Mould pressing device for fluorescent glue for illumination and illumination production process

A fluorescent glue, fluorescent glue layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of chip pins being easily pressed and used normally, to improve control stability, improve overall quality, improve The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

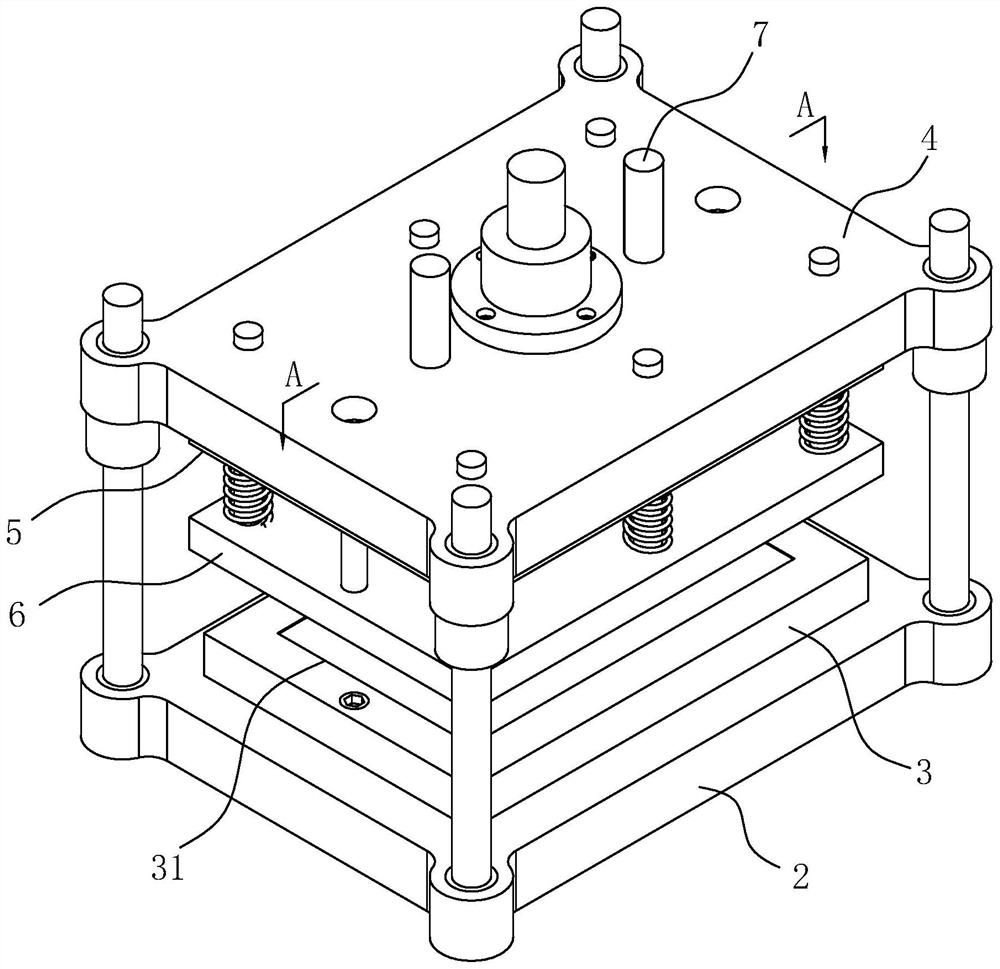

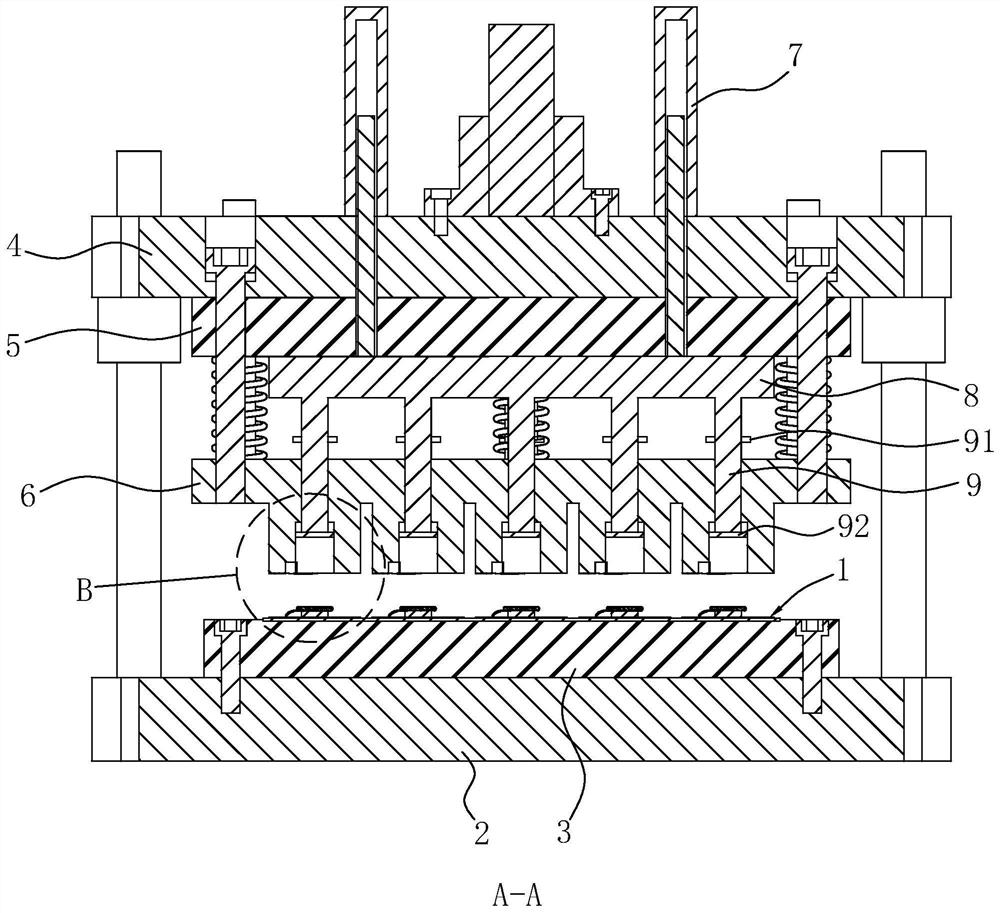

[0044] The following is attached Figure 2-4 The application is described in further detail.

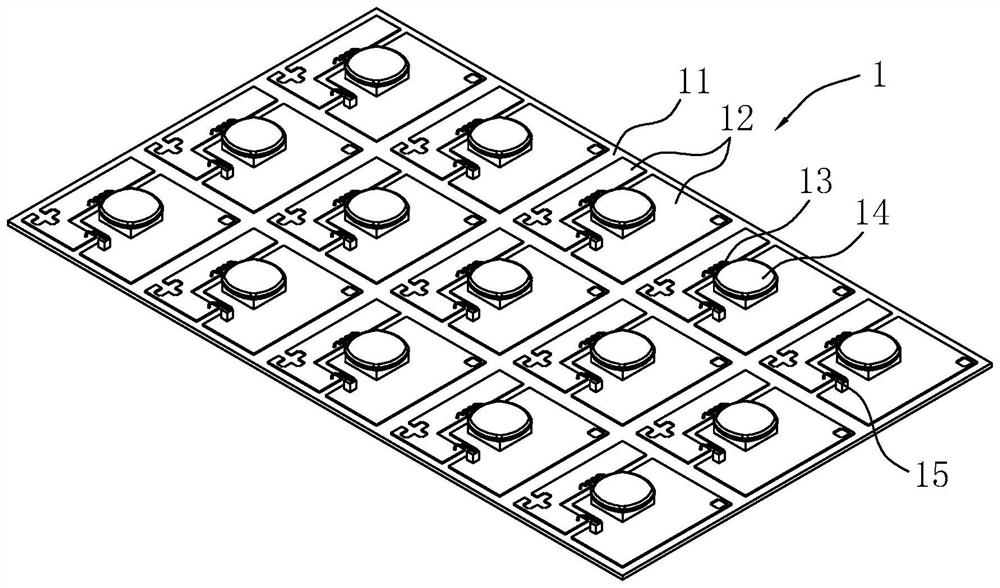

[0045] The embodiment of the application discloses a fluorescent glue molding device for lighting and a lighting production process.

[0046] refer to figure 2 and image 3 , the fluorescent plastic molding device for lighting includes a lower mold base 2 and an upper mold base 4, the lower mold base 2 is fixed with a lower template 3, the upper mold base 4 is equipped with an upper template 6, the upper template 6 is connected with a pressure column 9, and the upper mold base 4. A power part 7 that is connected with the pressure column 9 and can drive the pressure column 9 to move up and down is installed.

[0047] refer to figure 2 , the lower mold base 2 is a rectangular plate as a whole, and the four corners of the lower mold base 2 are respectively vertically fixed with guide posts. The upper mold base 4 is a rectangular plate as a whole, and the four corners of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com