A kind of explosive bolt box and preparation method thereof

A technology of explosive bolts and bolt boxes, which is used in offensive equipment, projectiles, self-propelled bombs, etc., can solve the problems of poor bearing capacity, difficult to control, and explosion power pollution, and achieve the effect of high bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

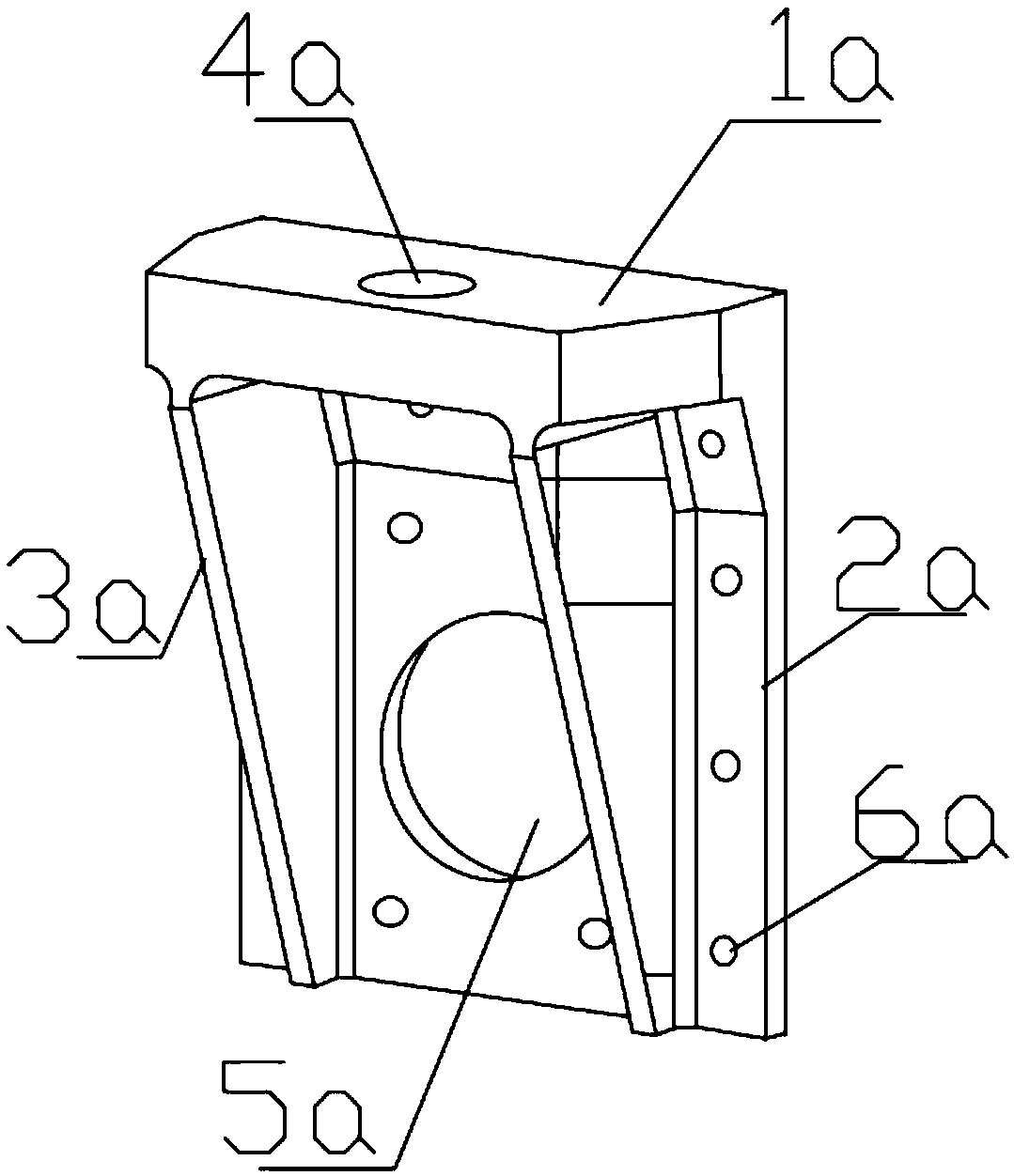

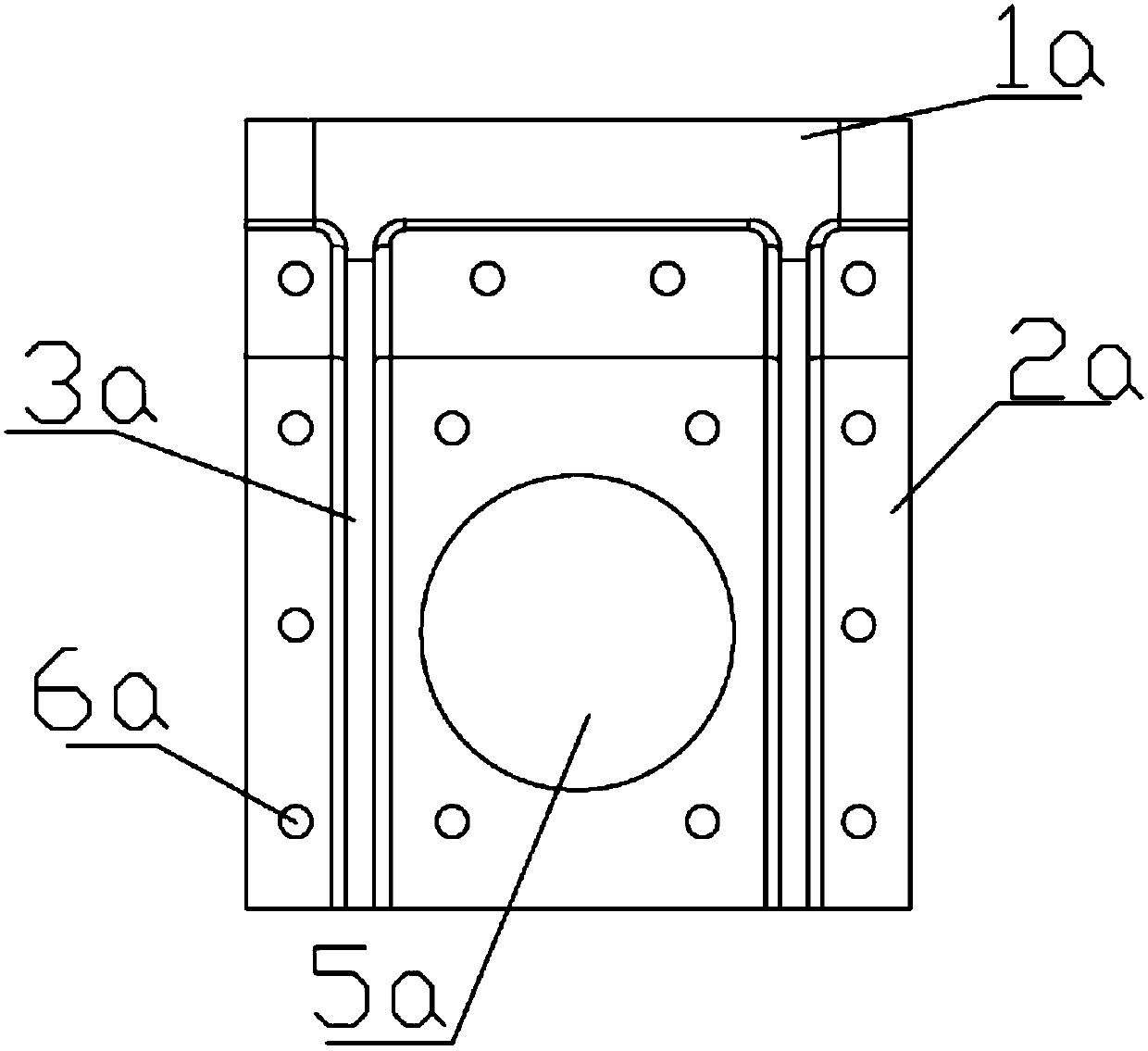

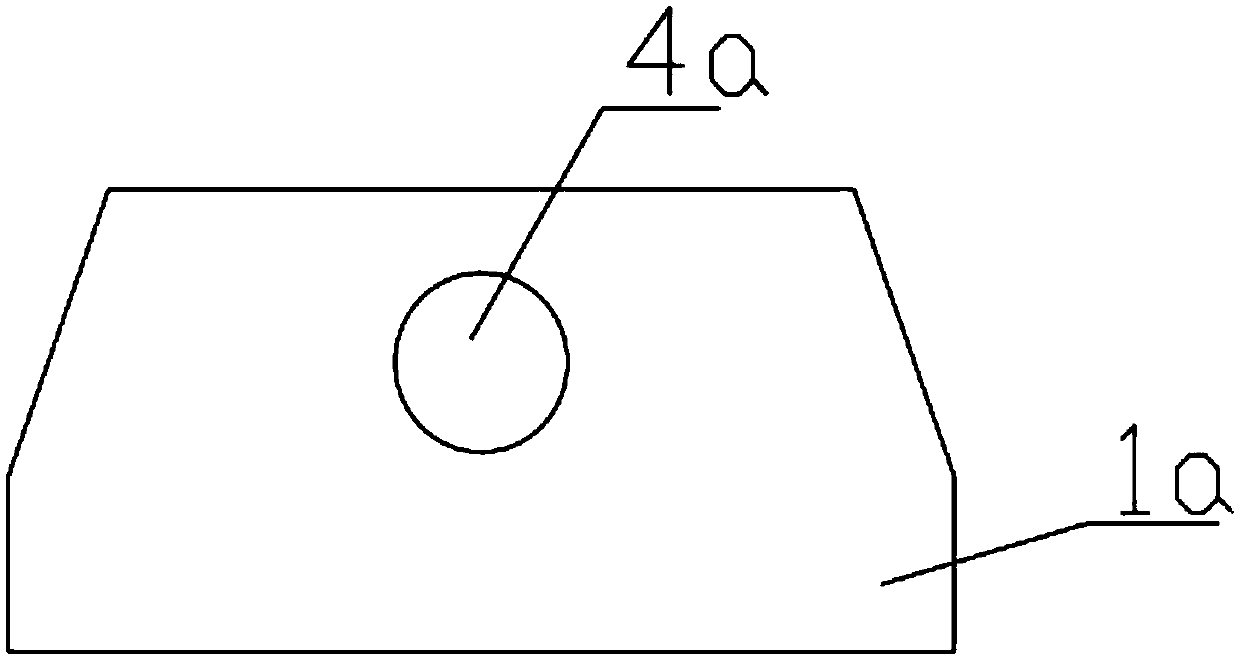

[0072] Specific embodiment one: a kind of explosive bolt box of this embodiment, it is made of top plate 1a, explosive bolt box back plate 2a, two explosive bolt box slant plates 3a; The bolt box slant plate 3a; the explosive bolt box back plate 2a and the top of the two explosive bolt box slant plates 3a are provided with a top plate 1a; the center of the top plate 1a is provided with an explosive bolt connection hole 4a; the explosive bolt box back plate 2a has a lightening hole 5a in the center;

[0073] The angle α formed by the vertical part of the back plate 2a of the explosive bolt box and the bent part is 160°, and the angle β formed by the bent part and the top plate 1a is 110°;

[0074] Several screw or rivet through holes 6a are opened on the back plate 2a of the explosive bolt box.

specific Embodiment approach 2

[0075] Embodiment 2: This embodiment is different from Embodiment 1 in that: the thickness of the back plate 2a of the explosion bolt box is 13mm; the thickness of the slant plate 3a of the explosion bolt box is 9mm; the thickness of the top plate 1a is 30mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0076] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the explosive bolt box is made of carbon fiber. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com