Method for extracting coix seed rice bran oil by utilizing supercritical CO2 technology

A technology for extracting barley and rice bran, which is applied in the production of fat oil/fat and fat production, etc., and can solve the problems of difficulty in ensuring the quality of rice bran oil, complicated extraction process, and low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

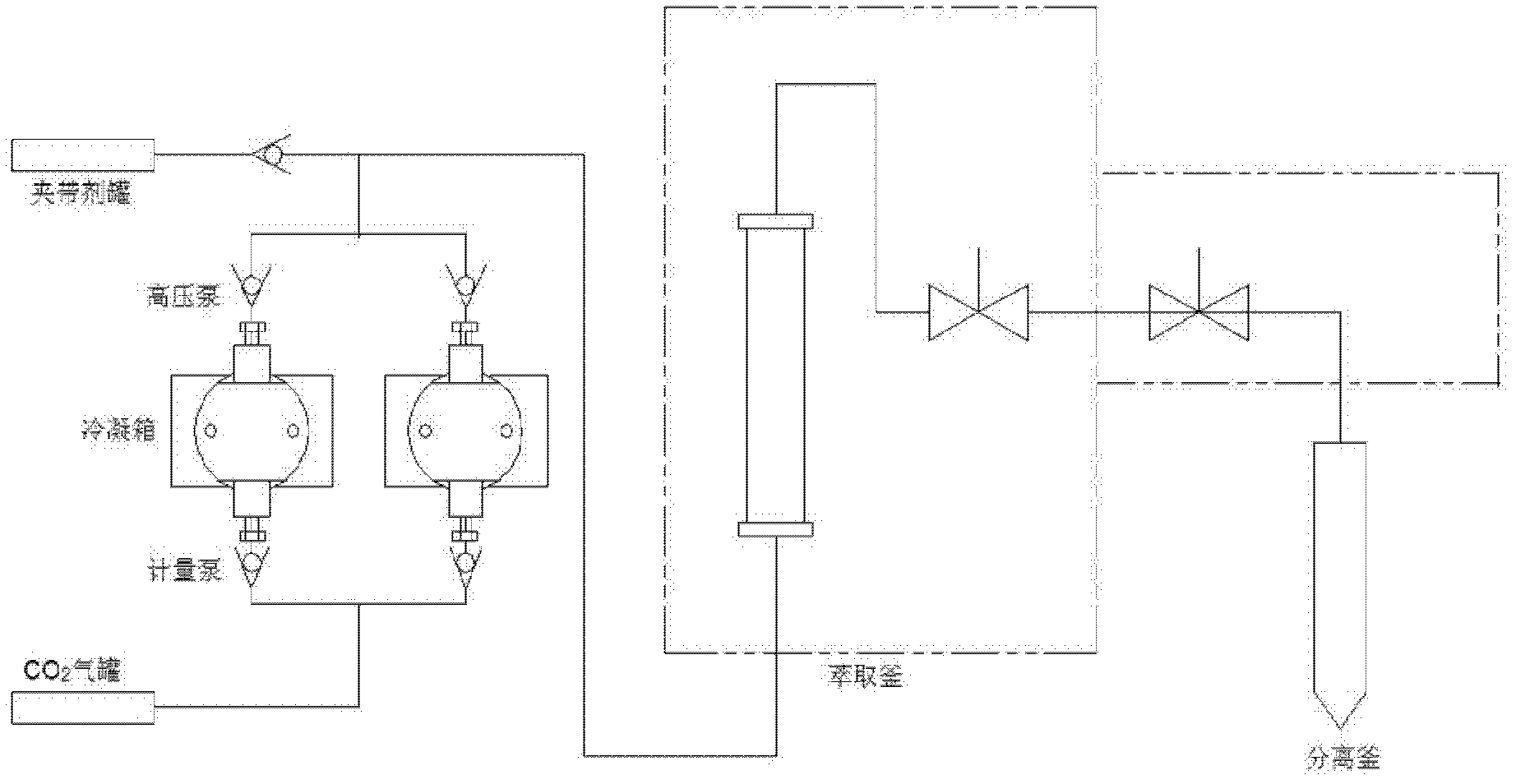

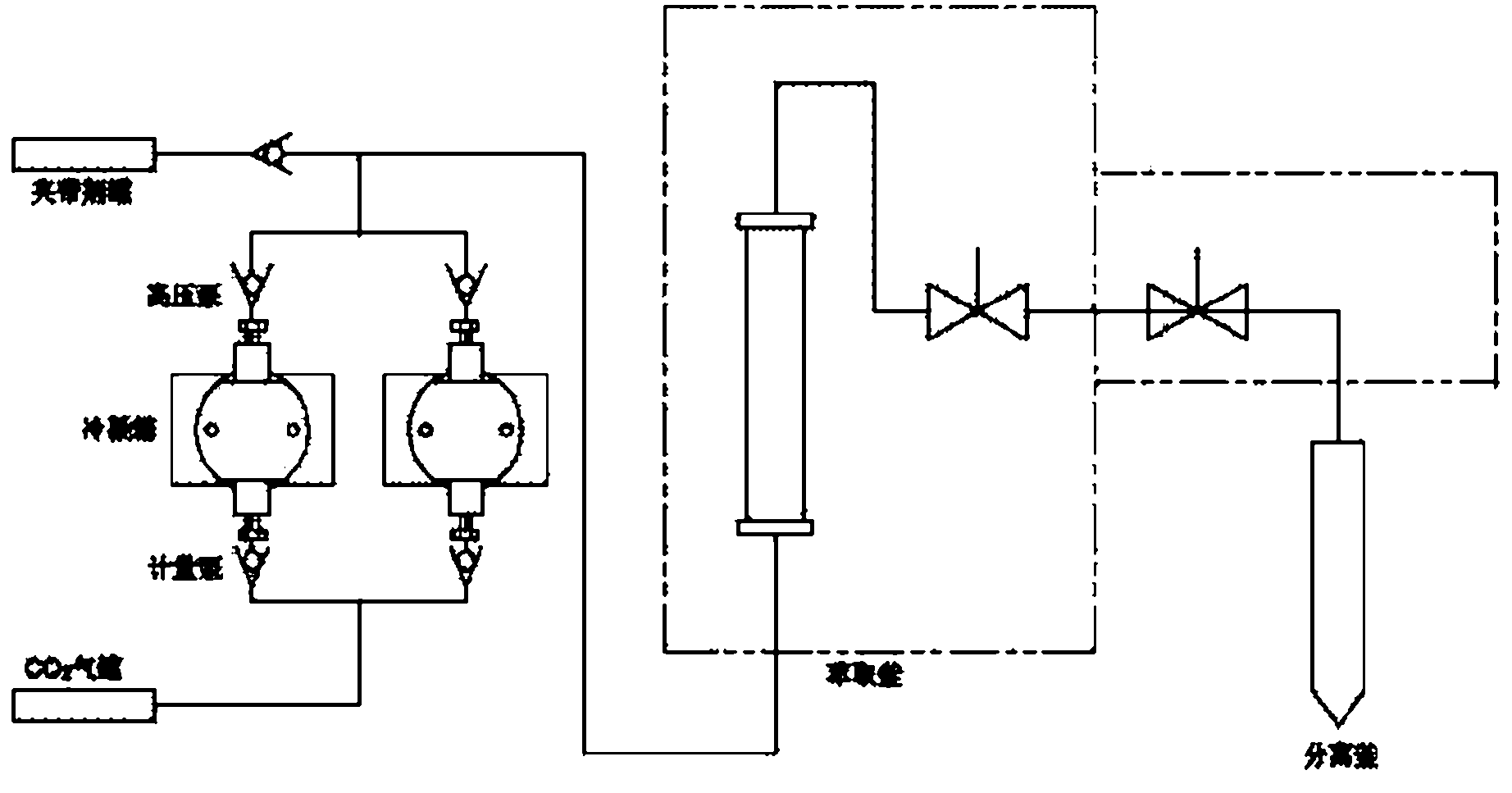

Image

Examples

Embodiment 1

[0027] Step 1, pre-treatment of barley and rice bran: the sample bran is crushed through a 80-mesh sieve with a pulverizer, and 50 g of the sample is weighed in a glass vessel, dried in a vacuum drying oven (60°C), taken out and weighed every 30 minutes, and dried to constant weight.

[0028] Step two, supercritical CO 2 Extractor Operation: Open CO 2 After the main power supply of the pump case, turn on the CO 2 Cylinder valve, and then observe the psi display value in the deflated state (psi>800, CO 2 adequate). Open the purge valve, purge for 10-15s, and then close the CO 2 Cylinder valve, when the pressure shows 0, close the release valve. Turn on the power switch, turn on the temperature control switch of the main box, and set the temperature of the extraction kettle to 50°C and the temperature of the separation kettle to 55°C. Turn on the pre-cooling switch of the pump head under the display screen, and pre-cool for 10-15 minutes. After cooling, after the heating t...

Embodiment 2

[0033] Step 1, rice bran pre-treatment: the sample bran is crushed through a 80-mesh sieve with a pulverizer, and 50 g of the sample is weighed in a glass vessel, dried in a vacuum drying oven (60° C.), taken out and weighed every 30 minutes, and dried to a constant weight.

[0034] Step two, supercritical CO 2 Extractor Operation: Open CO 2 After the main power supply of the pump case, turn on the CO 2 Cylinder valve, and then observe the psi display value in the deflated state (psi>800, CO 2 adequate). Open the purge valve, purge for 10-15s, and then close the CO 2 Cylinder valve, when the pressure shows 0, close the release valve. Turn on the power switch, turn on the temperature control switch on the left side of the main box, and set the temperature of the extraction kettle to 50°C and the temperature of the separation kettle to 55°C. Turn on the pre-cooling switch of the pump head under the display screen, and pre-cool for 10-15 minutes. After cooling, after the he...

Embodiment 3

[0038] Step 1, rice bran pre-treatment: the sample bran is crushed through a 80-mesh sieve with a pulverizer, and 50 g of the sample is weighed in a glass vessel, dried in a vacuum drying oven (60° C.), taken out and weighed every 30 minutes, and dried to a constant weight.

[0039] Step two, supercritical CO 2 Extractor Operation: Open CO 2 After the main power supply of the pump case, turn on the CO 2 Cylinder valve, and then observe the psi display value in the deflated state (psi>800, CO 2 adequate). Open the purge valve, purge for 10-15s, and then close the CO 2 Cylinder valve, when the pressure shows 0, close the release valve. Turn on the power switch, turn on the temperature control switch on the left side of the main box, and set the temperature of the extraction kettle to 40°C and the temperature of the separation kettle to 45°C. Turn on the pre-cooling switch of the pump head under the display screen, and pre-cool for 10-15 minutes. After cooling, after the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com