Rapid delivery poultry feeding machine

A feeding machine and feeding technology, which is applied in the field of fast feeding poultry feeding machines, can solve the problems of slow running speed of the conveying chain, chain jamming, and difficult maintenance, so as to improve the uniformity of feeding, increase the speed of conveying, and improve the operation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

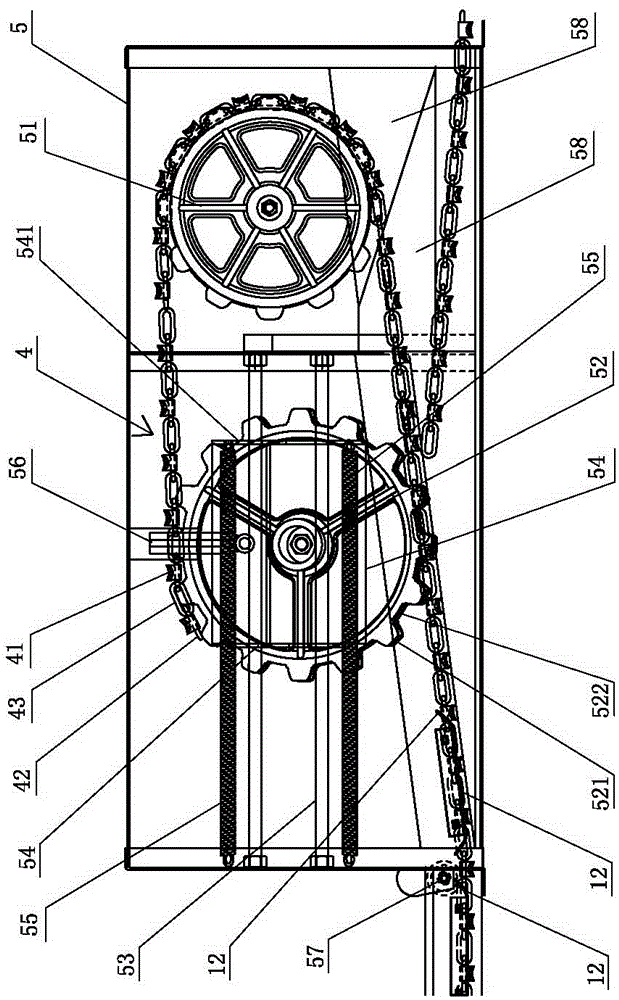

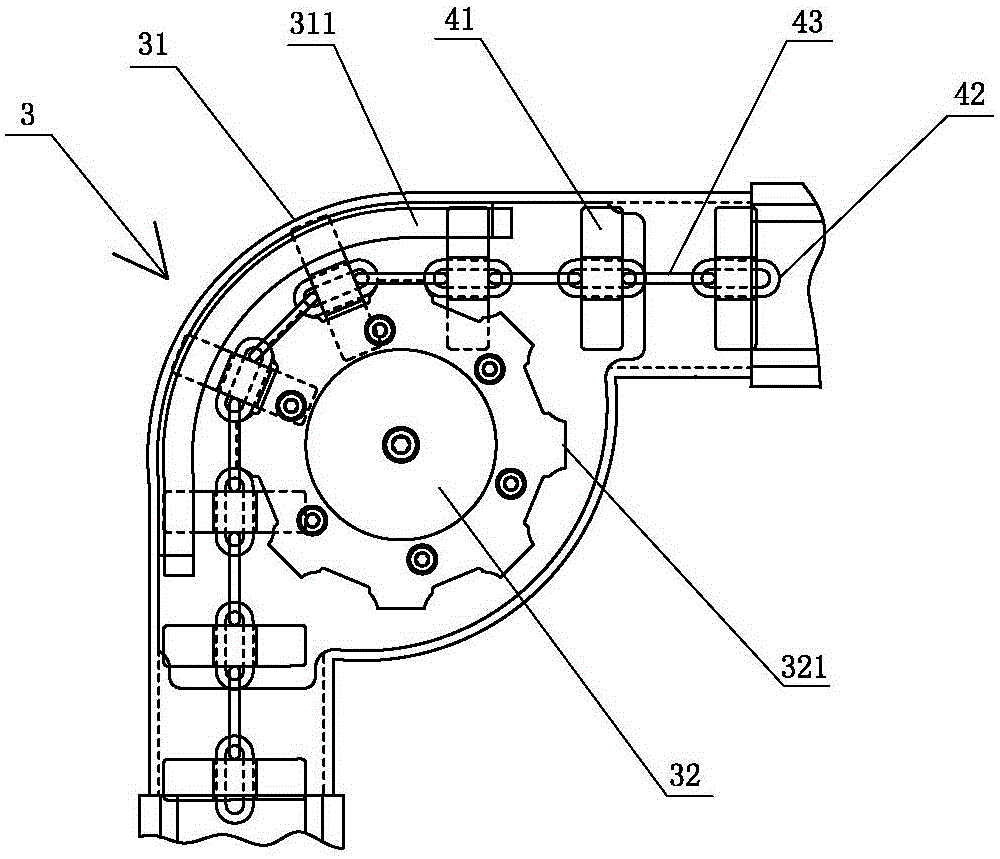

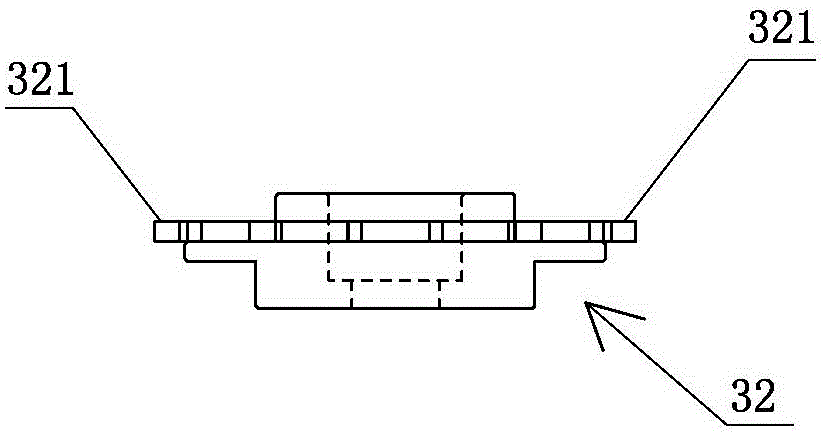

[0035] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 shown, a kind of fast conveying poultry feeder, comprises the feeding trough 1 of flat bottom section, the corner that is positioned at the corner of feeding trough 1 The device 3, and the conveyor chain 4 running in the feeding trough 1 and equipped with a scraper 41, and the drive box 5 that drives the conveyor chain 4 to run, the conveyor chain 4 is mutually arranged by horizontal chain buckles 42 and vertical chain buckles 43 arranged at intervals. The upper part of the scraper 41 is fixedly connected to the horizontal chain buckle 42, and the bottom of the scraper 41 runs close to the bottom surface of the feeding tank 1, and the bottoms of both sides of the scraper 41 are arched. On both side plates of the feeding trough 1, above the scraper plate 41, chain presser feet 12 are installed in sections and in pairs, and a certain gap is maintained between the chain presser foot 12 and the conveying chain 4 to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com