Automatic-stuffing-supply wonton producing device

A production device and filling technology, which are applied in the directions of dough sheeter/roller/rolling pin, baking, dough forming and cutting equipment, etc. Thickness and other problems, to achieve the effect of completely practical cost, good taste, and good uniformity of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

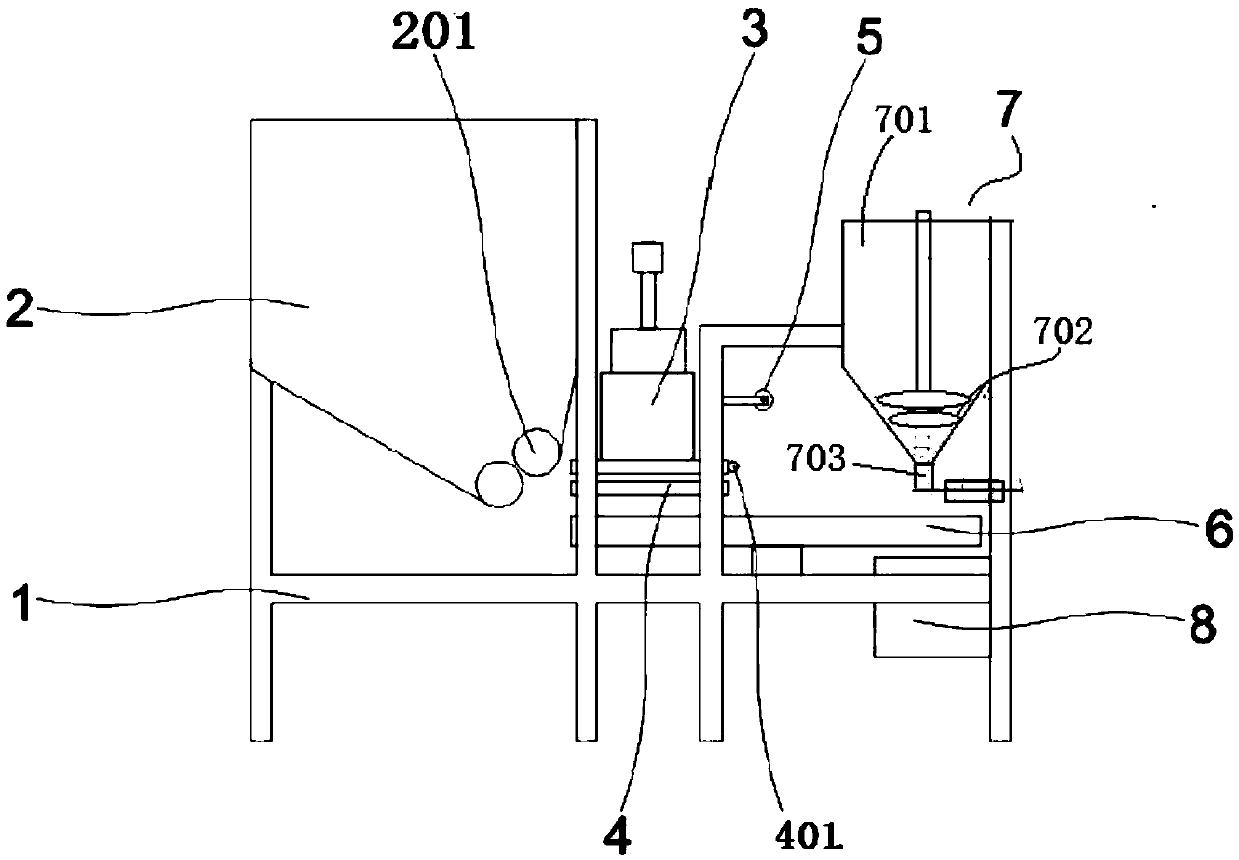

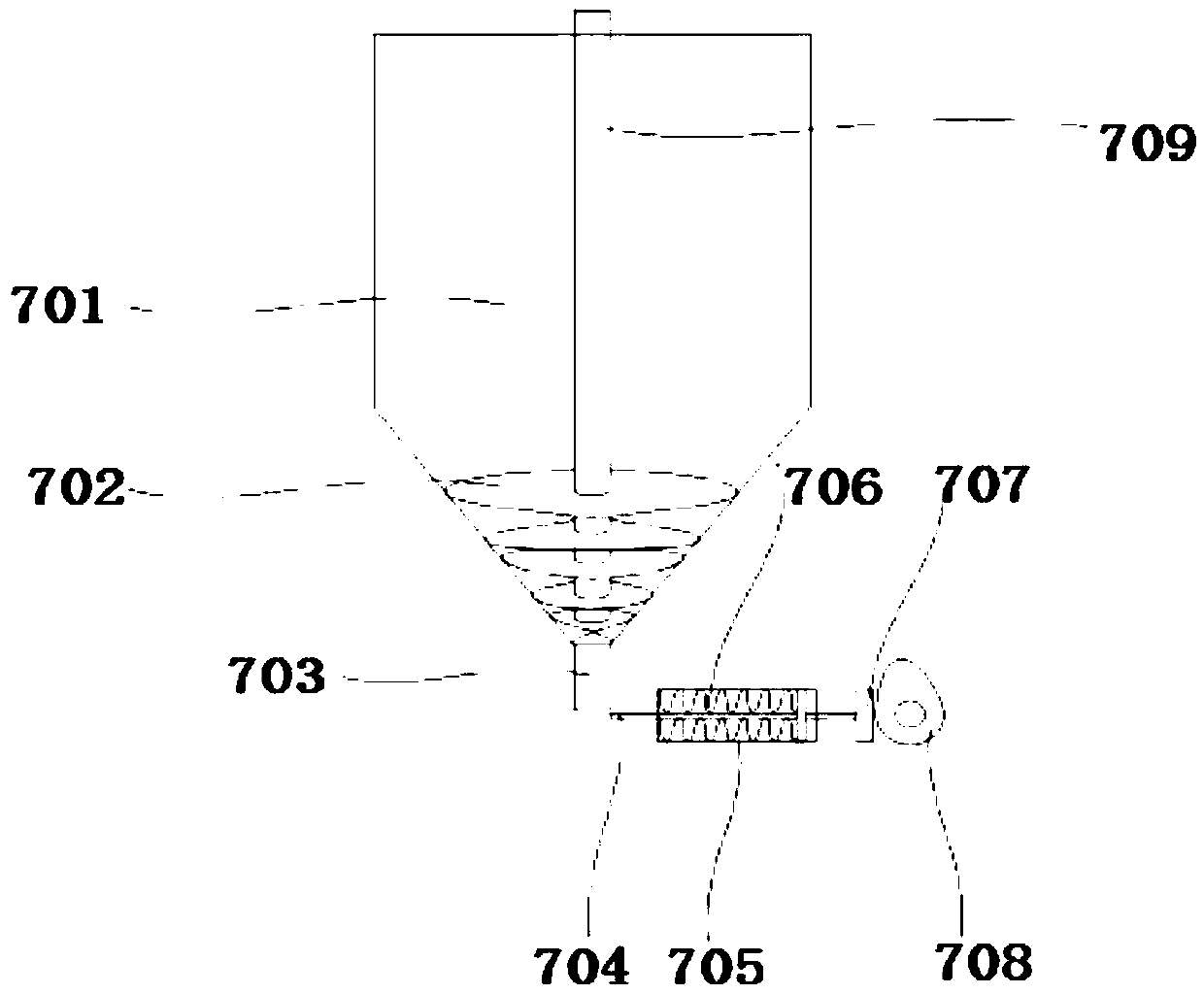

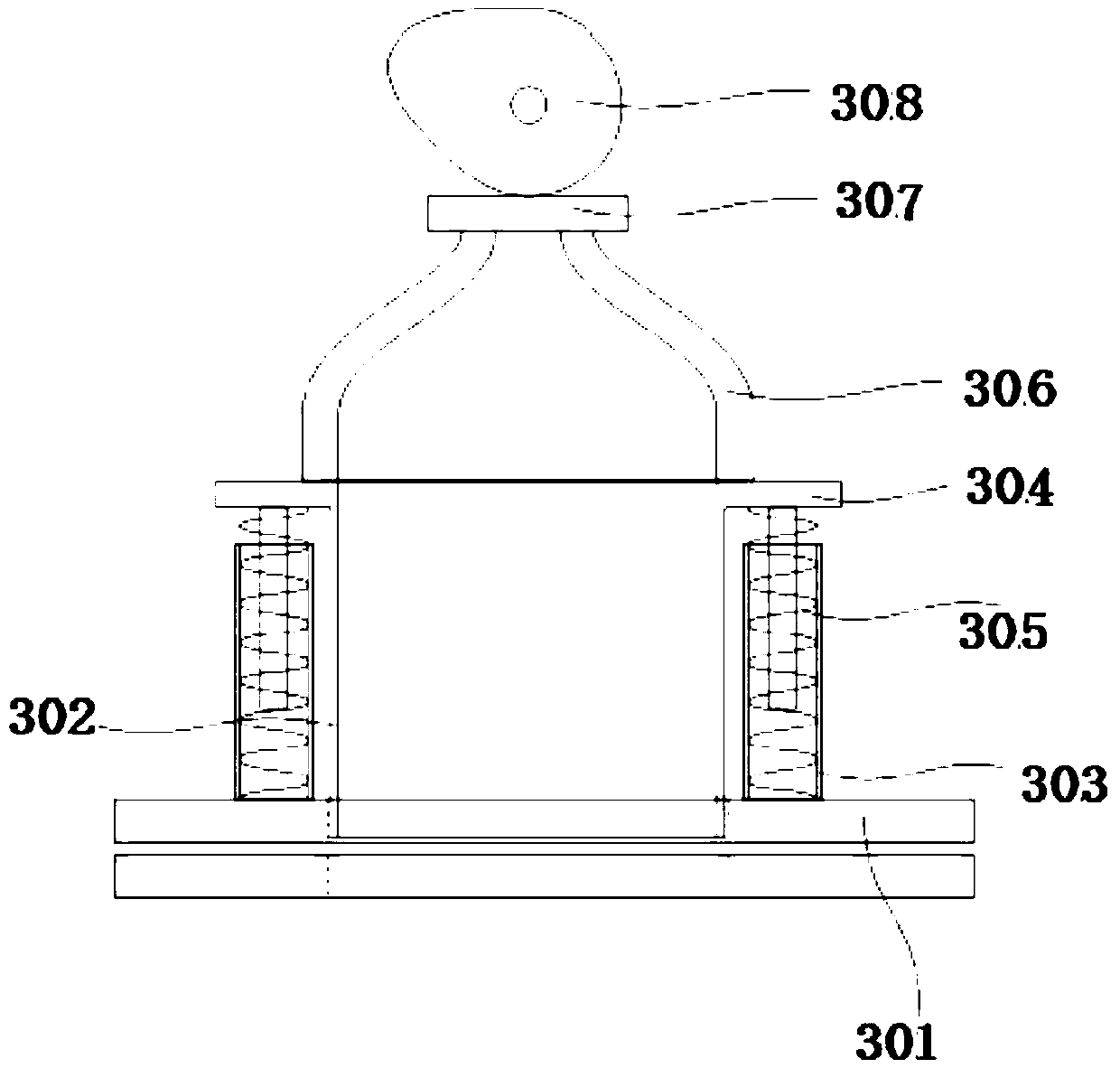

[0016] Such as figure 1 As shown, an automatic filling-feeding wonton production device includes a frame 1, a flour bucket 2, a pressing mechanism 3, a guide plate 4, a roll 5, a rotary mold 6, a filling bucket 7, an outlet slot 8, and a flour bucket 2 is set on the upper left side of the frame 1; the pressing mechanism 3 and the filling bucket 7 are respectively located in the middle and the right side of the frame 1, and the pressing mechanism 3 and the filling bucket 7 are correspondingly provided on the frame 1 Rotary mold 6, Rotary mold 6 has a circular structure and can be rotated along its center; there are two opposite pressing rollers 201 at the outlet below the flour bucket 2, and two guide plates 4 arranged side by side are connected below the pressing mechanism 3 , The gap between the two guide plates 4 corresponds to the above-mentioned two pressure rollers 21; the frame 1 above the end of the guide plate 4 is provided with a roll 5; the bottom of the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com