Crushing-screening integrated sorter

A technology of crushing, screening and sorting machine, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of sewer pipe network blockage, aggravate sewage pollution degree, etc. good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

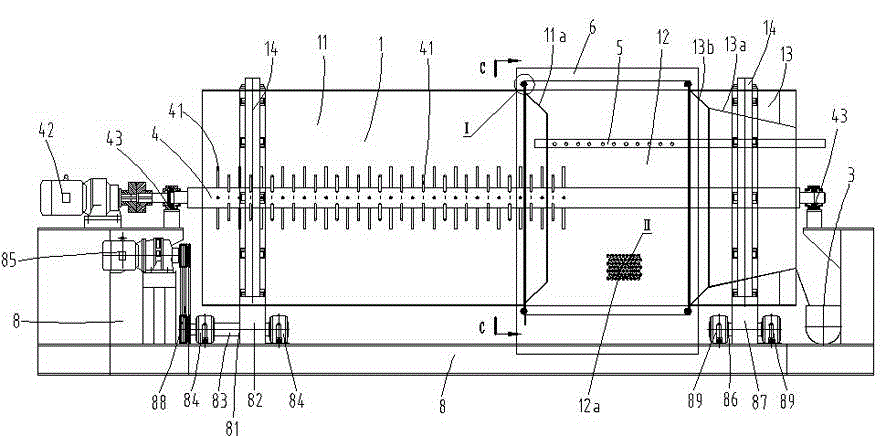

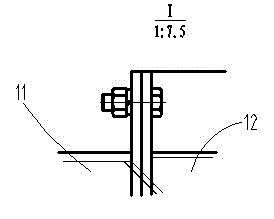

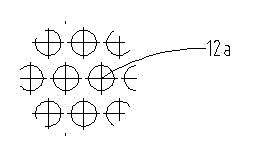

[0034] Such as Figure 1 to Figure 7 As shown, the icon numbers are explained as follows: cylinder body 1, crushing cylinder 11, first conical export ring 11a, screening cylinder 12, unit screening hole 12a, discharge cylinder 13, third deriving ring 13a, second conical Outlet ring 13b, guide ring body 14, feed body 2, discharge body 3, stirring and crushing shaft 4, unit crushing blade body 41, driving device 42, stirring seat 43, water spray pipe body 5, diversion cover body 6, Unit plate 7, base 8, active supporting device 81, driving wheel 82, driving shaft 83, driving seat 84, main transmission device 85, driven supporting device 86, driven wheel 87, driving belt 88, driven seat 89, fixed cover9.

[0035] The embodiment of the present invention is an integrated sorting machine for crushing and screening. The sorting machine includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com