Preparation method of hollow polymer microsphere sensitized emulsion explosive for explosive welding

A technique of emulsified explosives and explosive welding, applied to explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve problems such as the uniform distribution of sensitizers and clay, destruction of surrounding vegetation, and soil pollution, etc., to achieve Good market prospects, promotion of technology development, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

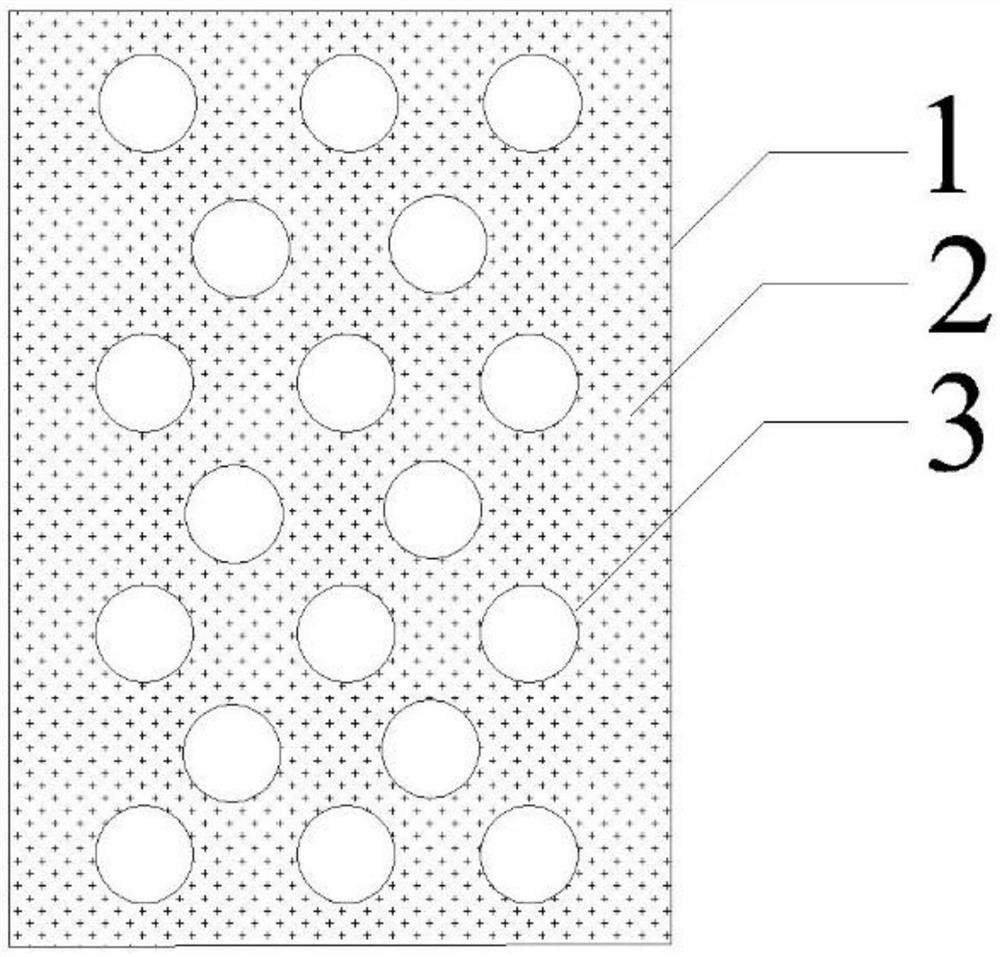

[0028] Polymethyl methacrylate microsphere sensitized emulsion explosive, the mass percentage of the emulsified matrix is 80%, the mass percentage of the microsphere is 20%, and the detonation velocity of the prepared emulsion explosive is 2500m·s -1 , with a density of 0.8g cm -3 .

[0029] St1: Water phase preparation: Add raw material water (8%-12%) and sodium nitrate (8%-12%) into the water phase dissolving tank, heat and stir under the steam pressure of 0.4MPa, and mix the crushed ammonium nitrate (75%-85%) is added into the water phase melting tank according to the set ratio by lifting the screw conveying hopper, and after being completely melted, it is kept at 105-110°C for standby, or put into the water phase storage tank for heat preservation for standby.

[0030] St2: Oil phase preparation: Add the composite oil phase (3%-5%) and emulsifier (1%-3%) into the oil phase melting tank, stir under the condition of indirect steam heating, until all melted and reach 90-10...

Embodiment 2

[0034] Polystyrene and polysiloxane microsphere mixed sensitized emulsion explosive, the mass percentage of the emulsified matrix is 70%, the mass percentage of the microsphere is 30%, and the detonation velocity of the prepared emulsion explosive is 2200m·s -1 , with a density of 0.65g cm -3 .

[0035] St1: Water phase preparation: Add raw material water (8%-12%) and sodium nitrate (8%-12%) into the water phase dissolving tank, heat and stir under the steam pressure of 0.4MPa, and mix the crushed ammonium nitrate (75%-85%) is added into the water phase melting tank according to the set ratio by lifting the screw conveying hopper, and after being completely melted, it is kept at 105-110°C for standby, or put into the water phase storage tank for heat preservation for standby.

[0036] St2: Oil phase preparation: Add the composite oil phase (3%-5%) and emulsifier (1%-3%) into the oil phase melting tank, stir under the condition of indirect steam heating, until all melted and...

Embodiment 3

[0040] Polyamide microsphere sensitized emulsion explosive, the mass percentage of the emulsified matrix is 60%, the mass percentage of the microsphere is 40%, and the detonation velocity of the prepared emulsion explosive is 1900m·s -1 , with a density of 0.5 g cm -3 .

[0041] St1: Preparation of water phase: Add raw material water (8%-12%) and sodium nitrate (8%-12%) into the water phase melting tank, heat and stir under the steam pressure of 0.4MPa, and mix the crushed ammonium nitrate (75%-85%) is added into the water phase melting tank according to the set ratio by lifting the screw conveying hopper, and after being completely melted, it is kept at 105-110°C for standby, or put into the water phase storage tank for heat preservation for standby.

[0042] St2: Oil phase preparation: Add the composite oil phase (3%-5%) and emulsifier (1%-3%) into the oil phase melting tank, stir under the condition of indirect steam heating, until all melted and reach 90-100 ℃ for later ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com