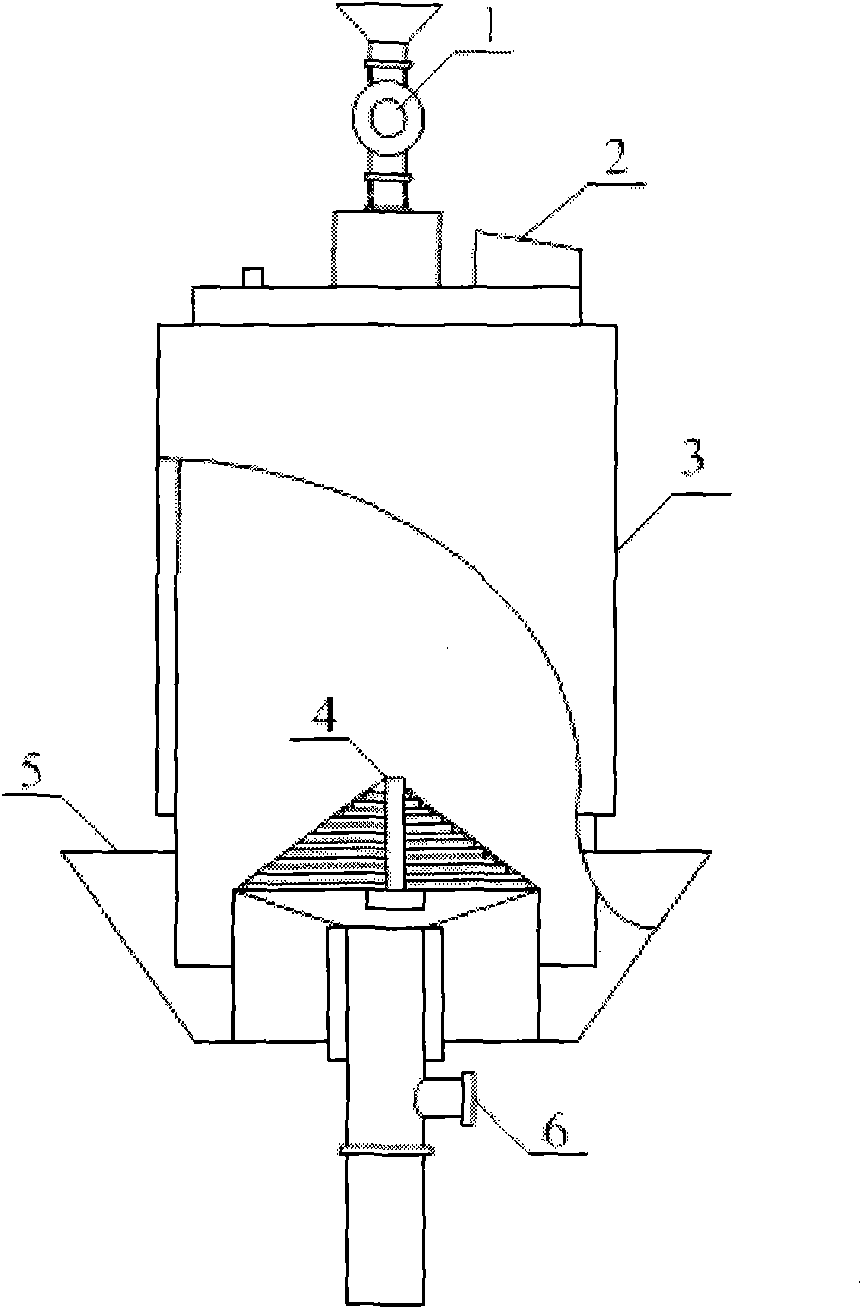

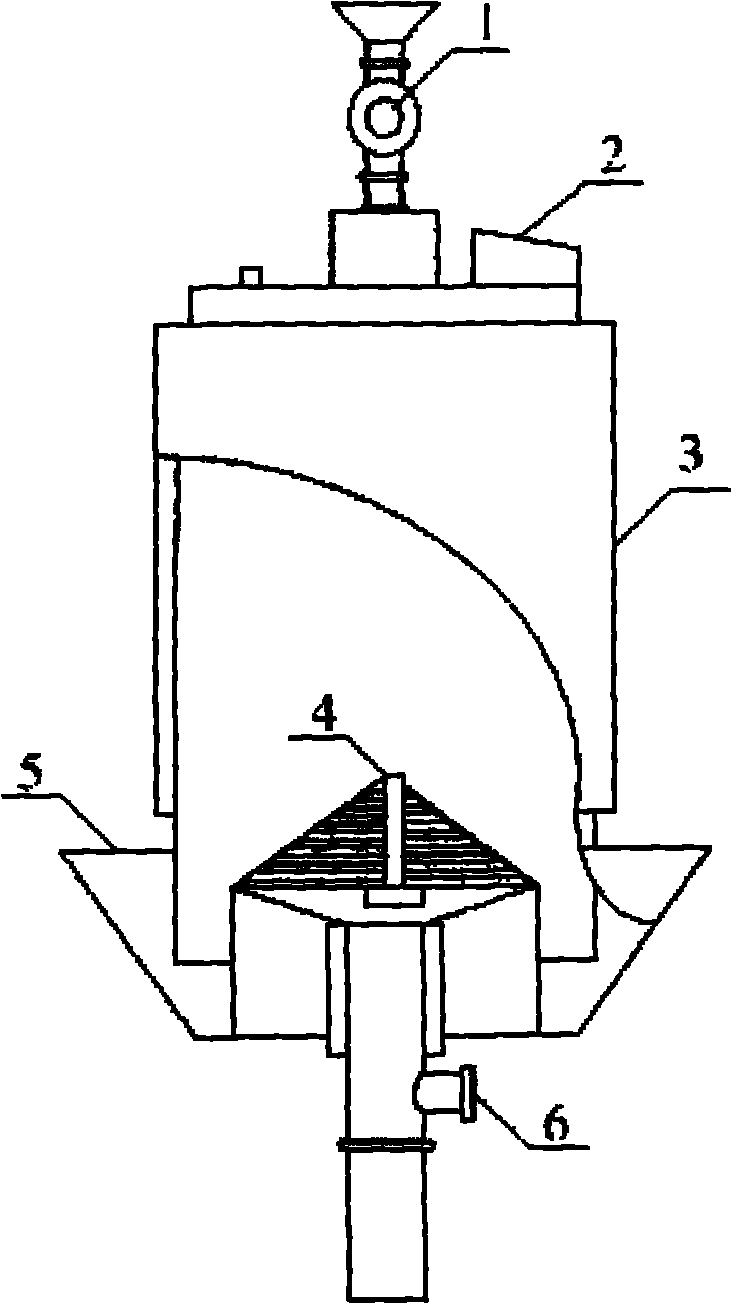

Large-scale fixed bed biomass gasification furnace and production process of gas with low oxygen content

A production process and gasifier technology, applied in fixed bed gasification, combustible gas production, petroleum industry, etc., can solve the problems of small bulk density, large natural stacking, low mechanical strength of charcoal, etc., and achieve high overall thermal efficiency and gasification The effect of high chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Biomass gasification furnace for power generation, the inner diameter of the furnace is 3m, the height is 3m, the daily processing of compressed rice straw is about 50 tons, the air is used as the oxidant, and the gas-to-carbon ratio is 1.48m 3 / kg, the biomass conversion rate is 98.7%, and the gasification intensity is 298kg / m 2 h, the oxygen content of the outlet gas is <0.5%, which shows that the performance of the gasifier is excellent, the quality of the gas product is good, and the effect is remarkable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com