveyor belt 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com