Specific HMX (cyclotetramethylene tetranitramine)

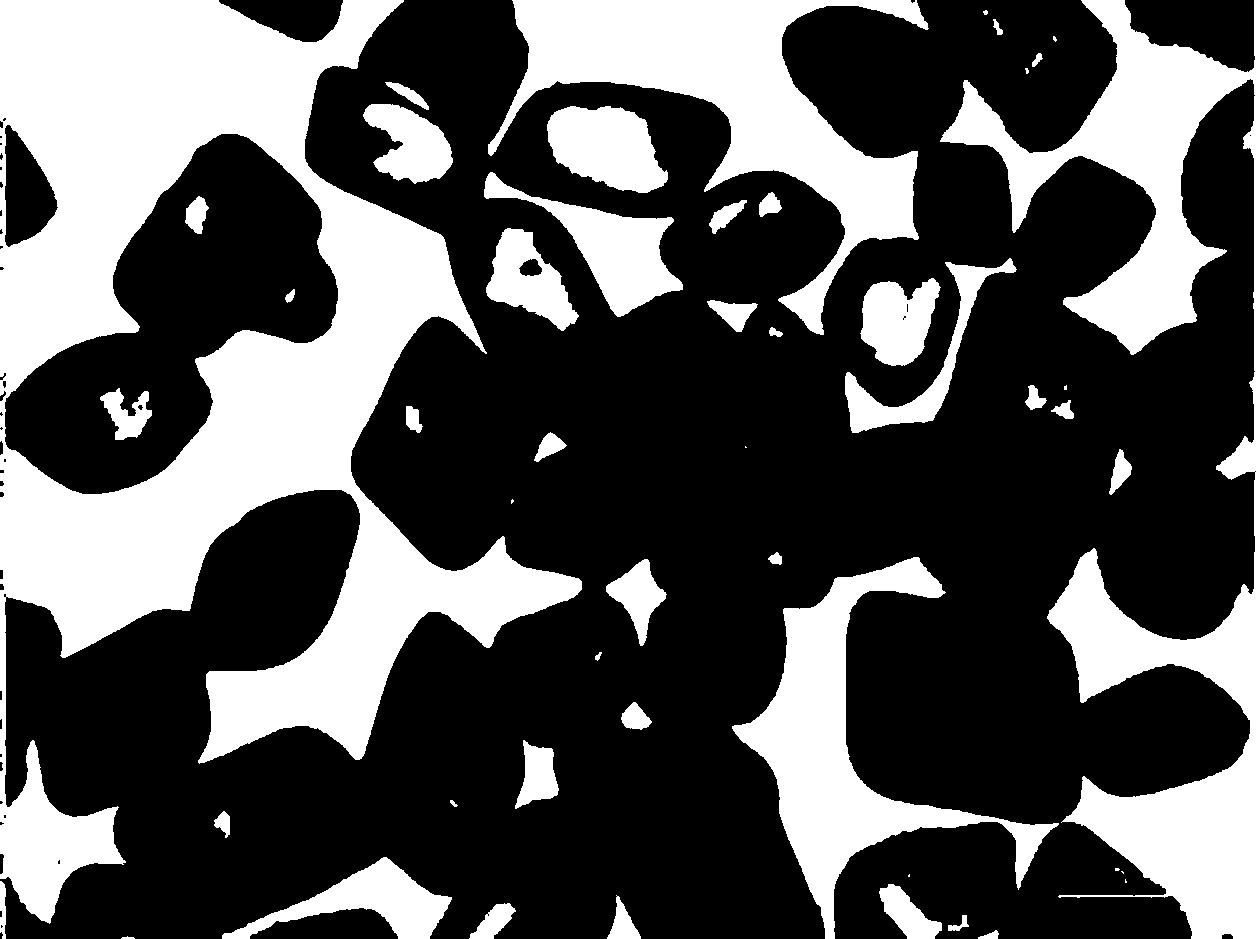

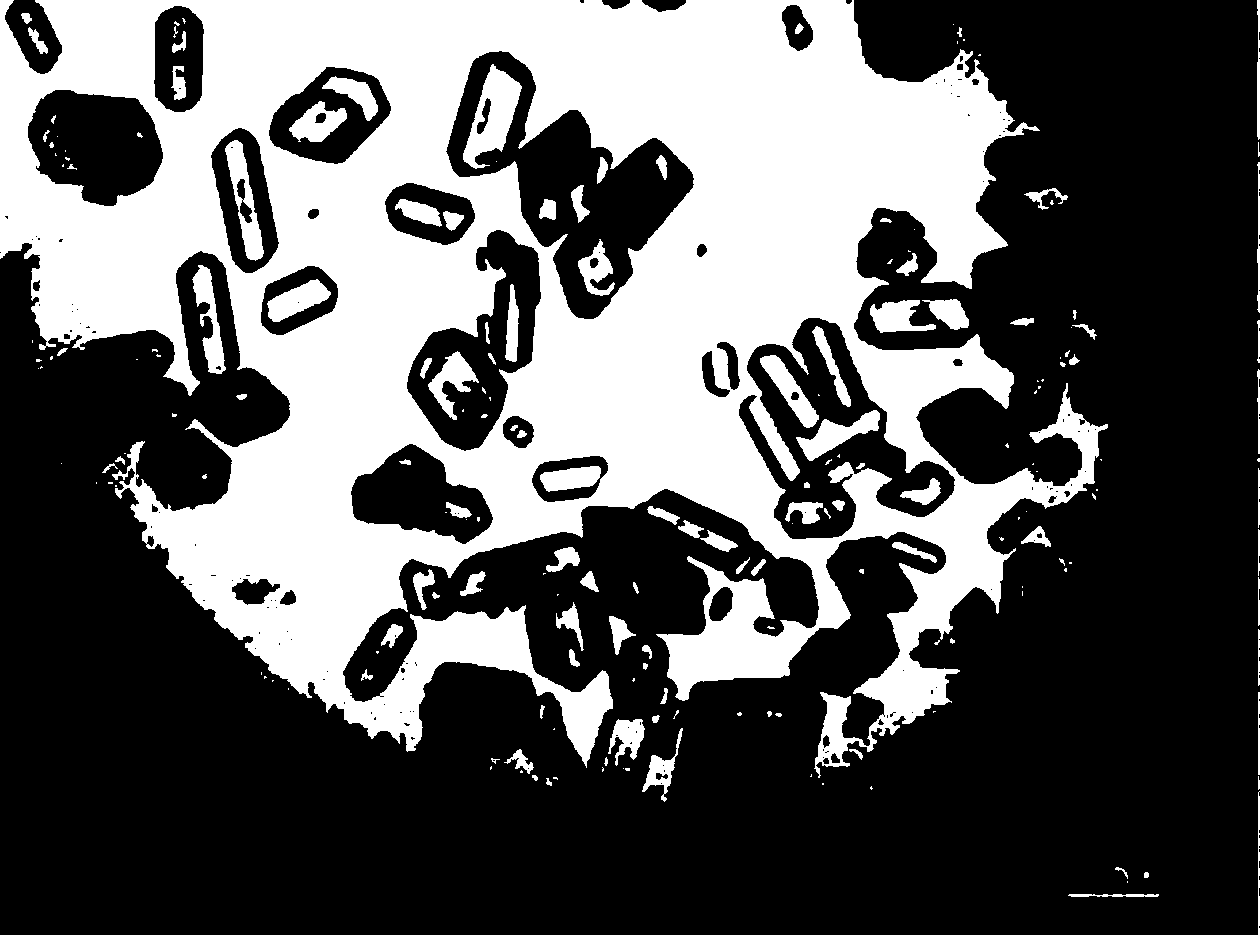

A kind of octogen and special technology, applied in the field of special octogen, it can solve the problems that the crystal surface is not smooth enough, not suitable for particle size grading, wide particle size distribution, etc., to achieve large particle size, high product yield, crystal surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

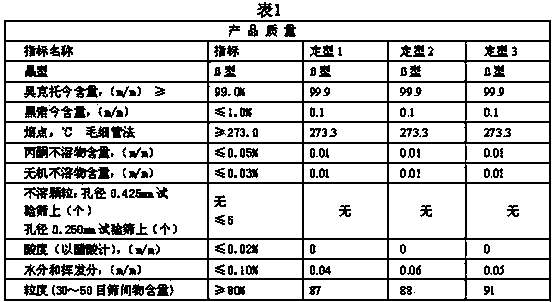

Embodiment 1

[0015] Example 1 A special Octogen was prepared by the following steps: (a) Dissolving Octogen in dimethyl sulfoxide at 58°C to make Octogen solution, Octogen The mass ratio of octogen to dimethyl sulfoxide is 1:1.3; (b) in the range of 64°C, add three kinds of dimethyl sulfoxide aqueous solutions with different concentrations at a uniform speed in order to dilute and crystallize the octogen solution; the first The concentration of the first dimethyl sulfoxide aqueous solution is 71%, and the adding rate is 0.8 kg / min; the concentration of the second dimethyl sulfoxide aqueous solution is 47%, and the adding rate is 0.9 kg / min; the third dimethyl sulfoxide The concentration of the sulfoxide aqueous solution was 38%, and the addition rate was 1.0 kg / min; after the addition of the three dimethyl sulfoxide aqueous solutions, a sufficient amount of water was added at a uniform speed, and the addition rate was 1.2 kg / min; The addition of sulfone aqueous solution is successively 0.5...

Embodiment 2

[0016] Example 2 A special Octogen was prepared by the following steps: (a) Dissolving Octogen in dimethyl sulfoxide at 40°C to make an Octogen solution, Octogen The mass ratio of octogen to dimethyl sulfoxide is 1:1.2; (b) within the range of 70°C, add three kinds of dimethyl sulfoxide aqueous solutions with different concentrations at a uniform speed in turn to dilute and crystallize the octogen solution; the first The concentration of the first dimethyl sulfoxide aqueous solution is 61%, and the adding rate is 0.9 kg / min; the concentration of the second dimethyl sulfoxide aqueous solution is 45%, and the adding rate is 1.2 kg / min; the third dimethyl sulfoxide The concentration of the sulfoxide aqueous solution was 28%, and the addition rate was 1.0 kg / min; after the addition of the three dimethyl sulfoxide aqueous solutions, a sufficient amount of water was added at a uniform speed, and the addition rate was 1.4 kg / min; The addition of sulfone aqueous solution is successive...

Embodiment 3

[0017] Example 3 A special Octogen was prepared by the following steps: (a) Dissolving Octogen in dimethyl sulfoxide at 49°C to make Octogen solution, Octogen The mass ratio of octogen to dimethyl sulfoxide is 1:1.5; (b) in the range of 82°C, add three kinds of dimethyl sulfoxide aqueous solutions with different concentrations in sequence to dilute and crystallize the octogen solution; the first The concentration of the first dimethyl sulfoxide aqueous solution is 63%, and the adding rate is 1.0 kg / min; the concentration of the second dimethyl sulfoxide aqueous solution is 53%, and the adding rate is 1.1 kg / min; the third dimethyl sulfoxide The concentration of the sulfoxide aqueous solution was 30%, and the addition rate was 1.2 kg / min; after the addition of the three dimethyl sulfoxide aqueous solutions, a sufficient amount of water was added at a uniform speed, and the addition rate was 1.6 kg / min; The addition of sulfone aqueous solution is successively 0.49 times, 0.97 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com