Shell-membrane structure plugging material as well as preparation method and use method thereof

A plugging material and shell membrane technology, which is applied in the field of oil and gas drilling engineering, can solve the problems of loss of drilling fluid, economic loss, and impact on the exploration and development process, and achieve the effect of cost saving and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

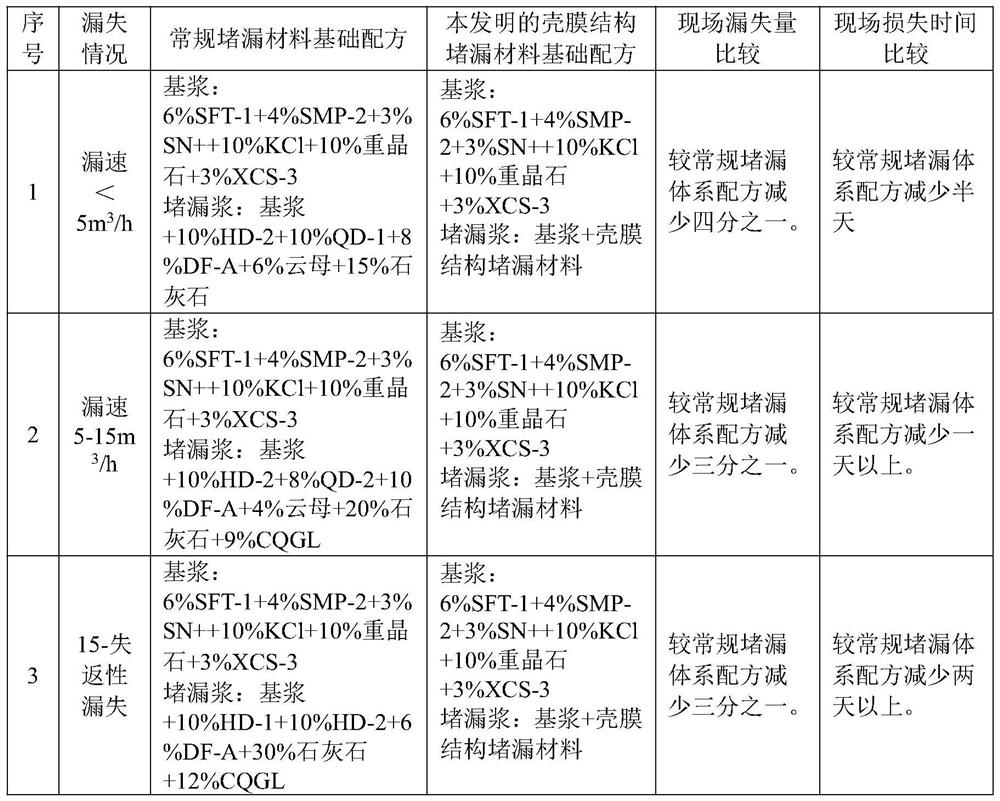

Examples

Embodiment 1

[0024] A plugging material with a shell-membrane structure, including aluminum film, Fe 3 o 4 and gelatin; the Fe 3 o 4 Wrap a layer of gelatin to form a capsule with gelatin as the shell and an inner cavity; Fe wrapped in gelatin 3 o 4 An aluminum film is wrapped outside, and a layer of gelatin is wrapped outside the aluminum film.

[0025] The size and direction of the magnetic field at the bottom of the well are basically stable, and the direction is basically north-south. After a magnetic field passes through the medium, its strength and direction will change. When several magnetic media Fe are put into the bottom hole fracture 3 o 4 After that, the magnetic medium Fe 3 o 4 Under the force of different sizes and directions at the bottom of the well, fixed structures of different shapes are formed in the fractures.

[0026] The mechanism of action of the aluminum film is as follows:

[0027] The main function of the aluminum film is to coat the shielding magnetic...

Embodiment 2

[0035] A kind of shell membrane structure plugging material, on the basis of embodiment one: described Fe 3 o 4 It is composed of Fe in the shape of ring, triangle, square, isosceles trapezoid, cylinder or prism 3 o 4 mixed.

[0036] In actual use, various shapes of Fe 3 o 4 , so that Fe 3 o 4 After entering the crack, the structure is more stable and can be fixed better.

Embodiment 3

[0038] A plugging material with a shell-membrane structure, on the basis of Example 1: the Fe packaged with gelatin 3 o 4 It is a sphere with a diameter of 2-20mm and a density of 0.92-2.1g / cm 3 .

[0039] Further, the Fe wrapped in gelatin 3 o 4 The sphere is filled with nitrogen gas.

[0040] In actual use, the use of industrial latex is beneficial to the bonding of crack skeletons and plugging materials, and is conducive to improving the plugging speed and pressure bearing capacity of cracks. gelatin-coated Fe 3 o 4 Adopting the technical scheme of a sphere with a diameter of 2-20mm, the production price is relatively cheap, and the density is stable after being mixed with the drilling fluid, which can be organically matched with the drilling fluid to better realize plugging.

[0041] gelatin-coated Fe 3 o 4 Nitrogen gas is injected into the inside of the sphere, and the density of the material is somewhat changed by the nitrogen gas injected, which facilitates the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com