Breeding feed feeding device

A technology of feed and feeding trough, applied in the field of breeding, can solve the problems of complex structure of feeding device, poor control of feeding uniformity, etc., and achieve the effect of avoiding the breeding of bacteria, improving feeding uniformity, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

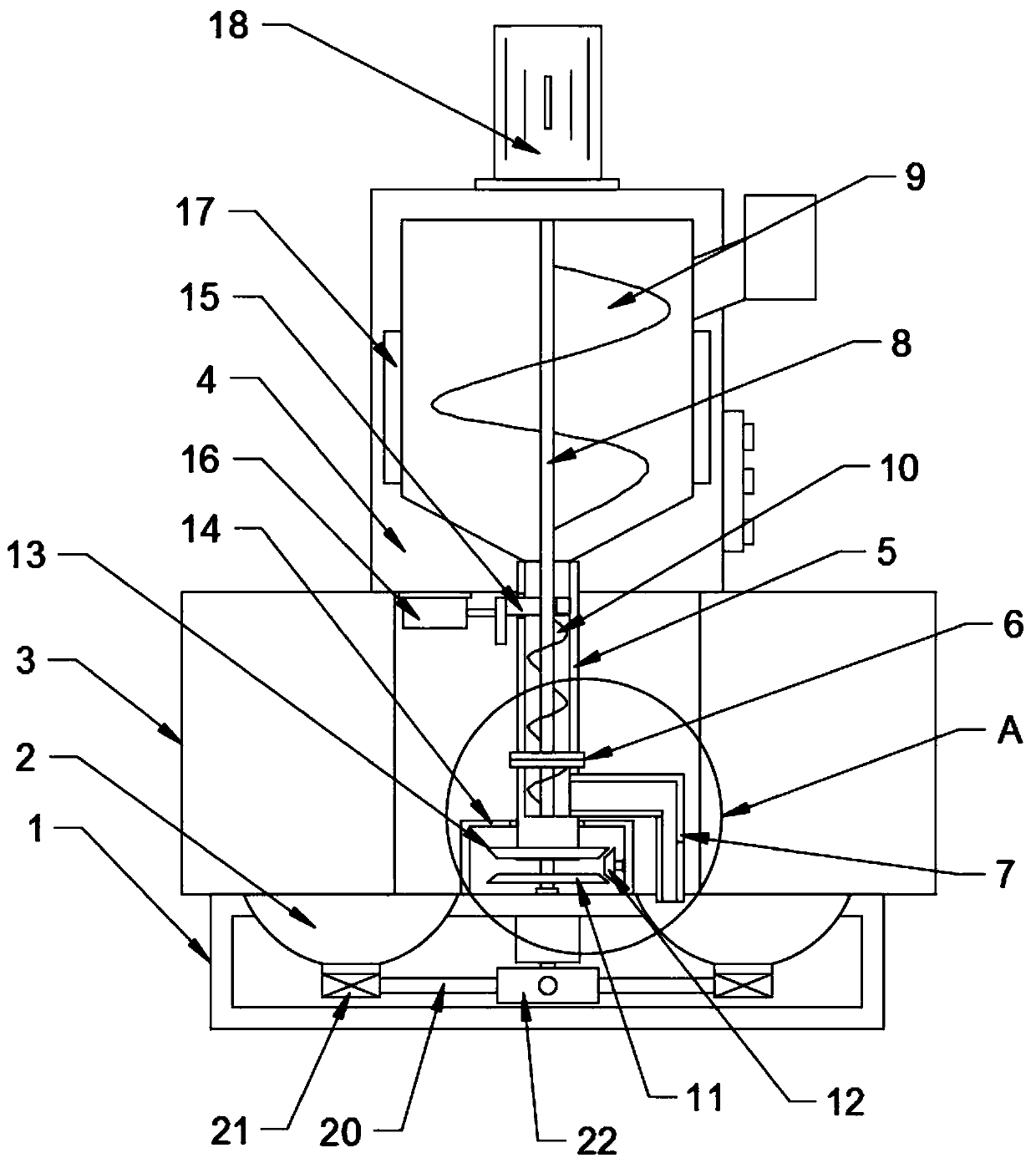

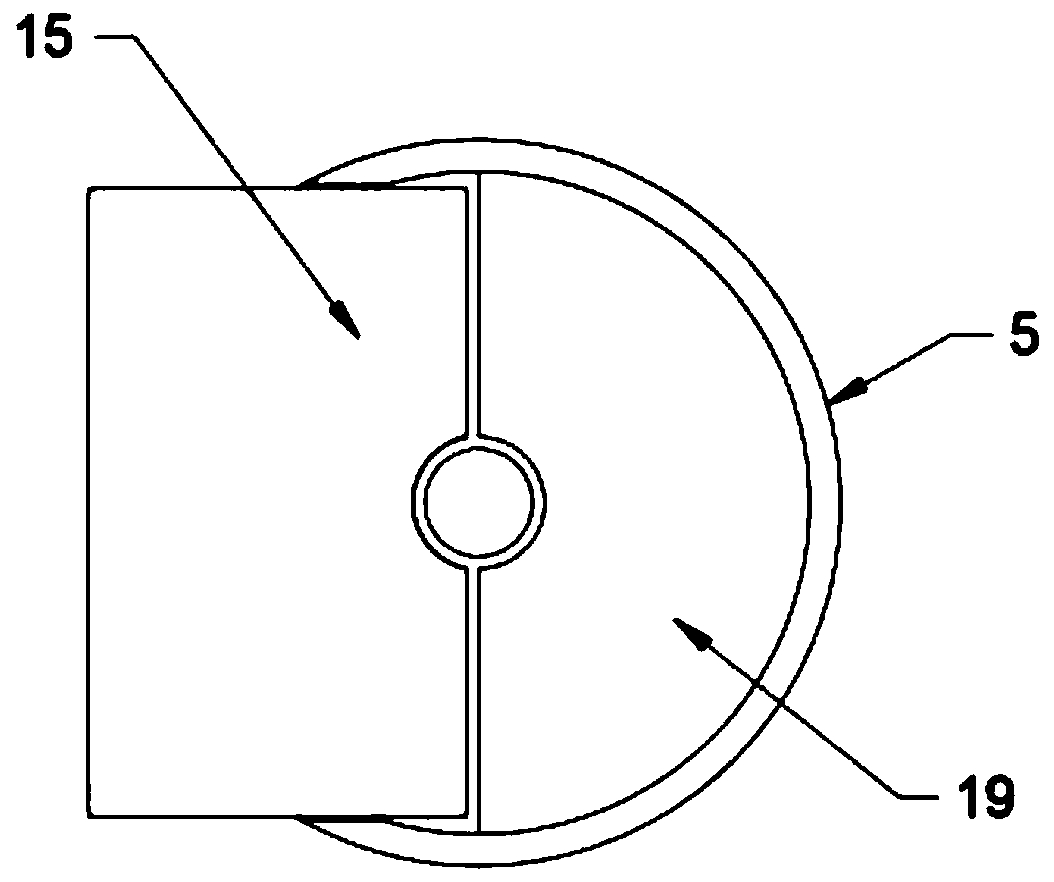

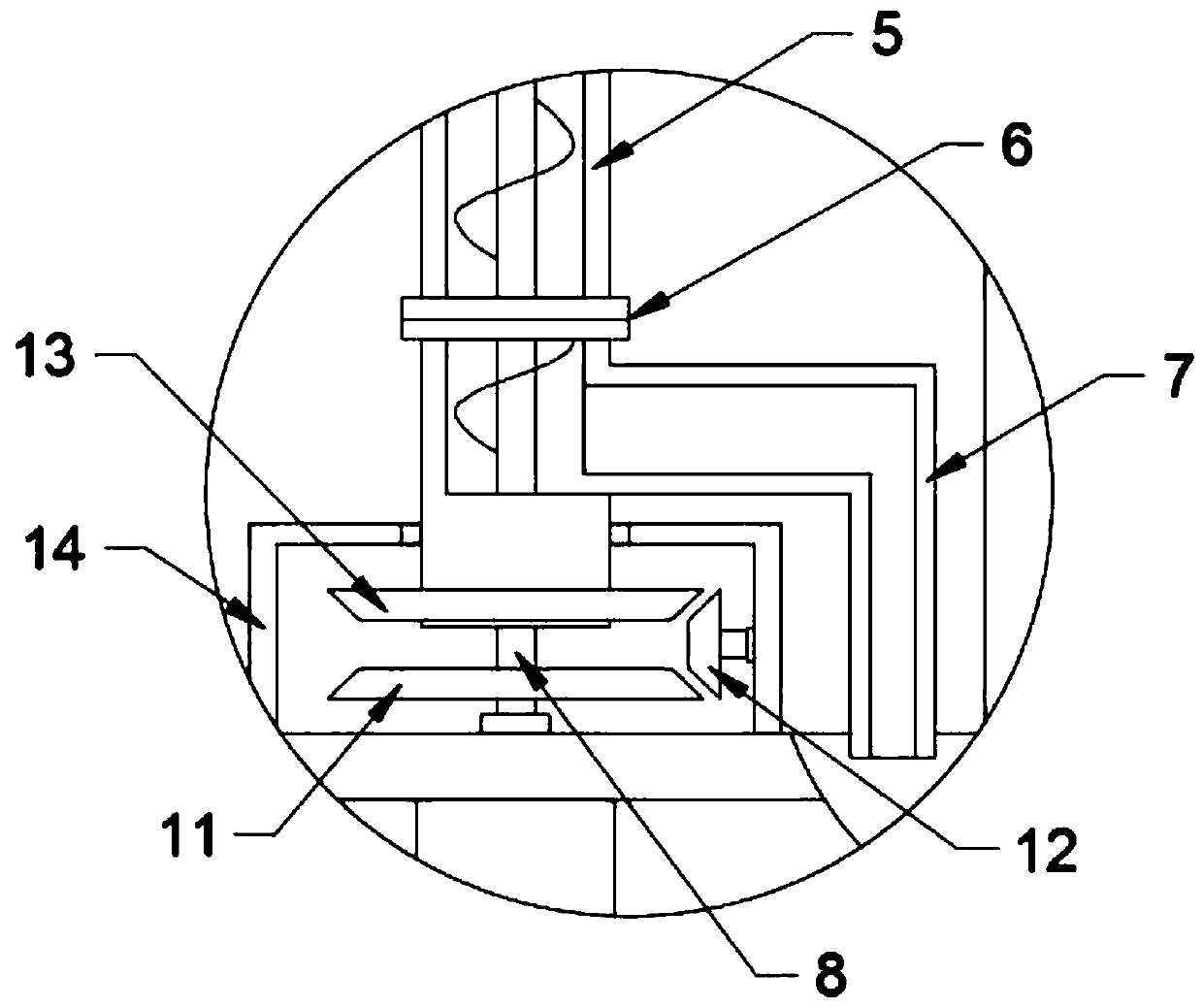

[0023] see Figure 1-4 , in the embodiment of the present invention, a breeding feed feeding device includes a feeding tank 1 and a preparation cylinder 4; the feeding tank 1 is a circular plate, the upper end surface of the feeding tank 1 is provided with an annular groove 2, and the cross section of the annular groove 2 is It is in the shape of a circular arc, which is convenient for holding feed and livestock to eat; above the feeding trough 1 is fixedly connected with a partition 3 distributed in a circle, and the partition 3 is fixedly connected with the edge of the feeding trough 1 by means of bolts, and the feeding trough The edge of 1 is provided with circumferentially distributed bolt holes to increase or decrease the number of partitions 3 to adapt to livestock of different sizes. The partition 3 divides the feeding trough 1 into a plurality of circumferentially distributed spaces to prevent livestock from competing for food. The feeding trough 1 is crushed and destr...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that in order to facilitate the cleaning of the annular groove 2 and avoid the breeding of bacteria in the feeding tank; the bottom of the annular groove 2 is connected with a sewage branch pipe 20 distributed in a circle, and the sewage branch pipe 20 and the annular groove 2 There is a solenoid valve 21 at the communication point, and the sewage branch pipe 20 is nested in the feeding tank 1. The sewage branch pipe 20 is connected with the sewage pump 22, and the sewage pump 22 is connected with the sewage main pipe; Inject into the hopper, start the drive motor 18, firstly stir and clean the inner wall of the configuration cylinder 3, after cleaning, open the shutter 15 through the electric telescopic rod 16, and open the solenoid valve 21 and the sewage pump 22, driven by the swing pipe 7 , the annular groove 2 is rotated and flushed, and the sewage and waste residue are discharged from the sewage branch pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com