Low-impact overall ejection type launching canister front cover

A catapult launch, low-impact technology, applied in launch devices, rocket launch devices, offensive equipment, etc., can solve the problems of safety impact, limited flight distance, complex structure, etc., to reduce the impact force of the projectile, and respond quickly. , the effect of reliable opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the drawings and embodiments.

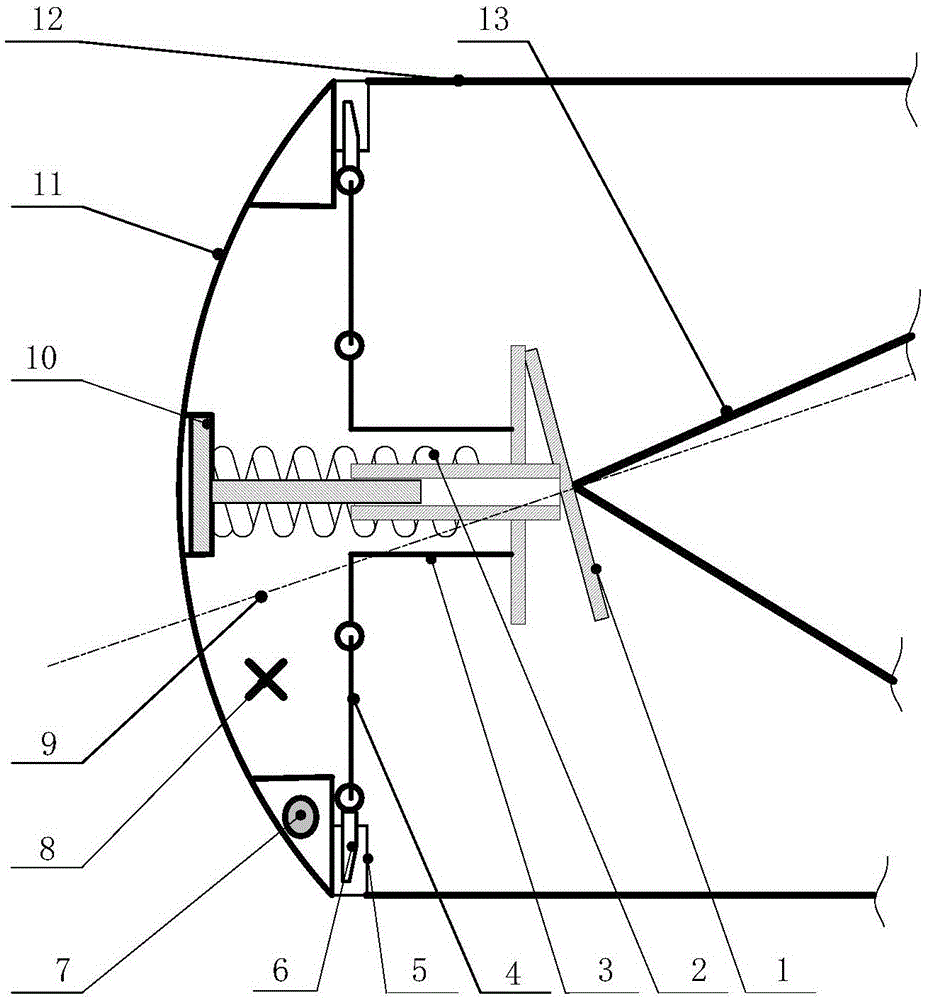

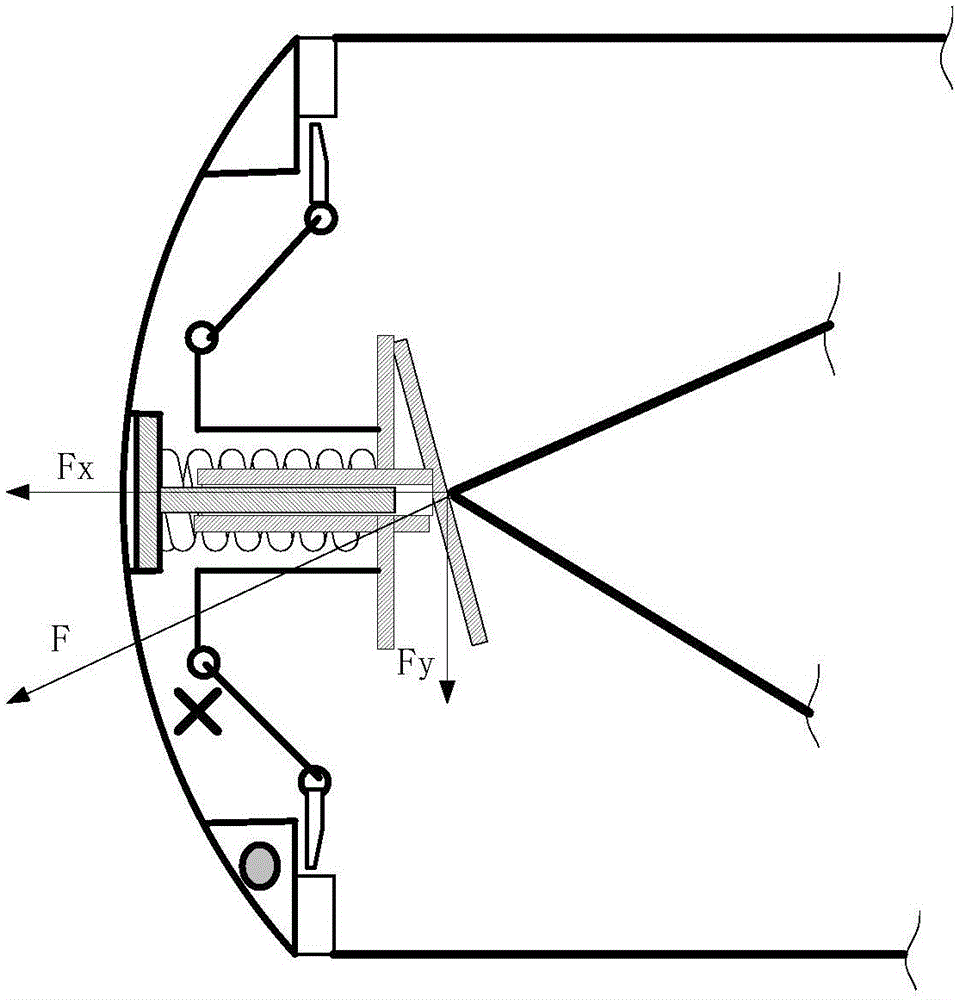

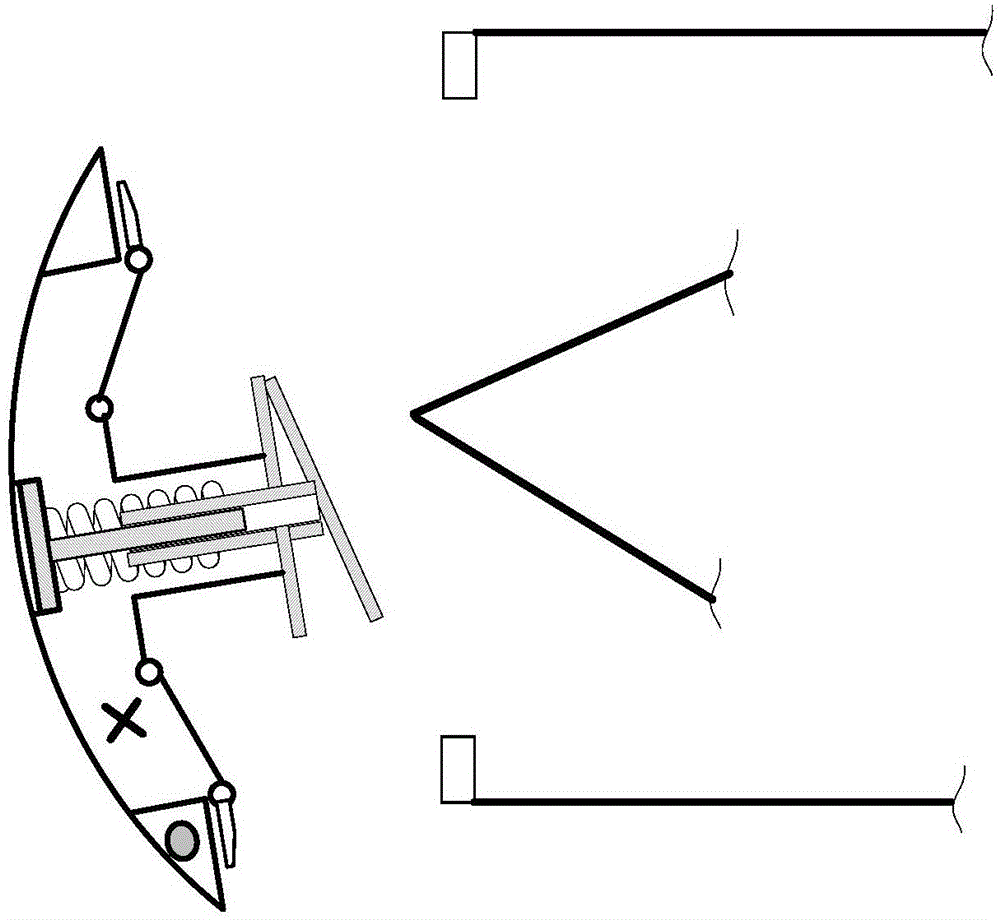

[0031] The invention provides a front cover of a low-impact integral ejection type launching box, see attached figure 1 , Including: energy storage ejection mechanism, locking / unlocking mechanism and front cover body structure;

[0032] Its peripheral equipment includes: launching box 12 and projectile 13;

[0033] The energy storage ejection mechanism includes: a movable impact component 1, an energy storage spring 2 and a fixed strut 3;

[0034] The locking / unlocking mechanism includes: pull rod 4, fixed locking ring 5 and locking tongue 6;

[0035] The front cover body structure includes: a front cover body 11, a fixed support 10 and a counterweight 7;

[0036] The movable impact component 1 is composed of a flat plate, an inclined plate and a hollow tube. The flat plate and the inclined plate are fixedly connected at an acute angle, and the hollow tube is vertically fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com