Emulsion explosive quality prediction and optimization method

A technology for emulsion explosives and quality prediction, applied in prediction, neural learning method, design optimization/simulation, etc., can solve problems such as long sampling period and unfavorable product quality, and achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in conjunction with the drawings.

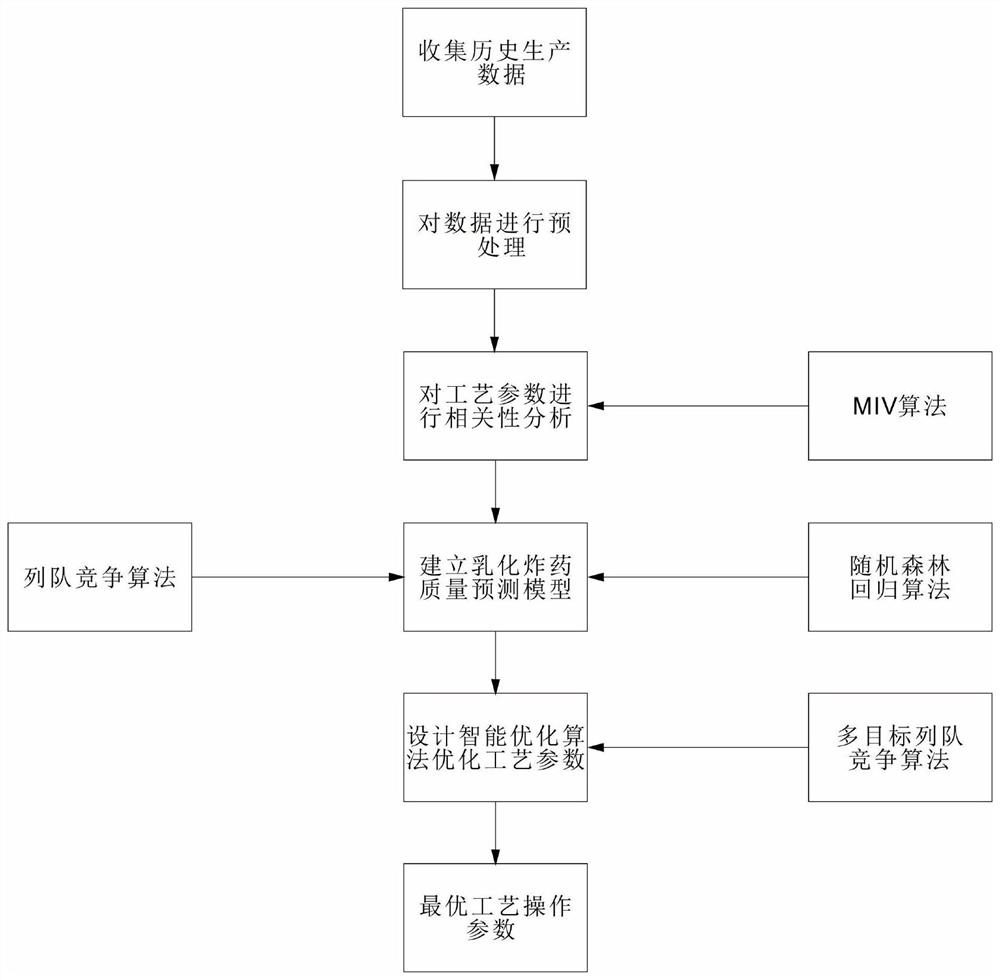

[0039] The present invention proposes an emulsified explosive quality prediction and optimization method, including the following steps:

[0040] Collect historical data from the emulsified explosive production process, preprocessing the collected data, correlates the process operation parameters of the emulsion explosive production process and the quality of the emulsion explosives, select the process parameters with large quality, delete independent variables;

[0041] Establish a random forest emulsifiable explosive quality prediction model, and design a series of queue competition algorithms to optimize the prediction model parameters of random forest emulsification explosives;

[0042] With the maximum target of emulsified explosives, the maximization of the optimization target is maximized, the process operation parameter operation range is constrained, established a double targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com