Patents

Literature

50 results about "Sympathetic detonation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sympathetic detonation (SD, or SYDET), also called flash over, is a detonation, usually unintended, of an explosive charge by a nearby explosion.

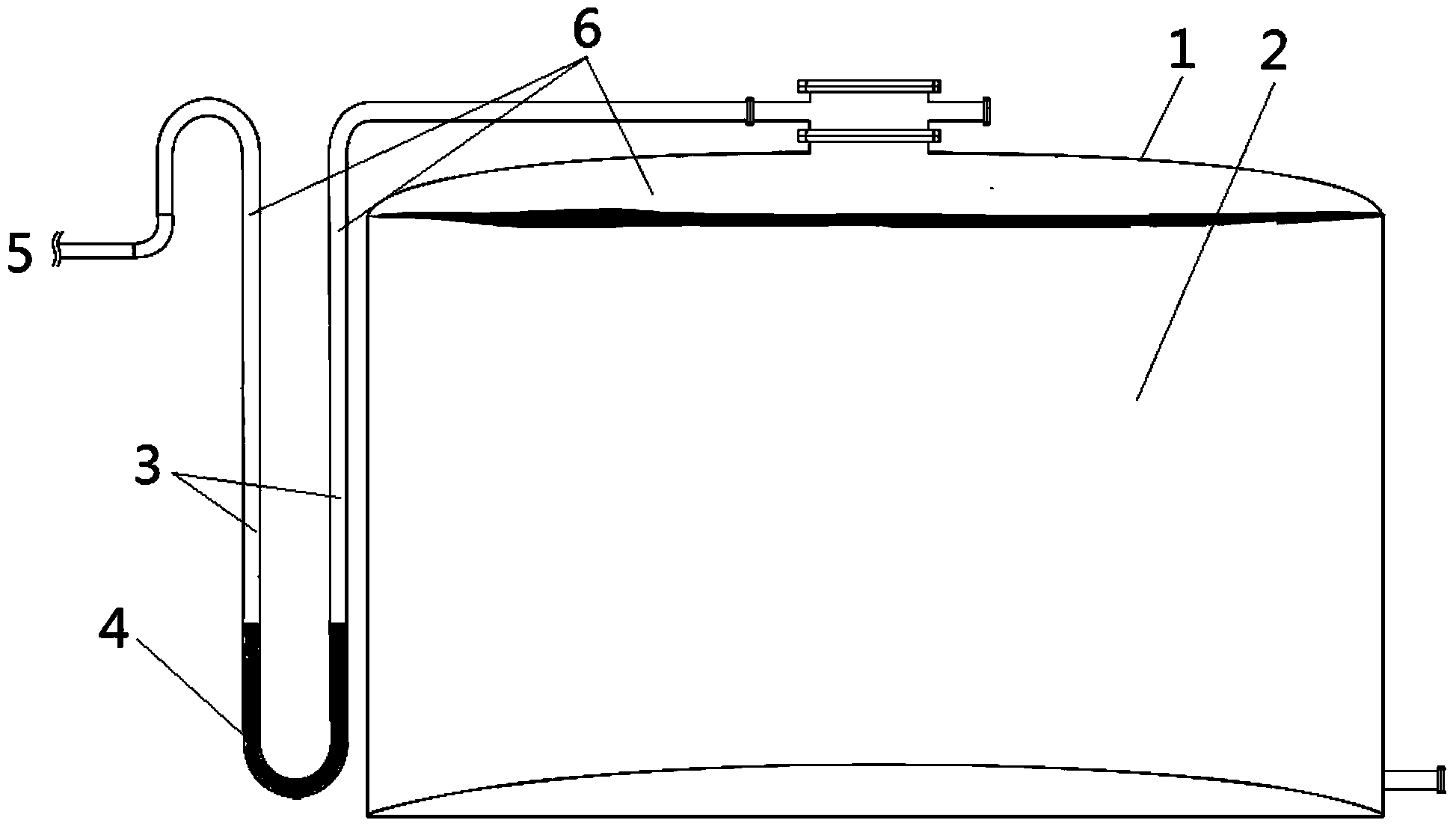

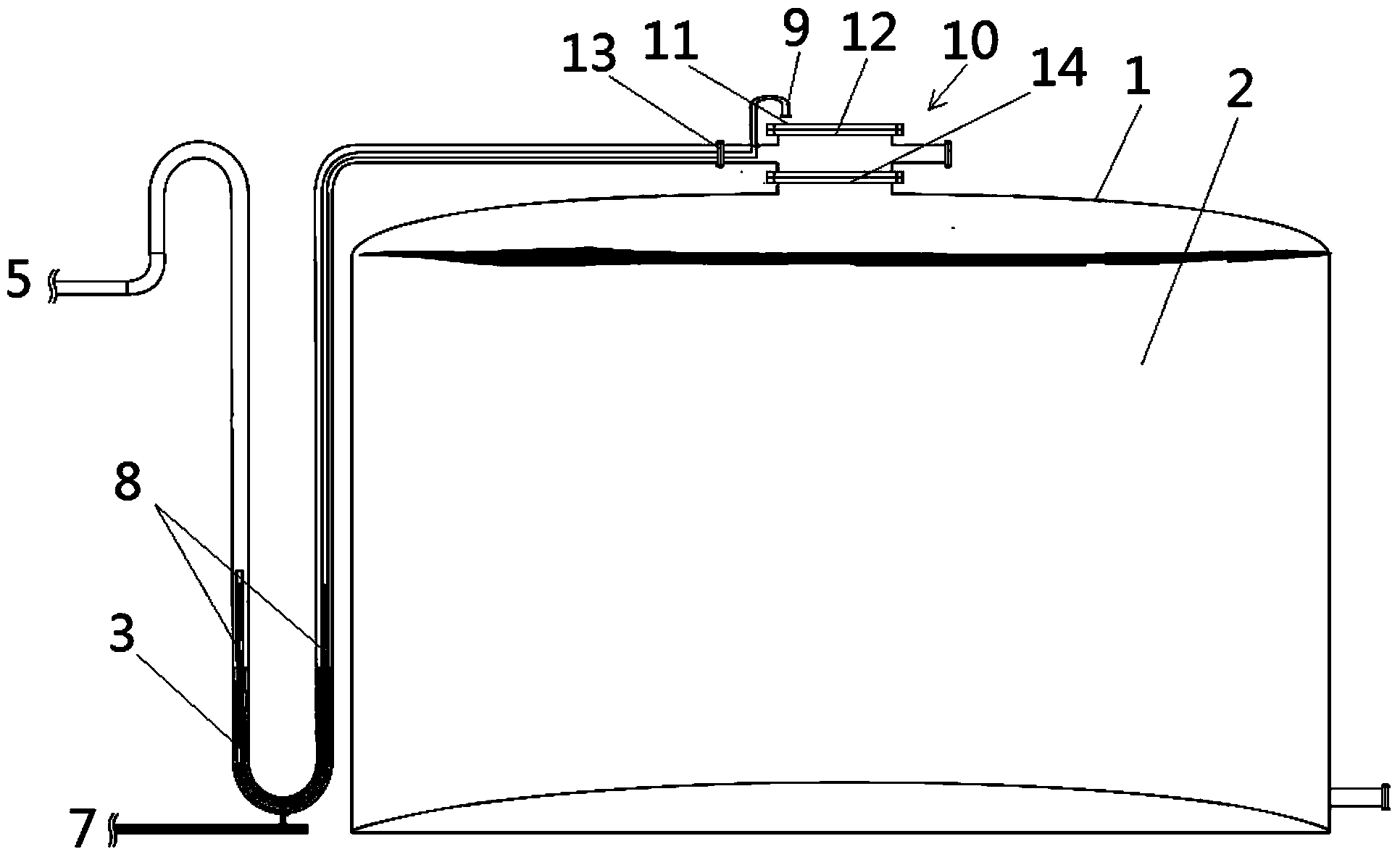

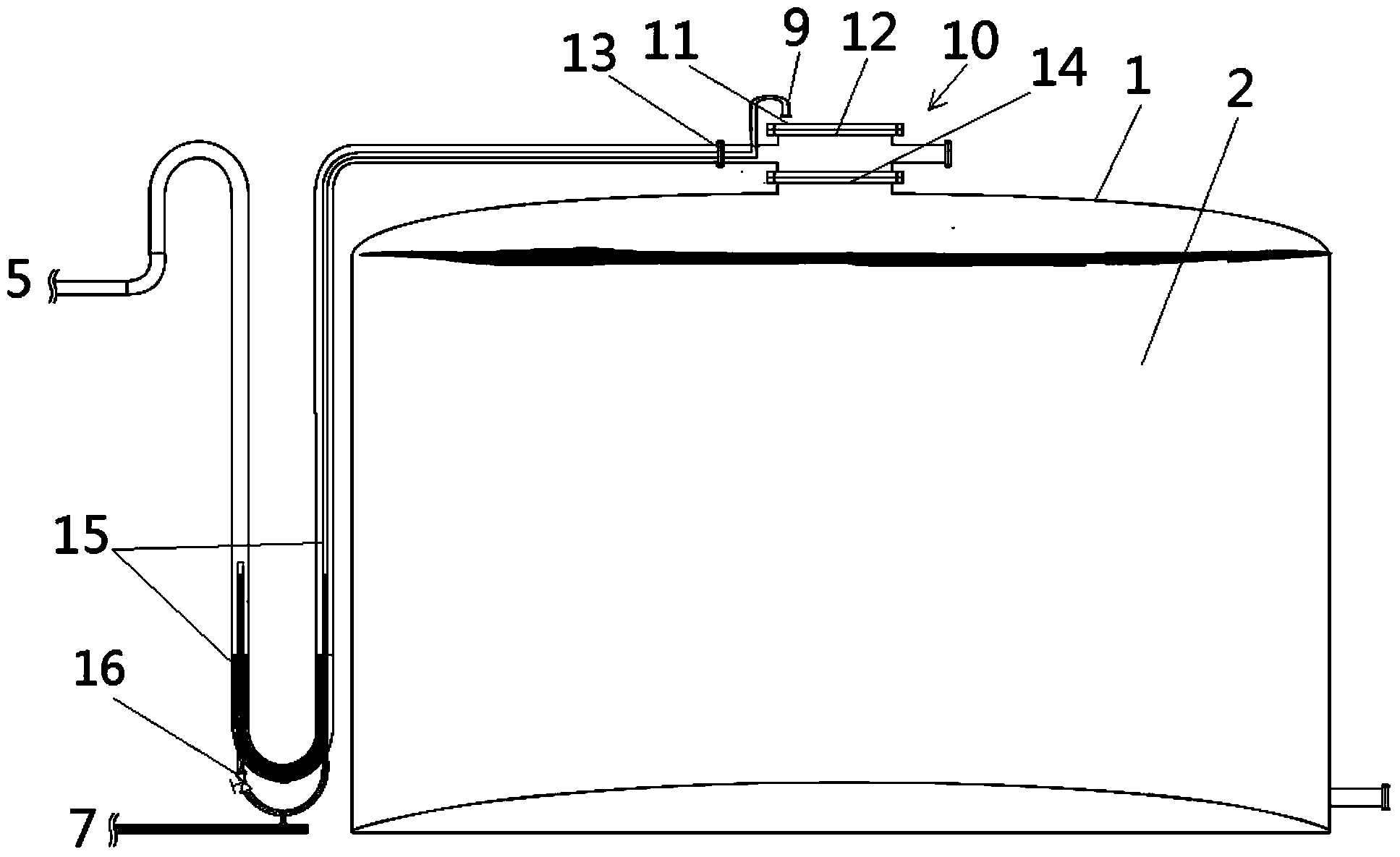

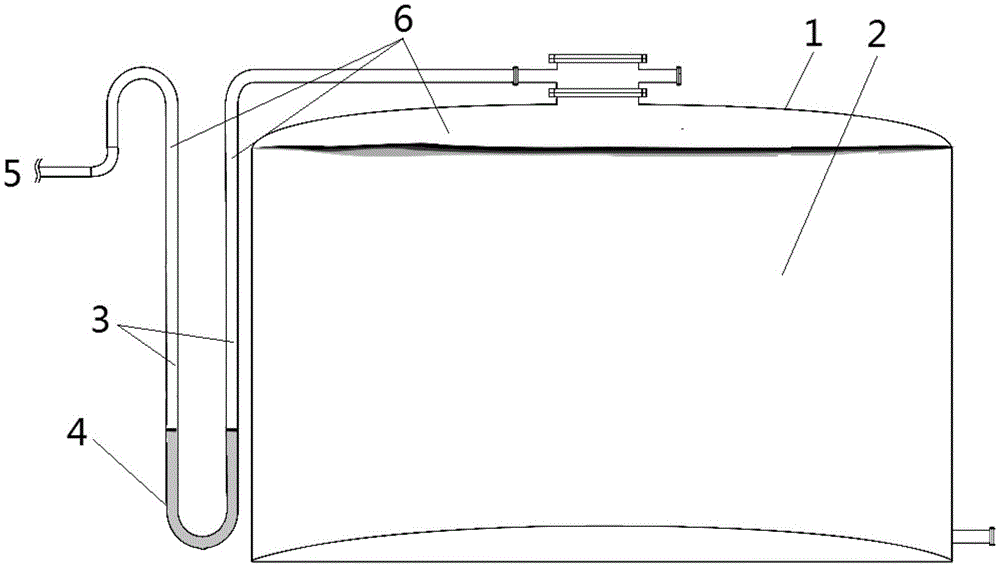

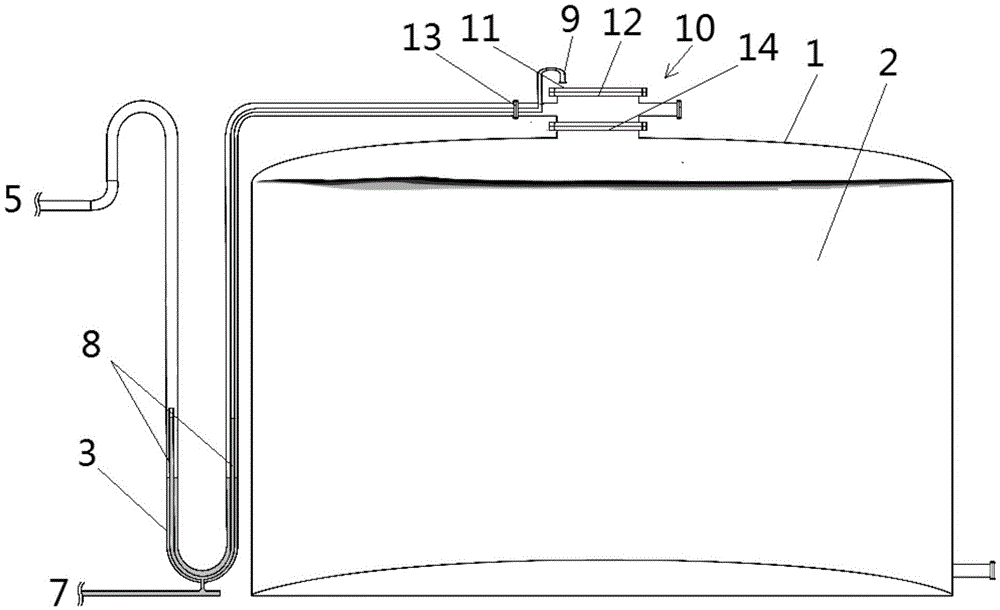

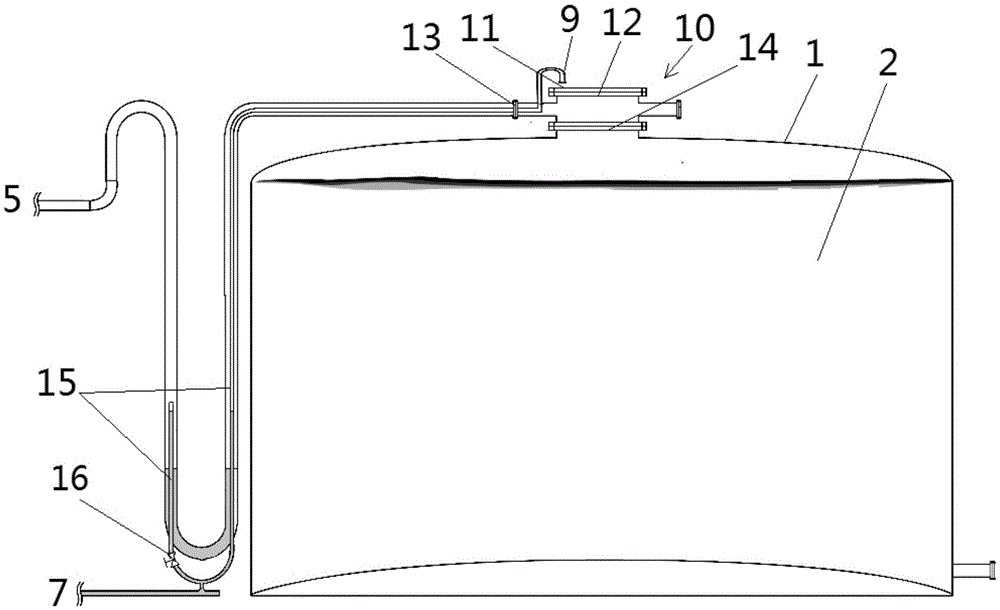

Idle sealing and explosion suppression device used for dangerous chemical containers and defense method

ActiveCN103922051AEliminate volatilizationEliminate fugitiveLarge containersPackaging under vacuum/special atmosphereFire protectionCombustion

The invention relates to an idle sealing and explosion suppression device used for dangerous chemical containers, and a defense method which responds to multistage shaped charge and aims at conducting sympathetic detonation on oxygen-contained hydrocarbon gas in gas-phase space of the container in a mode of entering the payload containers at any time. The device comprises idle sealing devices arranged on the dangerous chemical containers. Each idle sealing device comprises a U-shaped sleeve, wherein a Y-shaped penetrating pipe is arranged inside the U-shaped sleeve, one upper port of the U-shaped sleeve is communicated with the gas-phase of a gas idle sealing medium source, the other upper port of the U-shaped sleeve is communicated with the gas-phase of the corresponding container through an idle sealing disc on the top of the corresponding container, the port on the gas distribution side of the Y-shaped penetrating pipe is hung in a vertical pipe on the gas distribution side of the U-shaped sleeve, the port on the corresponding container side of the Y-shaped penetrating pipe is connected with a spraying pipe on the top of the corresponding container, the bottom port of the U-shaped sleeve is connected and communicated with a liquid-state fire protection medium source after penetrating out of a bottom connection pipe of the U-shaped sleeve, a liquid valve of the sleeve can serve as a large-breath and small-breath valve, a liquid valve of the penetrating pipe can serve as a safety relief valve, the atmosphere can be isolated in a systemic mode, and the combustion explosion condition of the gas-phase space of the corresponding container and pipelines can be permanently restrained.

Owner:国铠特种流体机械制造(青岛)有限公司

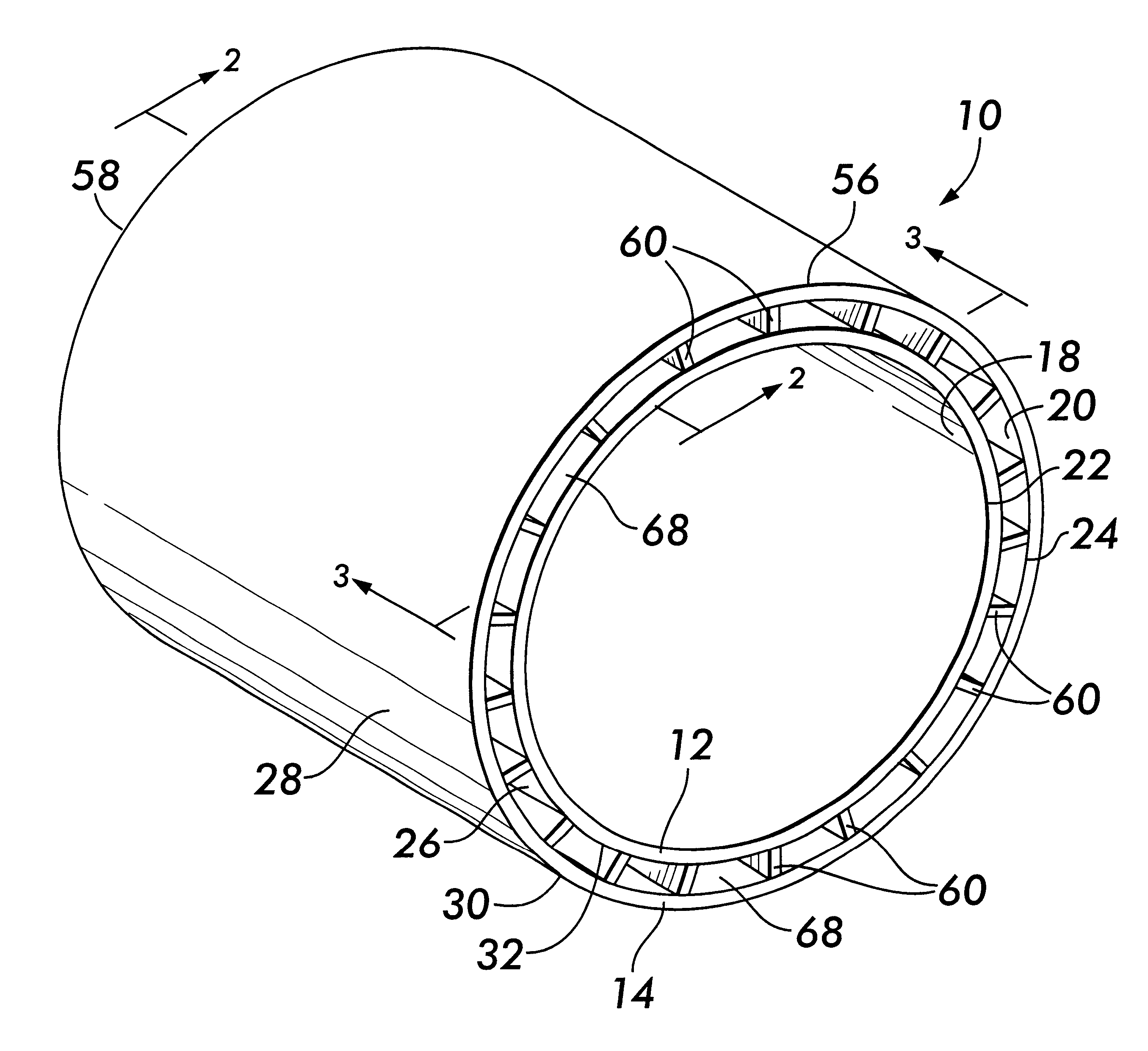

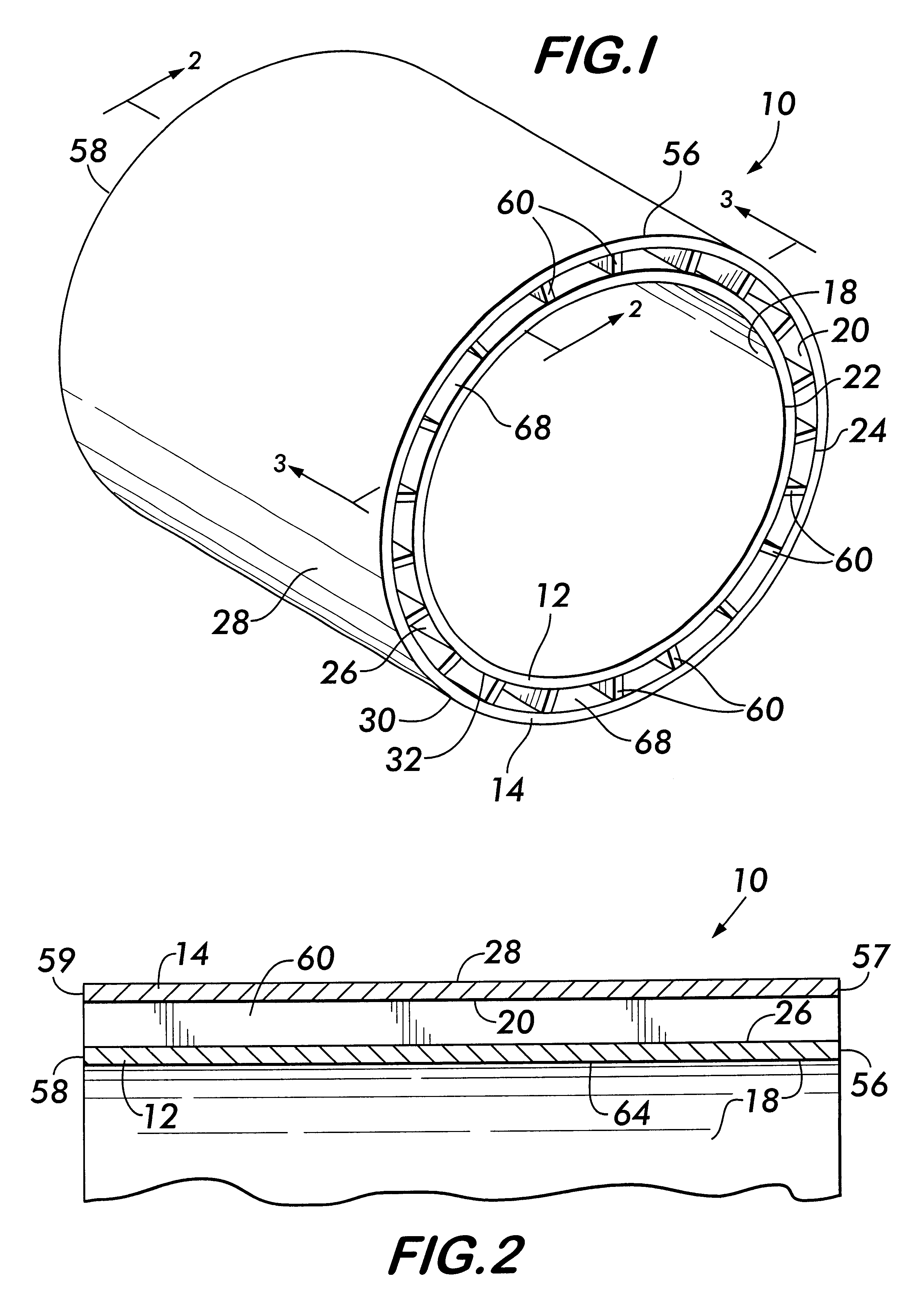

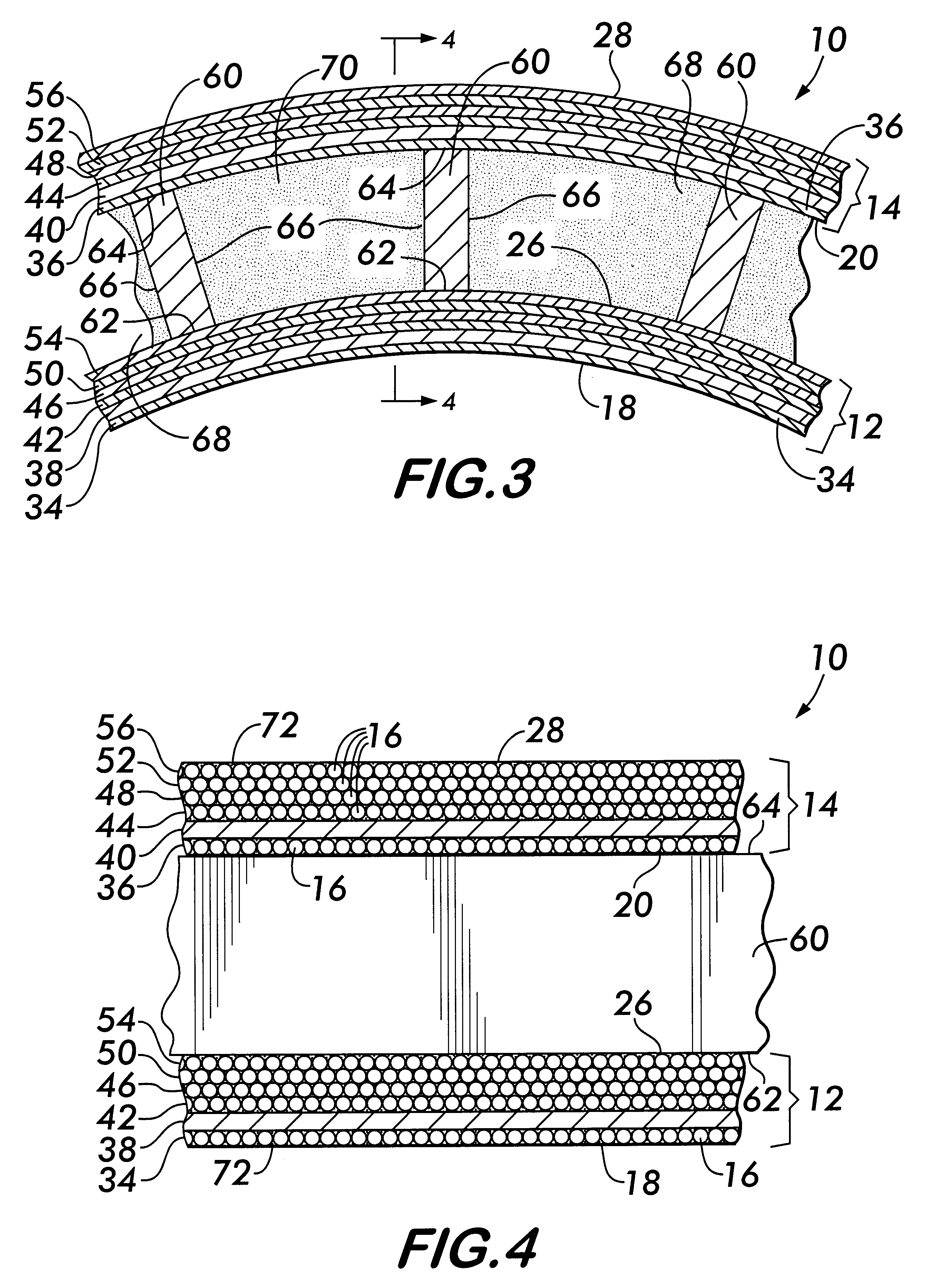

Deforming charge assembly and method of making same

InactiveUS6386110B1Efficient mass productionLight weightAmmunition projectilesBlasting cartridgesFiberCarbon fibers

A deforming charge assembly is provided which has an inner and an outer cylinder formed from carbon fiber. Each of the inner and outer cylinders have an inner circumference surface having an inner diameter and an outer circumference surface having an outer diameter. The inner diameter of the outer cylinder is greater than the outer diameter of the inner cylinder. Each of the inner and outer cylinders have a first layer of circumferentially wound carbon fiber, a second layer of unidirectional carbon fiber sheet and a plurality of layers of carbon fibers circumferentially wrapped around the second layer. A plurality of sympathetic detonation barrier members are provided and have an inner surface in contact with the outer circumference surface of the inner cylinder and an outer surface in contact with the inner circumference surface of the outer cylinder.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Low detonation velocity powdery emulsifying explosive

ActiveCN101423448ALow detonation velocityQuality assuranceExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsion explosiveUltimate tensile strength

The invention relates to a powdery emulsion explosive with low detonation velocity. A rock powdery emulsion explosive, talcum powder and coarse bran are placed into a mixer for fullly stirring to ensure that the mixture is mixed evenly and then is packaged and sold, wherein the bulk density of the rock powdery emulsion explosive is between 0.58 and 0.62 / g.cm<-3>, the detonation velocity is between 3,500 and 3,700 / m.s<-1>, the brisance is between 15 and 17 / mm, the sympathetic detonation is between 9 and 11 / cm, the capacity for work is 360 / ml, and the storage period is 6 months; the bulk density of the talcum powder is between 0.95 and 1.0 / g.cm<-3>, and the grain diameter is 300 meshes; and the bulk density of the coarse bran is between 0.28 and 0.35 / g.cm<-3>, and the grain diameter is between 0.8 and 1mmr. In the invention, the powdery emulsion explosive with low detonation velocity is applied to double metal explosive welding first, which ensures the quality of explosive welding of double metal explosive composite welding and ensures that the double metal explosive welding fully meets the requirement. The powdery emulsion explosive is safe, also has no pollution after the explosion, and has no harm to the health of blasters. The storage period of the powdery emulsion explosive with low detonation velocity can reach more than 180 days, so the powdery emulsion explosive can be mixed by manufacturers without field mixed-making and the labor intensity of the blasters is reduced.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

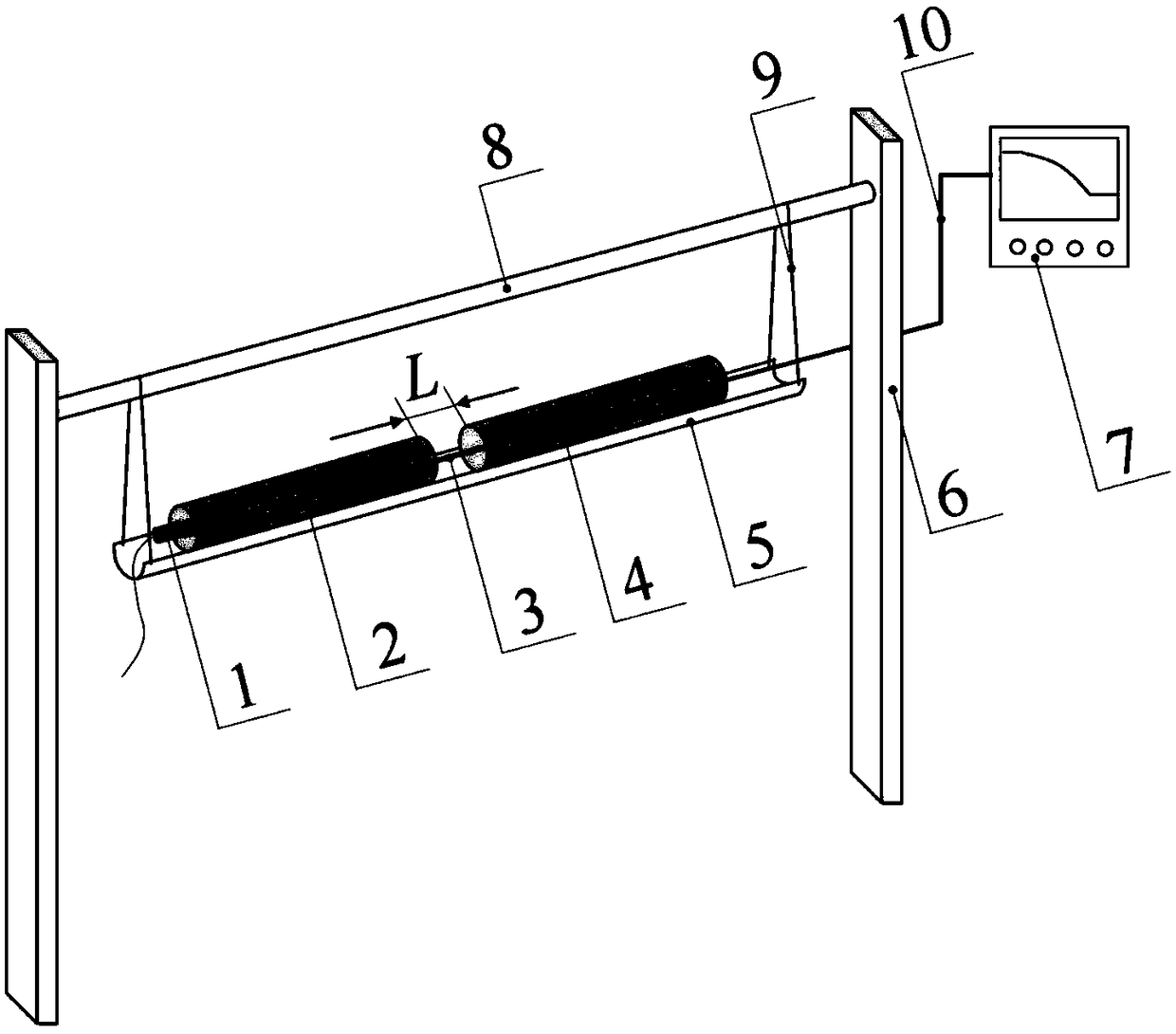

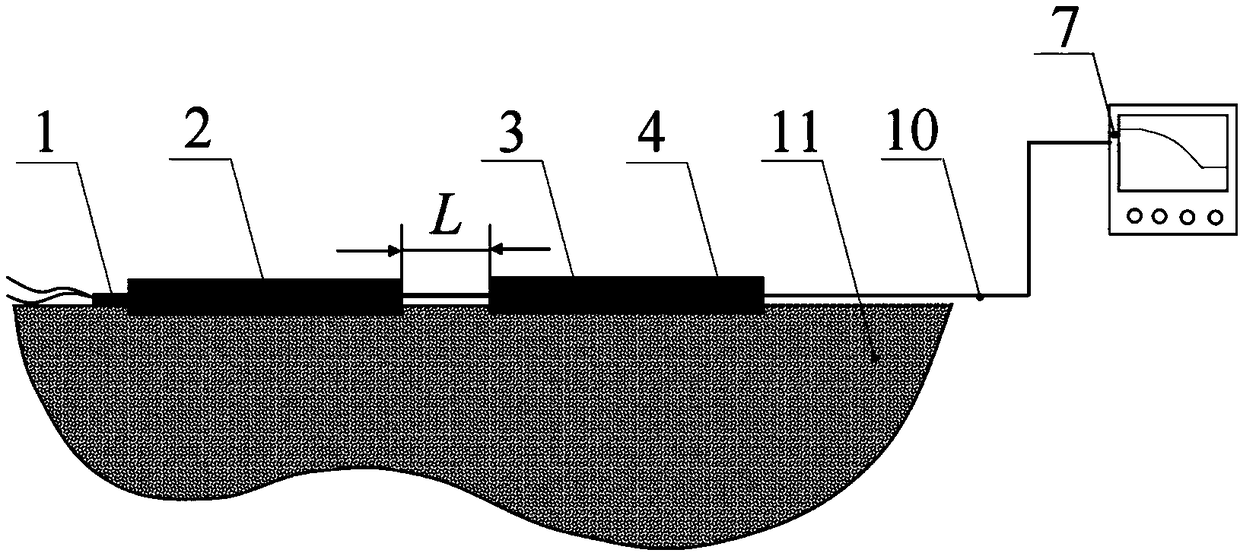

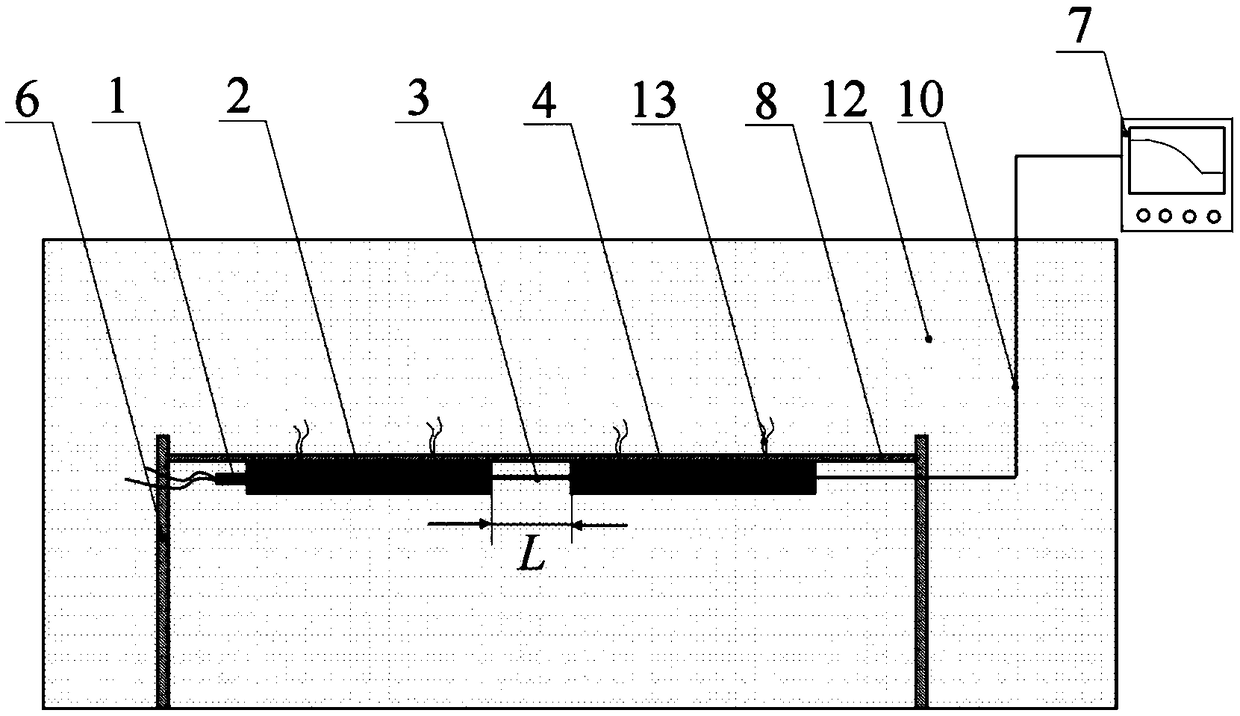

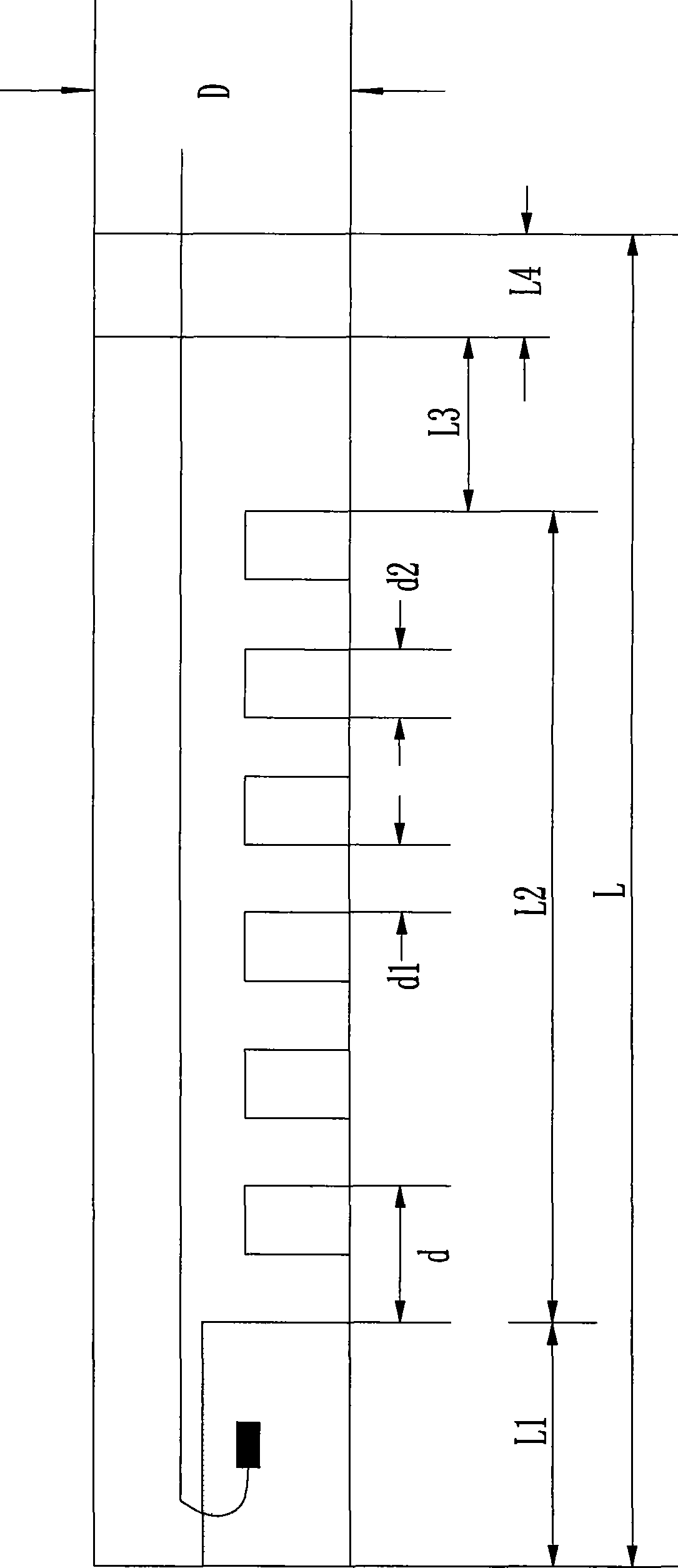

Method for quantitatively determining sympathatic detonation of explosive

ActiveCN108802328AIntuitive and reliable resultsAnalyzing Shock Wave SensitivityFuel testingDetonatorElectrical resistance and conductance

The invention provides a method for quantitatively determining sympathatic detonation of an explosive, and belongs to the technical field of blasting. The method comprises the following steps: fixinga continuous resistance wire probe to centers of a detonating cartridge and a detonated cartridge, integrally placing the detonating cartridge and the detonated cartridge with the continuous resistance wire probe in a semicircular pipe groove of a test support, and keeping the cartridges in the same axis; regulating the sympathetic detonation distance to be in preset value L by moving the detonated cartridge, and connecting a probe led out from the tail end of the detonated cartridge to a signal acquisition instrument through a coaxial cable; inserting a detonator into a detonating end of thedetonating cartridge, starting the signal acquisition instrument, detonating the explosive, and recording a voltage signal curve of the continuous resistance wire probe by the signal acquisition instrument; converting, thus obtaining a detonation wave-impact wave time travel curve; comparing a detonation wave travel with the length of the cartridges, thus judging whether the detonated cartridge isin sympathatic detonation or not. A measurement system is simple, the cost is lower, a result is direct and reliable and is basically not affected by a testing environment, and the explosive amount is not limited.

Owner:DALIAN UNIV OF TECH

Tunnel excavation smooth blasting method

The invention relates to a new method for tunnel excavation smooth blasting, which makes use of the common emulsion explosive instead of dedicated smooth explosive and detonating cords, and fills the explosive at interval in the holes and utilizes the sympathetic detonation phenomenon among different explosive scrolls to transfer the detonation in turn to achieve the goals. Compared with the traditional method, the materials required in the invention can be easily purchased, and the costs can be significantly reduced.

Owner:SINOHYDRO BUREAU 5

Fireworks detonating agent without chlorate and perchlorate

InactiveCN1640856ALow moisture absorptionReduced friction sensitivityExplosivesDecompositionFireworks

The firework exploding and sounding agent without chlorate and perchlorate comprises composite oxidant, inflammable sulfur, easy-to-burn aluminum powder and density regulating agent, and features the composite oxidant comprising potassium nitrate 10-50 wt%, barium nitrate 50-90 wt% and potassium permanganate 0-25 wt%. The firework exploding and sounding agent has also added pH regulating agent boric acid and deactivating agent magnesia or stearic acid. The firework exploding and sounding agent has high heat stability, no decomposition under 75 deg.c and minus 25-35 deg.c for 48 hr, friction sensitivity lower than 60 %, knocking sensitivity lower than 50 %, no burning and explosion in falling test and sympathetic detonation test, high fire approaching performance and no special requirement in firing line, and may be used in type B and type C firework products.

Owner:刘青春

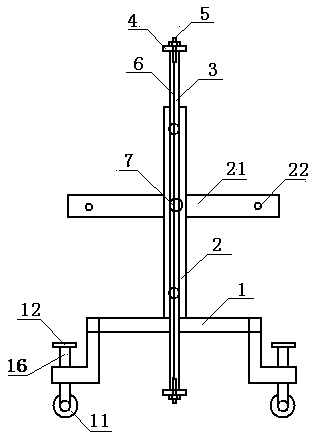

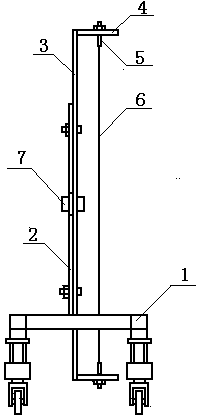

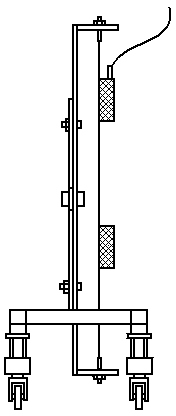

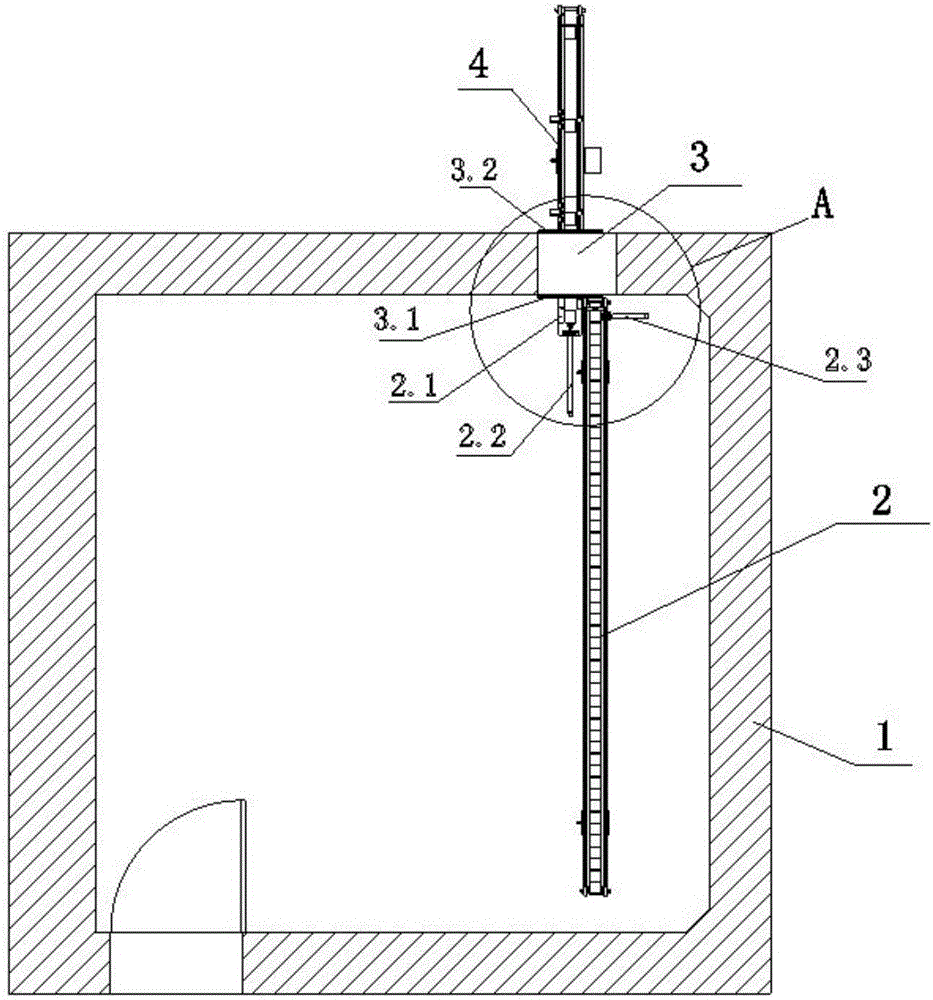

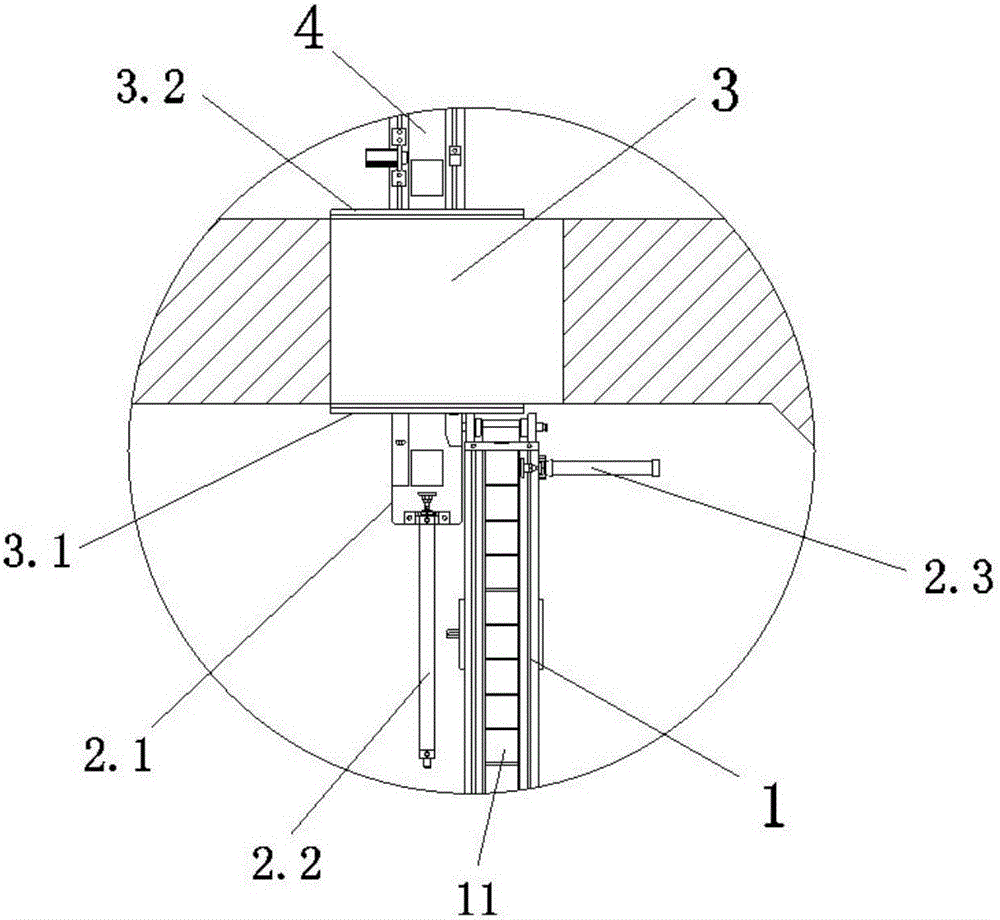

Explosive sympathetic detonation distance testing device

The invention discloses an explosive sympathetic detonation distance testing device which comprises a supporting frame and a connecting frame. The connecting frame is composed of two plates which are vertically crossed, a sectional tube is arranged on one plate of the connecting frame, a connecting plate is relatively arranged at the two ends of the sectional tube, a thread hole is relatively formed in the connecting plate, a screw rod are arranged in the thread hole, and the opposite end of the screw rod is connected with a flexible rope used for placing of a test explosive. An H shape is formed by two horizontal plates and one longitudinal plate on the upper end face of the supporting frame, the two ends of the two horizontal plates are further connected with supporting legs, the supporting legs vertically extend downwards, universal wheels with the heights capable of being adjusted in a lifting mode are further arranged at the lower ends of the supporting legs, and a level gauge is arranged on the upper end face of the longitudinal plate of the supporting frame. The explosive sympathetic detonation distance testing device is stable and reliable and is not influenced by natural wind, operation is simple and convenient, the sympathetic detonation distance can be tested when an explosive bag is in a horizontal state or in a vertical state, the sympathetic detonation distances obtained in the two states are compared and analyzed, and the precision of the explosive sympathetic detonation distance test can be improved.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

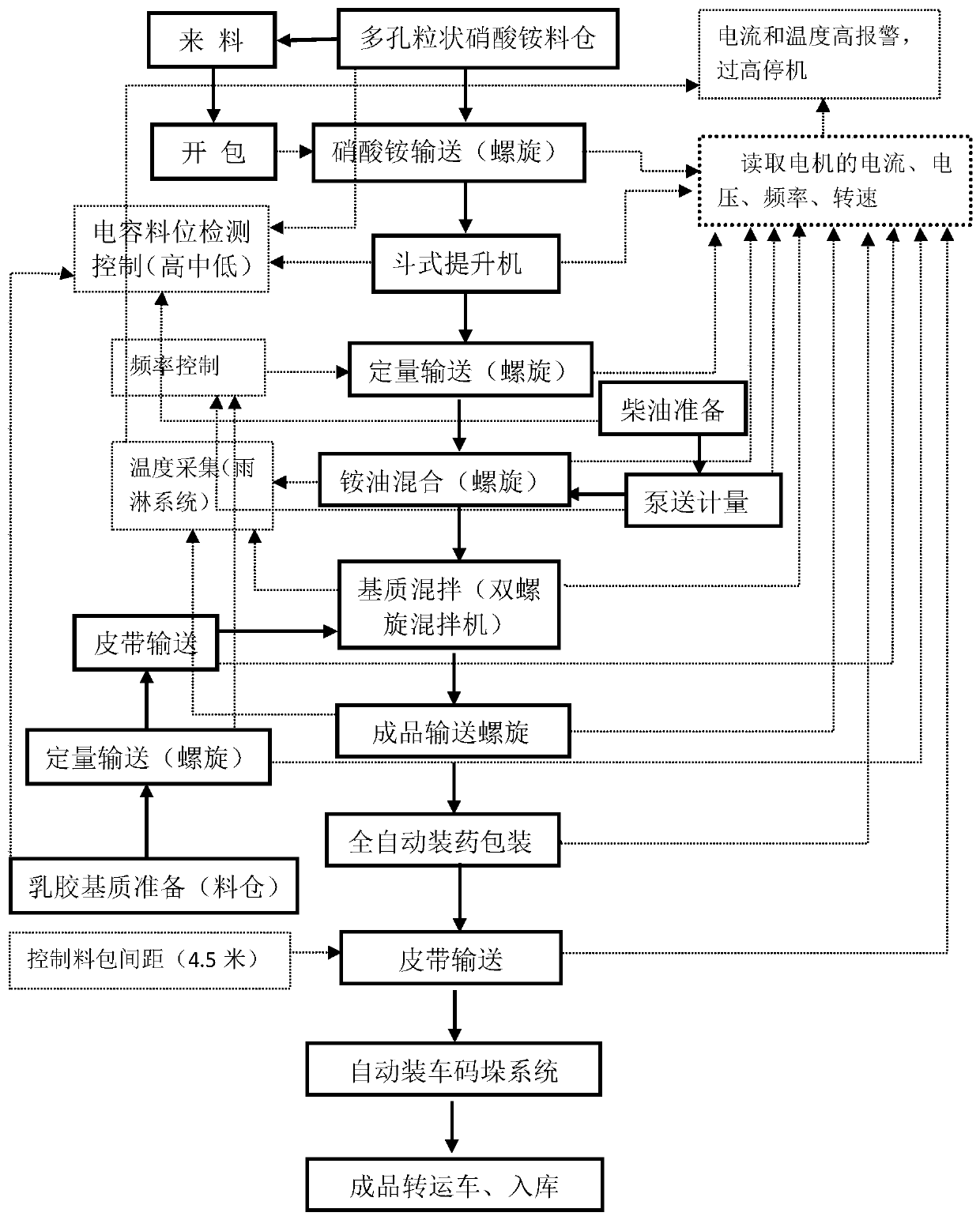

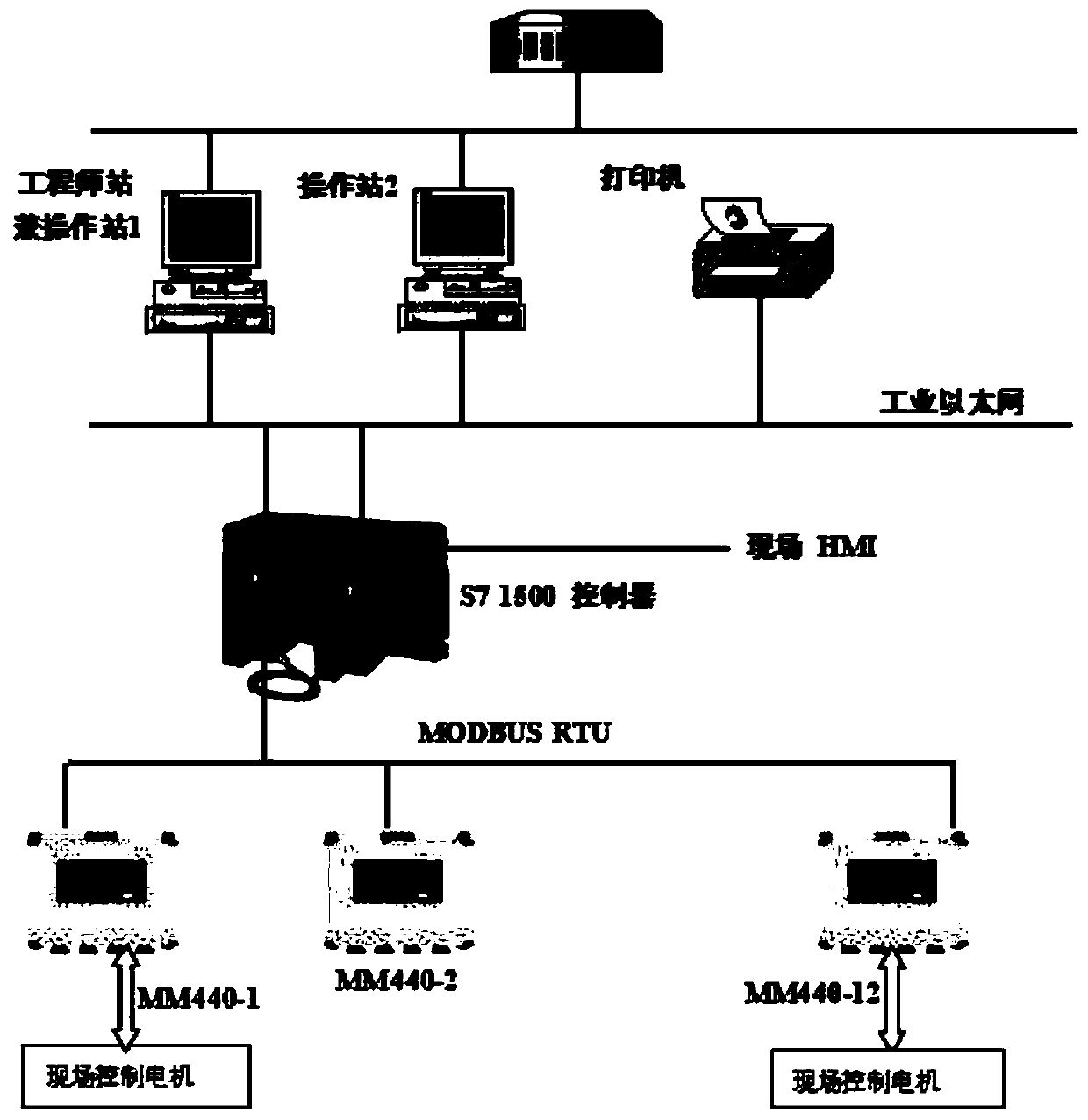

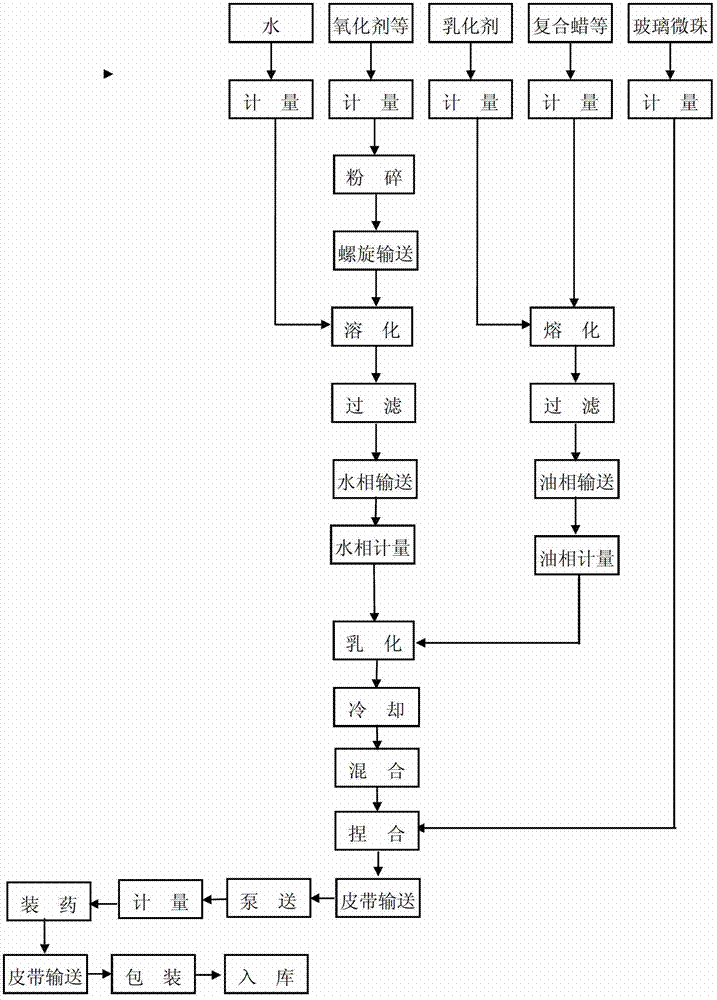

Automatic control system for producing emulsion ammonium nitrate-fuel oil explosive

ActiveCN110452074AReal-time and accurate information about feeding and dischargingEnsure safetyExplosive working-up apparatusAutomatic controlFuel oil

The invention relates to an automatic control system for producing an emulsion ammonium nitrate-fuel oil explosive. The automatic control system for producing the emulsion ammonium nitrate-fuel oil explosive is characterized in that the automatic production line comprises an explosive preparation assembly, a packaging assembly, a stacking assembly and a loading assembly which are sequentially arranged along the production order of the emulsion ammonium nitrate-fuel oil explosive, and the automatic control system includes a porous granular ammonium nitrate unpackaging control module, a materiallevel detection control module, a motor control module, a package spacing control module and an online explosive quantity control module. The system realizes continuous automatic and safe production,reduces the labor intensity, achieves the unmanned purpose, specifically realizes continuous automatic metering and feeding of raw materials, continuous automatic mixing, continuous automatic packingand large package automatic stacking and loading, achieves intelligent linkage across the entire line, and is provided with safety interlock protection; and the control of the spacing between the explosive packages effectively realizes the anti-sympathetic detonation function, reduces the possibility of explosion in the production process, and further improves the safety of the production line.

Owner:JIANGXI JIAN GUOTAI SPECIAL CHEM

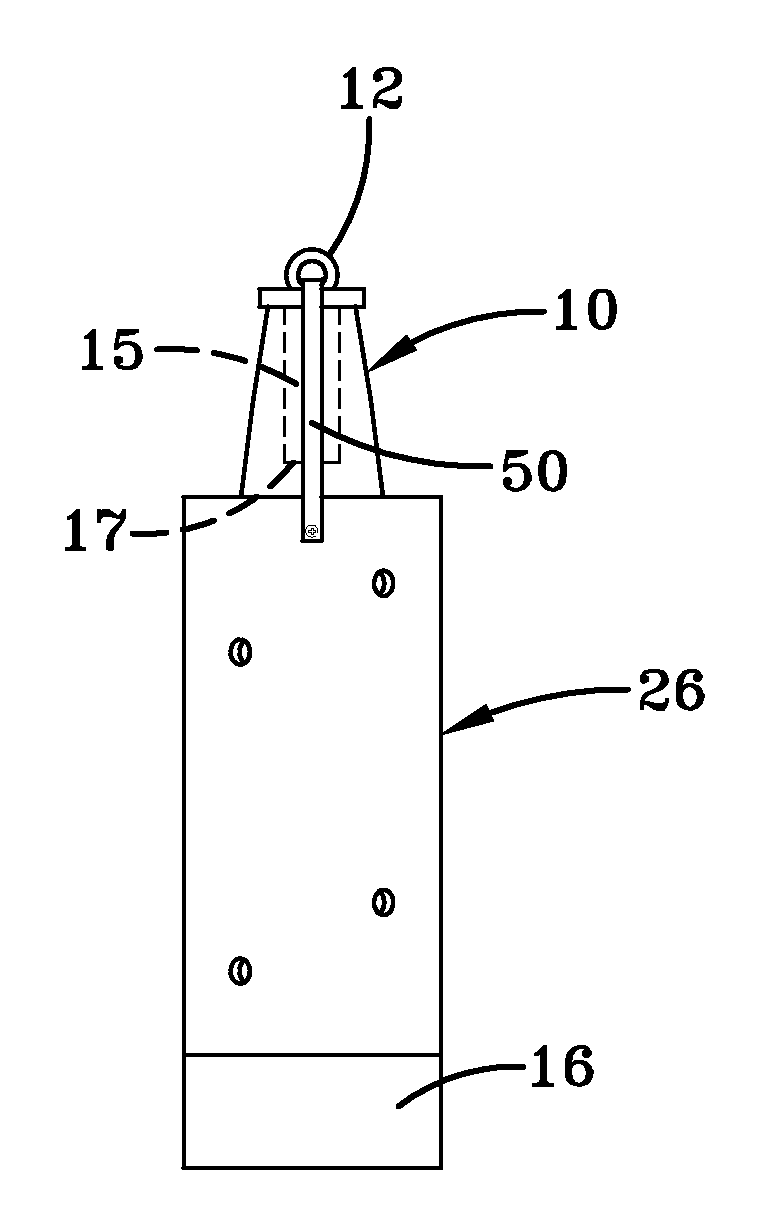

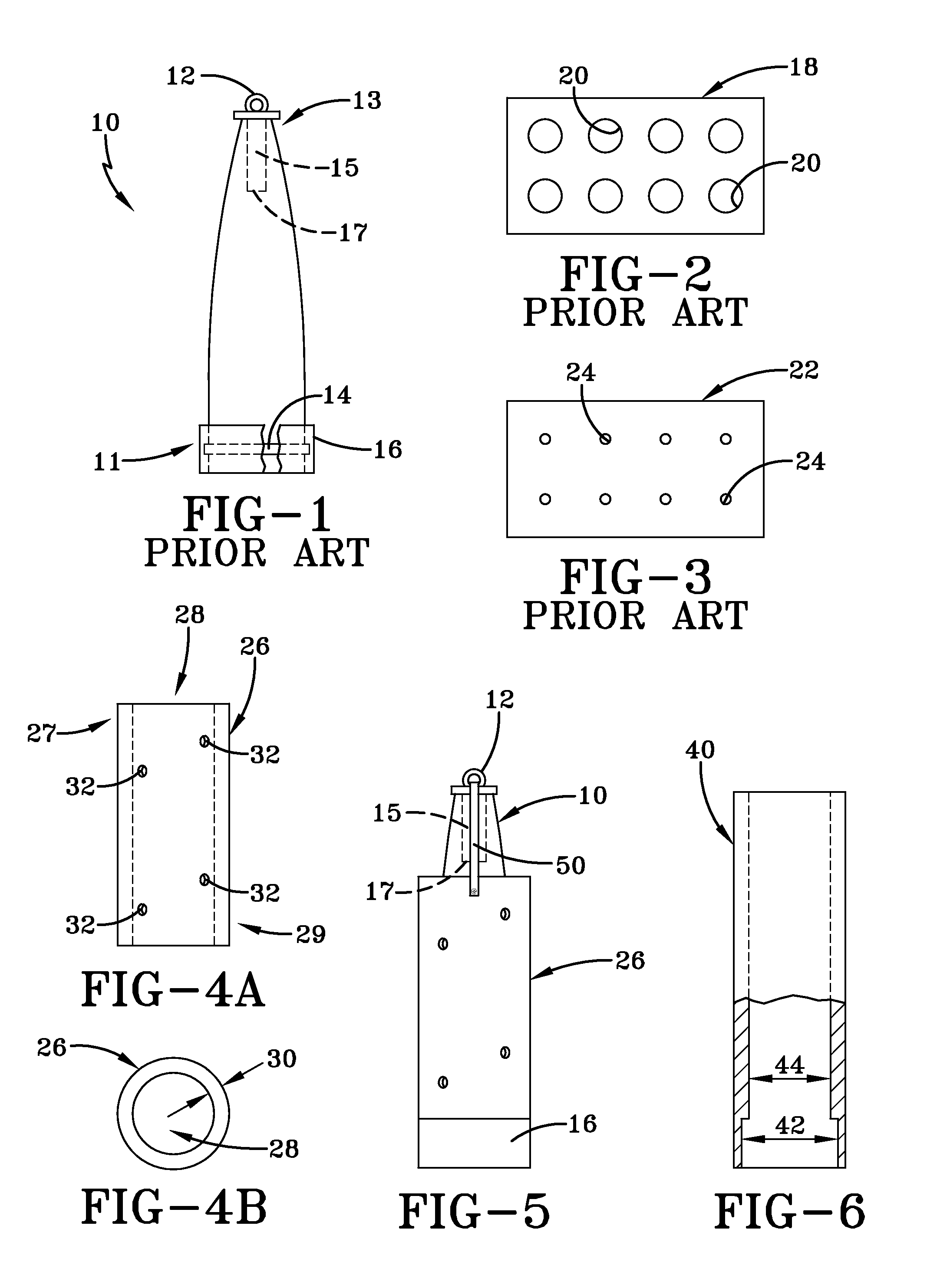

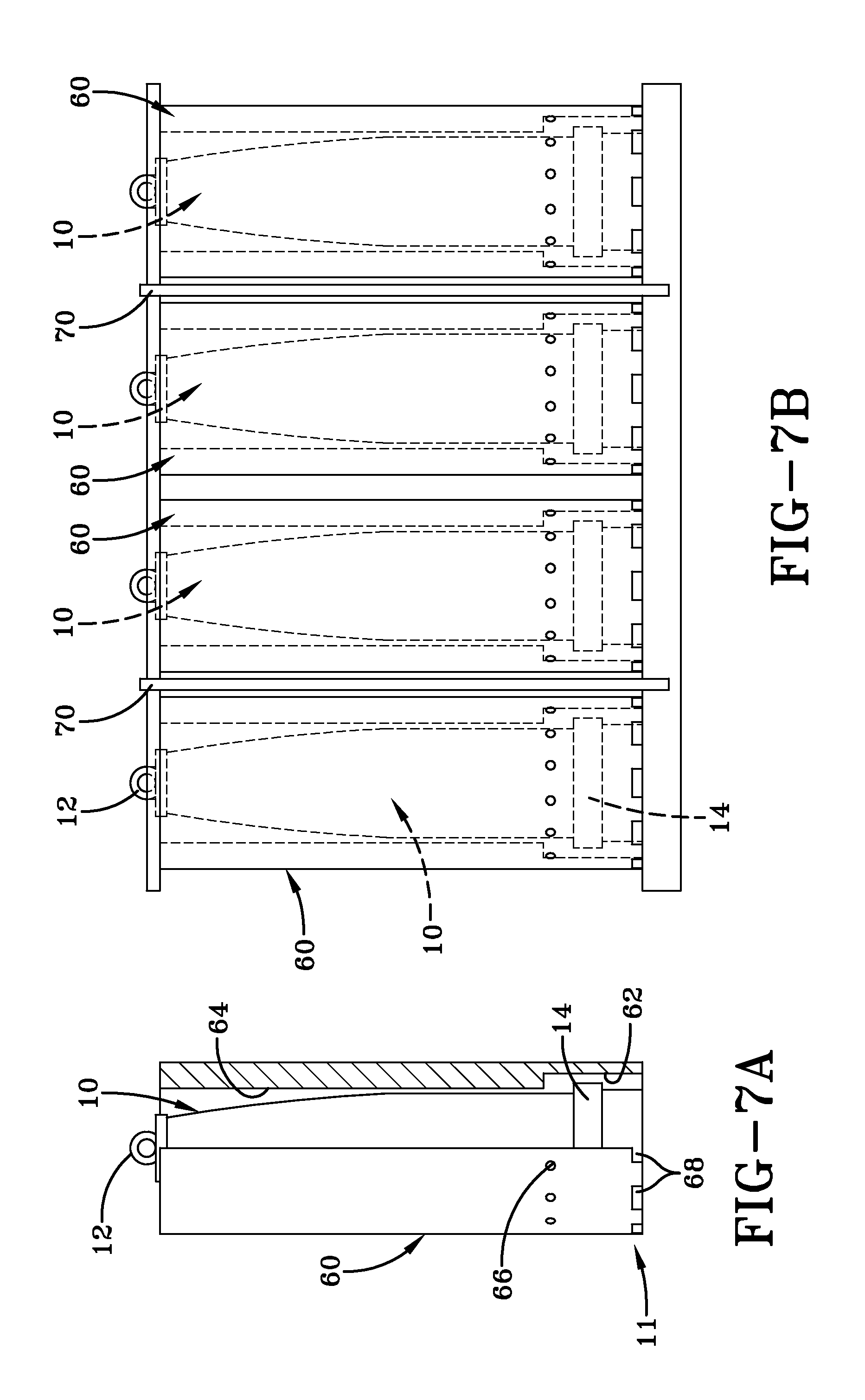

Insensitive munitions barrier

InactiveUS7752975B1Avoid explosionMitigate SDAmmunition projectilesAmmunition storageEngineeringMechanical engineering

A sympathetic detonation barrier for a munition includes a generally cylindrical polyethylene sleeve disposed over the munition. Preferably, the sleeve comprises HDPE. The sleeve may include vent openings in a side wall. In one embodiment, the sleeve extends from substantially a rear end of the munition to substantially a rear end of a fuze well of the munition.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

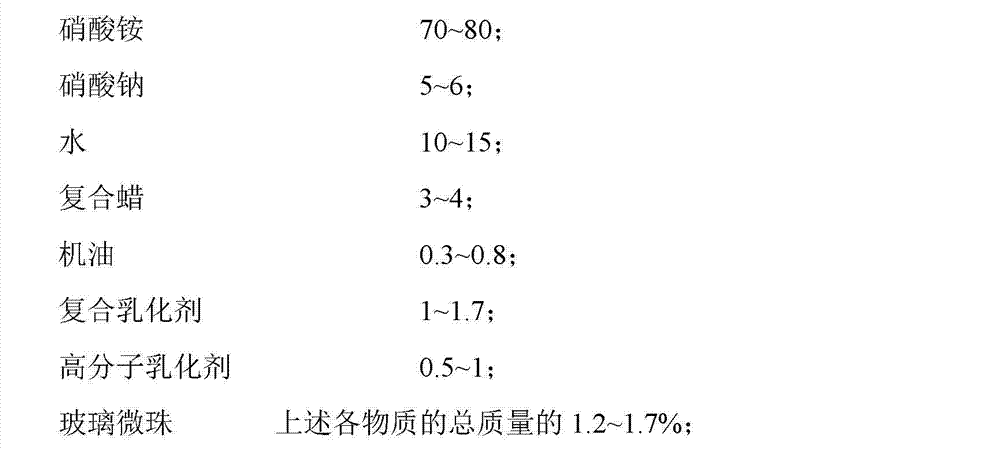

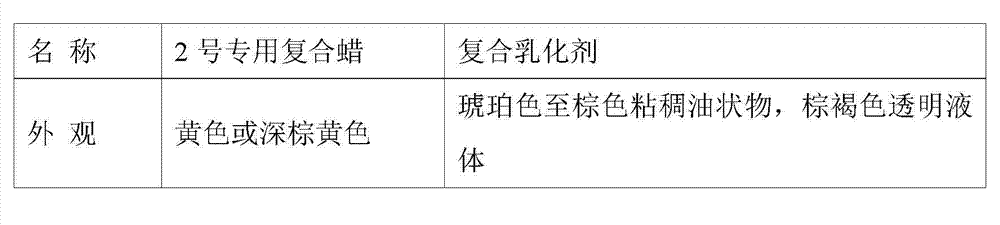

Emulsion explosive and preparation method thereof

ActiveCN103172477ALong storage periodReduce storage costsExplosive working-up apparatusNon-explosive/non-thermic compositionsWaxBurst effect

The invention relates to an emulsion explosive and a preparation method thereof. The emulsion explosive comprises the following components in parts by weight: 70-80 parts of ammonium nitrate, 5-6 parts of sodium nitrate, 10-15 parts of water, 3-4 parts of composite wax, 0.3-0.8 part of engine oil, 1-1.7 parts of composite emulsifying agent, 0.5-1 part of polymer emulsifying agent and 1.2%-1.7% (based on total weight of the components) of glass beads, wherein the composite emulsifying agent is a mixture of Span 80 and T152 emulsifying agent in a weight ratio of 6 to 4. According to the emulsion explosive disclosed by the invention, various indexes satisfy the relevant national regulations, and the performances reach three international standards, the gap distance for sympathetic detonation reaches 5, the performance quality of the explosive is improved and the burst effect is ideal. Moreover, the high polymer emulsifying agent is added to the explosive formula, so that the storage period of the emulsifying explosive is prolonged to one year from half a year, and therefore, the storage cost of the explosive is reduced. Meanwhile, the composite wax and the engine oil are used in the formula, so that the price is low, the resources are extensive and the production cost is reduced.

Owner:TIANJIN HONGTAI CHEM

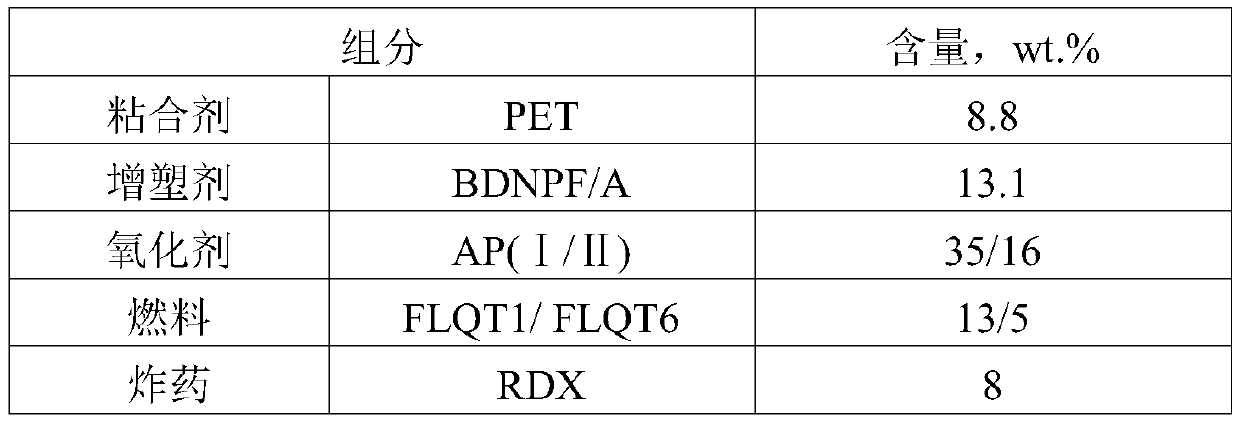

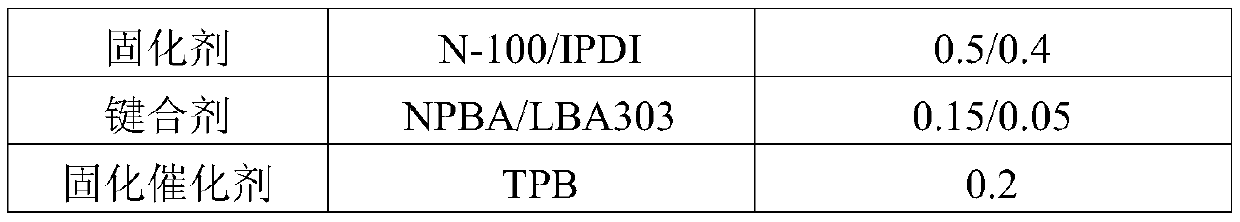

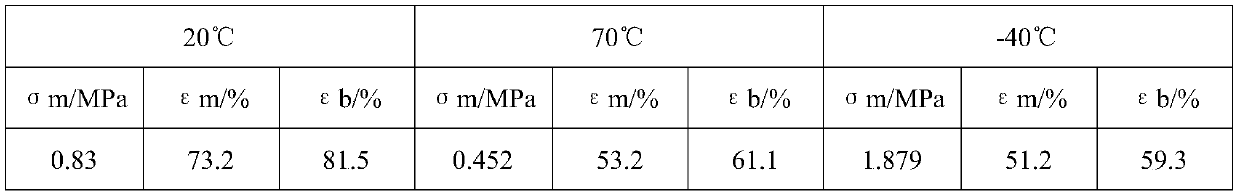

Low-vulnerability propellant and preparation method thereof

InactiveCN111592436ALow vulnerability responseReduced Vulnerability ResponseNon-explosive/non-thermic compositionsPressure gas generationExplosive AgentsPtru catalyst

The invention discloses a low-vulnerability propellant and a preparation method thereof. The solid content of the propellant is 75.0-77.0%, and the propellant specifically comprises, by weight, 7.92-8.95 parts of an adhesive, 13.0-15.50 parts of a plasticizer, 47-57 parts of an oxidizing agent, 18-20 parts of a fuel, 5-8 parts of an explosive, 0.2-0.35 part of a bonding agent and 0.80-1.10 parts of a curing agent, and a curing catalyst accounting for 0.05-0.2% of the total mass of the components is also added. The propellant disclosed by the invention takes the insensitive adhesive and the low-sensitivity plasticizer as matrixes, and the oxidizing agent, the metal fuel and the explosive are used in the formula, so the solid content, the oxidizing agent and the explosive are reduced, the formula has high energy, moderate combustion speed and good mechanical properties, and the low-vulnerability requirements of weapons and ammunition are met through six low-vulnerability test assessmentsof quick baking, slow baking, sympathetic detonation, bullet impact, fragment and jet impact.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

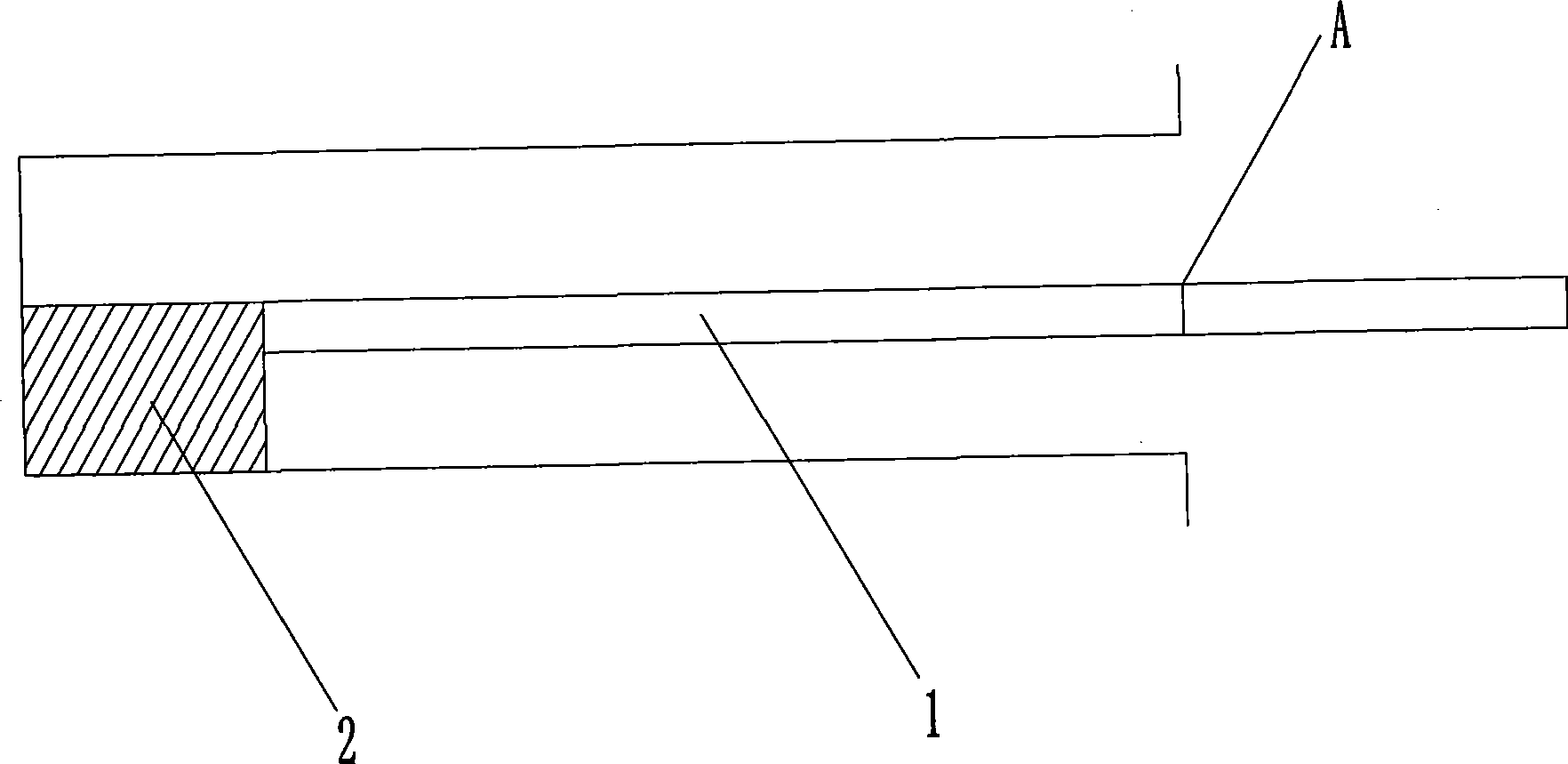

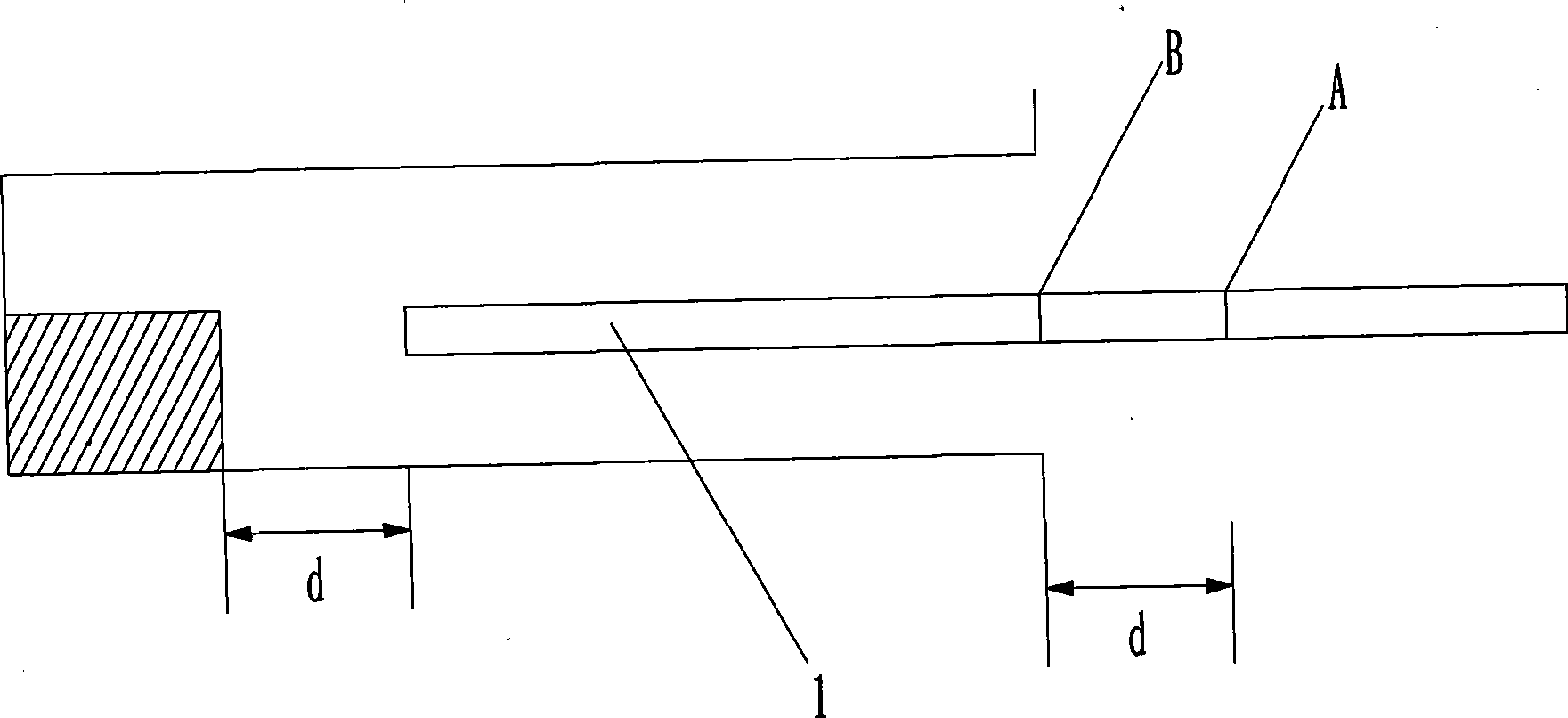

Method and device for improving blasting propagation reliability of plastic film-packaged emulsified explosive

The invention provides a method and device for improving the blasting propagation reliability of a plastic film-packaged emulsified explosive. The method is characterized by comprising the steps that when blasting charging is conducted on site, the plastic film-packaged emulsified explosive is taken out first, one end of a plastic film-packaged emulsified explosive cartridge is inserted into the device, the explosive cartridge is rotated a round when the explosive cartridge is inserted into the portion, where a blade is arranged, of the bottom of the device, an explosive cartridge buckle and plastic film remnants are cut off and fall from a hole formed in the bottom, operation in the above steps is conducted on the other end of the explosive cartridge, blast hole charging is conducted on the explosive cartridge of which the two-end remnants are cut off, and then the charging continuity is guaranteed. The device is portable, simple and convenient to carry and can be used on a blasting construction site. The blade is arranged, and therefore the buckles and the plastic film remnants on the two end faces of the plastic film-packaged emulsified explosive can be cut off through the blade. According to the device, the buckles can be efficiently and quickly cut off, the on-site charging efficiency is improved, the blasting propagation reliability is improved, blasting sympathetic detonation incompletion is avoided, and the safety in blasting engineering is improved.

Owner:FUJIAN HAIXIA KEHUA FUXING CONSTR ENG CO LTD

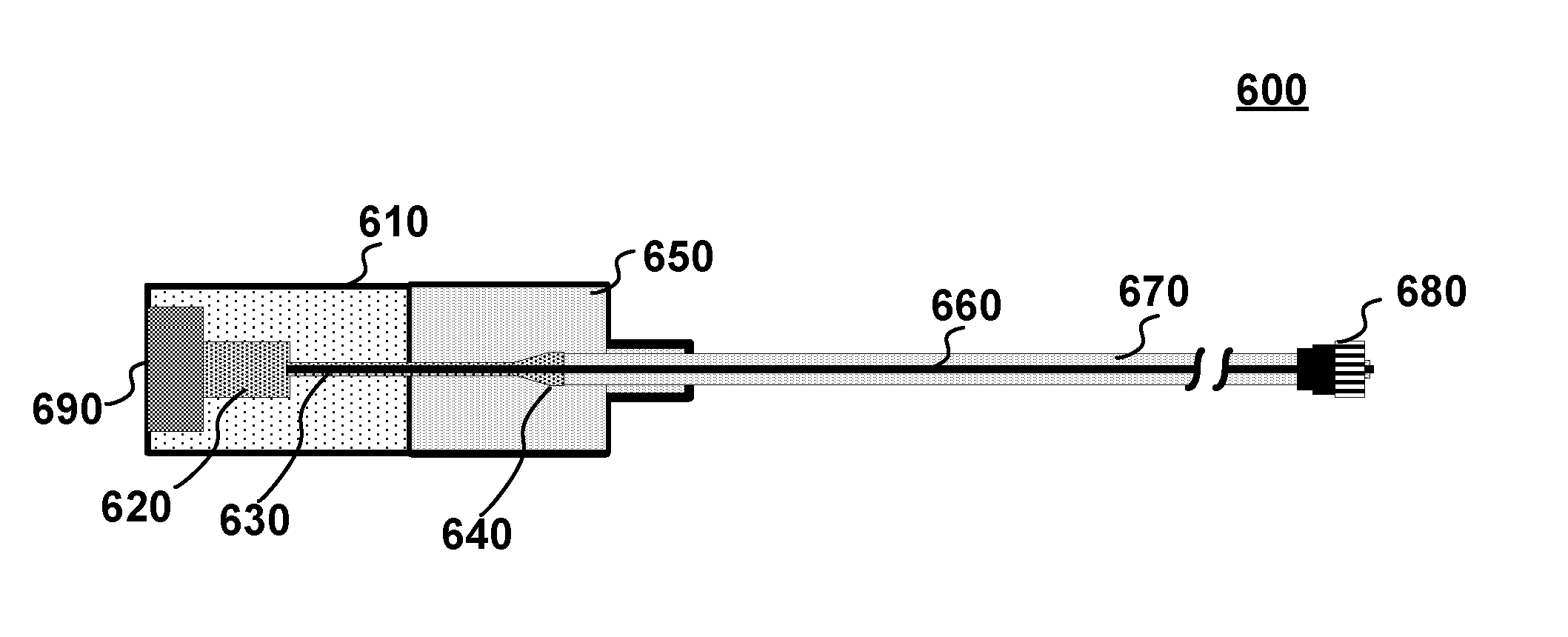

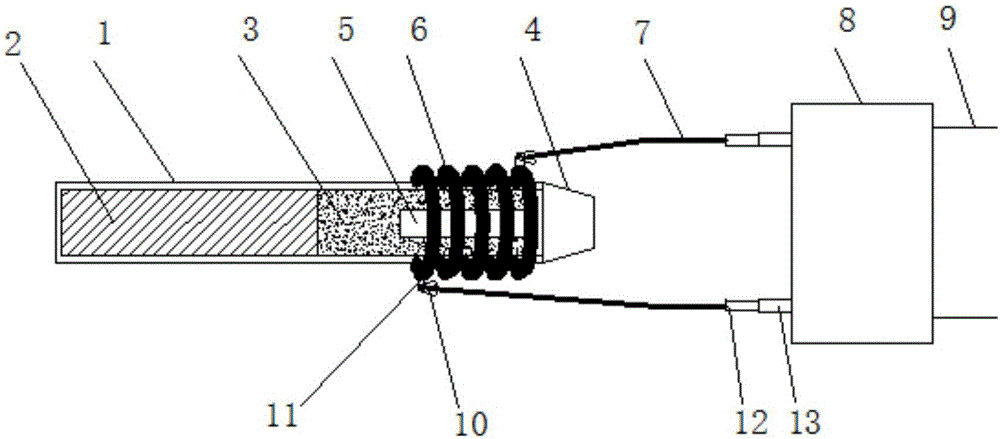

Laser primer

InactiveUS7478594B1Efficient couplingProviding environmentalBlasting cartridgesAmmunition fuzesOptical powerOptical energy

An explosive primer responsive to optical energy is constructed from an energetic composition optically coupled to an optical power source by a pigtailed optical fiber. The pigtailed portion of the optical fiber is positioned proximate to the energetic composition such that optical power emitted preferably by a laser diode initiates the detonation of the energetic composition thereby further initiating an additional, sympathetic detonation.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

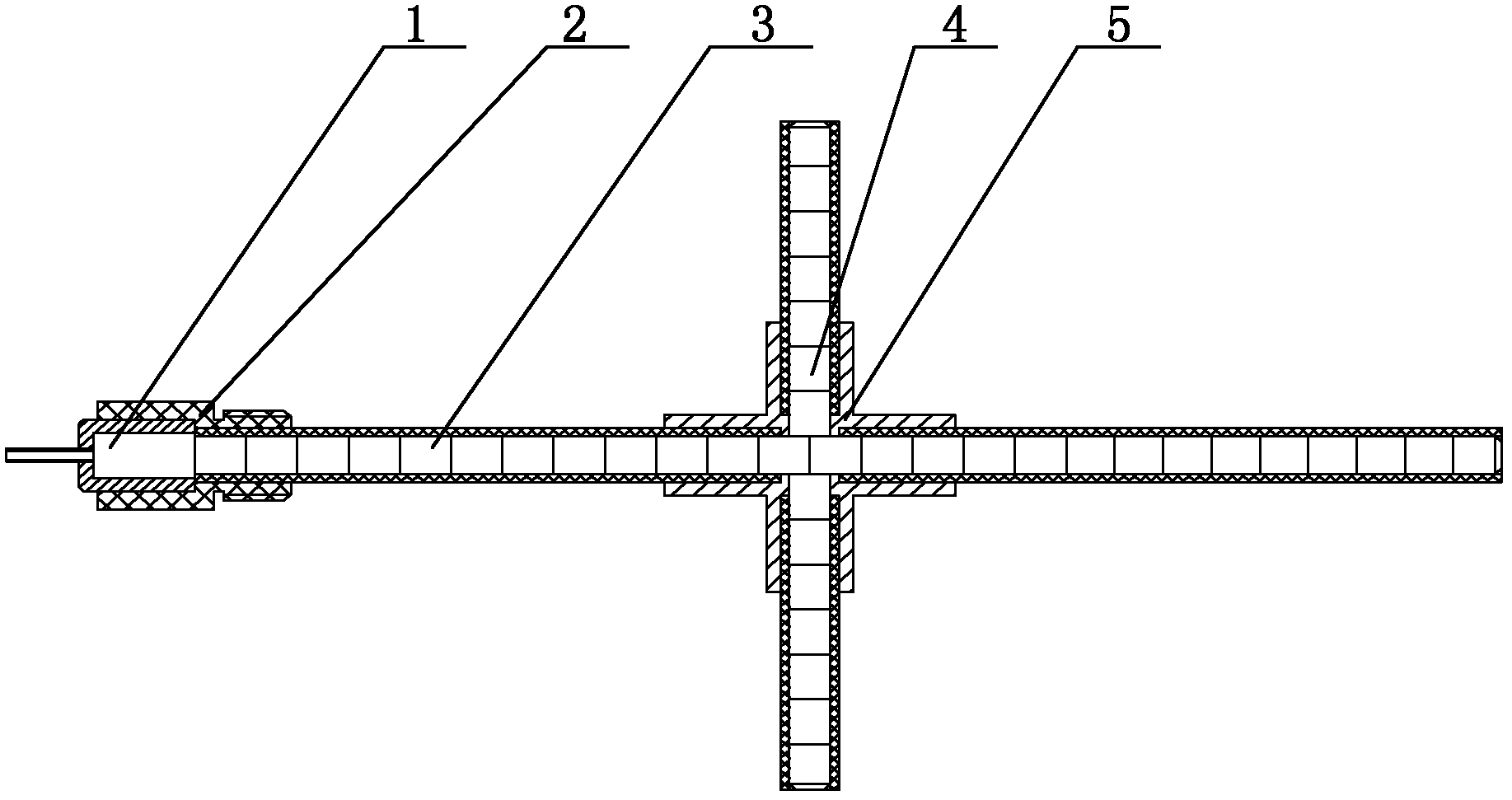

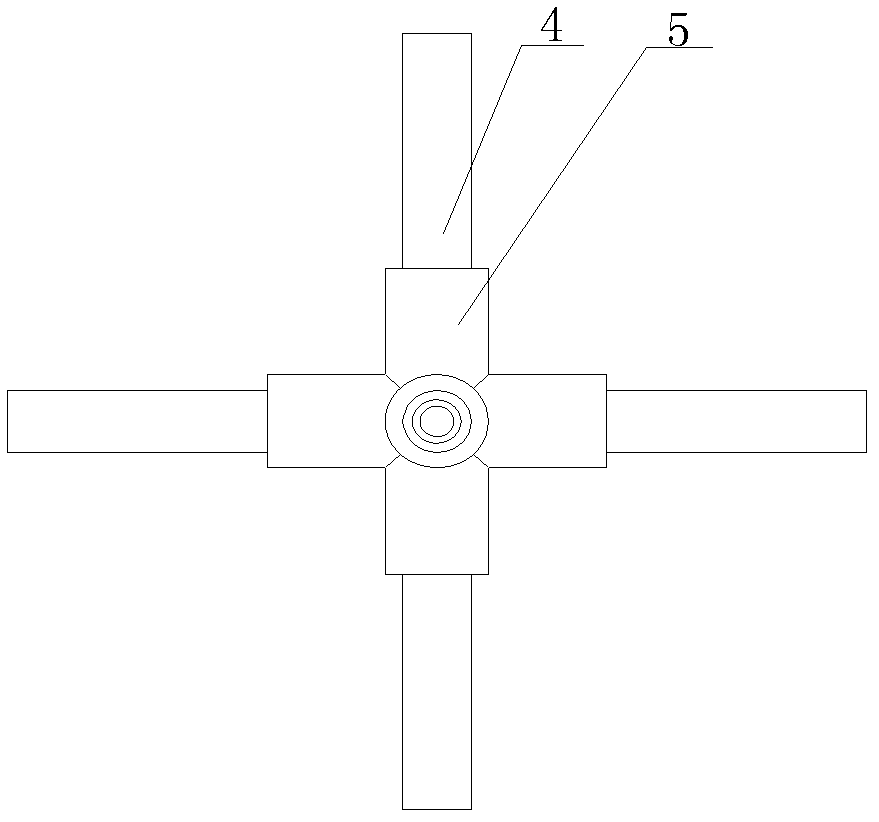

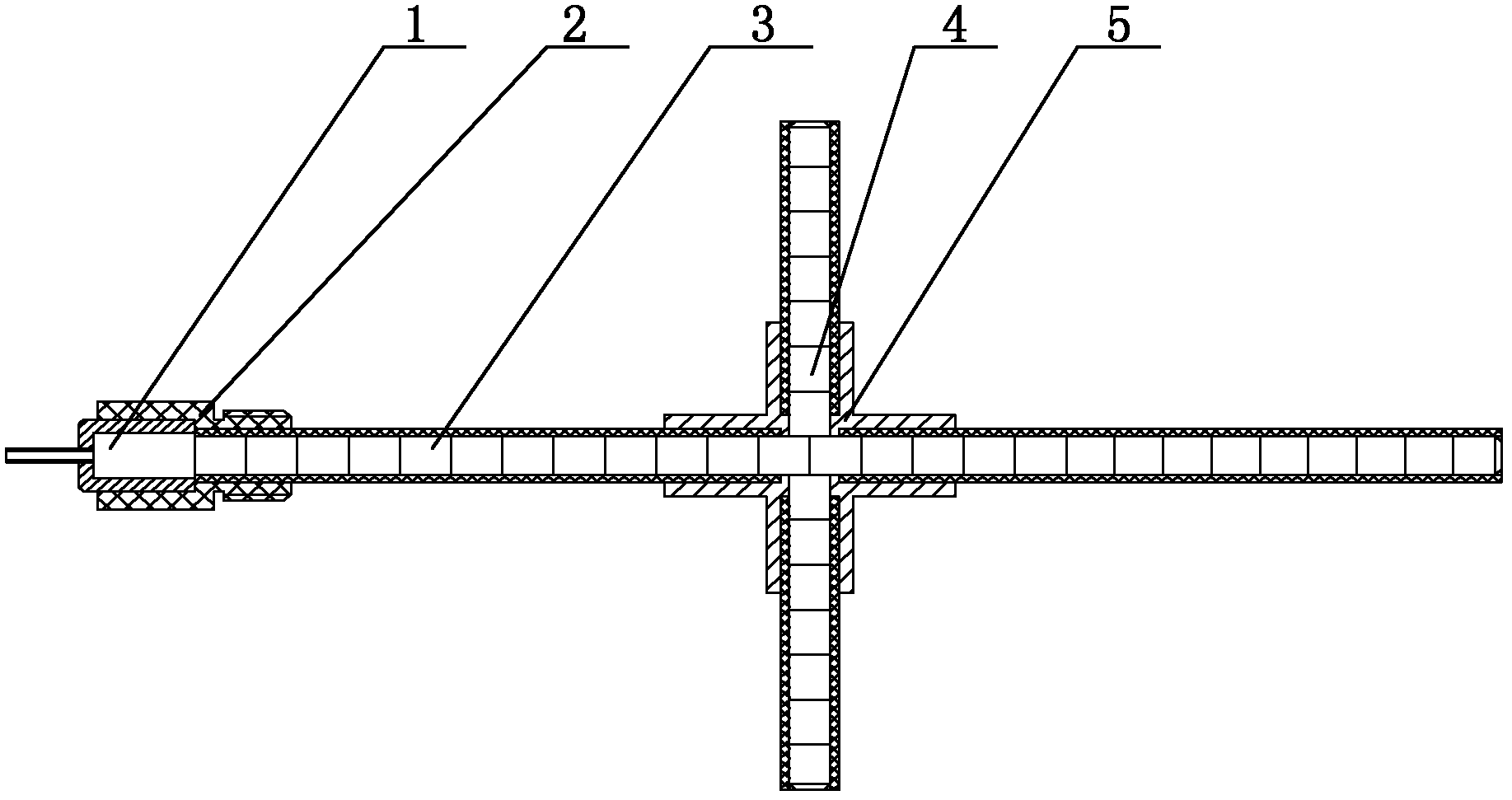

Spatial cross central explosion tube

InactiveCN102631758AImprove fire extinguishing efficiencyAmmunition projectilesFire rescueEngineeringSympathetic detonation

The invention aims to provide a spatial cross central explosion tube comprising a sympathetic detonation device, a positioning connecting conduit, a longitudinal explosion tube, a transverse explosion tube and a connecting sleeve, wherein the sympathetic detonation device is connected to the longitudinal explosion tube through the positioning connecting conduit; and the longitudinal explosion tube is connected to the transverse explosion tube through the connecting sleeve. According to the invention, an ultrathin dry powder extinguishing agent can disperse into ellipsoids so as to evenly disperse inside a fire scene at a flooding concentration; and therefore a lot of extinguishing agents can be saved and the fire extinguishing efficiency of a forest fire fighting aerial bomb can be improved.

Owner:HARBIN ENG UNIV

Blank cartridge with anti-sympathatic-detonation function for deicing devices

PendingCN109818323AAct as a barrierSolve the problem of martyrdomAmmunition projectilesOverhead installationEngineeringBarrier function

The invention discloses a blank cartridge with an anti-sympathatic-detonation function for deicing devices, comprising a cartridge case, a primer and a primer base. The primer base is arranged at theinner bottom of the cartridge case. The primer is arranged in the middle of the primer base and the cartridge case. A gun propellant is arranged above the primer base. A liner is arranged between thegun propellant and the cartridge case. A slider is arranged above the liner. A support block is arranged between the slider and the cartridge case. The support block is of an inverted barrel structure, and has a work hole in the top middle thereof. By changing the internal structure of the blank cartridge and adding a slider capable of moving up and down inside the blank cartridge, a barrier function is achieved, and the flame cannot be passed downward. Therefore, the problem of sympathetic detonation is solved, and a better using effect is achieved.

Owner:GUIZHOU POWER GRID CO LTD

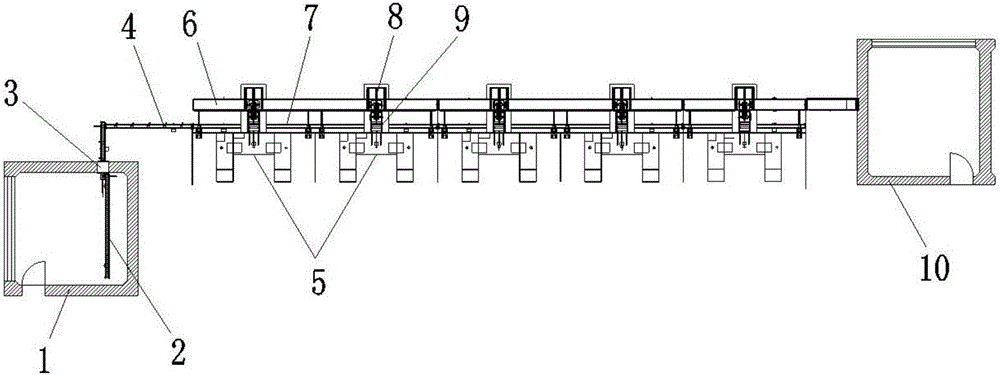

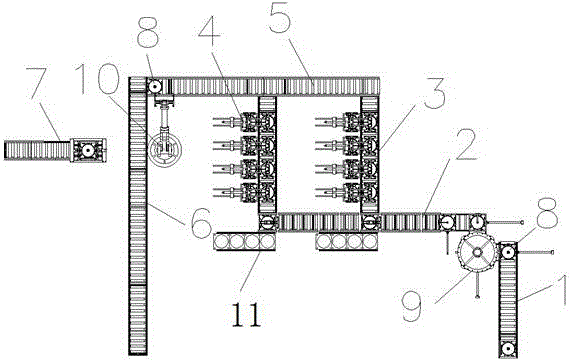

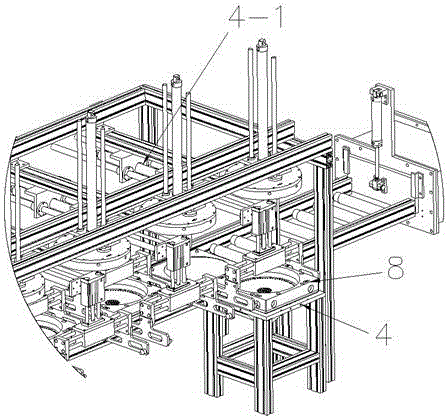

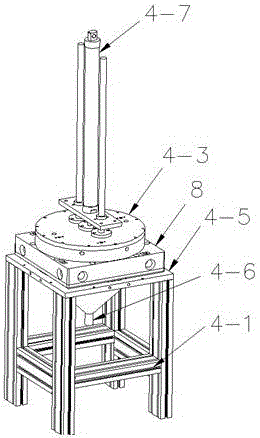

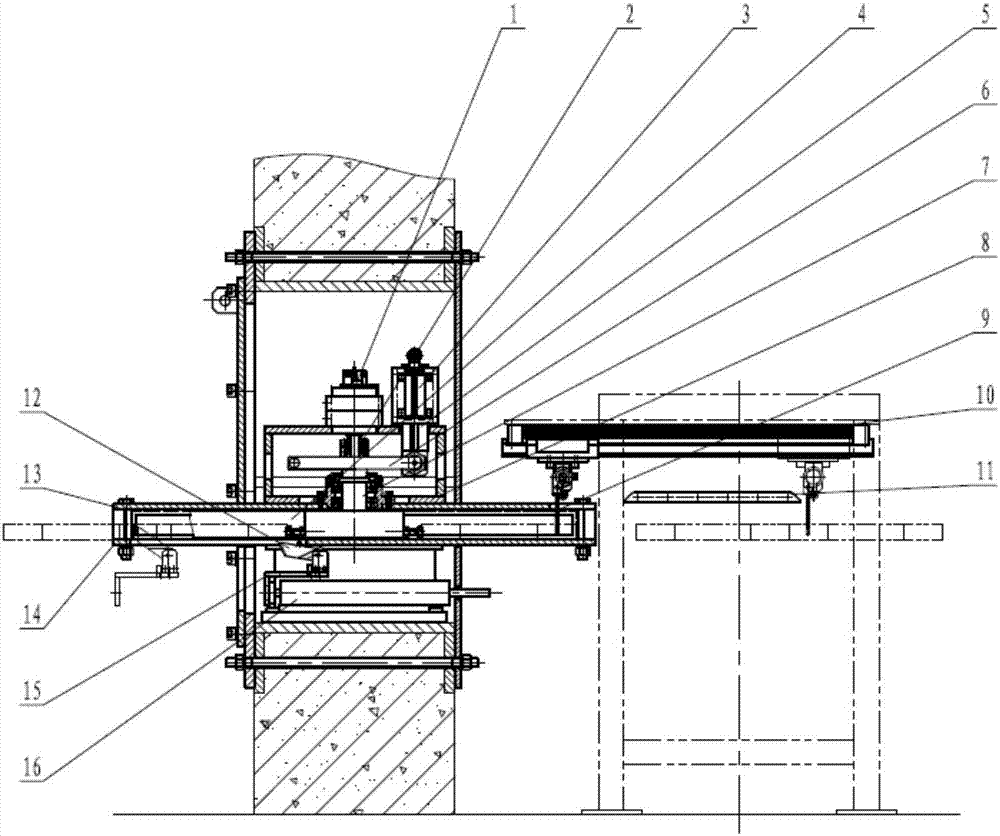

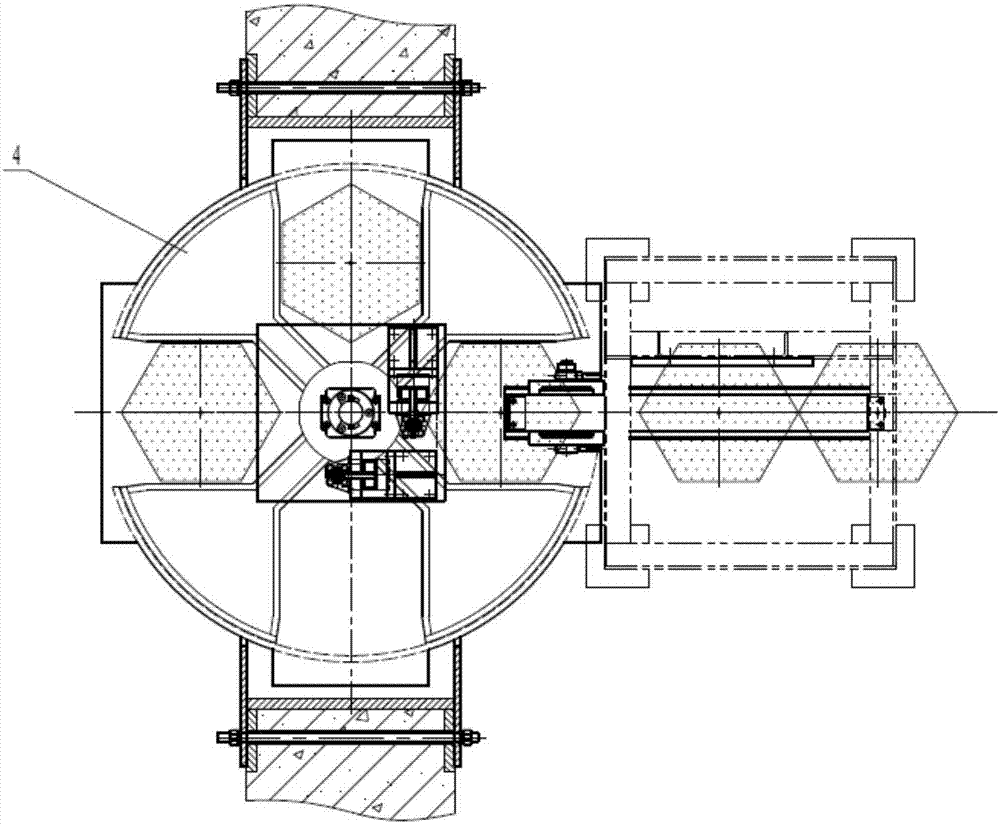

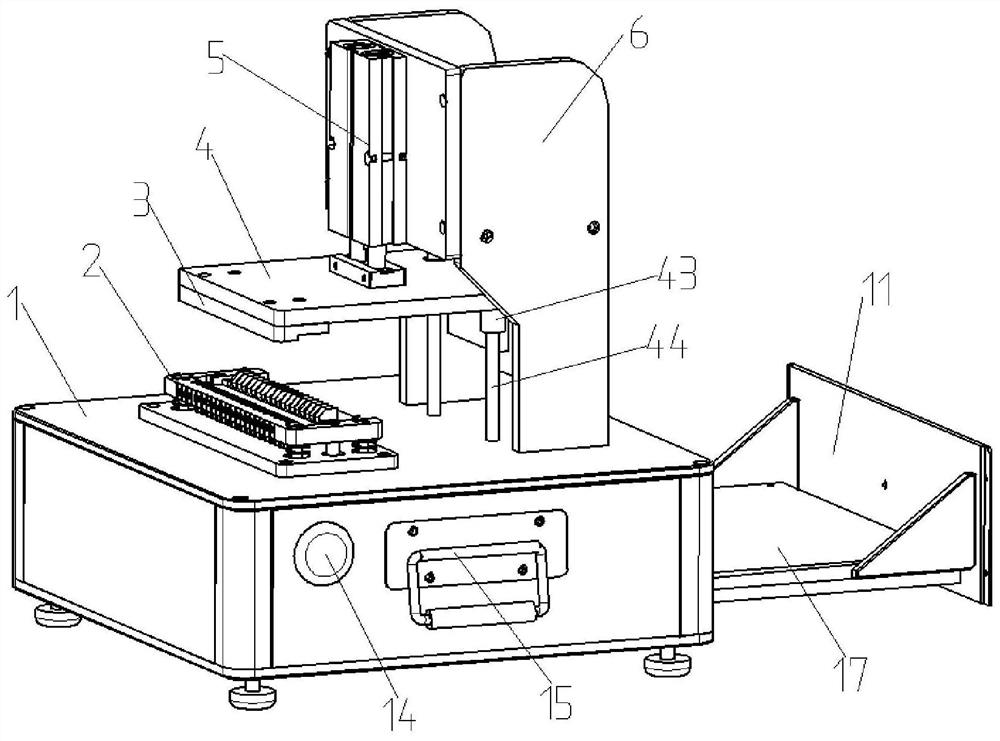

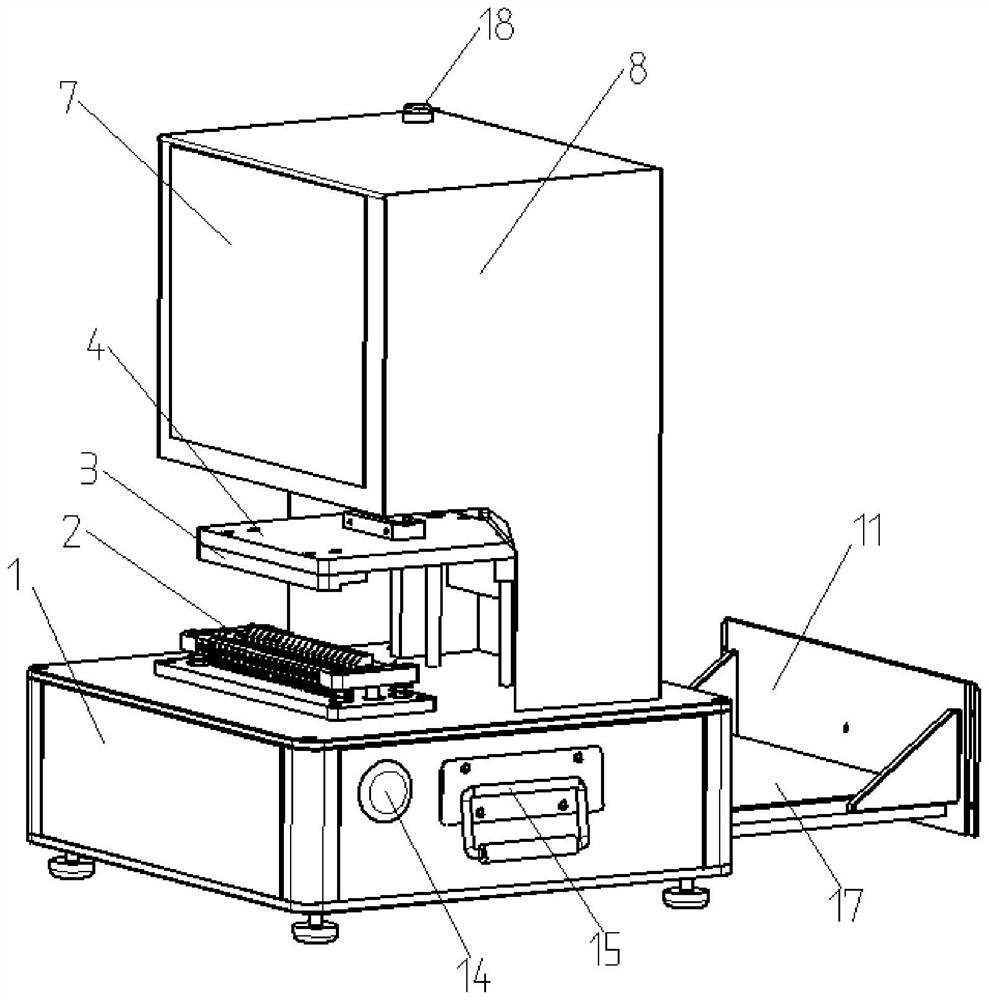

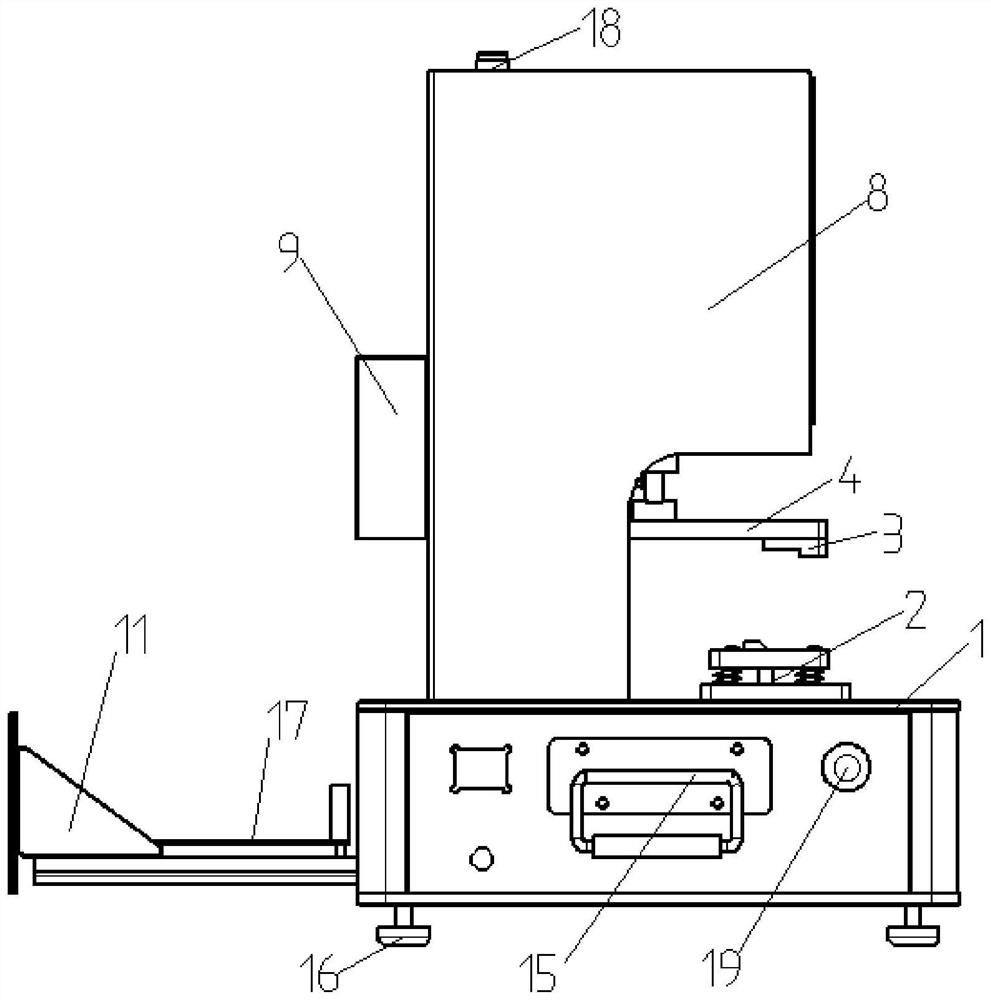

Automatic transmission production line and production method for detonator assembly

ActiveCN106518588AResolve automatic teleportationSolve the problem of automatically assigning to the detonator tight mouth positionDetonatorsConveyor partsProduction lineDetonator

The invention discloses an automatic transmission production line and a production method for detonator assembly. The production line comprises a basic detonator conveying belt, a finished detonator conveying belt, detonator assembly chambers and a finished detonator collection station. The basic detonator conveying belt comprises a temporary storage detonator conveying belt, a sympathetic detonation preventing separation conveying belt and a basic detonator assembly conveying belt, wherein the basic detonator assembly conveying belt is connected with the sympathetic detonation preventing separation conveying belt arranged outside the basic detonator assembly conveying belt, and the temporary storage detonator conveying belt is arranged in a basic detonator placement chamber. The finished detonator conveying belt parallel to the basic detonator assembly conveying belt is arranged on one side of the basic detonator assembly conveying belt. The automatic transmission production line and the production method for detonator assembly have advantages that problems of manual transferring of finished detonators and transmission and distribution of basic detonators in a detonator assembly process are solved, automatic transmission of the basic detonators and the finished detonators in the detonator assembly process is realized, potential safety hazards are reduced, labor intensity is relieved for workers, operators are reduced, and production efficiency and safety in the detonator assembly process are improved.

Owner:GUIZHOU JIULIAN IND EXPLOSIVE MATERIALS DEV

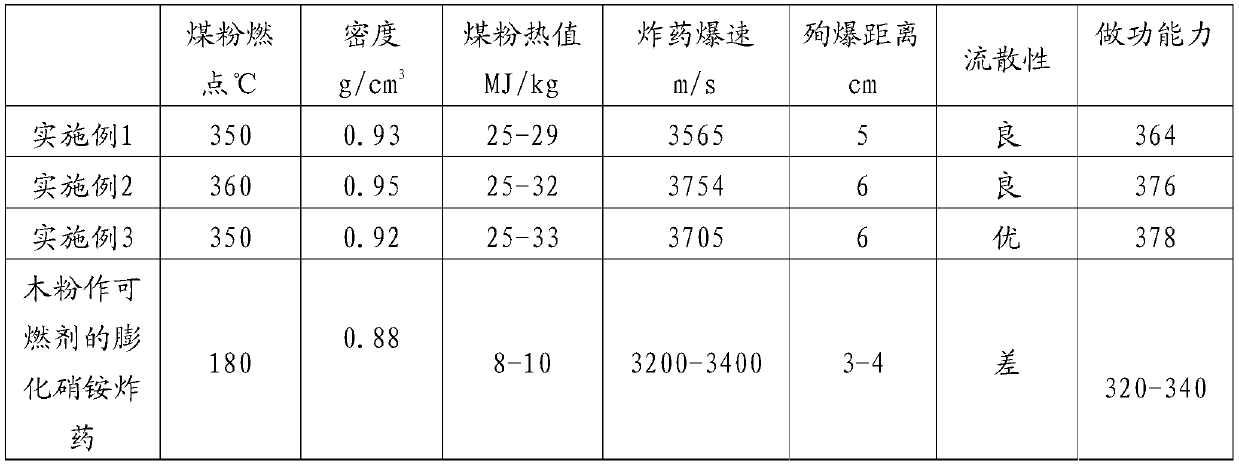

Expanded ammonium nitrate explosive and preparation method thereof

The invention relates to the field of explosive production, in particular to an expanded ammonium nitrate explosive and a preparation method thereof. The expanded ammonium nitrate explosive is prepared from the following raw materials in parts by weight: 91-93 parts of expanded ammonium nitrate, 3.5-4.5 parts of pulverized coal, 3-4 parts of a composite oil phase and 3-4 parts of copper sulfate; and the composite oil phase includes diesel oil and composite wax, and the weight ratio of the diesel oil to the composite wax is (3 to 4):(1 to 2). The pulverized powder is selected to replace wood flour to serve as a combustible agent of the expanded ammonium nitrate explosive, meanwhile, the copper sulfate is added, the composition proportion of the composite oil phase is synergistically improved, thus compared with traditional wood flour, the prepared expanded ammonium nitrate explosive serves as expanded ammonium nitrate explosive of the combustible agent, the property is greatly improved,the expanded ammonium nitrate explosive has the advantages of high combustion heat value, high density, low cost and stable quality, the improved explosive is good in free-flowing property and not liable to absorb moisture, sympathetic detonation is obviously improved, and the detonation velocity is obviously increased.

Owner:青海海西东诺化工有限公司

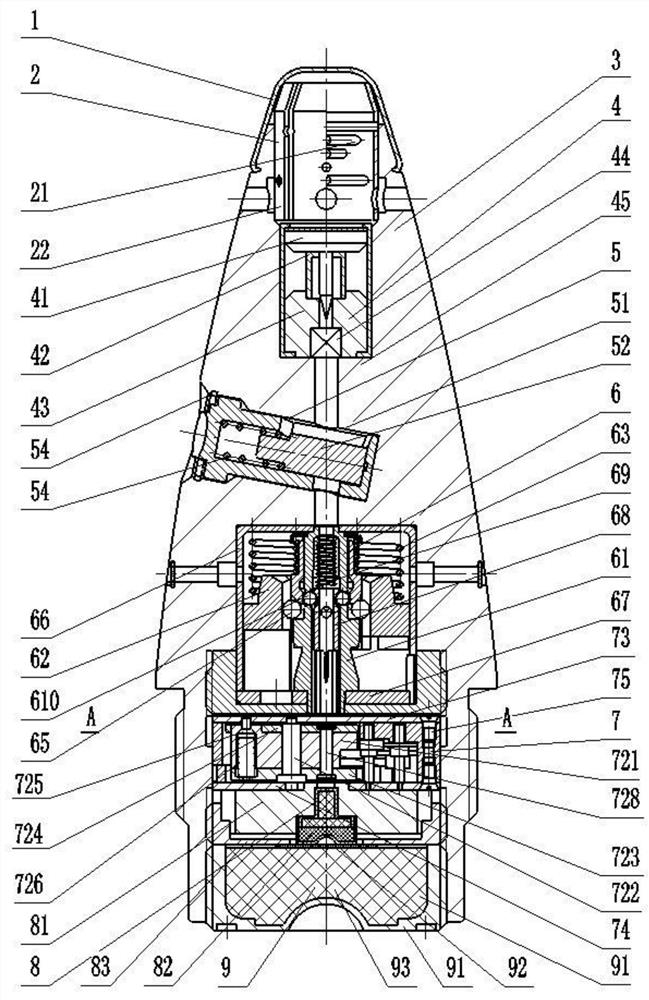

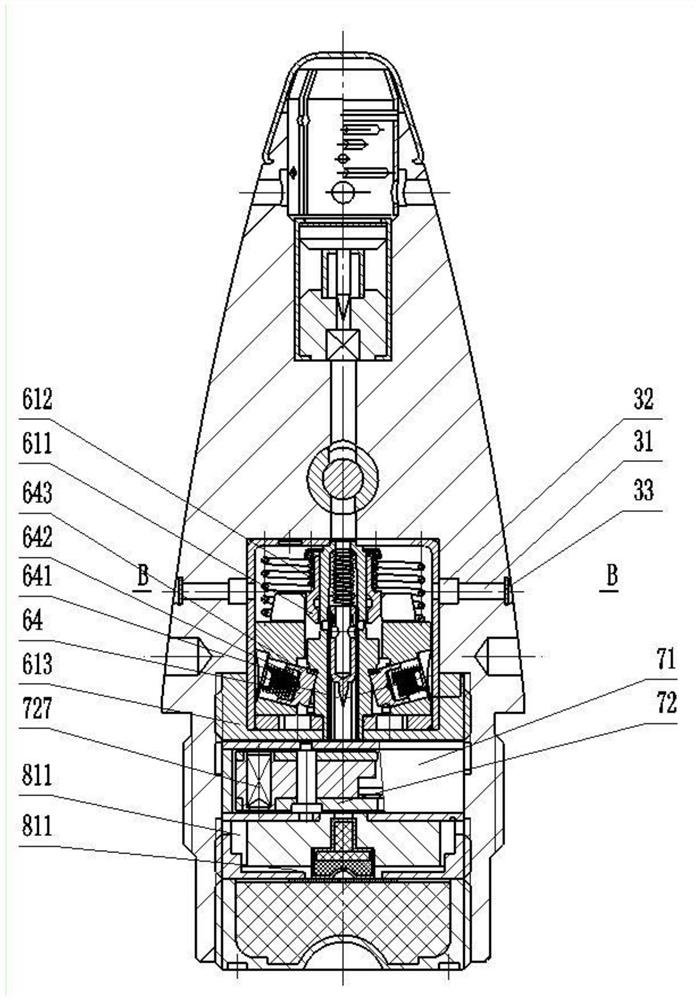

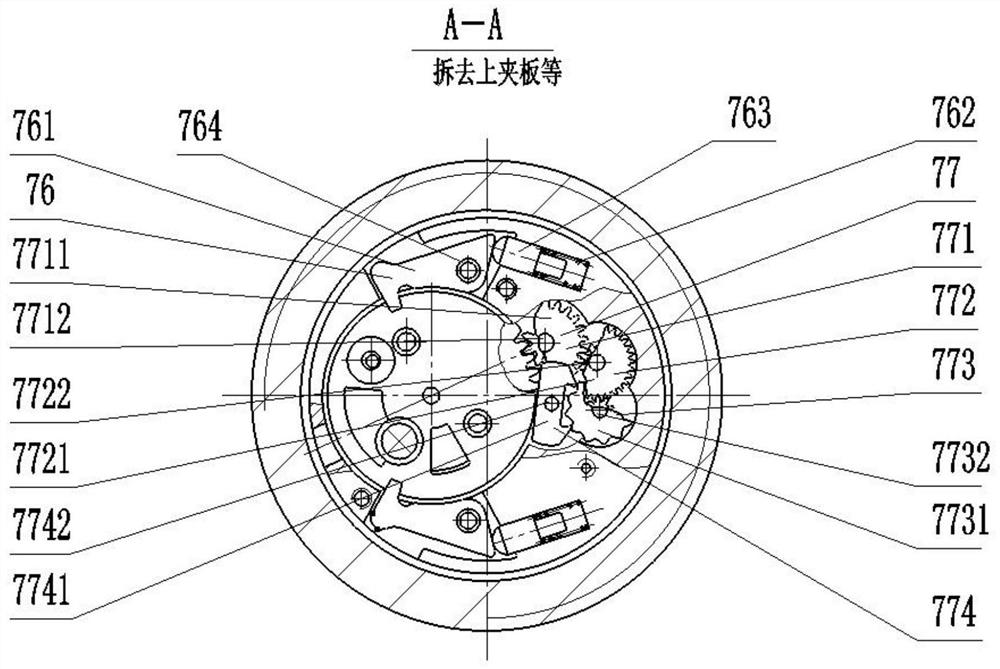

Insensitive bullet mechanical trigger fuse for shell

PendingCN112945031ANo explosive reactionOpen reliableImpact fuzesNitrated aromatic explosive compositionsMuzzleStructural engineering

The invention discloses an insensitive bullet mechanical trigger fuse for a shell. The insensitive bullet mechanical trigger fuse for the shell comprises a hood, a rainproof mechanism, a fuse body, a collision trigger mechanism, a setting mechanism, an inertia delay trigger mechanism, a safety and safety release mechanism, a detonating tube component and a booster tube component, wherein the hood, the rainproof mechanism, the collision trigger mechanism, the setting mechanism, the inertia delay trigger mechanism, the safety and safety release mechanism, the detonating tube component and the booster tube component are sequentially arranged along the axis of the fuse body from top to bottom; a through hole is formed in the middle of the fuse body in the radial direction and communicates with a ring groove in the fuse body; a fusible metal sheet is arranged at a sealing step hole at the outer end of the radial through hole; and the ring groove communicates with the detonating tube component and the booster tube component through the inertia delay trigger mechanism and the safety and safety release mechanism. The insensitive bullet mechanical trigger fuse for the shell is good in safety, not only meets service processing safety, launching safety and muzzle safety, but also can meet related cook-off test, gun test, fragment test and sympathetic detonation test requirements for insensitive fuses.

Owner:NANJING UNIV OF SCI & TECH

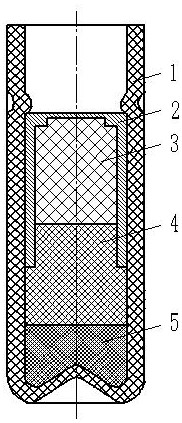

Engineering blasting foundation detonator capable of improving safety

PendingCN113091539AImprove securityReduce the risk of fragmentationBlasting cartridgesAmmunition fuzesDetonatorTEX-explosive

The invention discloses an engineering blasting foundation detonator capable of improving safety. The engineering blasting foundation detonator capable of improving safety comprises a detonator shell, a reinforcing cap, an initiating explosive, a first-stage high explosive and a second-stage high explosive. The detonator shell is made of conductive engineering plastic; the reinforcing cap is axially fixed by the detonator shell in a hot riveting, spot riveting, tightening or bonding manner; the reinforcing cap is changed into a bottom sealing structure from a bottom opening structure, and is made of steel instead of pure aluminum or red copper; and the initiating explosive is completely pressed into the reinforcing cap, and no initiating explosive exists at the joint of the reinforcing cap and the detonator shell. The engineering blasting foundation detonator capable of improving safety is simple in structure, sympathetic detonation prevention safety of the detonator can be effectively improved, fragment damage caused by accidental explosion of the detonator is reduced, and the safety of the detonator during impact resistance, vibration resistance, falling resistance, accidental rolling compaction resistance and striking resistance is improved.

Owner:NANJING UNIV OF SCI & TECH

Integrated primary explosive production line, and workshop plane layout structure thereof

The invention discloses an integrated primary explosive production line, and a workshop plane layout structure thereof. The primary explosive production line which effectively saves space in length is designed in the invention. The production line is an automated production line and is free of artificial contact, thereby effectively ensuring safety performance. An explosive air-drying and cooling apparatus in the production line can quickly and safely dry the primary explosive better. The production line is arranged in an anti-explosion room so as to save occupied area and reduce workshop length, wherein the total workshop length is only about 20 m. The spaces of the anti-explosion room of the primary explosive and explosion venting yard are greatly increased, so that the production line is signficiantly improved in anti-explosive capability. The production completely overcome the defect of possible sympathetic detonation by means of increase of the anti-explosive capability, and on the contrary, the anti-explosive effect is better than that in a separated structure in the prior art. Meanwhile, number of anti-explosive walls is significantly reduced and construction cost is greatly reduced. Compared with a scheme in the patent ZL201320616040.X, the production line is only 30% in total production cost.

Owner:贵州特可科技开发有限公司

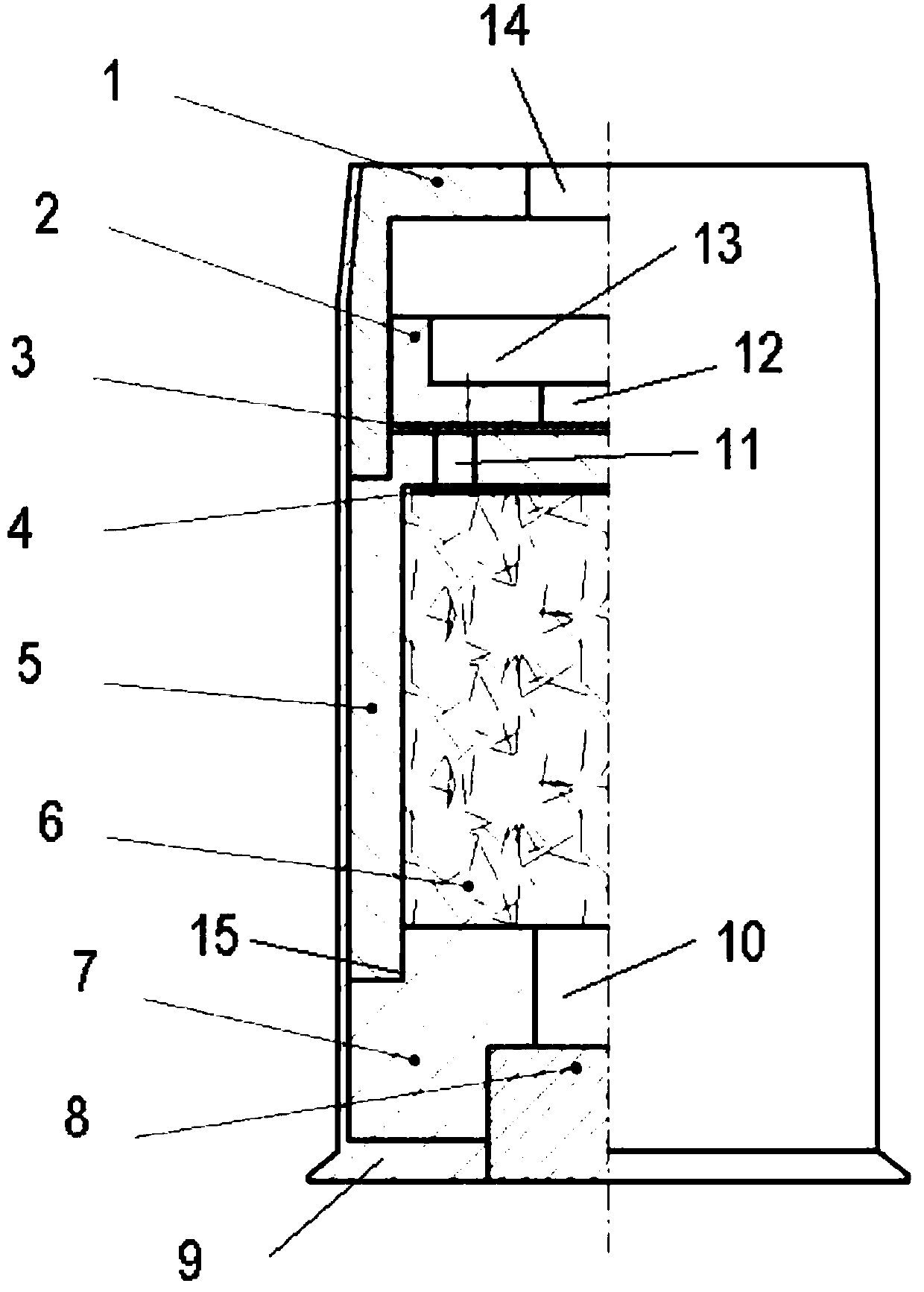

Inert sealing explosion suppression equipment and defense method for hazardous chemical containers

ActiveCN103922051BEliminate volatilizationEliminate fugitiveLarge containersPackaging under vacuum/special atmosphereCombustionFire protection

An inert seal explosion suppression device used for hazardous chemical container, and a defense method responding to multistage shaped charge that aims at conducting sympathetic detonation on oxygen-contained hydrocarbon gas in gas-phase space of the container in a mode of detonation inside the follow-through warhead container. The device comprises an inert seal device arranged on the hazardous chemical containers. The device comprises an U-shaped sleeve (3), a Y-shaped penetrating pipe is arranged inside the U-shaped sleeve, one upper port of the U-shaped sleeve is communicated with the gas-phase of a gas inert seal medium source, the other upper port of the U-shaped sleeve (3) is communicated with the container in gas-phase state through an inert seal disc on the top of the corresponding container, a port on the gas distribution side of the Y-shaped penetrating pipe is hung in a vertical pipe on the gas distribution side of the U-shaped sleeve, a side port of the container is connected with a spraying pipe on the top of the container, a bottom port communicated with a liquid-state fire protection medium source through a bottom connection pipe of the U-shaped sleeve, that can use a liquid valve of the sleeve as a large and small breath valve, and can use a liquid valve of the penetrating pipe as a safety relief valve, that can isolate systematically the atmosphere and restrain permanently the combustion explosion condition of the gas-phase space in the container and the pipelines.

Owner:国铠特种流体机械制造(青岛)有限公司

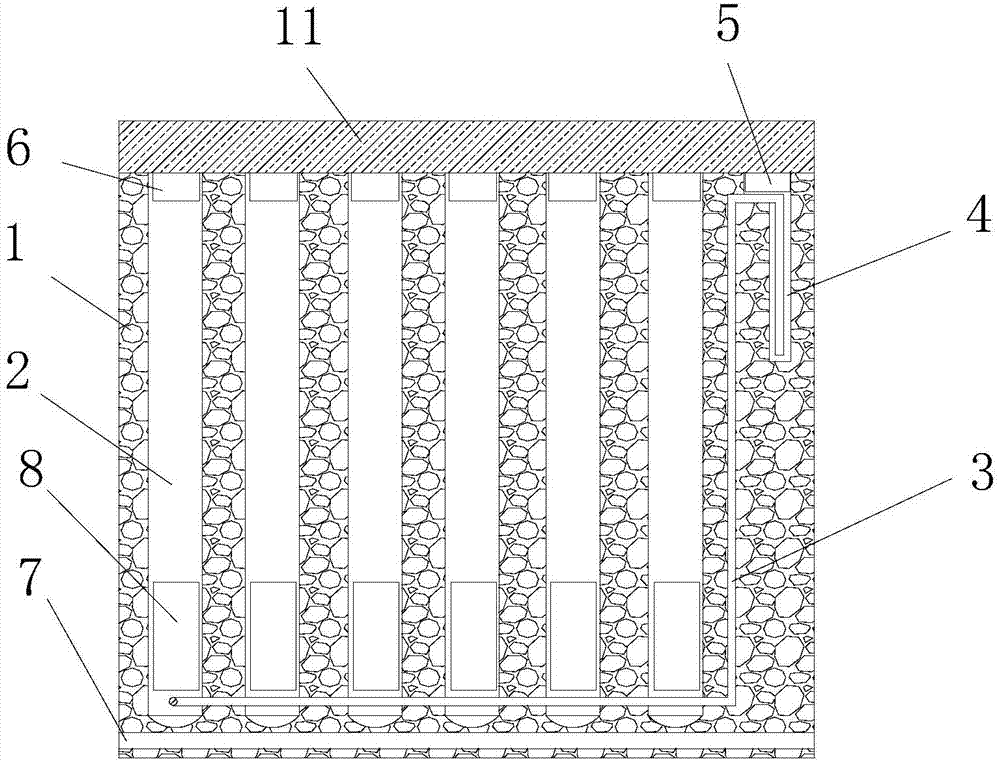

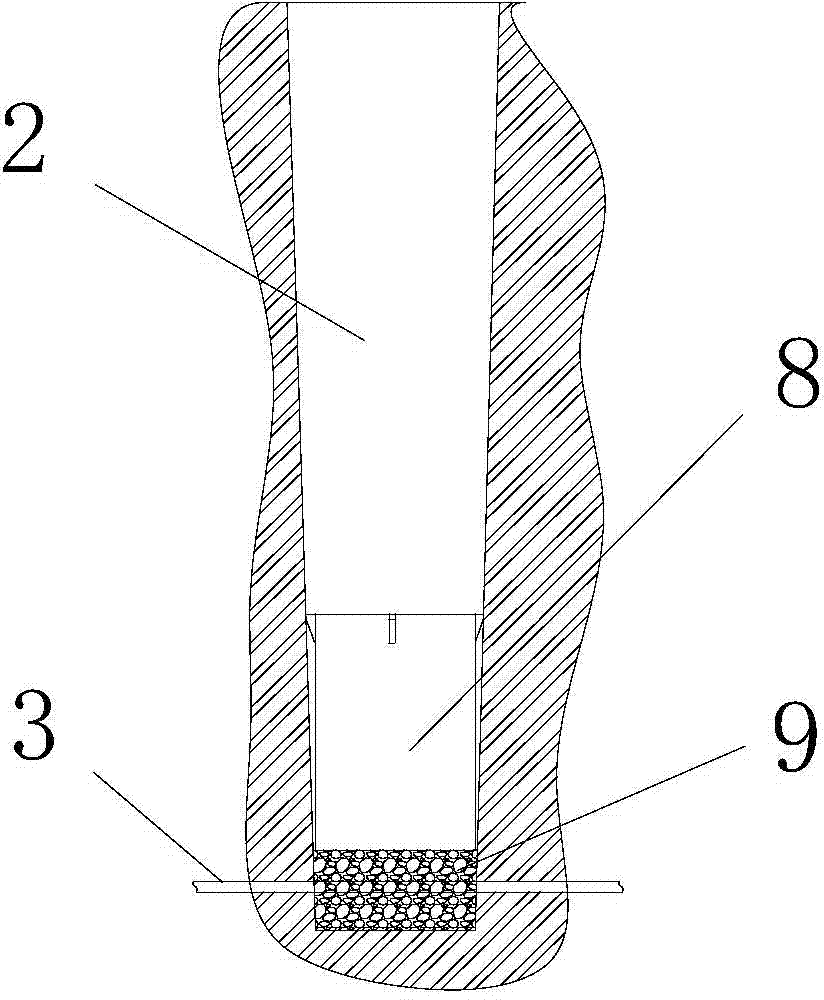

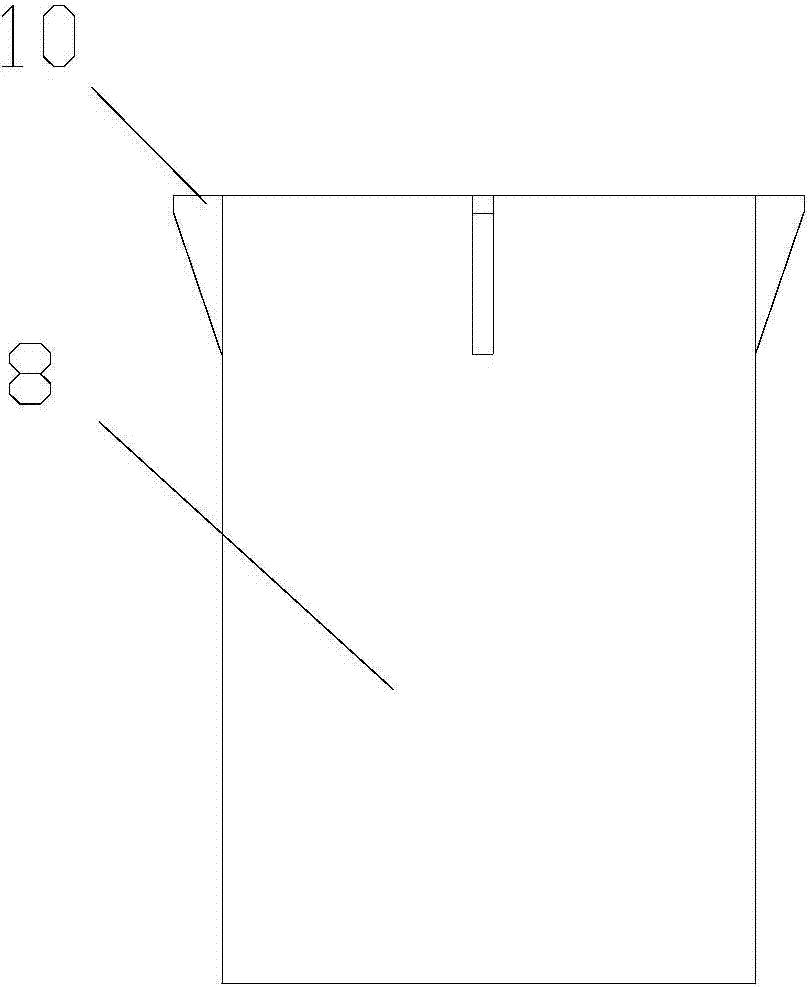

Fireproof and explosion-proof combined fireworks

ActiveCN104729362ADoes not affect the firing effectGuaranteed discharge effectFireworksFireworksEngineering

The invention discloses fireproof and explosion-proof combined fireworks which comprise a transmitting seat body (1), transmitting holes (2) of the transmitting seat body (1) and a fireproof cover plate (11). The transmitting seat (1) is made of light fireproof materials, a lead wire (3) is embedded in the transmitting seat body (1), the bottoms of the transmitting holes (2) are communicated with one another by the lead wire (3), inner barrels (8) are arranged in the transmitting holes (2), a lead hiding hole (4) is formed in the transmitting seat body (1), an ignition portion of the lead wire (3) is hidden in the lead hiding hole (4), the fireproof cover plate (11) is made of light fireproof materials, fireproof plugs (6) for the transmitting holes and a fireproof plug (5) for the lead hiding hole are formed in the fireproof cover plate (11), the fireproof cover plate (11) covers the transmitting seat body (1), the fireproof plugs (6) for the transmitting holes are inserted into the transmitting holes (2), and the fireproof plug (5) for the lead hiding hole is inserted into the lead hiding hole (4). The fireproof and explosion-proof combined fireworks have the advantages that the fireproof and explosion-proof combined fireworks are high in transmission precision and low in transmission powder usage, the transmitting holes are short, the manufacturing cost can be saved, the safety coefficient can be increased, the fireworks can be prevented from being ignited by external fire sources, and accordingly sympathetic detonation accidents can be completely eradicated during production, transportation and storage.

Owner:浏阳市源泰烟花制造有限公司

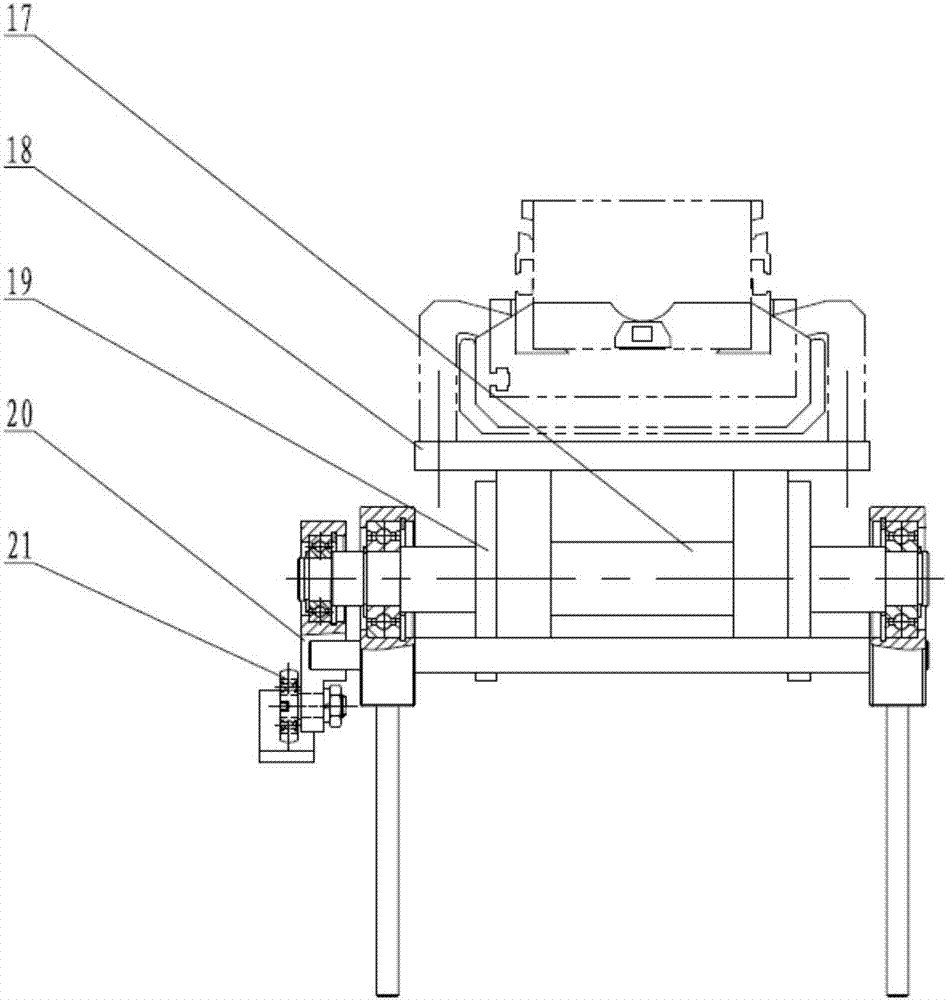

Rotary-type antiknock conveying device

PendingCN107504868AProtection securityAvoid the phenomenon of sacrificial explosionFireworksFireworksMechanical engineering

The invention relates to a rotary-type antiknock conveying device, in particular to a rotary-type antiknock conveying device used for producing fireworks and crackers, and belongs to the field of fireworks and crackers manufacturing. When the rotary-type antiknock conveying device works, a push-in air cylinder drives a push-in assembly to push a gunpowder disc into an isolation cavity of the conveying device, and after the push-in action is completed, the push-in assembly returns to the original position. A rotational window sash is driven to conduct unidirectional rotation through combination of an oscillating cylinder and a unidirectional bearing, the gunpowder disc is pushed to be rotated to a next station, when the gunpowder disc is rotated to an outlet station, a push-out cylinder drives a push-out assembly to push the gunpowder disc out of the isolation cavity, and after the gunpowder disc is conveyed to a next working procedure, the push-out assembly returns to the original position to wait for a next gunpowder disc. According to the rotary-type antiknock conveying device, dangerous working procedures and operators and other working procedures can be completely isolated, a sympathetic detonation phenomenon is avoided, the personnel safety can be ensured, the property loss is reduced, and the production requirements for automated fireworks and crackers production and large production can be met.

Owner:CHINA WUZHOU ENG GRP +1

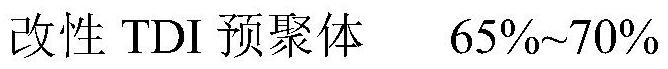

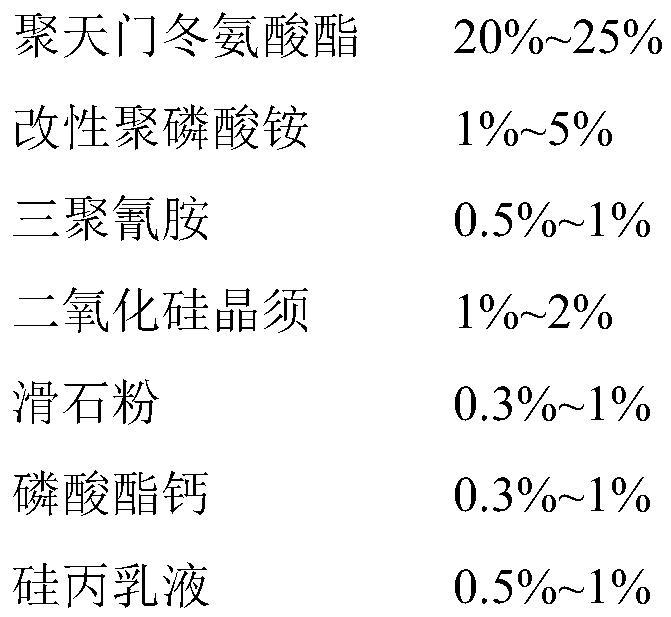

Preparation method of sympathetic detonation prevention polyurea coating for projectile body

ActiveCN112143353AGood weather resistanceImprove protectionFireproof paintsAnti-corrosive paintsPhosphoric Acid EstersSilicon oxide

The invention relates to a preparation method of a sympathetic detonation prevention polyurea coating for a projectile body, and belongs to the field of projectile body system defense and polymer composite material preparation. The coating disclosed by the invention comprises the following components: a modified TDI prepolymer, polyaspartic acid ester, modified ammonium polyphosphate, melamine, silicon dioxide whiskers, talcum powder, calcium phosphate and silicone acrylic emulsion. According to the preparation method of the sympathetic detonation preventing polyurea coating for the projectilebody, the polyurea coating is selected as a coating matrix, and has the advantages of being good in weather resistance, capable of being used for a long time in a severe environment, high in thermalstability, capable of keeping the original molecular structure and property at a high temperature, good in mechanical property, and excellent in explosion-proof property, and can effectively protect the ammunition body.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Explosive special for explosive welding, and manufacturing method thereof

ActiveCN107793281AGood explosive performanceImprove securityExplosive working-up apparatusDipotassium phosphateOil phase

The invention relates to explosive and a manufacturing method thereof, in particular to explosive special for explosive welding, and a manufacturing method thereof. The explosive comprises the following raw materials in parts by weight: 75 to 85 parts of ammonium nitrate, 10 to 20 parts of diluent, 3 to 5 parts of biological composite oil phase and 3 to 5 parts of dispersing agent, wherein the diluent is formed by combining one or more of dipotassium phosphate, potassium phosphate, calcium superphosphate, potassium chloride and ammonium sulfate. Mixing is conducted and then expansion is conducted, the ammonium nitrate aqueous phase solution, the biological composite oil phase and the diluent are mixed, the diluent is attached to the internal parts and the surfaces of the ammonium nitrate granules after expansion, the prepared explosive has small water content, the detonation velocity is 1800 to 2600 m / s, the explosive violence is 8 to 10 mm, the gap distance of sympathetic detonation is more than or equal to 4 cm, and the compound rate reaches to 100 percent through explosive compound test and ultrasonic flaw detectionafter explosion of different metal stainless steel and carbon steel, copper and copper alloy as well as titanium and titanium alloy.

Owner:FUJIAN HAIXIA TECH

Sympathetic detonation system

Owner:SOUTHWEAT UNIV OF SCI & TECH

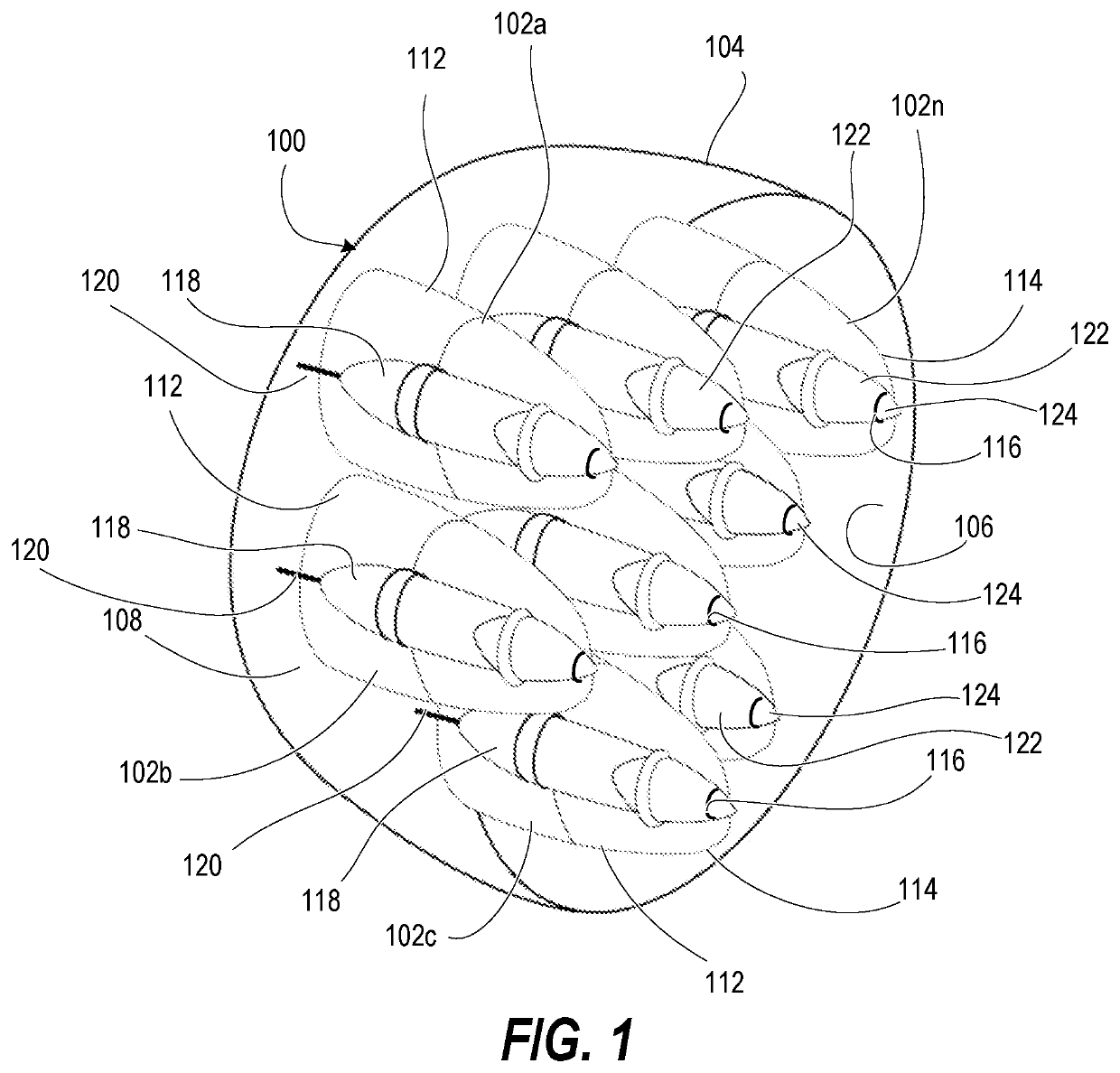

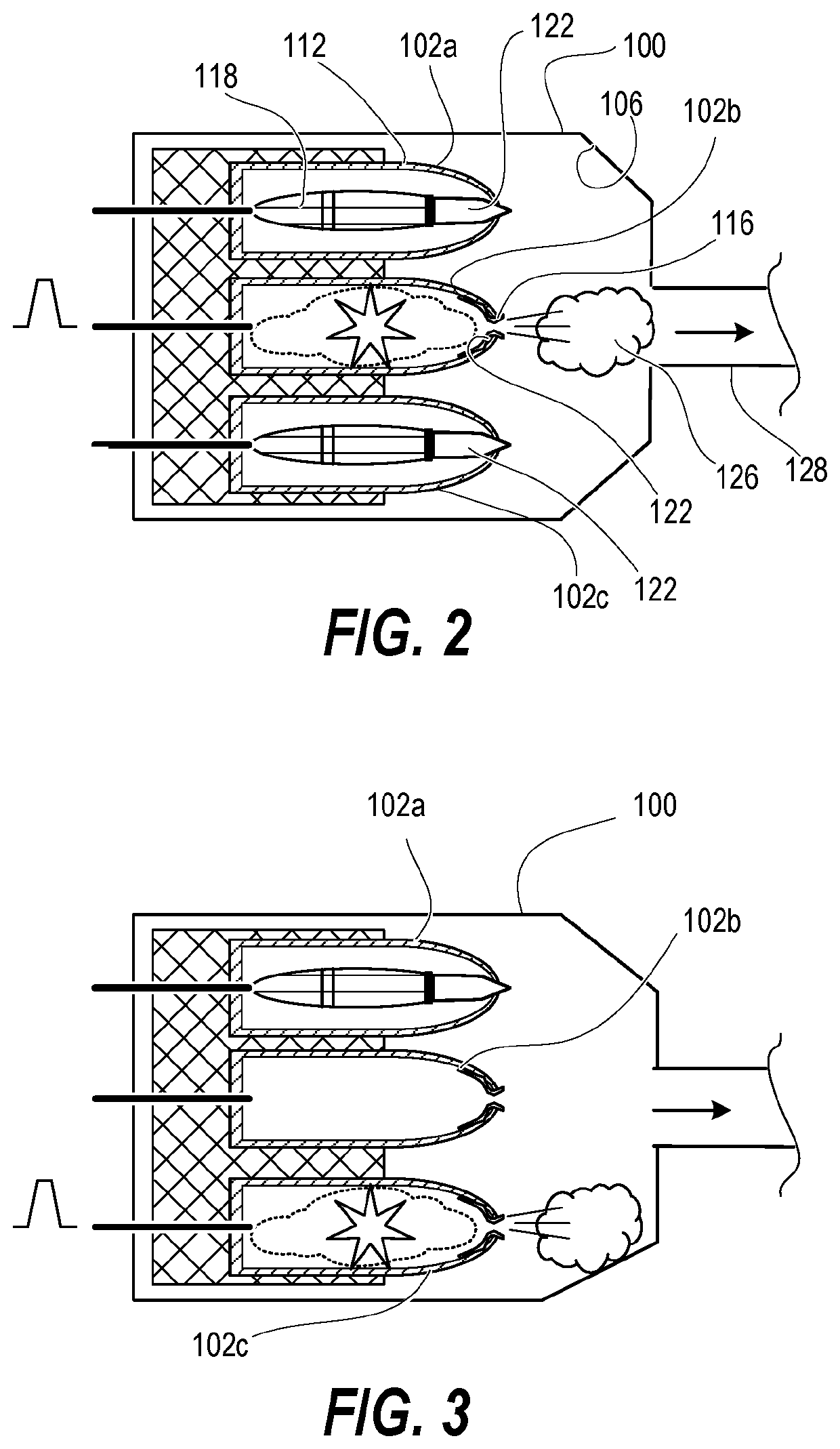

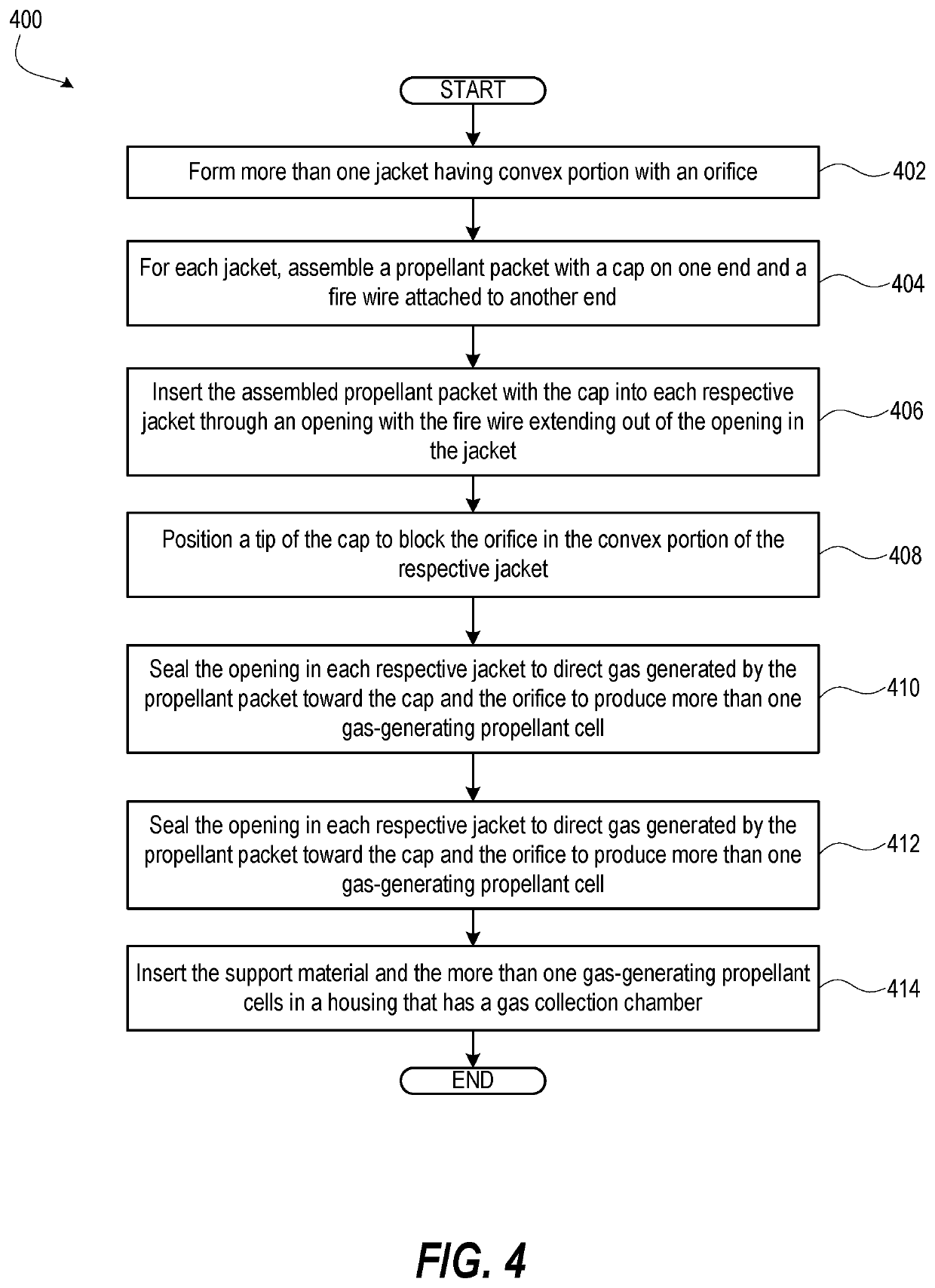

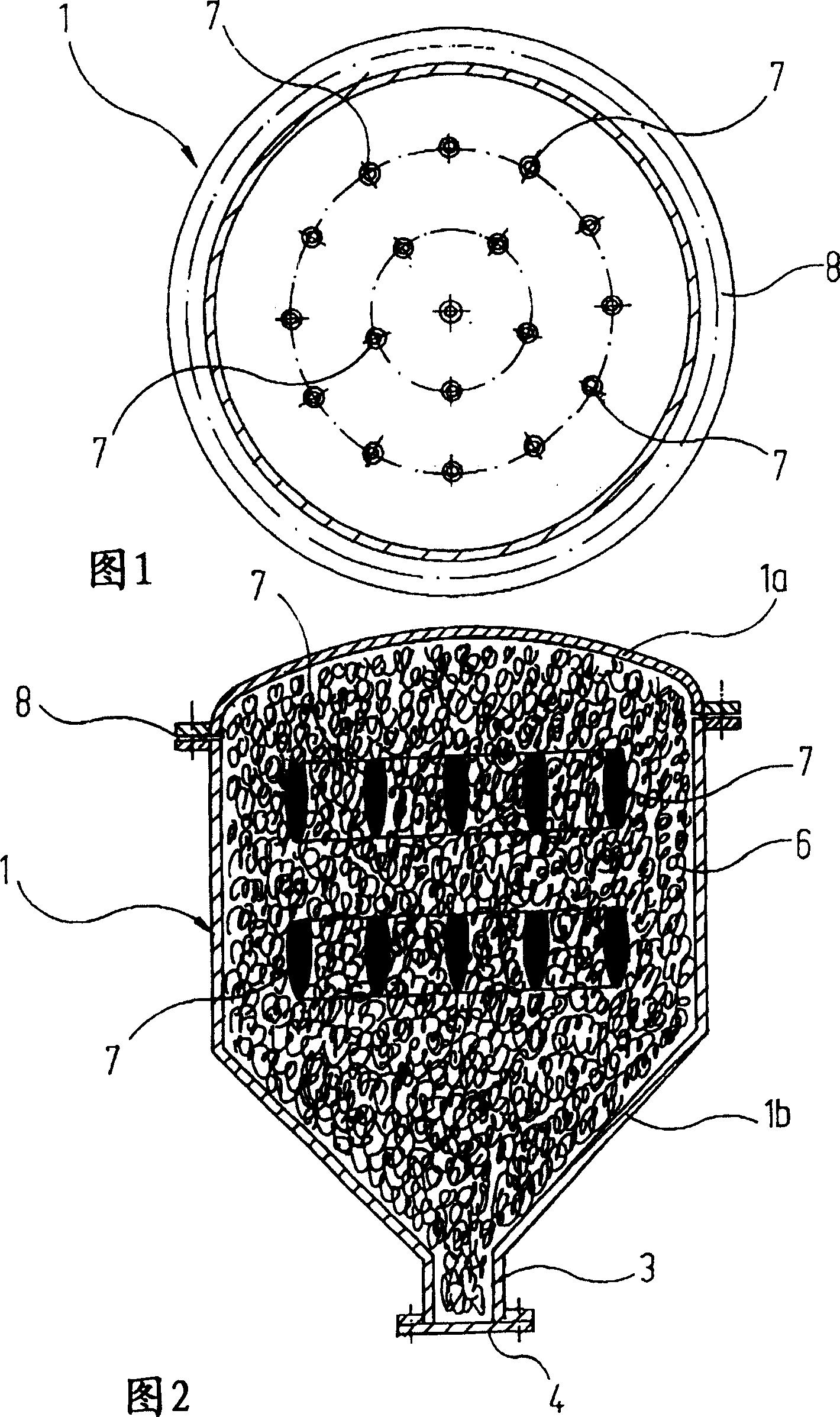

Selectable force gas generator

A selectable force gas generator (SFGG) includes support material of honeycomb structure and a gas collection chamber contained in a housing. Gas-generating propellant cells are partially embedded in the support material. Each of the gas-generating propellant cells includes a steel jacket having a convex portion exposed to the gas collection chamber. The steel jacket has an orifice through the convex portion. Each propellant cell includes a propellant packet contained in the jacket. Each propellant cell includes a fire wire electrically connectable to an electrically-fired initiator and electrically connected to the propellant packet. The fire wire transmits a firing signal that causes the propellant packet to produce gas. A cap is positioned between the propellant packet and the jacket. The cap has a tip that blocks the orifice of the jacket and the thickness of the jacket is sufficient to prevent sympathetic detonation of the propellant packet.

Owner:US GOVERNMENT REPRESENTED BY SEC OF THE AIR FORCE

Detection equipment and detection method

PendingCN113310369AAvoid Shaky Unstable ConditionsPush smoothAmmunition fuzesDetonatorMechanical engineering

The invention relates to the technical field of civil explosive testing, and particularly discloses detection equipment. The detection equipment comprises a detection table, a crimping mechanism, a detection connecting part and a mounting framework. The detection connecting part and the mounting framework are arranged on the detection table in a spaced mode, and the mounting framework fixes the crimping mechanism above the detection connecting part. The detection connecting part comprises a probe plate provided with a plurality of probes, a telescopic supporting assembly, a module mounting plate and an explosion-proof structure used for separating explosive head parts of adjacent electronic detonator control modules. The probe plate is fixed on the detection table. The telescopic supporting assembly is arranged on the probe plate, and the module mounting plate is suspended above the probe plate. The explosion-proof structure is arranged on the module mounting plate. When the detection equipment is used for carrying out batch testing on the electronic detonator control modules, the situation of sympathetic detonation between the explosive heads of the adjacent electronic detonator control modules can be prevented, the production cost is reduced, and the equipment is high in overall framework integration degree, light, simple, easy to carry and beneficial to marketization transaction.

Owner:BEIJING QAML OF SCI & TECH CO LTD

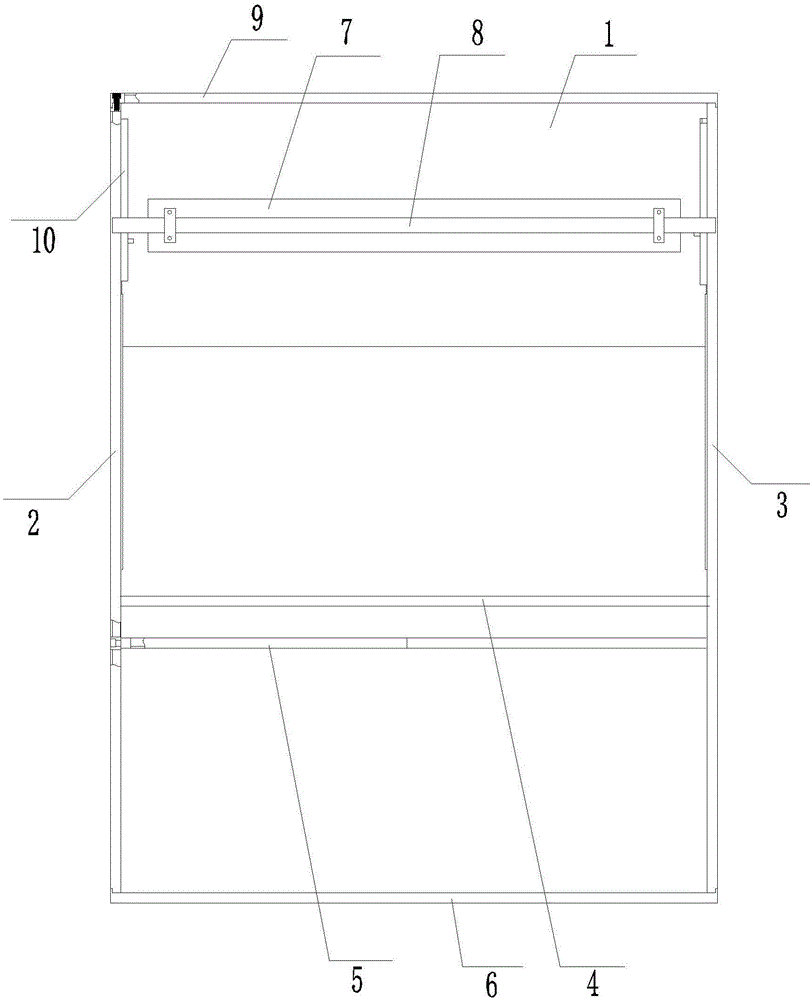

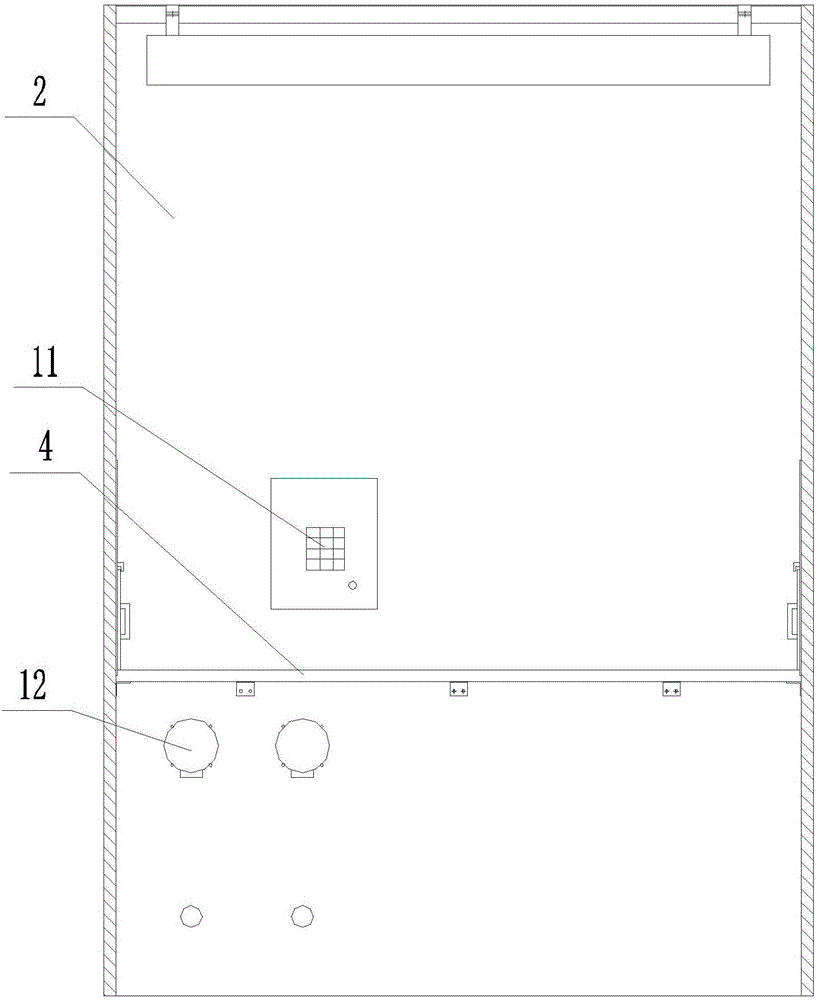

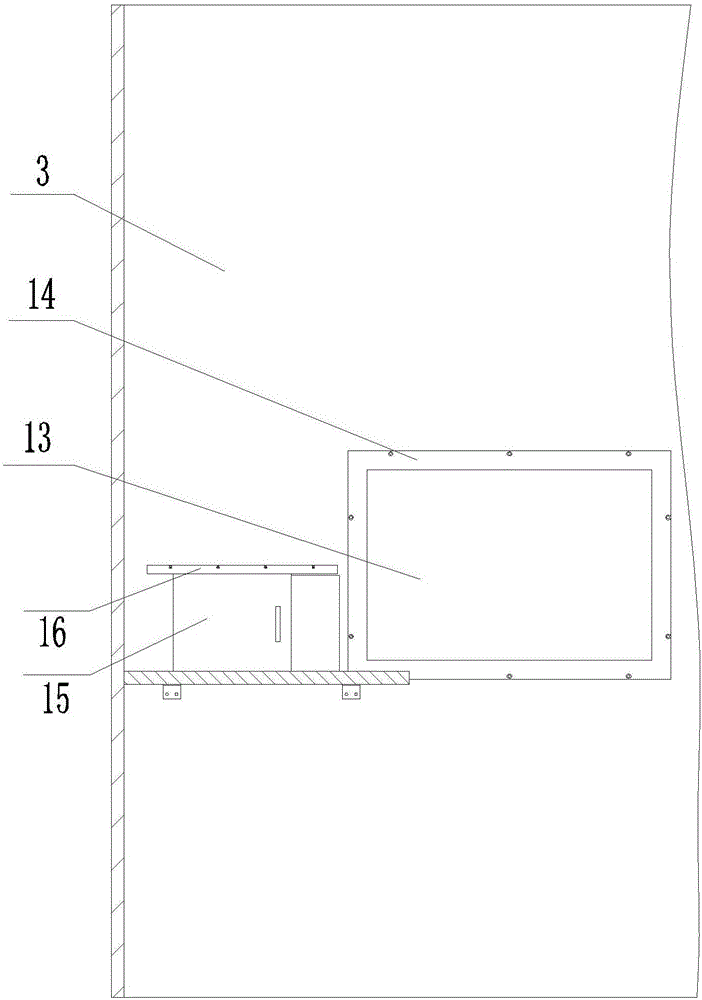

Explosive-proof station with window

InactiveCN106123717AMeet the operation anti-static requirementsIncrease contactBlastingWire gauzeIlluminance

The invention discloses an explosive-proof station with a window and relates to the field of safety protection equipment in manual operations of explosives. The station comprises a backboard and a left partition plate and right partition plate which are fixed on the left and right sides of the backboard, wherein a worktable is arranged between the left partition plate and the right partition plate; grounded anti-static rubber is arranged on the table-board of the worktable, a explosion venting window is formed in the top of the backboard, a steel wire gauze is arranged on the explosion venting window, an outward outer baffle plate and an inward inner baffle plate are arranged at the lower ends of the left and right partition plates from bottom to top, the inner baffle plate is located below the worktable, a left transfer window and an explosive-proof telephone are arranged on the left partition plate, a right transfer window and an observation window are arranged on the right partition plate, an explosive-proof fluorescent lamp is mounted above the worktable, and 220V and 380V sockets are further arranged on the backboard. The explosive-proof station can bear explosive action of 50GTNT without inducing sympathetic detonation of products in adjacent stations. The table-board of the worktable is grounded by the anti-static rubber, so that the operating anti-static requirement of initiating explosive devices can be satisfied, the explosive-proof fluorescent lamp satisfies the illuminance demand, and the explosive-proof telephone can be used for understanding transfer information conveniently.

Owner:四川浩康科技有限公司

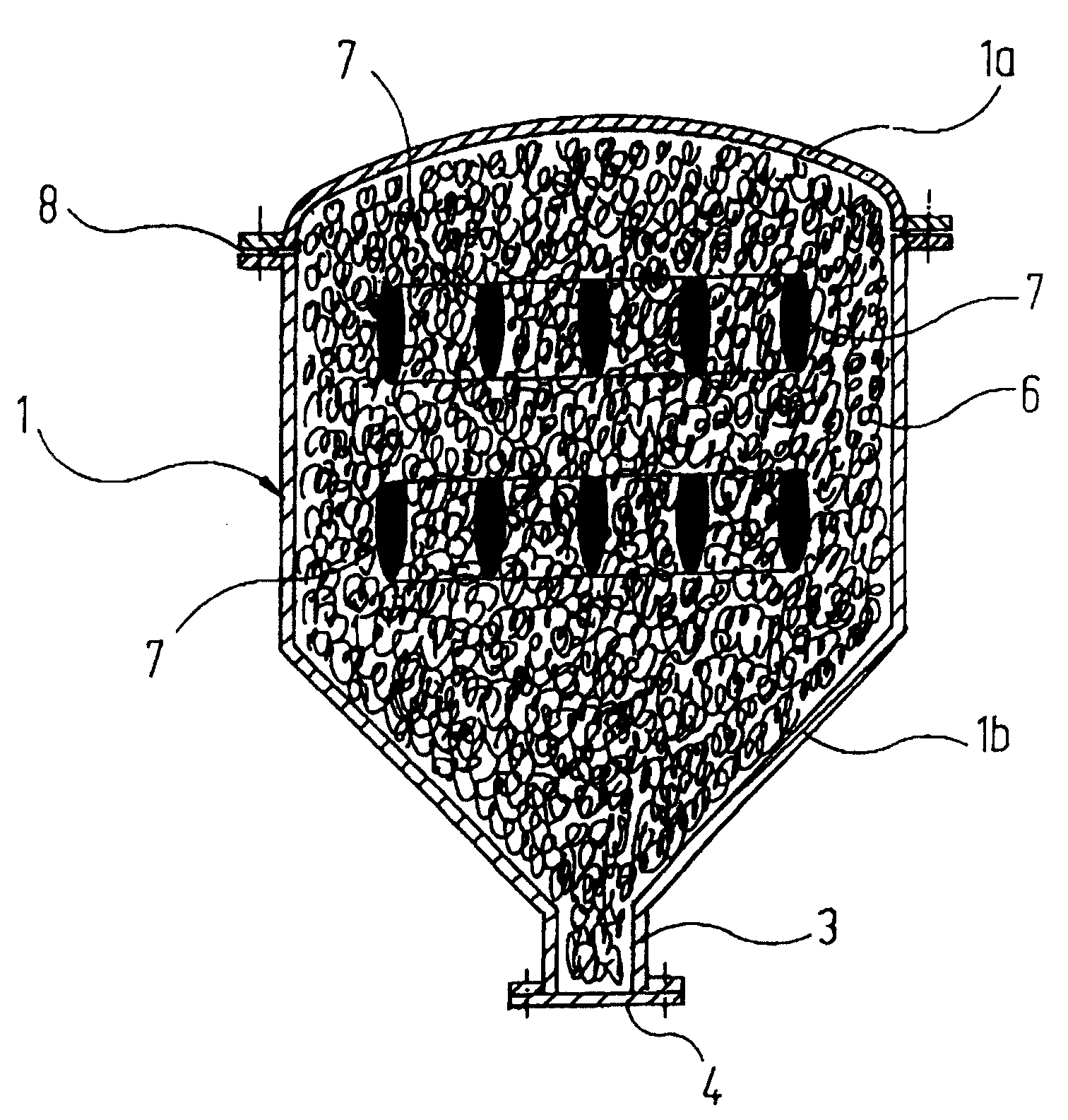

Conveying device for explosive article, especial for shell

InactiveCN1324295CSufficient compressive strengthWon't moveAmmunition storageInterior spaceEngineering

A conveying device for an explosive article (7), especially for shell, comprises a pressure-resistant container (1) with a plurality of inner holders (5) each to fix the explosive article (7). The container (1) is filled with loose distorting metal pieces (6) for enclosing the explosive article (7) and filling the spaces without the explosive article. The holders (5) are at a minimum gap from each other, so that, when the explosive article (7) explodes, the released energy from the detonation is dissipated by the deformation of the metal material over a distance between two explosive articles (7) to ensure that other explosive article (7) do not explode in a sympathetic detonation.

Owner:GFE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com