Insensitive bullet mechanical trigger fuse for shell

A fuze and sensitive technology, applied in the field of artillery shell fuze, can solve the problems of martyrdom, explosion, detonation and booster explosion, etc., and achieve high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

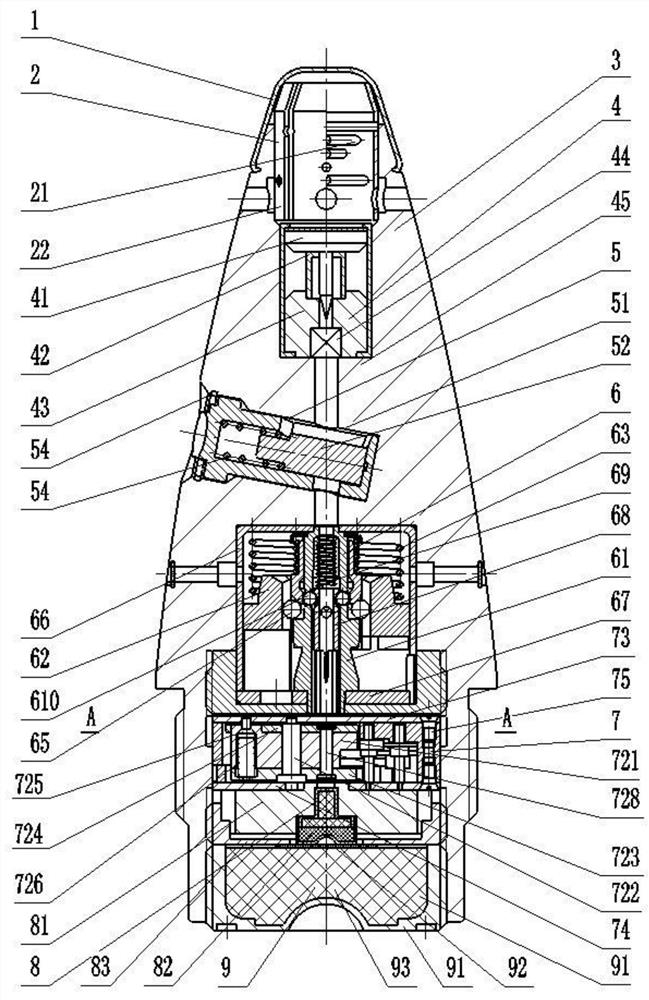

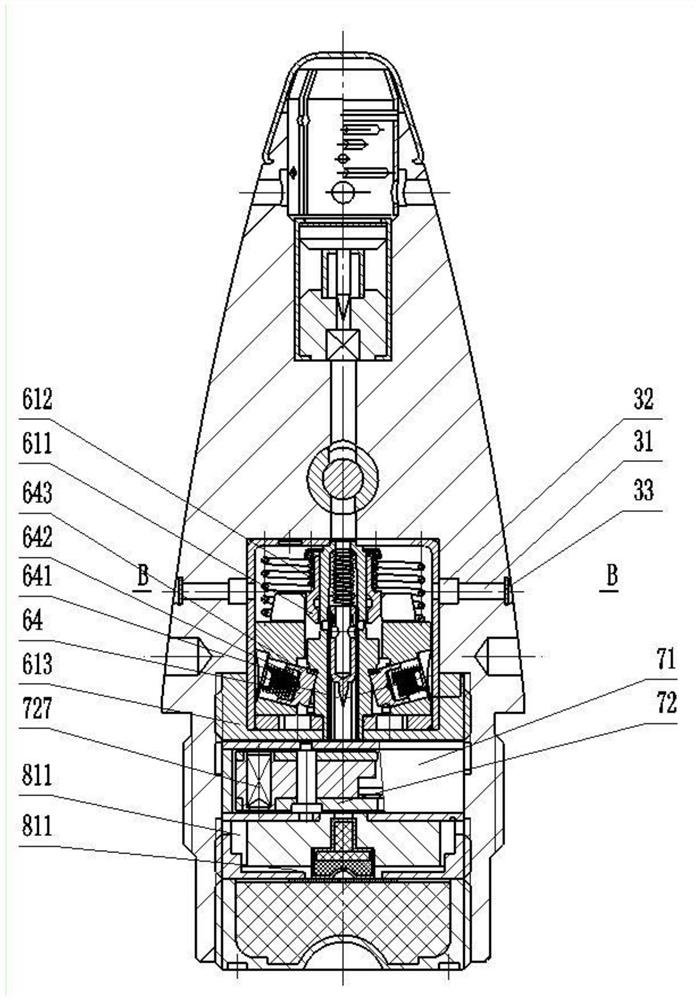

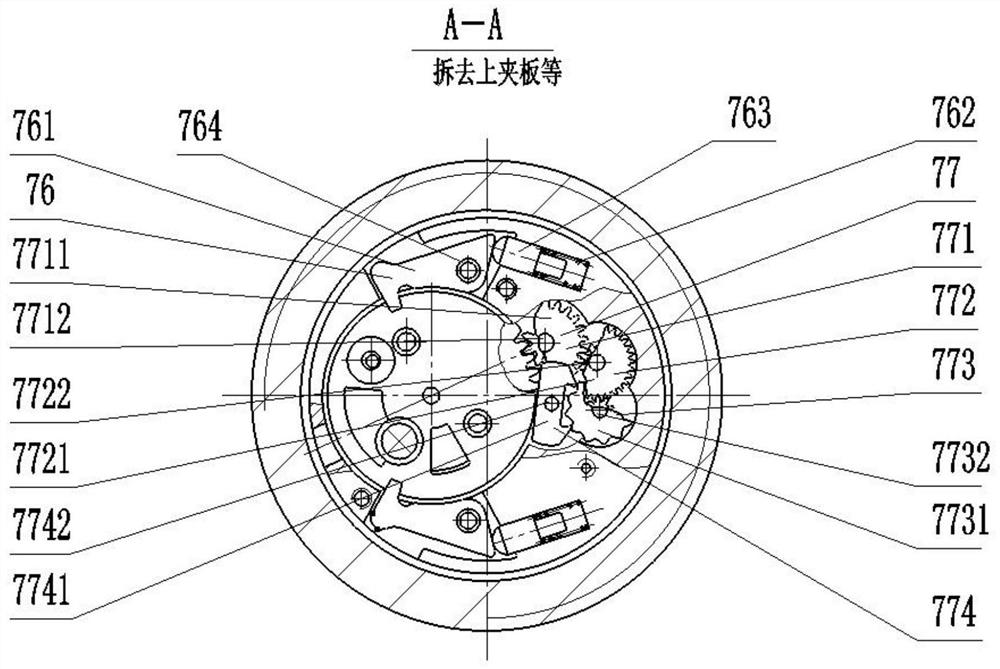

[0025] combined with figure 1 , a mechanical trigger detonation fuze for an insensitive warhead, comprising a wind cap 1, a rainproof mechanism 2, a fuze body 3, an impact trigger mechanism 4, a setting mechanism 5, an inertial delay trigger mechanism 6, a safety and release mechanism 7, and a detonating mechanism The pipe part 8 and the detonator pipe part 9 are characterized in that the wind cap 1, the rainproof mechanism 2, the impact trigger mechanism 4, the setting mechanism 5, the inertia delay trigger mechanism 6, the safety and release mechanism 7, the detonation mechanism The tube part 8 and the detonator tube part 9 are arranged sequentially along the axis of the fuze body 3 from top to bottom.

[0026] The middle part of the fuze body 3 is provided with a through hole 31 in the radial direction to communicate with the internal ring groove 32 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com