Uniform feeding device with vibrating screen

A technology of feeding device and vibrating screen, which is applied in the fields of filtering, transportation and packaging, solid separation, etc., can solve the problems such as difficult cleaning of soft sundries, misalignment of feeding materials, and inability to fully utilize the screen surface. The effect of feeding deviation, improving utilization rate and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

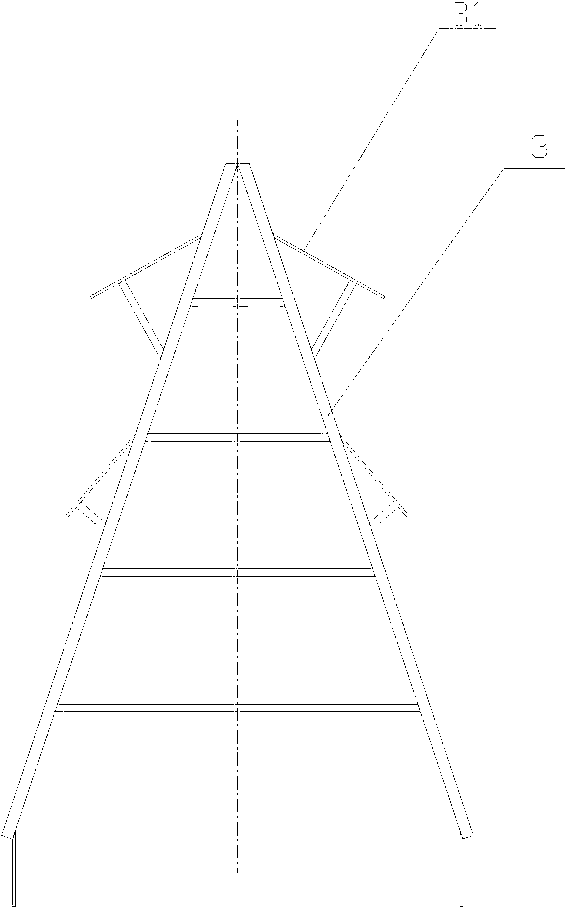

[0017] Please refer to the attached figure 1 To attach Figure 4 As shown, the present invention is a vibrating screen uniform feeding device, which is composed of a belt conveyor 1, a bulk material net 2, an unloader 3, a platform 4, a vibrating screen 5, and a distribution chute 6.

[0018] Wherein, the belt conveyor 1 straddles the feeding end of the vibrating screen, which is a flat belt, thereby facilitating the unloading of the unloader 3 and adjusting and distributing the material flow at both ends of the unloader 3. The width of the belt is based on the amount of incoming material and The length of the screen surface of the vibrating screen depends on the length, and the width is generally 650mm, 800mm, 1000mm.

[0019] The bulk material net 2 can also be called a soft debris cleaning net, which is fixed on both sides of the belt conveyor 1. The mesh is a welded net of 100×100mm, the length is slightly smaller than the inner width of the screen surface, and the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com