Paddy feed granulator

A feed pellet and paddy technology, applied in the field of paddy feed pellet machine, can solve the problems that the heat of the equipment cannot be effectively recycled, the feed pellets are not tight enough, and the cost performance of the equipment is reduced, so as to save electricity consumption, reduce temperature, and increase energy consumption. regulatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

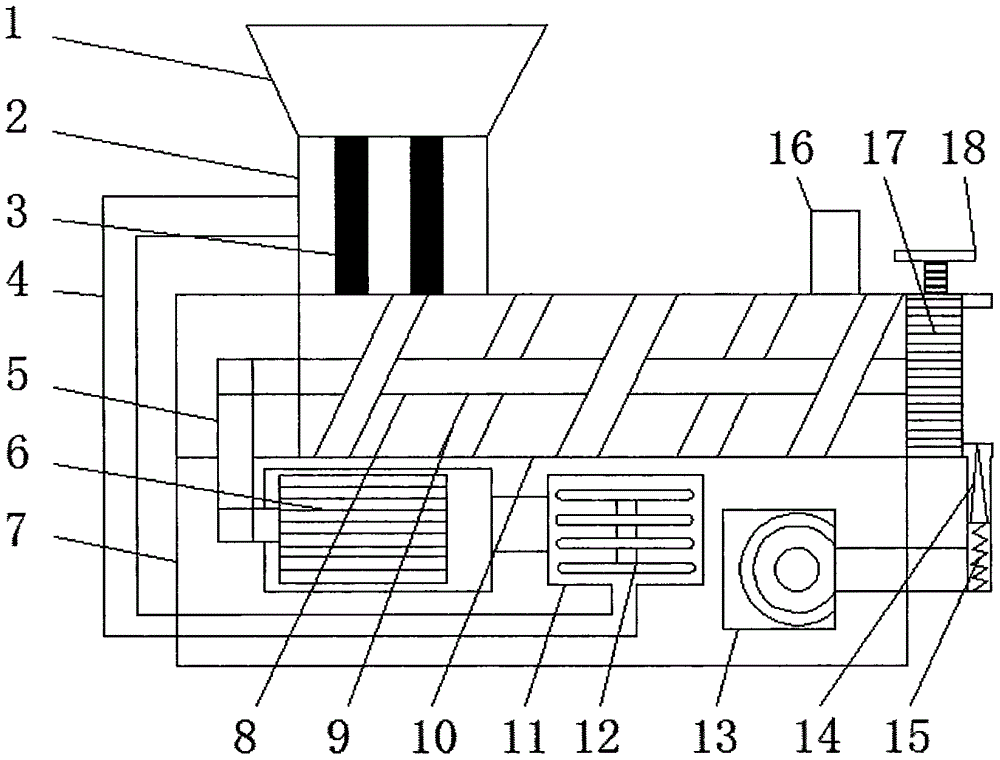

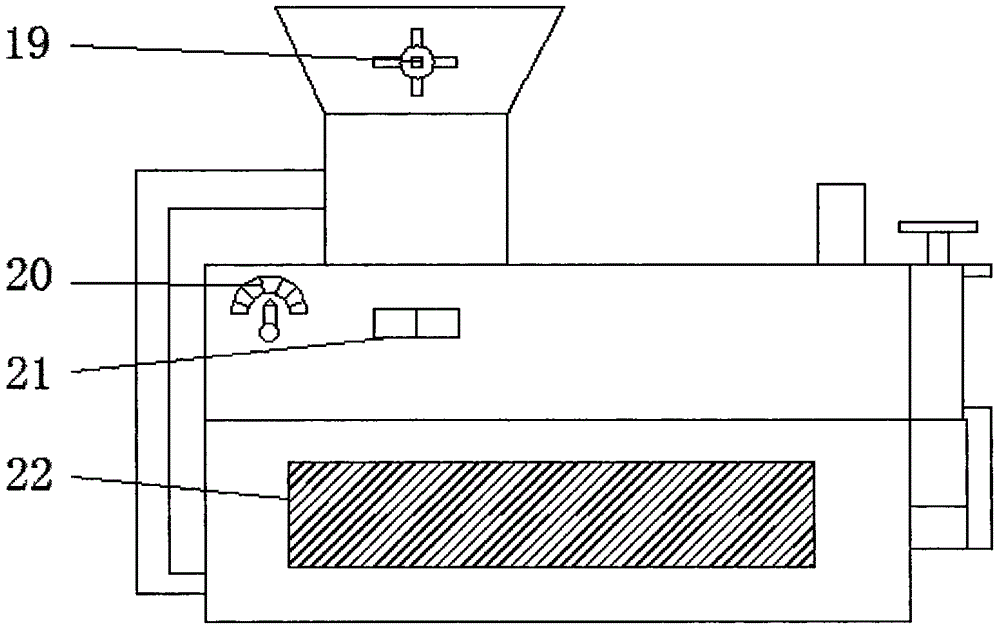

[0015] refer to Figure 1-2 , a rice feed pellet machine, comprising a drying box 2, a base 7, a pushing box 10 and a discharge plate 17, a feeding funnel 1 is installed above the drying box 2, and a feeding adjustment knob 19 is installed on the surface of the feeding funnel 1, A drying pipe 3 is installed inside the drying box 2, a propelling box 10 is installed below the drying box 2, and an air outlet 16 is installed above the propelling box 10, a rotating shaft 8 is installed inside the propelling box 10, and a screw propeller 9 is installed on the surface of the rotating shaft 8 , a discharge plate 17 is installed on the right side of the push box 10, a speed k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com